Cochleus,

You are the king of foam core projects! You like building tall waveguides, I like thin flat ones... thanks for sharing your stash of tubes.

Xrk971

You are the king of foam core projects! You like building tall waveguides, I like thin flat ones... thanks for sharing your stash of tubes.

Xrk971

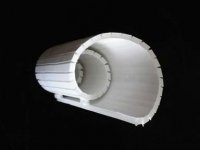

Here is a pic of some of my experiments...

I like this guy. 🙂 But I don't see any in the shape of a snail.

thanks for the comments,

just thinking out loud here for a moment, if i was to make the throat chamber larger, and the horn path shorter, what would that do to the response?

just thinking out loud here for a moment, if i was to make the throat chamber larger, and the horn path shorter, what would that do to the response?

@ klampykixx

I don't see the two speakers, just one big....are you going to separate them ?

I wish.

Then, looking at the mouth of the horn which partially covers the lower driver, you should try a quasi-series arrangement of the two, shunting the lower speaker with a cap. So only one of them would emit the higher frequencies, which is the higher driver 🙂

I don't see the two speakers, just one big....are you going to separate them ?

I wish.

Then, looking at the mouth of the horn which partially covers the lower driver, you should try a quasi-series arrangement of the two, shunting the lower speaker with a cap. So only one of them would emit the higher frequencies, which is the higher driver 🙂

thanks for the comments,

just thinking out loud here for a moment, if i was to make the throat chamber larger, and the horn path shorter, what would that do to the response?

The throat, or the pre-chamber behind the drivers larger? Making it shorter pushes the tuning freq of the design higher by proportional amount. For example, if length is 73 cm and you decrease length by 7.3 cm (10%), the 114 Hz freq will rise by about 11 Hz. If your channel width was not so skinny as to be the limiting area or choke point, increasing it helps increase the efficiency of the bass output, to a point. Increasing the throat area greater than the piston area does no good. Making the actual chamber larger is a more complex effect that must be modeled using MJK's Mathcad worksheets as it adds capacitance to the acoustic impedance of the tml.

@ klampykixx

I don't see the two speakers, just one big....are you going to separate them ?

I wish.

Then, looking at the mouth of the horn which partially covers the lower driver, you should try a quasi-series arrangement of the two, shunting the lower speaker with a cap. So only one of them would emit the higher frequencies, which is the higher driver 🙂

That would solve your undersized throat problem as the throat is only needed for bass extension.

@xrk971

well actually, the cornu has been fuel for thought...I have a "new" idea...🙄

What is the new idea? We are all in suspense... Maybe a snail shaped horn using Fibonacci's golden ratio? I have been starting on a design with 1:1:2:3:5:8:13 expansion that looks like a snail. It ends up quite big compared to the Cornu which is very compact.

Im not sure i understand what you mean by shunting the speaker ? Do u mean to have a cap.in parallel with just one driver leaving the other open? Being as theyre bot lh in parallel to give 4ohm wouldnt that then filter both drivers?

I think what was said earlier about the horn not being sealed is definately playing a big part in how it sounds (more so, doesnt sound) as i flipped the box onto the carpet today and it sounded much better..

Ill wait till i get my little chip amp before i seal her up. After listening to it more and more im getting used to it and its not bad. I have to remind myself its a quad of three inchers not fifteen inchers.... Lol

Also stuffing helped 🙂

I think what was said earlier about the horn not being sealed is definately playing a big part in how it sounds (more so, doesnt sound) as i flipped the box onto the carpet today and it sounded much better..

Ill wait till i get my little chip amp before i seal her up. After listening to it more and more im getting used to it and its not bad. I have to remind myself its a quad of three inchers not fifteen inchers.... Lol

Also stuffing helped 🙂

Hope this helps

Nice work! This is more of a sub woofer cabinet as I think your stereo imaging would be shot. One more tip, I glue a piece of wood onto the foam core where the screws go and drill hole for wood screws to bite, this relieves stress on foam which will not hold drivers for long. I think the capacitor the previous poster was referring to can be placed in series with the positive wire leading from the driver where the speaker cables come in and are attached, but between the first and second driver. Essentially making a high pass for the second driver. You probably want to switch the high freq driver to the front and have the bass in the back. It can still be wired like you have in parallel (8 ohms at low freq and 4 ohms at high when the cap kicks in). Probably effective impedance is between 4 and 8 ohms.

Last edited:

...nearly !! I said quasi-series...maybe quasi was a strange term !

As long as I see the drivers are not identical. maybe it is not doable perfectly.

By putting the drivers in series and putting a cap across one's terminals , you'll

get the same 'effect' as doing it with a series cap in a parallel crossover circuit, but

in this case the impedance Z doubles- It's good with 4 Ω drivers to have a Z=8Ω and only one emitting the highs, which is the most important thing .

I suggest Mr. Klampy to cut that thing into two parts and make two distinct boxes , then try different nets ( crossovers). A 20 uF cap would be ok ( if they are 4Ω ), bipolar of course.

As long as I see the drivers are not identical. maybe it is not doable perfectly.

By putting the drivers in series and putting a cap across one's terminals , you'll

get the same 'effect' as doing it with a series cap in a parallel crossover circuit, but

in this case the impedance Z doubles- It's good with 4 Ω drivers to have a Z=8Ω and only one emitting the highs, which is the most important thing .

I suggest Mr. Klampy to cut that thing into two parts and make two distinct boxes , then try different nets ( crossovers). A 20 uF cap would be ok ( if they are 4Ω ), bipolar of course.

xrk971

do you have a link or url for MJK's paper or will a google search lead to the promised land!

by Sd do you mean speaker diameter?

I ran across this tutorial on designing horns and transmission lines that is very helpful. I think it was suggested by diyaudio member Charcoal - maybe his blog. S.A.M. "Saburov Audio Manufacture"

Before I start I want to say that klampy's unit sure looks trick. I hope it sounds that much better when you seal it up.

I wonder how Cal's front baffles came out and if he is listening to the Cornu's right now?

We are 3 hours different so it doesn't happen that early. I think I hear SWMBO stirring in the bedroom and that's where I'll be setting them up. This is how far I got this morning. You can see the planet10 mods to the drivers with the EnABLe, cone coating, basket damping with duct seal and a felt pad on the magnet. [Thanks Dave].

The cabinets came out fine and for now I have just a small gauge wire running through the back. It's a really tight squeeze so I'm not worried about leakage. Now I go hook them up and report back. I have to fit in a shower and breakfast too so be patient. Today is also our annual curling day so I won't have a lot of time to listen. I remember now that Dave does the driver break-in and T/S matching so we really are going to see the best these drivers can deliver.

Back in a while.

Attachments

We are 3 hours different so it doesn't happen that early. I think I hear SWMBO stirring in the bedroom and that's where I'll be setting them up. This is how far I got this morning. You can see the planet10 mods to the drivers with the EnABLe, cone coating, basket damping with duct seal and a felt pad on the magnet. [Thanks Dave].

The cabinets came out fine and for now I have just a small gauge wire running through the back. It's a really tight squeeze so I'm not worried about leakage. Now I go hook them up and report back. I have to fit in a shower and breakfast too so be patient. Today is also our annual curling day so I won't have a lot of time to listen. I remember now that Dave does the driver break-in and T/S matching so we really are going to see the best these drivers can deliver.

Back in a while.

Congratulations on finishing the build! The suspense is killing me...🙂 Those are trick looking drivers.

Last edited:

- Home

- Loudspeakers

- Full Range

- Foam Core Board Speaker Enclosures?