No baffle step correction needed as the speaker is 'flat' and against wall so infinite baffle. Direct drive from amp is always cool. No waste, nothing added. Don't have condensation problem with my window, but may spray with artists varnish at some point.

Last edited:

And just in case anyone doesn't have a copy shop that is nearby (like me -- I am in the no man's land of large sheet copy places). When I am alone and have spare time, I rasterbate...

That didn't come out right.

I am using an old and trusty program called the "Rasterbator". It is pretty good and very cool, input your jpeg image and select your output size. It spits out a single .pdf file that when you print on your printer, prints it as tight to the edge as your printer allows, it then collates the pages, and you just have to tile them like so and add tape.

You can get it here:

The Rasterbator 1.2 at arje.net

You can also read about it on Wikipedia and google it to make sure you are within the system requirements (and that you aren't downloading malware of some sorts).

That didn't come out right.

I am using an old and trusty program called the "Rasterbator". It is pretty good and very cool, input your jpeg image and select your output size. It spits out a single .pdf file that when you print on your printer, prints it as tight to the edge as your printer allows, it then collates the pages, and you just have to tile them like so and add tape.

You can get it here:

The Rasterbator 1.2 at arje.net

You can also read about it on Wikipedia and google it to make sure you are within the system requirements (and that you aren't downloading malware of some sorts).

Cal,

Your wood facers look awesome though. Home Depot has sheets of acrylic (1/8 in thick I think) but size is 24 x 24 in. You may need to contact place that fabs custom acrylic display cases and they get you a sheet of quarter inch for next build. Clear on both sides for window mount. A see through window speaker... Heck, make the faces out of glass! Fragile but would work well I bet. 🙂

Your wood facers look awesome though. Home Depot has sheets of acrylic (1/8 in thick I think) but size is 24 x 24 in. You may need to contact place that fabs custom acrylic display cases and they get you a sheet of quarter inch for next build. Clear on both sides for window mount. A see through window speaker... Heck, make the faces out of glass! Fragile but would work well I bet. 🙂

... with this being a single full range driver, why is there no snubber thing-a-majiggy on the back end where other single full range driver speakers often do?

None of those around here. Use of a Zobel is more an amp related thing, helping adjust the top end to the amp's output impedance.

dave

Use of a Zobel is more an amp related thing, helping adjust the top end to the amp's output impedance.

dave

Certainly true for fullrangers. Not so much in multiways, where impedance compensation is critical to making passive XOs work.

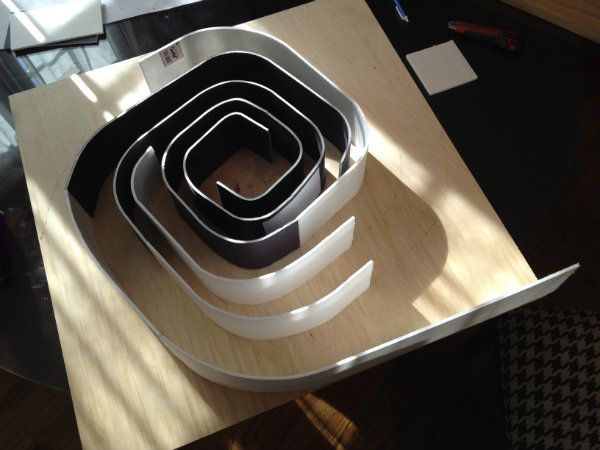

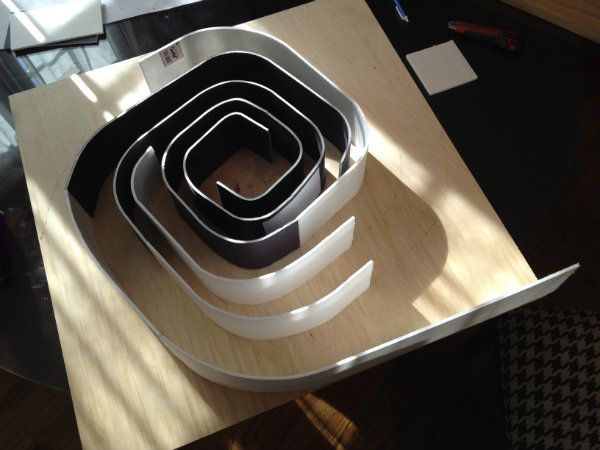

The other horn coming along, it took about 1.5hr from a bare board to here -

Layout is quite fast once you have holes in the paper. 🙂 I wish I figured that out on the first one. Yes, this spiral is mirrored from the first.

Layout is quite fast once you have holes in the paper. 🙂 I wish I figured that out on the first one. Yes, this spiral is mirrored from the first.

Last edited:

Nice to see the progress. To do the trace, I used one of those tiny Philips screw drivers and made about 100 pokes per divider. When the paper was removed it was easy to follow and do the trace but as xrk said, make sure you do one spiral at a time.

6L6,

You have some really nice bends/curves - I can't tell where the scores are. Great progress. The second one goes so much faster because you know what you are doing. Is the black stuff the same as the Dollar Store white foam core? It looks really nice and thick facing paper.

Did you power up the first one with a driver yet?

You have some really nice bends/curves - I can't tell where the scores are. Great progress. The second one goes so much faster because you know what you are doing. Is the black stuff the same as the Dollar Store white foam core? It looks really nice and thick facing paper.

Did you power up the first one with a driver yet?

I've played around with the simulation and things change quite a lot with a few changes in the horn definition (number of horn segments or segment area). At this point I don't trust this simulation but I'll trust an spl measurement. Cal, are you equipped for such a thing?

Anyone know, are copying paper used in old typewriters are still available in thees days?To do the trace, I used one of those tiny Philips screw drivers and made about 100 pokes per divider. When the paper was removed it was easy to follow and do the trace but as xrk said, make sure you do one spiral at a time.

With this job would be much simpler.

Carbon paper. Easy to poke holes with pen and then trace. Cal is already saving time by printing enlargement, I actually enlarged by hand with grid technique. You can always make carbon paper by rubbing charcoal on paper. The plan is not that hard to draw once dots are there.

i know its no Cornu, but still foam core. heres my box 98% finished still waiting on the little chip amp to arrive from china. totally shoulda bought a few at $3.50 each...

its a thin marine carpet in the mouth, helps to attenuate the midbass frequencies.

and a short vid off my phone for XRK

20121211_193632.mp4 video by klampykixx | Photobucket

on a different note, if im considering making a pair of cornu's to house a 6x9 car speaker each, i really need to pick a speaker thats brighter sounding yes? otherwise its gonna end up bassy as anything and otherwise dull? i really need to measure the specs of my drivers... alpine are hopeless... they emailed me back and dont have the spec on any of the lower class drivers..

its a thin marine carpet in the mouth, helps to attenuate the midbass frequencies.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

and a short vid off my phone for XRK

20121211_193632.mp4 video by klampykixx | Photobucket

on a different note, if im considering making a pair of cornu's to house a 6x9 car speaker each, i really need to pick a speaker thats brighter sounding yes? otherwise its gonna end up bassy as anything and otherwise dull? i really need to measure the specs of my drivers... alpine are hopeless... they emailed me back and dont have the spec on any of the lower class drivers..

I mean put the carbon paper on foam core board or wood panel, then put paper with spiral drawing on top, then just redraw spiral with pen, with little pushing.

Spiral is copied on board perfectly, without holes in paper.

I use this technique as a child, using for drawing copy🙂

Spiral is copied on board perfectly, without holes in paper.

I use this technique as a child, using for drawing copy🙂

Klampy,

Nice job with the quad driver single mouth horn! I like the carpet treatment, very pro audio touring crew look. I can't seem to see the vid - it just goes to a photobucket page and nothing happens. No biggie.

Xrk971

Nice job with the quad driver single mouth horn! I like the carpet treatment, very pro audio touring crew look. I can't seem to see the vid - it just goes to a photobucket page and nothing happens. No biggie.

Xrk971

klampykixx,

I pondered producing an AkAbak model for your design, it's quite complex - a combination of tapped horn and back-loaded horn. Do you have T-S parameters for the drivers?

I've also considered a "Bose Wave Radio" design, with two small front facing full-range drivers. One has a relatively small sealed enclosure behind, the other has a back-loaded horn. Having only one driver with a horn allows a longer horn (therefore deeper bass) in a given space. It works, even with the tiny drivers, because the listening distance for a clock radio is usually only a couple of feet.

It would be a perfect candidate for building with 1/8" foam board for the internal walls. it could be used with an iPhone or similar providing the "clock radio" functions. The horn path could be "serpentine", like yours, or a Cornu-type spiral but reversed - spiral inwards, rather than outwards, with an exit through a hole in the centre of the bottom plate. The whole thing would be supported on feet so that the gap between the bottom plate and the table-top would form the final expansion of the horn. (This expansion can be set to any desired rate by filling in part of the space.) And finally, because the (white) foam board is somewhat translucent, you could fit internal LED lights to make it into a night light...

Run it off a small plug pack supply, add a signal-operated switch (senses the audio signal, turns on a MOSFET to supply power to the amp and LEDs).

I pondered producing an AkAbak model for your design, it's quite complex - a combination of tapped horn and back-loaded horn. Do you have T-S parameters for the drivers?

I've also considered a "Bose Wave Radio" design, with two small front facing full-range drivers. One has a relatively small sealed enclosure behind, the other has a back-loaded horn. Having only one driver with a horn allows a longer horn (therefore deeper bass) in a given space. It works, even with the tiny drivers, because the listening distance for a clock radio is usually only a couple of feet.

It would be a perfect candidate for building with 1/8" foam board for the internal walls. it could be used with an iPhone or similar providing the "clock radio" functions. The horn path could be "serpentine", like yours, or a Cornu-type spiral but reversed - spiral inwards, rather than outwards, with an exit through a hole in the centre of the bottom plate. The whole thing would be supported on feet so that the gap between the bottom plate and the table-top would form the final expansion of the horn. (This expansion can be set to any desired rate by filling in part of the space.) And finally, because the (white) foam board is somewhat translucent, you could fit internal LED lights to make it into a night light...

Run it off a small plug pack supply, add a signal-operated switch (senses the audio signal, turns on a MOSFET to supply power to the amp and LEDs).

Don Hills,

I like your reverse spiral horn clock radio. I think the old Bose gen 1 had only a serpentine path on 1 driver and they went to 2 on later generations exiting a single common port like Klampy's. Are you thinking 2 in drivers or 3 inchers? The TB W3 881si for $10 ea comes to mind.... The led's with auto mosfet is a really good idea too. Do you have a schematic for that? I just had a thought, if the spirals are relatively thin, stack two one fires up and the other down, or they could both fire to common down port?

Xrk971

I like your reverse spiral horn clock radio. I think the old Bose gen 1 had only a serpentine path on 1 driver and they went to 2 on later generations exiting a single common port like Klampy's. Are you thinking 2 in drivers or 3 inchers? The TB W3 881si for $10 ea comes to mind.... The led's with auto mosfet is a really good idea too. Do you have a schematic for that? I just had a thought, if the spirals are relatively thin, stack two one fires up and the other down, or they could both fire to common down port?

Xrk971

Last edited:

6L6, You have some really nice curves

Lol. 😀 😀 😀

Is the black stuff the same as the Dollar Store white foam core? It looks really nice and thick facing paper.

It's the same junky stuff from the dollar store, just black. But it is easy to work with! I actually decided not to use the sheet of 'good' foamcore because it will be much harder to bend.

Also, a bit of PVA in the scores once the hot glue is set is making the curves much more solid.

Did you power up the first one with a driver yet?

I don't have a face on it. I need a tube of liquid nails.

- Home

- Loudspeakers

- Full Range

- Foam Core Board Speaker Enclosures?