Hello guys, I'm new here and have in the last year rediscovered my passion for building speakers. Many years ago i was involved in the car audio scene and became disillusioned with power being the goal and quality thrown out the window, My last car system i built after only 15minutes of listening i stopped the car and pulled the fuse in disgust, removed the subs and sold it off, no more doof doof.

Recently after visiting a friend and hearing his rather expensive home sound system it gave me a new direction to head in, so after reading many reviews of speakers and deciding the type of music i enjoy listening to i started building the fostex back loaded horn.

Once again being in my shed building with timber brought back what i enjoyed most about audio, for me its more about the construction of the boxes as well as the listening that gives me the most satisfaction, store bought speakers no matter how expensive don't do it for me.

The project took roughly 2 months as most of the time was spent waiting on materials to arrive and waiting for stock to come in (FE166 drivers)

My listening impressions of the speakers i have trouble verbalizing so i won't go into much detail, all i can say is i'm very impressed for the type of music i relax too and can't imagine needing the recommended super tweeter with my high quality tracks.

I changed the plans somewhat to my own taste but most is just cosmetic.

Thank you for looking and if you have any questions ask away, i enjoy sharing and talking about my new found passion.

Recently after visiting a friend and hearing his rather expensive home sound system it gave me a new direction to head in, so after reading many reviews of speakers and deciding the type of music i enjoy listening to i started building the fostex back loaded horn.

Once again being in my shed building with timber brought back what i enjoyed most about audio, for me its more about the construction of the boxes as well as the listening that gives me the most satisfaction, store bought speakers no matter how expensive don't do it for me.

The project took roughly 2 months as most of the time was spent waiting on materials to arrive and waiting for stock to come in (FE166 drivers)

My listening impressions of the speakers i have trouble verbalizing so i won't go into much detail, all i can say is i'm very impressed for the type of music i relax too and can't imagine needing the recommended super tweeter with my high quality tracks.

I changed the plans somewhat to my own taste but most is just cosmetic.

Thank you for looking and if you have any questions ask away, i enjoy sharing and talking about my new found passion.

I'm struggling a little with the replies as it seems it all must be approved before posting, that's cool though i understand how much rubbish most forums attract.Please bear with me...

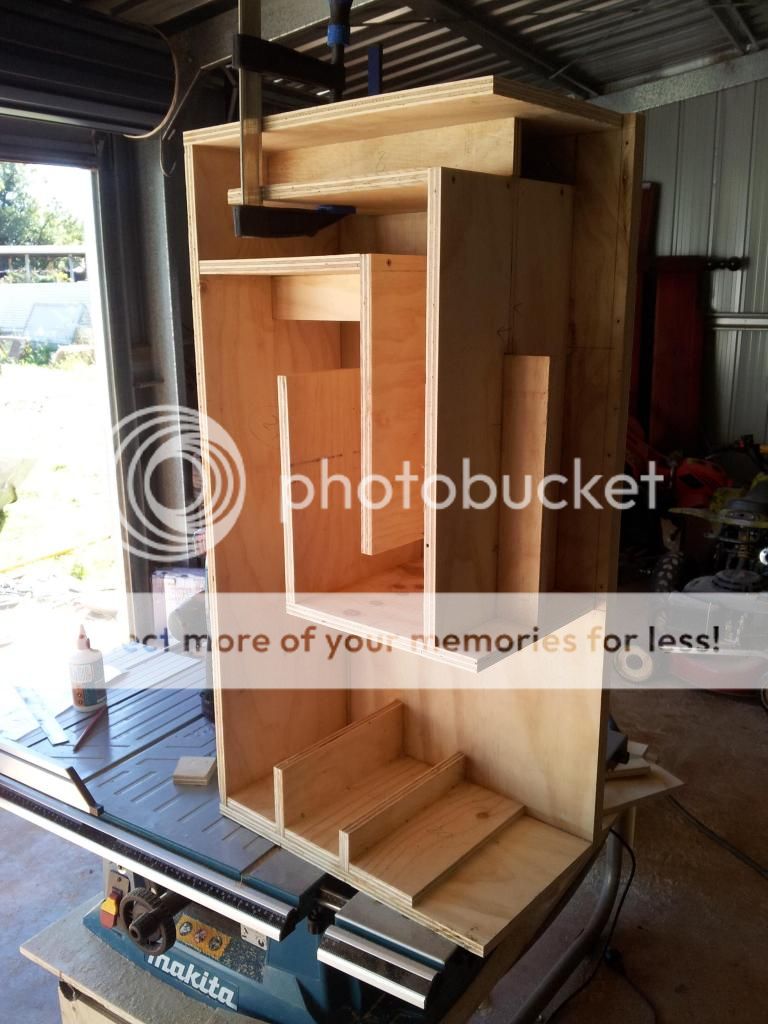

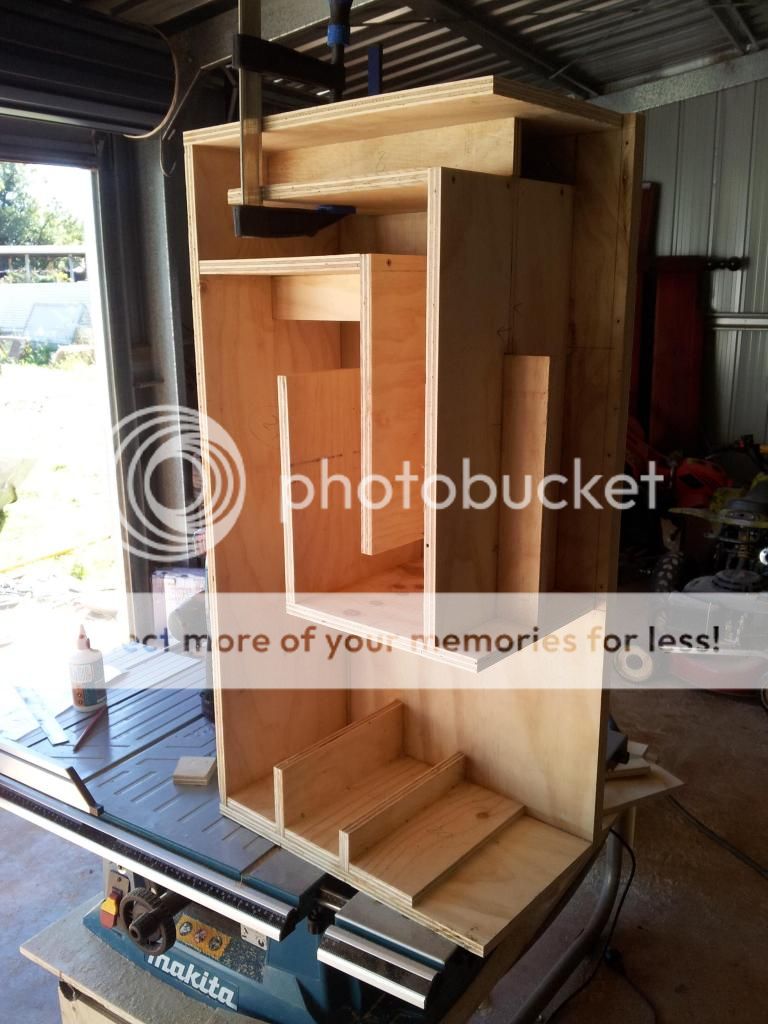

Picture shows another angle and also you can see the saw i used for this project.The Makita mlt was fine once it was calibrated to cut straight, and although it's nothing like im used to it (my father used to own a cabinet making shop) seems to be good enough if you put in the time and effort.

Picture shows another angle and also you can see the saw i used for this project.The Makita mlt was fine once it was calibrated to cut straight, and although it's nothing like im used to it (my father used to own a cabinet making shop) seems to be good enough if you put in the time and effort.

So here is the speaker boxes assembled starting to undergo the usual sand and bogging procedure. I realise that many people like ply wood to be left as the final finish once sanded with maybe some stain but this plywood quality wasn't a perfect surface so i took a different path.

The plywood thickness i used was 15mm for the inner panels and sides and back were 25mm.

I contemplated painting the whole speaker but after much consideration decided a paper backed veneer would give me the look i was after, with a vinyl wrapped face plate.

The plywood thickness i used was 15mm for the inner panels and sides and back were 25mm.

I contemplated painting the whole speaker but after much consideration decided a paper backed veneer would give me the look i was after, with a vinyl wrapped face plate.

So here is where i tested small off cuts of veneer with various stains and top coat clears and decided to give the cherry some additional stain to create a colour i was happy with.The final coat of clear is a two part poly applied in 4 coats, very thick.

You can see i added the felt positioned behind the rear of the driver and also made up some grills to suit my taste, the open mouths of the horn looked to become a likely place for dust to gather so another good reason to make them.

The face plates wrapped in vinyl are held by stainless nutserts and stainless socket head cap screws sealed with small rubber o-rings. once you start using them it's hard to stop lol.

Underneath the face plate is a custom made rubber gasket.

You can see i added the felt positioned behind the rear of the driver and also made up some grills to suit my taste, the open mouths of the horn looked to become a likely place for dust to gather so another good reason to make them.

The face plates wrapped in vinyl are held by stainless nutserts and stainless socket head cap screws sealed with small rubber o-rings. once you start using them it's hard to stop lol.

Underneath the face plate is a custom made rubber gasket.

So after finishing the inside throat of the horn with filler and primer is was coated in a satin black finish and several coats of clear.

The final fitting of speakers was done, tested termination of wires and took them inside to show the wife for final approval.lol Yes she was happy, well that's a start.

Time to take them into my upstairs media room im fitting out and test different filling/ angles/ settings..e.t.c to find a sound im happy with.

The final fitting of speakers was done, tested termination of wires and took them inside to show the wife for final approval.lol Yes she was happy, well that's a start.

Time to take them into my upstairs media room im fitting out and test different filling/ angles/ settings..e.t.c to find a sound im happy with.

Assorted pics of finished boxes. Speakers have roughly 60 hours on them in listening time and no issues so far.

Found that tracks from Michael Jackson seem to be there strong point funny enough as well as anything with a lot of vocals. Some jazz and orchestral also complement them.

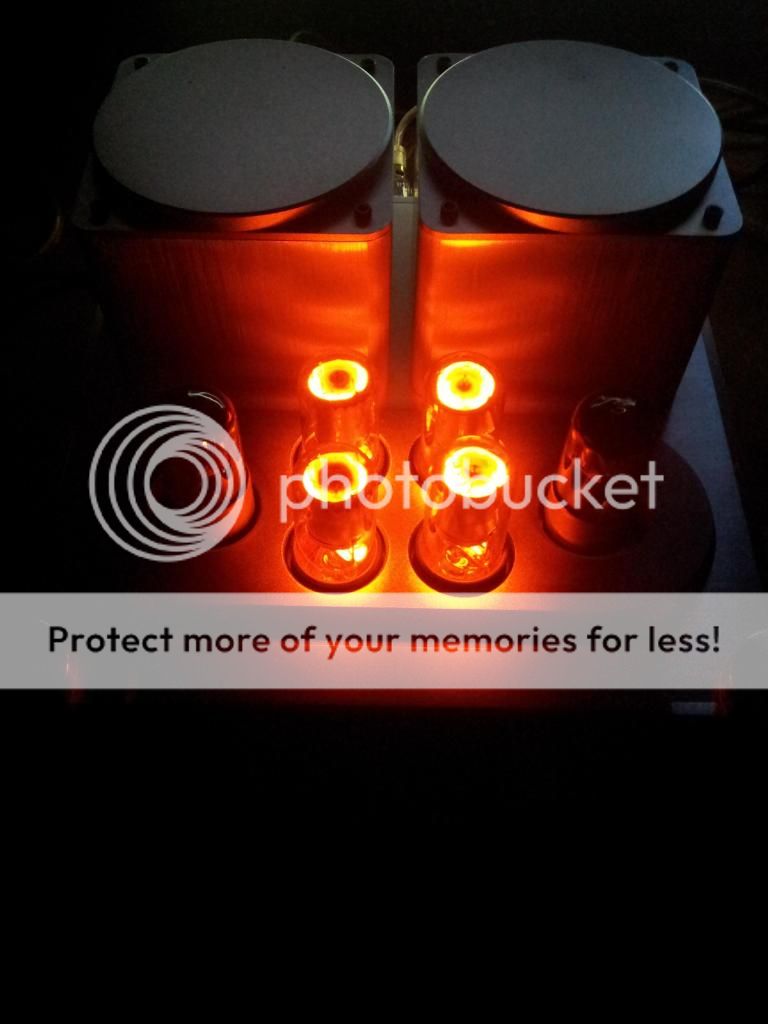

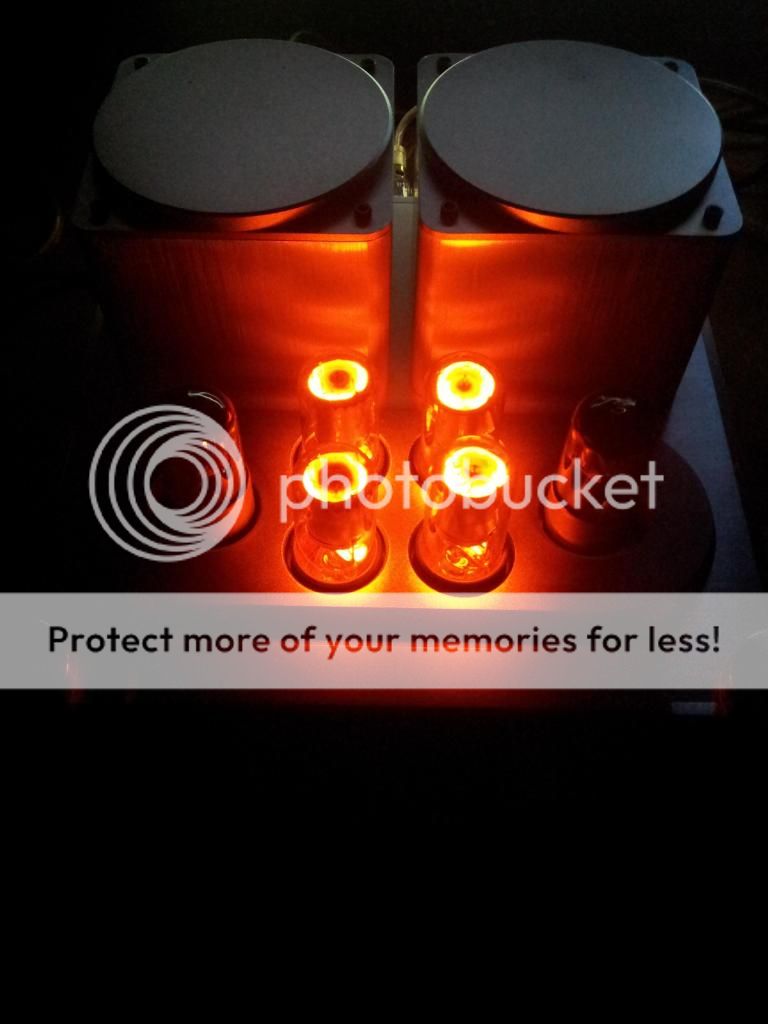

The best so far is probably the track, "Thriller" ripped from his c.d to loss-less played through my Dac and small valve amp, probably the first time i've ever really heard how detailed the song is.lol

Can't wait to finish the room properly so it's much better acoustically for further testing.

Also awaiting some mono blocks to hear any difference that may make.

Found that tracks from Michael Jackson seem to be there strong point funny enough as well as anything with a lot of vocals. Some jazz and orchestral also complement them.

The best so far is probably the track, "Thriller" ripped from his c.d to loss-less played through my Dac and small valve amp, probably the first time i've ever really heard how detailed the song is.lol

Can't wait to finish the room properly so it's much better acoustically for further testing.

Also awaiting some mono blocks to hear any difference that may make.

Thank you Godzilla, i appreciate it. Ihope the other pics i uploaded get approved soon.The speakers came out beautiful! Enjoy them!

Anyone know what these type of speakers sell for in shops?

Horn loudspeakers cost always a lot as it is difficult to automate the process. You save a lot of money by providing your own working hours.

Congratulations with your speakers, they are very nicely done.

Anyone know what these type of speakers sell for in shops?

Very nice work on the speakers! Finding a Fostex back loaded horn in a retail shop in the United States would be rare. From time to time, some diy back loaded horns sell on Audiogon, but usually for not a lot more than what the materials and drivers cost.

Enjoy the new speakers!

Thank you Talaerts, they are my favourite speakers so far. Yes time is quite a lot more than standard bass reflex or ported design but i'm sure it's worth it.Horn loudspeakers cost always a lot as it is difficult to automate the process. You save a lot of money by providing your own working hours.

Congratulations with your speakers, they are very nicely done.

Cervelorider i've looked quite hard to find some in shops but came up with nothing, that's why i asked if others had seen somthing along the same type.I think they might be hard to sell to the normal public as it's hard to justify the cost in building to them when they can buy some cheap multi ways that cost half as much and look more impressive.Very nice work on the speakers! Finding a Fostex back loaded horn in a retail shop in the United States would be rare. From time to time, some diy back loaded horns sell on Audiogon, but usually for not a lot more than what the materials and drivers cost.

Enjoy the new speakers!

Thanks IG81, yes there is definitely a certain satisfaction from building your own speakers that can't be replaced by store bought, the ladder section nearly didn't make it as bogging and finishing around it was a major time consuming pain.Great job man, they look great! I like that you used the recommended ladder-brace on the back. I've made one for a 12" Karlson I built and it really made that flabby back-panel rock-solid.

I'm with you on the "commercial speakers just don't do it" side of things.

IG

Next time i think i'd use 25mm ply on the back and do away with it.

Next time i think i'd use 25mm ply on the back and do away with it.

That's another brute-force solution that works. I doubled-up my 18mm BB-ply on a recent large speaker build and it does the job.

IG

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Full Range

- fostex project start to finish