This is the completed Tunnel Reflex hybrid. The front panel is 1/4" plywood glued over the foam front panel for rigidity and provides a better material to anchor the driver. The tweeter is housed in a foam box with the crossover cap and a SPST toggle switch so I can do both full range and two way testing, as I intend to try other drivers in the reflex. The sound is fantastic for such a small drive. The bass is more than adequate and the mid-range is superb. I think this size box is about the limit for this type of foam board. If I build any larger enclosures I am going to try the 1/2" insulation foam.

Attachments

Ken,

Fantastic job! I really like the plywood suprabaffle. Looks great and it sounds great too I bet. You have given me some ideas for the next driver to try. How does it sound without the tweeter? Can you tell me which tweeter you are using and the cap used for the xover?

Sounds like you are enjoying your foam core creation though. Oh, and can you show us the dimensions or plan for your box, maybe more detailed internals photos?

Thanks,

X

Fantastic job! I really like the plywood suprabaffle. Looks great and it sounds great too I bet. You have given me some ideas for the next driver to try. How does it sound without the tweeter? Can you tell me which tweeter you are using and the cap used for the xover?

Sounds like you are enjoying your foam core creation though. Oh, and can you show us the dimensions or plan for your box, maybe more detailed internals photos?

Thanks,

X

Last edited:

he tweeter is a 3/8ths inch dome bought from PE in 2004. They had trailer loads of Delco and Nissan car speakers on sale and I bought 50 of the tweeters for.50 each. They are housed in a metal frame and work well from about 5K up. I've used them in many projects including a line array featured on the cover of Audio Express in, May, 2008. The cap is a 4.7uF. without the tweeter you do lose some higher dimensions, especially on orchestral triangles, bells, ect. Most people would be satisfied without the tweeter. The external dimensions are 16 in D, 12" high, 6" in. wide.

Attachments

This is the completed Tunnel Reflex hybrid. The front panel is 1/4" plywood glued over the foam front panel for rigidity and provides a better material to anchor the driver. The tweeter is housed in a foam box with the crossover cap and a SPST toggle switch so I can do both full range and two way testing, as I intend to try other drivers in the reflex. The sound is fantastic for such a small drive. The bass is more than adequate and the mid-range is superb. I think this size box is about the limit for this type of foam board. If I build any larger enclosures I am going to try the 1/2" insulation foam.

Really nice loo, where you always planning on adding a tweeter, or it was an afterthought?

I pre-tested the FR 10 in a .4 cu ft. box and found liked it better with a tweeter. At my age, I need all the highs I can muster. It has a toggle switch so I can test other drivers with and with out the tweeter.

Nice idea (toggle)! I have a pair of Tang Band W3-1364SA, 3" Bamboo Paper Cone, coming in, as well as a pair of TB W3-881SI. I might leave the 881's in the uFonken, and design a similar enclosure to yours for the 1364's. Or, I might just keep going with the OB hybrid bookshelf (vented 5-1/4" woofer) that I wan to do and test with the 1364's.

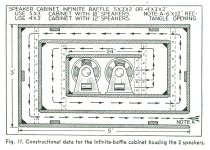

The attached would be a real challenge to build in foam or any other material. It is from an article in Radio Craft Magazine in 1938. They call it an infinite baffle but it looks like a labyrinth and the sound path is over 30 feet long. The two 12" drivers are filed coil types.

Anybody game for this one?

Anybody game for this one?

Attachments

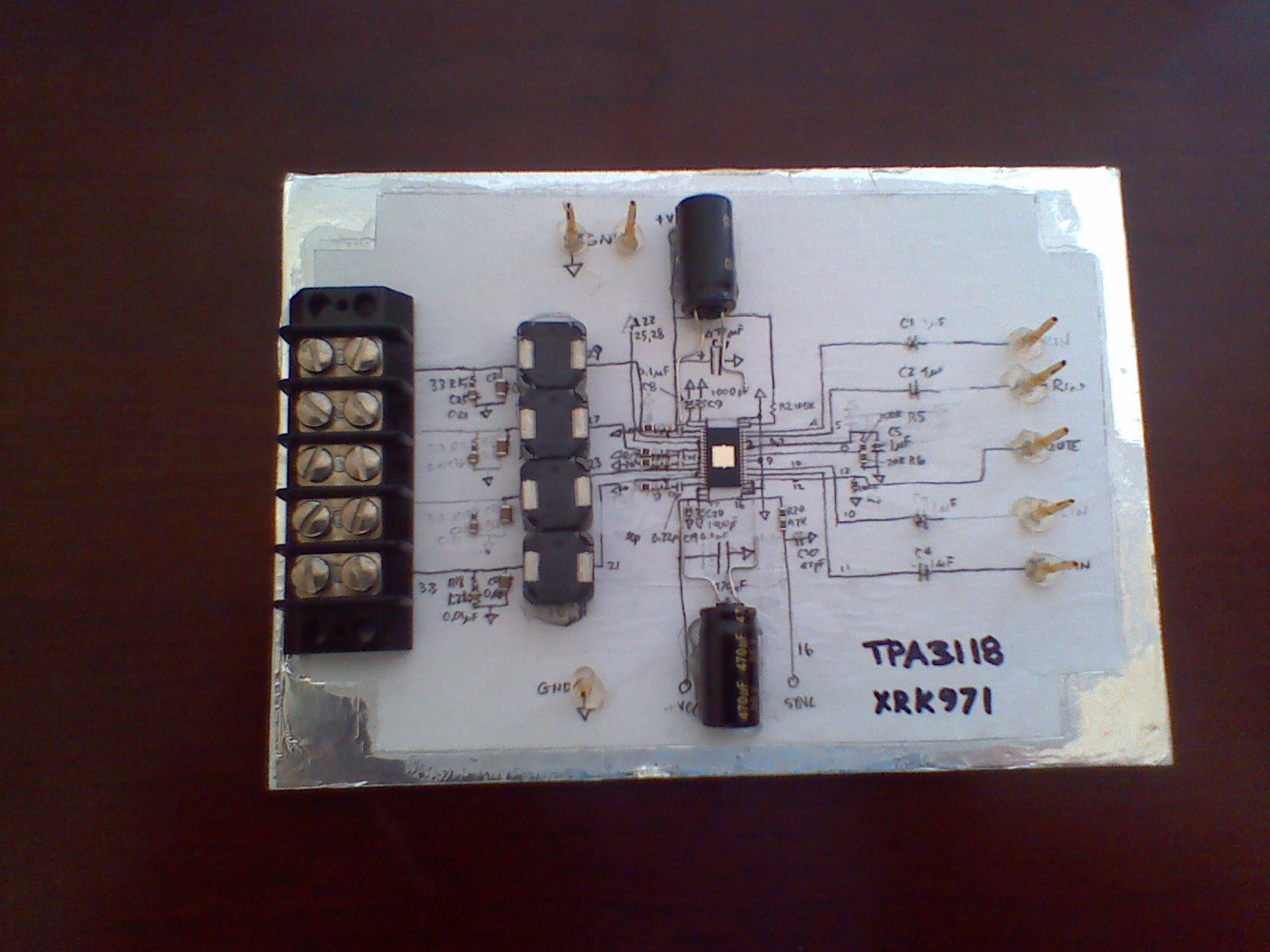

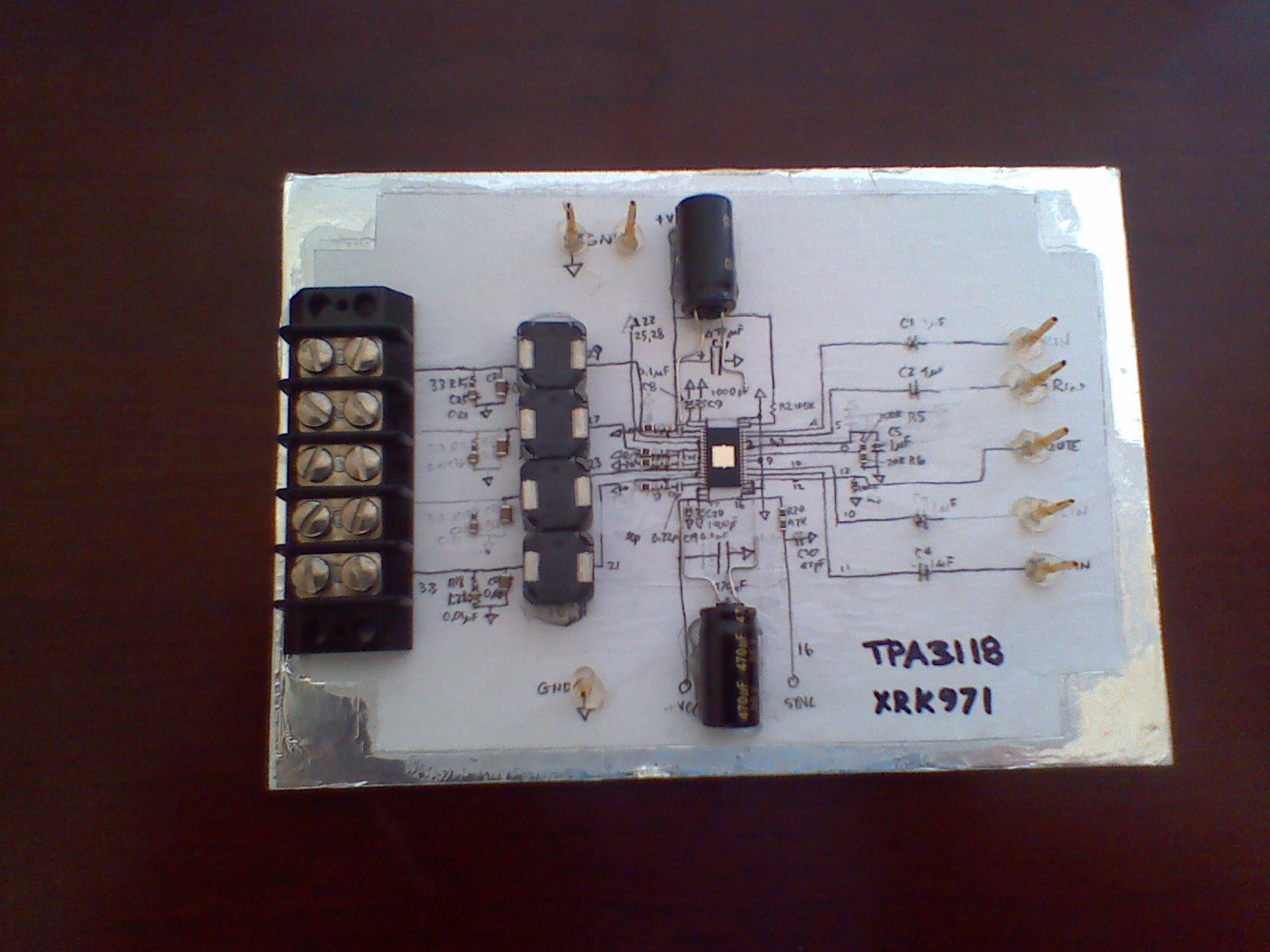

Foam Core Amplifier !

For all you Foamers out there, I just started building a foam core class D amp with the new TI TPA3118D2 chip.

http://www.diyaudio.com/forums/class-d/219730-tpa3118d2-2.html#post3383983

For all you Foamers out there, I just started building a foam core class D amp with the new TI TPA3118D2 chip.

http://www.diyaudio.com/forums/class-d/219730-tpa3118d2-2.html#post3383983

Last edited:

The attached would be a real challenge to build in foam or any other material. It is from an article in Radio Craft Magazine in 1938. They call it an infinite baffle but it looks like a labyrinth and the sound path is over 30 feet long. The two 12" drivers are filed coil types.

Anybody game for this one?

I would sim it in Hornresp first, looks like a tapered TL. The WAF is terrible on this one!

The attached would be a real challenge to build in foam or any other material. It is from an article in Radio Craft Magazine in 1938. They call it an infinite baffle but it looks like a labyrinth and the sound path is over 30 feet long. The two 12" drivers are filed coil types.

Anybody game for this one?

Heard and seen the concept before, but how about taking it further, a single 5-1/4" woofer, and try to keep it compact by using the infinite baffle. Where could it lead? Could be the enclosure for my OB Hybrid bookshelf. I have been looking at the 5-1/4" Silver Flute for this. But, PE has a 6" Aura at Buyout cheap price, that I had discarded, as it needed a larger than what I want vented enclosure. Wonder if using the 6" in an infinite baffle enclosure will be compact enough for what I want.

As you can see, I would be game, but at a smaller scale.

What do you mean by OB hybrid bookshelf? I have been thinking of making a very low cost acoustical bandpass subwoofer with the NS6 buyout. It is a really efficient driver and in a 4th order bandpass reflex cabinet can provide a flat 40 hz to 100 hz at 87 db to 89 db efficiency with no xover needed. The design can be easily made in foam core: 24 liter back chamber with 7 liter front chamber with 2x2 inch x 8 inch long vent on front chamber. I sim'd it in WinISD. If you just need a sub, not sure if a horn or TL is needed unless you want really loud and low freq HT stuff. In which case a foam core tapped horn would be the thing to build. Lots of ideas for those in the subwoofer forum.

1938. They call it an infinite baffle

Is that because those drivers can't produce a wavelength that long so it qualifies as an OB?

Just askin'.

Is that because those drivers can't produce a wavelength that long so it qualifies as an OB?

Just askin'.

30 ft path is quarter wavelength of 9 Hz not too many drivers can hit that low of a frequency. It would sound like a big fat cicada buzzing away. 9 Hz is not even sound unless you like the rhythm of a jack hammer or machine gun.... thunk, thunk, think, thunk, thunk, thunk,....

What do you mean by OB hybrid bookshelf? I have been thinking of making a very low cost acoustical bandpass subwoofer with the NS6 buyout. It is a really efficient driver and in a 4th order bandpass reflex cabinet can provide a flat 40 hz to 100 hz at 87 db to 89 db efficiency with no xover needed. The design can be easily made in foam core: 24 liter back chamber with 7 liter front chamber with 2x2 inch x 8 inch long vent on front chamber. I sim'd it in WinISD. If you just need a sub, not sure if a horn or TL is needed unless you want really loud and low freq HT stuff. In which case a foam core tapped horn would be the thing to build. Lots of ideas for those in the subwoofer forum.

I call it "hybrid" for the lack of a better word. It is an Open Baffle on top of an enclosed woofer. Very common, but don't know the exact term for such an speaker. So, I call it a Hybrid OB.

The problem with the NS6 is that for the design I want, I would like to keep the woofer ported enclosure outside dims. to +/- 8" Wide x 9" High x 10" Deep. Then on top, place the baffle with a 3" Full Range driver (the good thing of having the enclosure is that, if needed, you can fold the baffle to increase baffle width, and still be within the desired W x D dims.), and add a tweeter, only if needed. The OB baffle will add about 5" to 6" to the final Height.

But, if by doing a horn or IB I can keep the desired enclosure dims, and get the lowest Hz I can get from the NS6, that would be awesome.

Guangui,

For the small cabinet you describe you may be better off buying a couple of computer monitor 2.1 speakers and use the sub cabinet and driver. The cabinet I have in mind for the 40 Hz to 100 Hz with the NS6 is about 27 in tall x 8 in wide x 12 in deep - kind of big but the performance you get is good. A very long folded transmission line might be able to fit in the dimensions you have to reach 40 Hz. You need about a 2.2 m pathlength to get to 40 Hz so the channel will probably spiral around like a Cornu but not be a horn - a tapered TL spiral that gets smaller at the port.

For the small cabinet you describe you may be better off buying a couple of computer monitor 2.1 speakers and use the sub cabinet and driver. The cabinet I have in mind for the 40 Hz to 100 Hz with the NS6 is about 27 in tall x 8 in wide x 12 in deep - kind of big but the performance you get is good. A very long folded transmission line might be able to fit in the dimensions you have to reach 40 Hz. You need about a 2.2 m pathlength to get to 40 Hz so the channel will probably spiral around like a Cornu but not be a horn - a tapered TL spiral that gets smaller at the port.

Another run around trying to find the foam but I finally found it. We are lucky that we seem to have a 1/2 dozen Dollarama's within a 30 minute drive.

Fronts and backs are double layered foam, offset to make 30" square, now gluing with the help of some 416's.

I will go to the repro place tomorrow to enlarge my drawing.

Fronts and backs are double layered foam, offset to make 30" square, now gluing with the help of some 416's.

I will go to the repro place tomorrow to enlarge my drawing.

Attachments

- Home

- Loudspeakers

- Full Range

- Foam Core Board Speaker Enclosures?