Greetings,

I've been following this thread on and off with interest and need to give some of these foam core builds a try. Saw that the small Tc9 Vifa's were on sale at PA so I order up a dozen. My first built was a set of the Manzi's which quickly morphed into a much bigger MTMWW OB project. The bigger set was fun, they turned out great, sound great... it was just a lot of time on one project...like all last winter 🙂. Went a bit overboard, nothing new.

Hoping to start on a foam core project with a pair of xrk971's 30" f3 variants (back around the #1020 post mark). After that, onto a set of the 20" Cornu's.

xrk971, I noticed after you posted the sound bit of these, the thread headed into another direction. Did you by chance save your cut patterns or other dimensional build info? If so, any chance of posting that? If not, no worries, I can always go onto the Frugel Horn site for some plans. I really liked the scale of them and loved the lower flare detail...very nice touch.

Kindest,

Marko

I've been following this thread on and off with interest and need to give some of these foam core builds a try. Saw that the small Tc9 Vifa's were on sale at PA so I order up a dozen. My first built was a set of the Manzi's which quickly morphed into a much bigger MTMWW OB project. The bigger set was fun, they turned out great, sound great... it was just a lot of time on one project...like all last winter 🙂. Went a bit overboard, nothing new.

Hoping to start on a foam core project with a pair of xrk971's 30" f3 variants (back around the #1020 post mark). After that, onto a set of the 20" Cornu's.

xrk971, I noticed after you posted the sound bit of these, the thread headed into another direction. Did you by chance save your cut patterns or other dimensional build info? If so, any chance of posting that? If not, no worries, I can always go onto the Frugel Horn site for some plans. I really liked the scale of them and loved the lower flare detail...very nice touch.

Kindest,

Marko

Marko,

Sounds like you have been busy! Good to hear you are having fun with the Vifa's. The Fh3-inspired speaker has its own thread with a rough plan. Jim Shearer was able to build them using these plans although he did not flare the horn mouth.

Good luck!

X

Sounds like you have been busy! Good to hear you are having fun with the Vifa's. The Fh3-inspired speaker has its own thread with a rough plan. Jim Shearer was able to build them using these plans although he did not flare the horn mouth.

Good luck!

X

mnsouthpaw, he gave the design software's name and the figures to put into it in message #2005, about 16 messages before yours.

Those Vifas are getting pretty popular. My build has 8 of them and two Vifa mini-subs. xrk971, how about posting some stuff on Parts Express's forum? Might get some good feedback there.

Those Vifas are getting pretty popular. My build has 8 of them and two Vifa mini-subs. xrk971, how about posting some stuff on Parts Express's forum? Might get some good feedback there.

You made a sub woofer with the Vifa TC9FD?!! Please share photos. 🙂

I barely have enough time to post stuff in one forum - posting in PE might raise too much interest and the drivers will sell out. I hope it's not a sign that they are going to discontinue them. You guys should get those 6.5 in woofers for $4.88 and build some foam core TH subs with them. Or use them as bass drivers in a Synergy. You can't go wrong at that price. It looks to be the same driver as what Dayton uses in their popular B652's - that and a $1.75 Mylar dome tweeter XO'd with a single cap. Explains how they can sell those speakers for $30/pair.

I barely have enough time to post stuff in one forum - posting in PE might raise too much interest and the drivers will sell out. I hope it's not a sign that they are going to discontinue them. You guys should get those 6.5 in woofers for $4.88 and build some foam core TH subs with them. Or use them as bass drivers in a Synergy. You can't go wrong at that price. It looks to be the same driver as what Dayton uses in their popular B652's - that and a $1.75 Mylar dome tweeter XO'd with a single cap. Explains how they can sell those speakers for $30/pair.

Last edited:

Last edited:

Doc McClain,

Those look like the buyout 16 ohm 5 in Tang Band subs from PE. Nice drivers - used in qnty 4 gets 4 ohms net.

Those look like the buyout 16 ohm 5 in Tang Band subs from PE. Nice drivers - used in qnty 4 gets 4 ohms net.

Aye, laddie, that they are, and a good eye on ye to be sure. The two in parallel come to 8 ohms, matching the 68W sub channel of the Lepai 2.1 amp on top. They do a creditable job despite the less than optimal enclosure (I was going for compact, not efficiency). It all currently resides in the middle seat of my minivan, fed by an MP3 player, as the selection of radio material here in central Appalachia leaves something to be desired. Twas supposed to serve as a portable guitar amp combo originally, but the Tang Band full rangers were still sounding pretty at warp factor 5 when I wanted them to distort. I gave 'em all we got Coptin, and I donna think they can handle much more, and *still* sounding pretty. Seriously, they're some fine woofer/subs. A bit heavy for foam board constructions maybe.

Thanks fellas for the input. I ended up purchasing a used pair with ch70's?? from a gentlemen in the Chicago area. This will help to me acquainted with a full ranger sound and I can use them as a bench mark for working with the tc9's.

Kindest,

Marko

Kindest,

Marko

Cochlear sealed TL

I always wanted to see what a sealed spiral TL sounds like - the famous B&W Nautilus being the inspiration. Supposedly it has very clean dynamics because there is very little back wave reflection to the cone. Anyhow, I thought I would give it a try with the trusty Vifa TC9FD. I think sealed TL's follow lambda/2 for setting the length. The total path is about 3 ft. I have no idea how it will sound and actually did not bother to model it - I just hand drew the spiral on a piece of foam and hot melted away 🙂

Here is what I have so far, now waiting for the PVA glue to dry on the capping operation.

I always wanted to see what a sealed spiral TL sounds like - the famous B&W Nautilus being the inspiration. Supposedly it has very clean dynamics because there is very little back wave reflection to the cone. Anyhow, I thought I would give it a try with the trusty Vifa TC9FD. I think sealed TL's follow lambda/2 for setting the length. The total path is about 3 ft. I have no idea how it will sound and actually did not bother to model it - I just hand drew the spiral on a piece of foam and hot melted away 🙂

Here is what I have so far, now waiting for the PVA glue to dry on the capping operation.

Attachments

Cochlear sealed TL - Build Completed

This things sounds great! I am surprised how much bass actually comes out of the direct radiator cone. The mids and highs are exceptionally clear - the transparency and detail are quite astonishing with the few test tracks I have listened to. I like how it sounds and I think when in stereo the sound stage will be very nice.

It is 12 in tall x 5 in wide x 9 in deep. Here it is sitting on top of the old Yamaha RX360 amp with a TPA3116D2 and a TPA3110D2 (in blue snap top lid box). Second photo is the back side so you can see the nice curves that the foam core can make.

This things sounds great! I am surprised how much bass actually comes out of the direct radiator cone. The mids and highs are exceptionally clear - the transparency and detail are quite astonishing with the few test tracks I have listened to. I like how it sounds and I think when in stereo the sound stage will be very nice.

It is 12 in tall x 5 in wide x 9 in deep. Here it is sitting on top of the old Yamaha RX360 amp with a TPA3116D2 and a TPA3110D2 (in blue snap top lid box). Second photo is the back side so you can see the nice curves that the foam core can make.

Attachments

Pretty neat! Do you have a mic for some quick measurements? I'd like to see a near-cone plot for that one. How does it compare to the small Karlsonator?

I haven't done much enclosure experimentation lately, but had the FF85WK ¾-wave pipe trotting back in my mind lately for some reason. The foamcore prototype I made almost a year ago showed some promise. I'm pretty certain what I was going for worked to some extent, but I'd have to compare with a more standard pipe to see if it offers any advantages.

IG

I haven't done much enclosure experimentation lately, but had the FF85WK ¾-wave pipe trotting back in my mind lately for some reason. The foamcore prototype I made almost a year ago showed some promise. I'm pretty certain what I was going for worked to some extent, but I'd have to compare with a more standard pipe to see if it offers any advantages.

An externally hosted image should be here but it was not working when we last tested it.

IG

Last edited:

I will try to get a measurement in next few days but first have something to try...

Remember the tractrix foam core horn I made a while ago?

Remember the tractrix foam core horn I made a while ago?

This things sounds great! I am surprised how much bass actually comes out of the direct radiator cone. The mids and highs are exceptionally clear - the transparency and detail are quite astonishing with the few test tracks I have listened to. I like how it sounds and I think when in stereo the sound stage will be very nice.

It is 12 in tall x 5 in wide x 9 in deep. Here it is sitting on top of the old Yamaha RX360 amp with a TPA3116D2 and a TPA3110D2 (in blue snap top lid box). Second photo is the back side so you can see the nice curves that the foam core can make.

That speaker looks AWESOME!

I will try to get a measurement in next few days but first have something to try...

Remember the tractrix foam core horn I made a while ago?

Yeah I do, tried it much yet? I've made a Tractrix of my own as well a while ago. Paper petal variety:

IG

Cochlear w/ Tractrix

BP1Fan,

If you think that looks good, check out what it looks like with a front tractrix horn - now were cooking with fire! The sound is very wide dispersion and makes the driver appear substantially louder - although I detect some horn coloration as this was not at all optimized.

BP1Fan,

If you think that looks good, check out what it looks like with a front tractrix horn - now were cooking with fire! The sound is very wide dispersion and makes the driver appear substantially louder - although I detect some horn coloration as this was not at all optimized.

Attachments

Cochlear sealed TL- near cone measurements

IG,

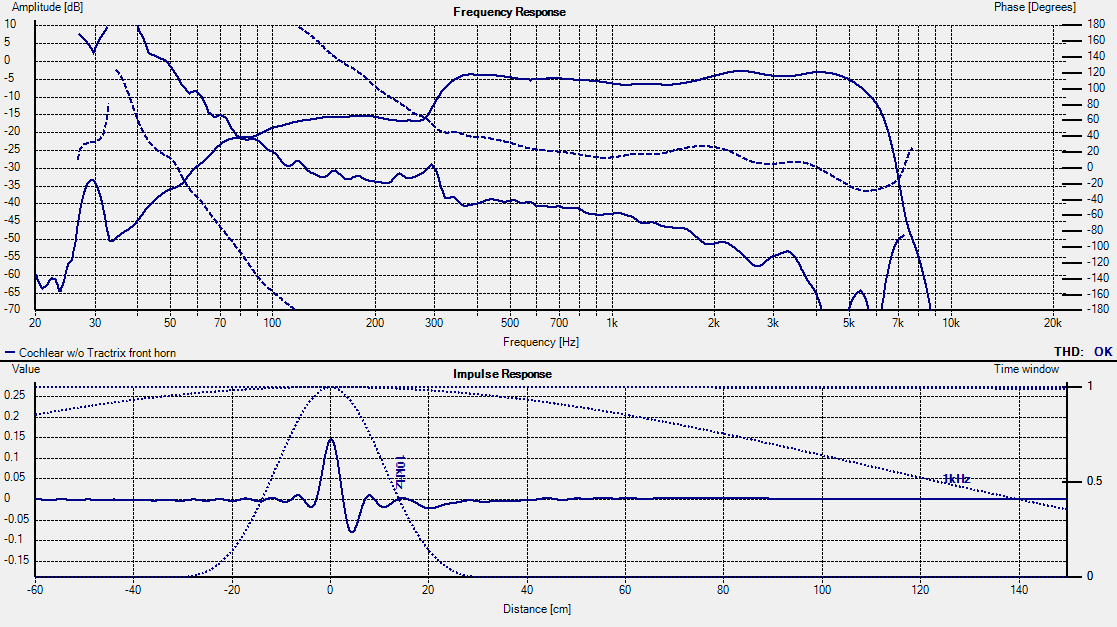

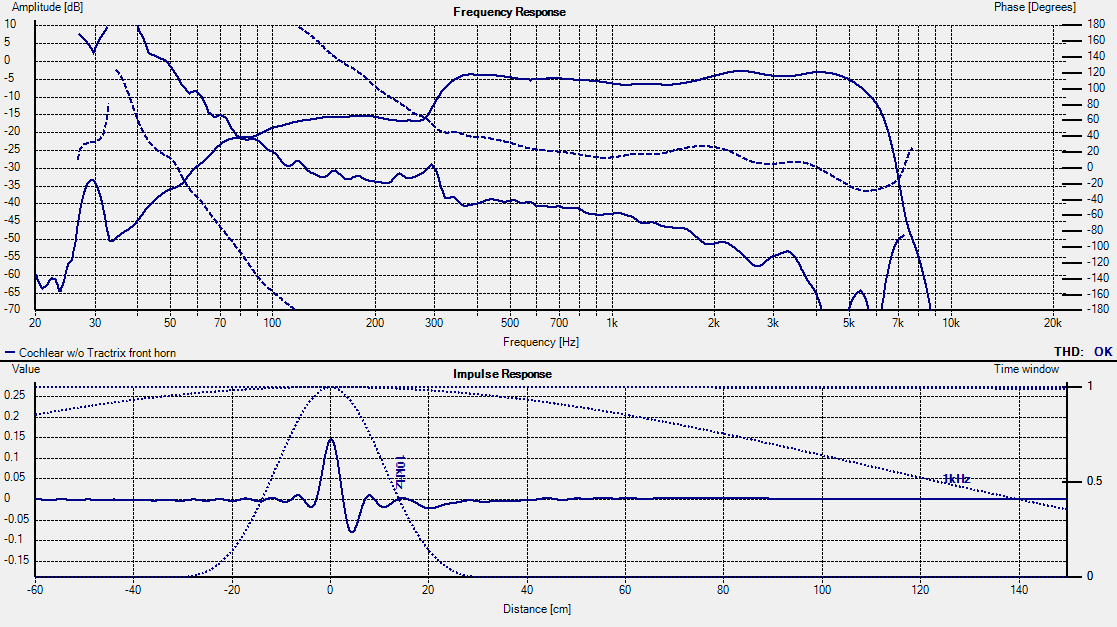

I have some near cone measurements (1 in from cone). My setup uses a Panasonic WM61A capsule and the built-in mic input on the laptop which was designed for video conferencing etc so I think it has a low pass filter at around 5kHz. I am pretty sure the speaker has plenty above this sharp falloff. What I can measure though is very flat - as expected from a cochlear spiral with stuffing. There appears to be NO reflections whatsoever and the response is amazingly flat. The bump at 30 Hz is the hum from the HVAC. The drop near 330 Hz probably corresponds to the closed-ended TL length of 36 inches (1-Lambda of 312 Hz)? Look at how clean the impulse response is, and the low THD of less than -40dB, and the nice -20 to 20 deg linear variation in phase.

IG,

I have some near cone measurements (1 in from cone). My setup uses a Panasonic WM61A capsule and the built-in mic input on the laptop which was designed for video conferencing etc so I think it has a low pass filter at around 5kHz. I am pretty sure the speaker has plenty above this sharp falloff. What I can measure though is very flat - as expected from a cochlear spiral with stuffing. There appears to be NO reflections whatsoever and the response is amazingly flat. The bump at 30 Hz is the hum from the HVAC. The drop near 330 Hz probably corresponds to the closed-ended TL length of 36 inches (1-Lambda of 312 Hz)? Look at how clean the impulse response is, and the low THD of less than -40dB, and the nice -20 to 20 deg linear variation in phase.

Attachments

Last edited:

MisterTwister,

No, I don't have a way to measure impedance - as it is a sealed alignment, I would imagine it is a single peak somewhere near the tuning freq of the TL at about 300 Hz.

X

No, I don't have a way to measure impedance - as it is a sealed alignment, I would imagine it is a single peak somewhere near the tuning freq of the TL at about 300 Hz.

X

- Home

- Loudspeakers

- Full Range

- Foam Core Board Speaker Enclosures?