One thing I know about horns is the length is the tuning factor and the expansion becomes the volume /response factor.

I figured if I can keep to about a 1.5 metre up to 2metre long horn path that I could keep the tuning frequency down around the 40-80hz mark.

What horn length are the cornu spirals??

I figured if I can keep to about a 1.5 metre up to 2metre long horn path that I could keep the tuning frequency down around the 40-80hz mark.

What horn length are the cornu spirals??

These are the drivers I plan on using, and going to base the folding on my Ss15 jbell's single sheet challenge horns.

So four of these >1pc Neodymium Hifi 40mm 5W 10W Full Frequency Bass Bluetooth Wifi Speaker NEW | eBay

So four of these >1pc Neodymium Hifi 40mm 5W 10W Full Frequency Bass Bluetooth Wifi Speaker NEW | eBay

These are the drivers I plan on using, and going to base the folding on my Ss15 jbell's single sheet challenge horns.

So four of these >1pc Neodymium Hifi 40mm 5W 10W Full Frequency Bass Bluetooth Wifi Speaker NEW | eBay

So you're not trying to run those speakers as full ranges?

Hi,

I've just completed a first stab at some "vifantastisch" speakers for hanging on the kitchen wall, in foam-core. Drivers are TC9FD 8ohm.

Tuned length seems to be around the 70hz mark for these speakers. I find them quite jangly and a bit boxy or maybe reverby though. Is this something I can likely reduce/resolve by stuffing the speaker, either down the line or around the speaker unit? Currently, an old pillow has been dissected and about 1/2 of its hollow fibre used to stuff the speakers. I'm also kicking myself as I let enthusiasm overrule method and forgot to add aluminium flashing tape to the fronts/backs.

Currently they're running off a RasPi B with output shaped by ALSAEQUAL to get a more acceptable balance. Ideally, I'd like to remove EQ as the intention is to run source through a Chromecast Audio.

J.

I've just completed a first stab at some "vifantastisch" speakers for hanging on the kitchen wall, in foam-core. Drivers are TC9FD 8ohm.

Tuned length seems to be around the 70hz mark for these speakers. I find them quite jangly and a bit boxy or maybe reverby though. Is this something I can likely reduce/resolve by stuffing the speaker, either down the line or around the speaker unit? Currently, an old pillow has been dissected and about 1/2 of its hollow fibre used to stuff the speakers. I'm also kicking myself as I let enthusiasm overrule method and forgot to add aluminium flashing tape to the fronts/backs.

Currently they're running off a RasPi B with output shaped by ALSAEQUAL to get a more acceptable balance. Ideally, I'd like to remove EQ as the intention is to run source through a Chromecast Audio.

J.

I turned them into MLTL's and like the sound better. Look in index for link to plans. Basically cap the opening with a vent tuned to 55Hz.

I tried the MLTL but it didn't work well.

WinISD shows my vent to be in the ballpark. 1.5"x1.5" by 2.6". It just didn't work well in combination with the Vifa.

Have now tried the Aura NS3 in the Vfantasticsh and it's a definite improvement. It's filled out the bottom end nicely and lost a lot of the high end tizz/zing/splash that was previously overpowering it.

I'm still not convinced that it's working as well as it should given the sims.

I should probably add that the boxes are currently as un-stuffed as I can reach with a bent coat hanger remnant.

J.

OK, I know this is the "Foam Core" thread... but I ran across some really high quality cardboard boxes that just felt so stiff and had great crisp lines and corners in about the right size for a bookshelf speaker so I had to try it. I figured that the box was basically built already and it would require minimal work to turn into a speaker - what did I have to lose?

Anyhow, this is one of those internal box within a box that they ship books in. It had dimensions of 13 in tall x 4 in wide x 10 in deep. At first I thought I would do a simple BR so I plugged in the volume (about 8.5 liters) into WinISD and set the tuning freq to 70 Hz for a nice balanced response with the TC9FD's. I used a toilet tissue paper tube (1.75 in dia) as the vent so WinISD calculated 3 in long vent. I started to build the speaker which really required nothing more than sealing the box with hot melt glue and cutting holes for the driver and vent. Then I got to thinking... 10 in deep, if I add two foam core dividers, I can get an internal path length of 30 in. At this point, the vent had already been cut and glued in so I had to live with whatever it was. I figured that at worst it will behave like a BR box and if the internal channels do their job, it will pull it lower like a MLTL. The internal cross sectional area was 4.0 x 4.33 in - a little on small side for a 3.5 in driver but like I said, I have nothing to lose.

You can see the photo of how I laid out the divider and where the vent is. I added wiring and some pillow stuffing. in the first 40% of the line and some at the end around the vent tube. I sealed it up with hot melt, installed the drivers with just drywall screws into the cardboard no reinforcement wood because I did not want to waste time in case it did not sound good.

I hooked it up to the amp, put in my usual test CD tracks, and...

Wow, this thing sounds surprisingly good! I mean the bass reaches down pretty deep. I set the two speakers up on some stools to get them to ear height, sat about 8 feet away and closed my eyes and listened. I was listening to Dave Brubeck's "Ode to a Cowboy" and wow, was it good! I can hear the nice deep notes on the bass, make out where the drum kit is, just very enjoyable, To confirm my suspicion that there was deep bass, I put a mic to the vent tube with Holmimpulse and sure enough, this little box was pumping out sound down to 50 Hz. There is some higher freq peaks leaking through but I am not sure if that is just the sound from the front getting around. Anyhow, very cool.

I am looking at making something like this out of foam, but I want to get the size down a bit because they will be sitting on the desk next to the PC monitor, and it would be nice to keep the 30" TL length. Is it practical to use a smaller CSA than 4" x 4 1/3" and introduce a 3rd baffle which creates another fold in the TL so I can have a smaller box?

Sorry I can't edit my posts for some reason. The 13" height is not the problem, it's the 10" depth on the desk that I want to reduce. I thought get the CSA down to about 12" and sneak in another fold in the TL might be possible.

"X" amount of time after you post, the system makes your post permanent and you cannot Edit. You can only Edit within certain time frame after you posted.

Celestion loudspeaker honeycomb panels...

The panels are actually referred to as "Aerolam" and are an extruded honeycomb construction. I know the SL600 and SL700 monitors used this for the enclosures, and IIRC, the SL6 used is as a front baffle.

This is one of the the preambles to the idea of "light, yet rigid" construction techniques in audio, including the use of torsion boxes, etc. to make enclosures and shelving (that sounds good---the revered original Ikea "Lack" tables are a similar concept, but used for knockdown furniture instead of shelves and why some swear by their "Lack racks" for audio equipment). To me the use of these sorts of materials is what the audio manufactures (like Celestion, B&W, and others) can bring to the audio world. This happily coincides with my own principles regarding construction methods, techniques and materials:

So an inexpensive and convent project that can help to reduce the effect on the environment. Who'd a thunk it?

The panels are actually referred to as "Aerolam" and are an extruded honeycomb construction. I know the SL600 and SL700 monitors used this for the enclosures, and IIRC, the SL6 used is as a front baffle.

This is one of the the preambles to the idea of "light, yet rigid" construction techniques in audio, including the use of torsion boxes, etc. to make enclosures and shelving (that sounds good---the revered original Ikea "Lack" tables are a similar concept, but used for knockdown furniture instead of shelves and why some swear by their "Lack racks" for audio equipment). To me the use of these sorts of materials is what the audio manufactures (like Celestion, B&W, and others) can bring to the audio world. This happily coincides with my own principles regarding construction methods, techniques and materials:

- often fewer resources are required to make such structures, regardless of size;

- these methods often allow for an order of magnitude reduction in the embedded energy and reduced shipping and packaging costs which are often the largest single cost of a manufactured product;

- and packaging.

So an inexpensive and convent project that can help to reduce the effect on the environment. Who'd a thunk it?

Tricel wood faced honeycomb panels also make nice speakers. They are used for marine and commercial furniture.

Tricel Honeycomb: Strong, Lightweight Panel Products

Great for curved or "bendy" panels. Very strong yet lightweight.

http://www.tricelcorp.com/wp-content/uploads/Marine_Article.pdf

I have made my own composite of triple ply corrugated cardboard faced with foam core all held together with either 777 Fastack or latex caulking for CLD dampening.

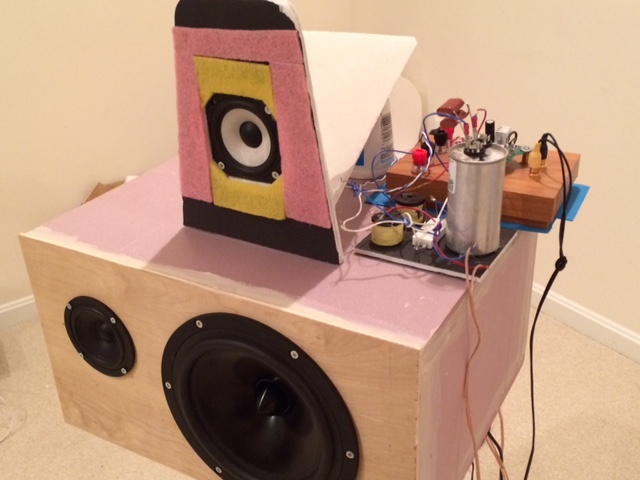

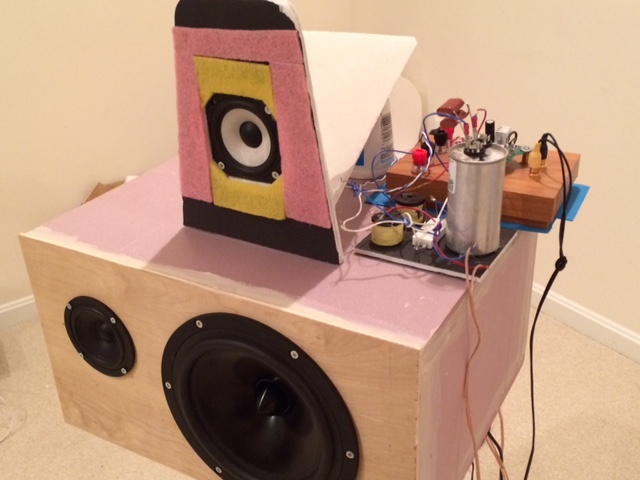

I am getting ready to build my first integrated cabinet for a passive XO FAST speaker. It will contain the following arrangement but in a tidy and sleek box.

http://www.diyaudio.com/forums/full-range/292130-ff85wk-rs225-8-passive-fast.html

Sound clips here:

http://www.diyaudio.com/forums/full...-blind-abx-test-enabled-ff85wk-round-6-a.html

Tricel Honeycomb: Strong, Lightweight Panel Products

Great for curved or "bendy" panels. Very strong yet lightweight.

http://www.tricelcorp.com/wp-content/uploads/Marine_Article.pdf

I have made my own composite of triple ply corrugated cardboard faced with foam core all held together with either 777 Fastack or latex caulking for CLD dampening.

I am getting ready to build my first integrated cabinet for a passive XO FAST speaker. It will contain the following arrangement but in a tidy and sleek box.

http://www.diyaudio.com/forums/full-range/292130-ff85wk-rs225-8-passive-fast.html

Sound clips here:

http://www.diyaudio.com/forums/full...-blind-abx-test-enabled-ff85wk-round-6-a.html

I built these about two months back just to see how they sounded compared to a pair of FC Lances. Not the best of finishes, I'd say.

I used 8mm (actually 9mm) thin film FC for the walls with sandwiched chipboard + 5mm FC + chipboard baffles for rigidity. I stuck to the plans, complete with felt linings and the holey brace and the speakers sounded surprisingly good. They had clear mids and highs and decent bass, which increased when placed up against the wall.

I used 8mm (actually 9mm) thin film FC for the walls with sandwiched chipboard + 5mm FC + chipboard baffles for rigidity. I stuck to the plans, complete with felt linings and the holey brace and the speakers sounded surprisingly good. They had clear mids and highs and decent bass, which increased when placed up against the wall.

- Home

- Loudspeakers

- Full Range

- Foam Core Board Speaker Enclosures?