You should start a thread on it in the SS forum or even Headphone forum. It’s a cool design and deserves its own thread and a nice layout and build which JPS64 and I are willing to do. JP and I simulated it with all BC860/850 and added a pair of outputs. It can drive 50ohm. We are off topic, but hey... It’s my thread.

How are your TPY3 black Kevlar line arrays holding up? Are you still using them? I have a pair of those drivers that Rockk got from you and sent to me. Excellent drivers - wish they did not discontinue them.

How are your TPY3 black Kevlar line arrays holding up? Are you still using them? I have a pair of those drivers that Rockk got from you and sent to me. Excellent drivers - wish they did not discontinue them.

Last edited:

Cool, I'll revisit the LF08 shortly and do the appropriate follow-ups. Regarding the Tymphany drivers, I kept a set for a line array, but haven't built the cabinets yet. I did use them in dual-driver TABAQs with 2x 12 ohms in parallel.

Recently, I built an oddball prototype 2-way TABAQ with a Panasonic T8PL19C6 3" 6-ohm plastic-cone sub driver and a Tymphany 3" 6-ohm Kevlar-cone driver as the mid/tweeter in the same enclosure, spaced 10 cm apart. The XO is a passive first-order with -3 dB at ~4 kHz for the sub and ~2.5 kHz for the mid/tweeter (i.e. some overlap from 2.5 kHz to 4 kHz). It appears to be audibly workable, though it should probably be crossed lower, maybe at 1.5 kHz or so. Maybe even an active higher-order XO or a FAST-type design, crossed much lower. Just a random brain-fart, but I was pleasantly surprised with the initial attempt, which probably can be improved with a larger (4" or 5") aperture woofer with a lower Fs.

Recently, I built an oddball prototype 2-way TABAQ with a Panasonic T8PL19C6 3" 6-ohm plastic-cone sub driver and a Tymphany 3" 6-ohm Kevlar-cone driver as the mid/tweeter in the same enclosure, spaced 10 cm apart. The XO is a passive first-order with -3 dB at ~4 kHz for the sub and ~2.5 kHz for the mid/tweeter (i.e. some overlap from 2.5 kHz to 4 kHz). It appears to be audibly workable, though it should probably be crossed lower, maybe at 1.5 kHz or so. Maybe even an active higher-order XO or a FAST-type design, crossed much lower. Just a random brain-fart, but I was pleasantly surprised with the initial attempt, which probably can be improved with a larger (4" or 5") aperture woofer with a lower Fs.

Well, I had written a nice long post about how these sound, but I opened one of the pictures full-size in the preview and lost the whole thing. Derp. Anyway, XPS MLTLs, 55L net volume, they sound pretty good. Bracing is key. A lesson from this is choose a driver well suited to ported designs if you're going to vent them.

Here's some pictures:

Here's some pictures:

These are a transplant from my first DIY bookshelf speakers, so I already had a second-order Butterworth crossover at about ~2.5k if memory serves. As far as whether or not the AMLTL worked out, they have much better bottom end extension than they did before. As I haven’t built a more typical BR with them at this tuning, I don’t really have an apples-to-apples comparison to make. Certainly not a disappointing result for the one afternoon of work.

Edit: to add onto my statement about choosing the correct drivers and something you said in the original AMLTL thread: high QTS didn’t really work out great, I think a moderate QTS driver would do better. These are 0.92.

Edit: to add onto my statement about choosing the correct drivers and something you said in the original AMLTL thread: high QTS didn’t really work out great, I think a moderate QTS driver would do better. These are 0.92.

Last edited:

Using foam core to line the inside of a speaker seems to reduce reflections and the "boxy" sound. It's nice in that it is very low cost and easy to apply with hot melt glue. I glued a layer to the inside of the K aperture of a wooden 0.53x Karlsonator and this really sounds great.

https://www.diyaudio.com/forums/ful...onator-0-53x-dual-tc9fds-296.html#post5577990

I am going to try this on the internals of my new wooden speaker cabinets from here on out.

https://www.diyaudio.com/forums/ful...onator-0-53x-dual-tc9fds-296.html#post5577990

I am going to try this on the internals of my new wooden speaker cabinets from here on out.

Very neat job, I love it.I love the removable panels.I usually stick m3 nuts with carpenter`s glue into the frame to prevent damage every time I open/close the enclosure.Then I apply the panel and I fasten it with m3 bolts. Thank you for these low cost but efficient ideas to seal the enclosures and remove boxiness.

I used to make “nuts” for the wood screws (actually drywall screws) by gluing a small square of triple ply corrugated cardboard on the back of the foamcore where the screws would go. For the front panel I would stack up a triple layer of foamcore in little 3/4in squares and glue them to the back as cleats for mounting the K aperture.

For this wooden Karlsonator build, the use of a long strip of 1/2in B.B. ply as a clear for flush mounting the aperture is a great approach developed by the builder (I can’t make wooden boxes anywhere close to this level of craftsmanship).

Detail of flush mount with square drive socket cap wood screws:

For this wooden Karlsonator build, the use of a long strip of 1/2in B.B. ply as a clear for flush mounting the aperture is a great approach developed by the builder (I can’t make wooden boxes anywhere close to this level of craftsmanship).

Detail of flush mount with square drive socket cap wood screws:

Last edited:

Very neat job, I love it.I love the removable panels.I usually stick m3 nuts with carpenter`s glue into the frame to prevent damage every time I open/close the enclosure.Then I apply the panel and I fasten it with m3 bolts. Thank you for these low cost but efficient ideas to seal the enclosures and remove boxiness.

One technique that helps to not strip out the screw hole is to lightly turn the fastener in the reverse direction until you feel it drop into the start of the existing threads. Makes it a bit easier to drive in, too.

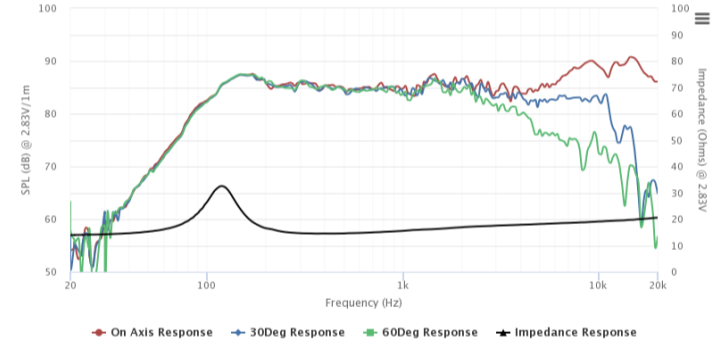

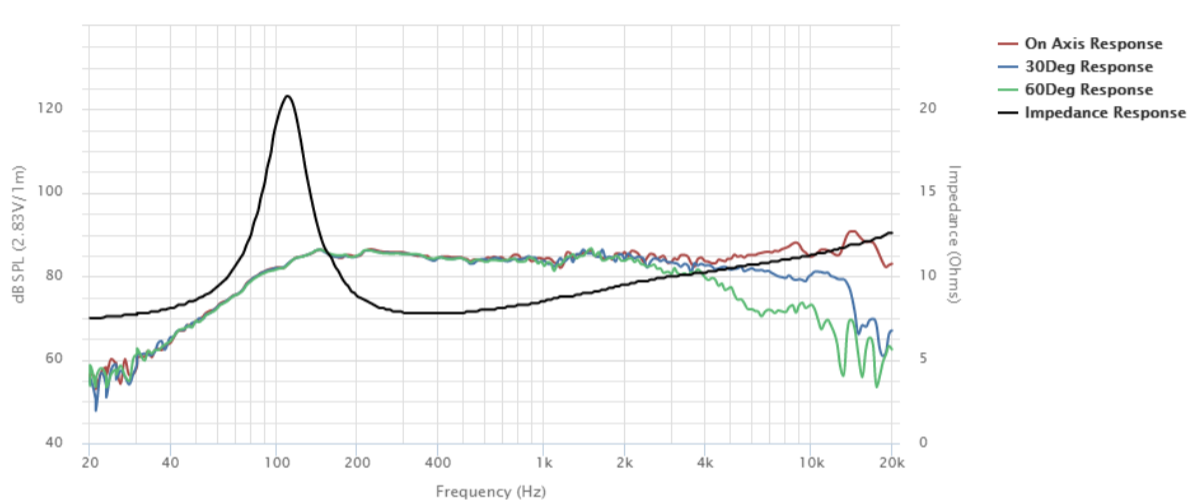

Has anybody had a chance to try out the TC9FD15-16? It looks like a pretty similar option to the TC9FD18-08 for those who wish to run a single 16 ohm driver (flea power tube amps, maybe?) or maybe for parallel applications to get back to 8 ohms nominal load. It's a bit hotter on-axis, but mellows down pretty quick it seems. May be useful for a pair of single driver Karlsonators, or in a cornu? Qts is a bit higher though...

15-16:

18-08:

I know it's a bit hard to compare directly with the scaling being different between the two graphs.

15-16:

18-08:

I know it's a bit hard to compare directly with the scaling being different between the two graphs.

Attachments

Hi xrk, sorry to hear about your flood, bad luck. I dare say this has been covered but can you advise as to how to fix speakers to foam core? I'm thinking about using foam core for a quick and dirty build but wonder how you attach the driver. I can imagine reinforcing the back of the foam with something but how do you prevent compression of the board when tightening the driver?

Thanks, Ian

Thanks, Ian

- Home

- Loudspeakers

- Full Range

- Foam Core Board Speaker Enclosures?