I think if we take speaker building into the high tech realm, let's not waste anytime and make it the same way F1 cars, aircraft, and spacecraft structures are made: carbon fiber faced nomex honeycomb panels. Very stiff and light and good vibration dampening from carbon fiber. Small pieces are reasonably priced nowadays. Here is a place where small samples are available.

http://dragonplate.com/mobile/produ...CUi0HlMDympS2EpiFH6Q6Ti5rRiwZ7LC_0aApNg8P8HAQ

Carbon fiber, kevlar, nomex are great materials with many applications. I also think they could make great enclosures in the same way they make great bicycles which can be engineered to be stiff in one flex mode but soft and damped in another. But I also suspect that a carbon-fiber enclosure will have huge sound reflections (like a sound mirror). Would probably need lots and lots of internal damping to remove all the reflections. For a material to damp sound, it first needs to absorb the sound, then damp it. I suspect that you would need to use something like mineral filed neoprene liners to absorb the sound, transmit it into the carbon fiber walls, and then let the carbon fiber damp the vibrations.

This is the stiffness which avoid th bafle to radiate while the honeycomb carbon linked has a good internal damping due to the structure ! I you insert the bafle or glue it on a foam/eva enclosure you have maybe the best of the two worlds !

Best of the three worlds ! ut liquid rubber of the bottom and front of the honeycomb bafle to avoid higher frequencies to have reflexion (damping réflexions !)... Maybe, I don't know ! I will like really find rubber/caoutchouc thin sheet (even better than EVA for damping but need a structure to be glued on ! (Eva, honeycomb carbon, whatever !)

ut liquid rubber of the bottom and front of the honeycomb bafle to avoid higher frequencies to have reflexion (damping réflexions !)... Maybe, I don't know ! I will like really find rubber/caoutchouc thin sheet (even better than EVA for damping but need a structure to be glued on ! (Eva, honeycomb carbon, whatever !)

I can give you the neoprene numbers : not so good iirc !

Best of the three worlds !

I can give you the neoprene numbers : not so good iirc !

I know that a shiny carbon fiber covered enclosure is tempting, but there is a chance that it might not actually be an improvement. We won't know until we try, but the cost and effort to work with carbon/kevlar fiber layup is not small. And as Vandersteen himself said in this Stereophile article on his Quatro woods, that the shiny wood veneers made his speakers sound worse.

Vandersteen Quatro Wood loudspeaker | Stereophile.com

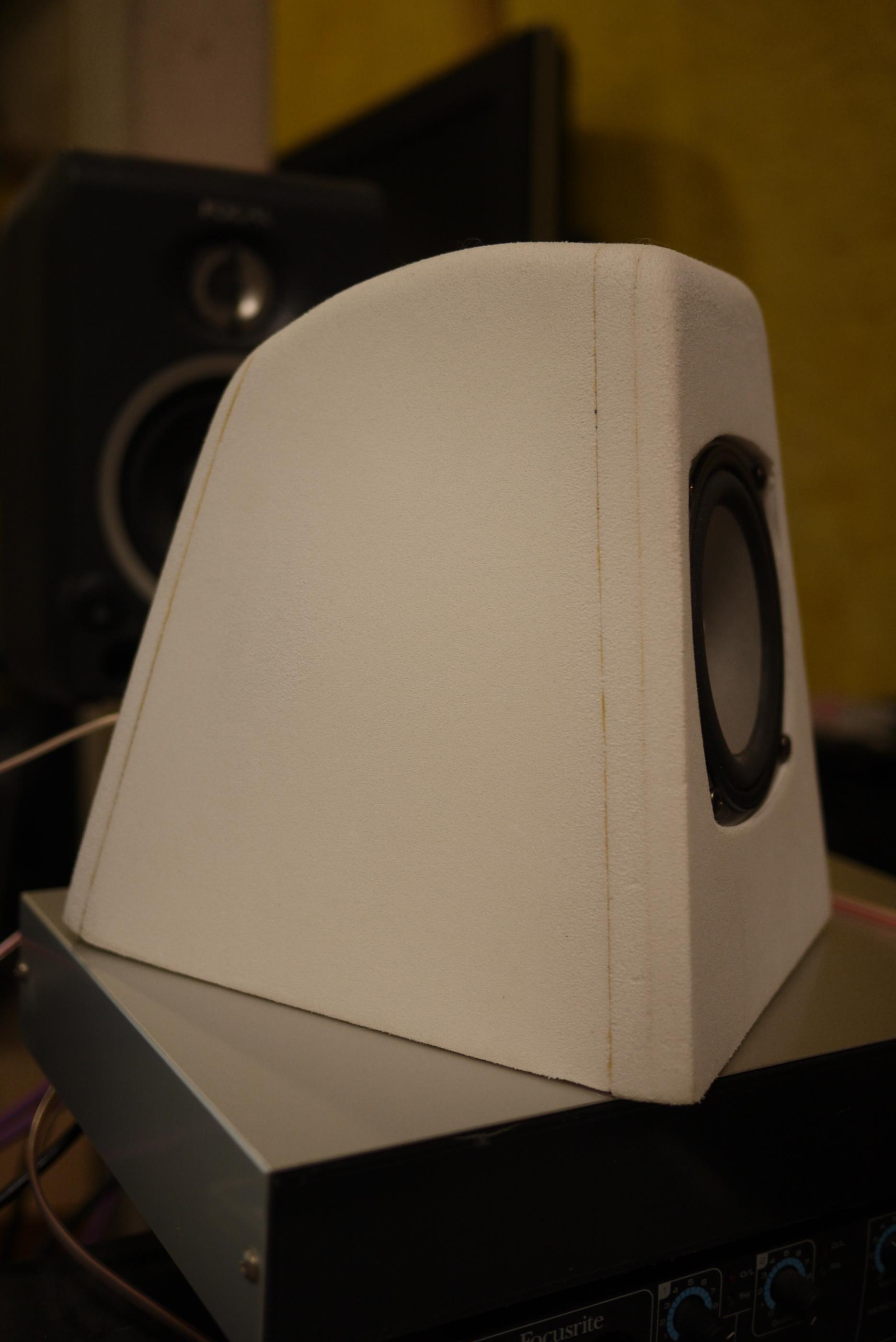

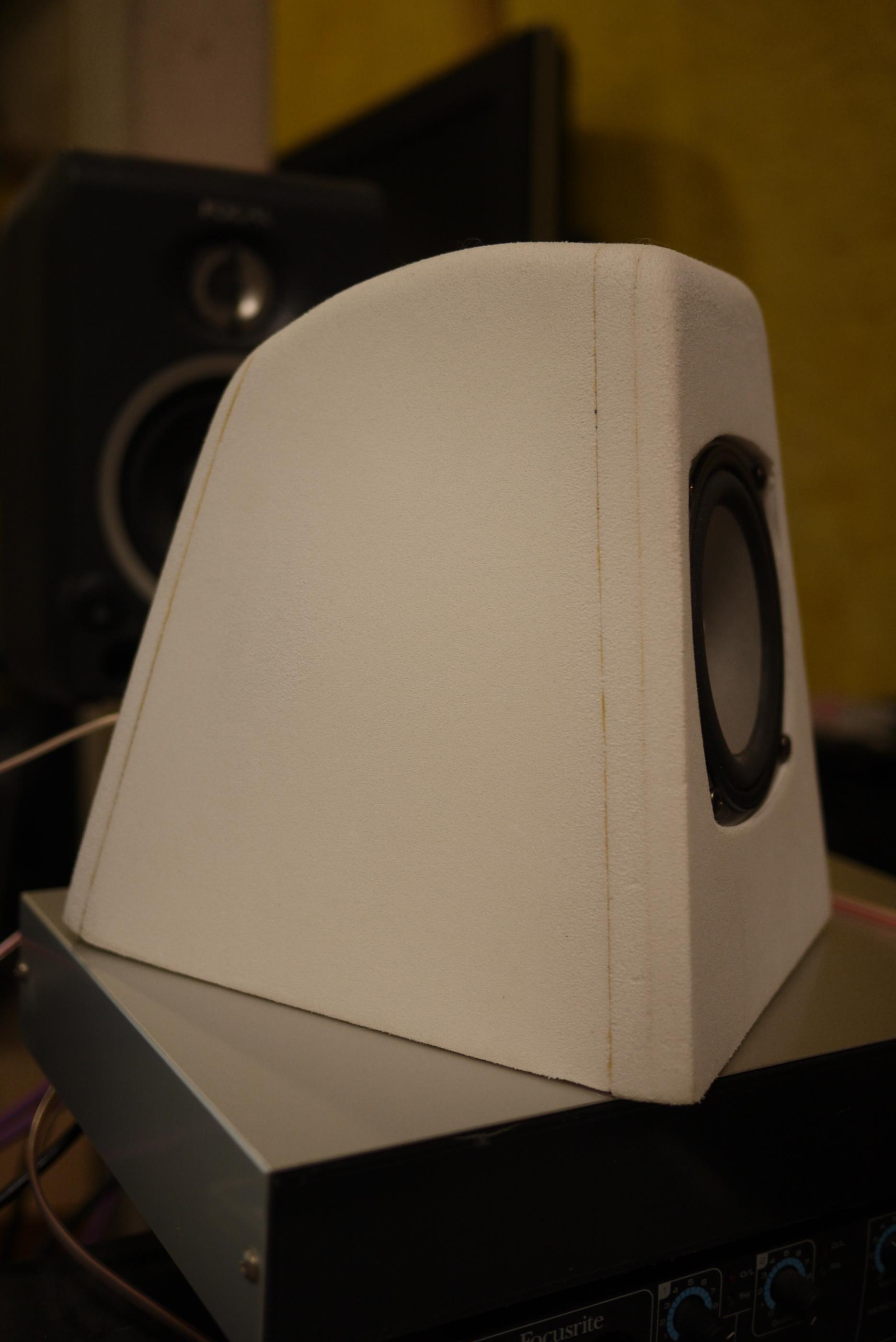

But in the end I am enjoying working with the EVA foam, it is an excellent material for enclosures, easy to work with, able to be sculpted, can be painted, and in the end imparts very little (to none) sound signature. As a DIY material is it really about perfect. Plus I like the white look.

Vandersteen Quatro Wood loudspeaker | Stereophile.com

Vandersteen has long been known for his iconoclastic opinions on audio design —views that have led him to wrap his speakers in plain-looking "socks" rather than in exotic veneers. "I just don't think people have a clue what sonic price they are paying for having that acoustically reflective wood next to the drivers," he told me.

"Well, our dealers begged me to make a version of the Quatro that looked more upscale," Vandersteen said. "I thought I could do it for a slightly higher price, so I just took a pair of Quatros off the line, squared off the edges, and wrapped them in veneer. We took it into the sound room, and it was just not the same loudspeaker. All that beautiful shiny veneer so close to the drivers had a catastrophic effect —I've known that for years, which is why we build speakers the way we do.

"Now we had a speaker that cost $1500 more and didn't sound as good as the fabric option. Initially, I added the new composite phenolic-epoxy plinth, which wasn't enough in itself, then I upgraded the tweeter, and we kept tweaking it until it was a little bit better everywhere than the fabric one —because I just wasn't going to charge more for a speaker that didn't deliver more. Ultimately, we got a speaker that was noticeably better, but it wasn't a $1500 upgrade, it was $3700."

I know for myself that I like the old vandersteen "covered in a sock" raw look. And my Acoustat 1+1 electrostatic speakers are also a sock covered design."Well, our dealers begged me to make a version of the Quatro that looked more upscale," Vandersteen said. "I thought I could do it for a slightly higher price, so I just took a pair of Quatros off the line, squared off the edges, and wrapped them in veneer. We took it into the sound room, and it was just not the same loudspeaker. All that beautiful shiny veneer so close to the drivers had a catastrophic effect —I've known that for years, which is why we build speakers the way we do.

"Now we had a speaker that cost $1500 more and didn't sound as good as the fabric option. Initially, I added the new composite phenolic-epoxy plinth, which wasn't enough in itself, then I upgraded the tweeter, and we kept tweaking it until it was a little bit better everywhere than the fabric one —because I just wasn't going to charge more for a speaker that didn't deliver more. Ultimately, we got a speaker that was noticeably better, but it wasn't a $1500 upgrade, it was $3700."

An externally hosted image should be here but it was not working when we last tested it.

But in the end I am enjoying working with the EVA foam, it is an excellent material for enclosures, easy to work with, able to be sculpted, can be painted, and in the end imparts very little (to none) sound signature. As a DIY material is it really about perfect. Plus I like the white look.

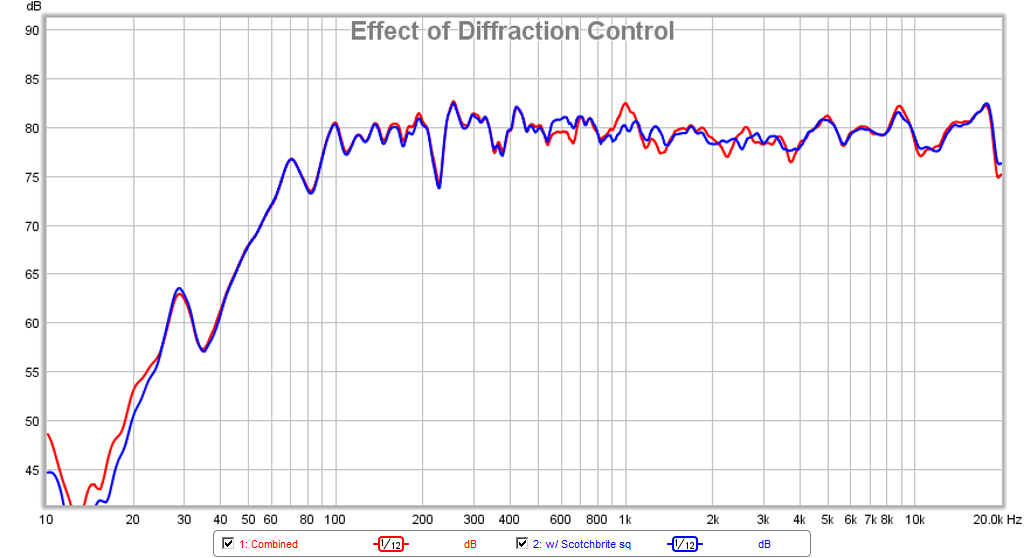

true about the brillo pad diffraction control. This is an improvement. But I am still not convinced about the shiny wood, black piano lacquer, or carbon fiber outer layers (like what vandersteen said above). Maybe putting a carbon/kevlar fiber sheet as the middle layer of sandwich of foam and then cover the outer surface in brillo pads. Maybe from inside to outside

felt pads or open-cell-foam

EVA (10-20mm) maybe higher density (~300KG/m3)

elastomere

carbon/kelvar structural sheet or honeycomb

EVA 10mm maybe lower density (~100kg/m3)

brillo pads or other diffraction control foams

but honestly just working with foamcore or EVA, felt liners and some brillo pads in critical locations can make awesome enclosures.

felt pads or open-cell-foam

EVA (10-20mm) maybe higher density (~300KG/m3)

elastomere

carbon/kelvar structural sheet or honeycomb

EVA 10mm maybe lower density (~100kg/m3)

brillo pads or other diffraction control foams

but honestly just working with foamcore or EVA, felt liners and some brillo pads in critical locations can make awesome enclosures.

Last edited:

You guys are getting exotic and complicating the simplicity of this thread, which is using a lightweight, inexpensive, easy to cut, and easy to assemble material.

Having said that, I would love to see a Carbon Fiber covered foam enclosure. Just remember to line with denim, felt, etc on the inside.

Having said that, I would love to see a Carbon Fiber covered foam enclosure. Just remember to line with denim, felt, etc on the inside.

You guys are getting exotic and complicating the simplicity of this thread, which is using a lightweight, inexpensive, easy to cut, and easy to assemble material.

Having said that, I would love to see a Carbon Fiber covered foam enclosure. Just remember to line with denim, felt, etc on the inside.

Nothing wrong with complicating a simple thing just for the fun of it

Nothing wrong with complicating a simple thing just for the fun of itlol

I agree! Hence, my comment about using carbon fiber. Actually, personally, I like to complicate simple things, or so says my wife..

I can't see the advantage of carbon fiber in this application, as its excellent MOE/mass ratio simply doesn't matter. For that matter UTS/mass doesn't matter much either.

Something like this is more suited for home speakers IMO: Plaster cloth.

Or, split the difference and use fiberglass/epoxy.

FWIW, I drive by this place once in a while. Foam Mart. There might be something of interest there for you foam enthusiasts. The only EVA they have is L200 (polyethylene)/EVA blend, but they do have it in white sheets.

Something like this is more suited for home speakers IMO: Plaster cloth.

Or, split the difference and use fiberglass/epoxy.

FWIW, I drive by this place once in a while. Foam Mart. There might be something of interest there for you foam enthusiasts. The only EVA they have is L200 (polyethylene)/EVA blend, but they do have it in white sheets.

Foammart. Cool store. It's there because Culver City is Hollywood studios and they buy to make movie props and sets. Tougher to find a place like that elsewhere.

Yeah mostly, props, sets, costumes. Sometimes you just need to make a big alien monster fast. There's a store in Burbank too. Actually more studios there these days. There's still remnants of aerospace here too.

When I was talking about carbon fiber, I was just referring to a normal foam core board enclosure with carbon fiber on the outside just for looks, it can also be accomplished using vinyl imitating carbon fiber. Brillo pads are very good to improve sound, but I wouldn't place speakers with brillo covered baffle in my living room, maybe in my private listening room.

EddieT, not sure I understand your question. Which "Steens" do you mean? The mainstay speakers have cloth that is simply a cosmetic treatment. The speakers are in boxes (a bit different from usual square boxes), then there are 4 posts around the boxes around which the cloth is wrapped. It differs with different models though. The construction can be seen here: http://www.soundandvision.com/images/styles/600_wide/public/correct2cebhr-1.jpg?itok=M1DO0wh4. For the 1C, there does appear to be some felt on the baffle of the tweeter box behind the tweeter (http://4.bp.blogspot.com/-4pYwB0ObbKY/TlY-VJUd7JI/AAAAAAAANKI/iWsRog0_nH8/s1600/Vandersteen+1c.JPG), but I've never seen a good image of it. I own the 1c and it is a very nice speaker (but I'm not up to removing the integrated cloth surround.

Last edited:

FWIW, I drive by this place once in a while. Foam Mart. There might be something of interest there for you foam enthusiasts. The only EVA they have is L200 (polyethylene)/EVA blend, but they do have it in white sheets.

that particular EVA looks good! Just a little more expensive than what I pay (about 33% more) but it comes in much larger sheets and a little thicker (1/2" vs 10mm) and might be slightly higher density than the koyosoftboard. EVA is not really a cheap material, but it is such a pleasure to work with and makes nice sounding speakers.

And yes I am sure it is being sold there for the costume and prop making. May also be used for prototyping. PE/EVA foam is used along with clay to build physical prototype models, especially cars and many car design houses are out in California (like toyota). But maybe the days of building foam and clay prototypes will start to fade into history with 3D printing becoming cheaper and being able to make bigger objects.

One Thing Isn't New in Car Design: Clay Prototypes - WSJ

https://www.youtube.com/watch?v=cEW4uE5sg6s

Last edited:

Thanks for the response, I wasn't sure whether the cloth served an accoustic purpose or was just an economical covering. I appreciate the links, I had never heard of these units. Cool!EddieT, not sure I understand your question. Which "Steens" do you mean? The mainstay speakers have cloth that is simply a cosmetic treatment. The speakers are in boxes (a bit different from usual square boxes), then there are 4 posts around the boxes around which the cloth is wrapped. It differs with different models though. The construction can be seen here: http://www.soundandvision.com/images/styles/600_wide/public/correct2cebhr-1.jpg?itok=M1DO0wh4. For the 1C, there does appear to be some felt on the baffle of the tweeter box behind the tweeter (http://4.bp.blogspot.com/-4pYwB0ObbKY/TlY-VJUd7JI/AAAAAAAANKI/iWsRog0_nH8/s1600/Vandersteen+1c.JPG), but I've never seen a good image of it. I own the 1c and it is a very nice speaker (but I'm not up to removing the integrated cloth surround.

Thanks for the response, I wasn't sure whether the cloth served an accoustic purpose or was just an economical covering. I appreciate the links, I had never heard of these units. Cool!

It actually does both: serve an acoustical purpose and economical. Vandeersteen designs his speakers first around sound. So this means he uses multiple enclosures for each driver, felt fronts for baffle diffraction, time aligned. The vandersteen model 2e entered production in 1977 so he may have been one of the first to use separate small enclosures for each driver and step them to get time alignment. The B&W 801 came after in 1979. Now it is really common. I had a friend in university who had the Model 1 and they sounded excellent and I almost bought a pair. The cloth sock is to cover up this rather raw look (unpainted rough non-reflective MDF, exposed felt covers, stepped boxes) and to create a transparent cover to not interfere with the sound.

You can see the felt front cover and how the sock works better in the model5

found this picture of the model3 without the socks

Reading the Model 3ce page is like stepping back in time. "The Model 3A Signature's enclosure is constructed of 1 to 1 1/2 inch thick MDF, an advanced material that resists vibration and reduces cabinet resonances.". But it is still very cool that they still make the original Model 1/2/3. They are still excellent speakers.

Last edited:

- Home

- Loudspeakers

- Full Range

- Foam Core Board Speaker Enclosures?