I see a few folks have tried different designs for the W5-1611SAF, so going to try my luck.

Since I typically dance to the beat of a different drum here is the direction I'm headed.

I had a few ideas but was inspired by plans found here (post 13):

http://www.diyaudio.com/forums/full-range/188620-onken-near-field-monitor-2.html

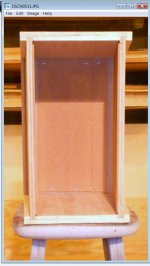

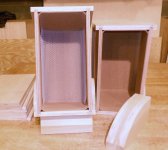

AND other full range boxes with a W shape & flare ports. This will be a combination of both (similar to red box). The tuning will be done on the work bench by trimming the flare ports. Not easy to see in pic. but glued 4 pieces of 5" x 1/2" poplar that will be cut/fit/sanded and again, trimmed as needed.

Cones are coated - thin layer of RTV 118.

Speaker Driver: http://www.tb-speaker.com/detail/0624_11/w5-1611saf.htm

Since I typically dance to the beat of a different drum here is the direction I'm headed.

I had a few ideas but was inspired by plans found here (post 13):

http://www.diyaudio.com/forums/full-range/188620-onken-near-field-monitor-2.html

AND other full range boxes with a W shape & flare ports. This will be a combination of both (similar to red box). The tuning will be done on the work bench by trimming the flare ports. Not easy to see in pic. but glued 4 pieces of 5" x 1/2" poplar that will be cut/fit/sanded and again, trimmed as needed.

Cones are coated - thin layer of RTV 118.

Speaker Driver: http://www.tb-speaker.com/detail/0624_11/w5-1611saf.htm

Attachments

Fs is 20hz off? I'll check that here.

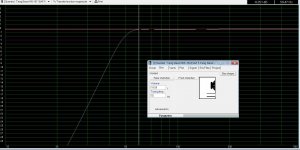

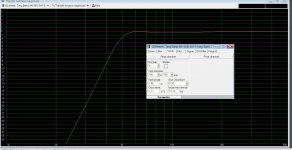

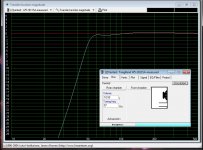

Jeff, went back to WinIsd, found out could not work vent sizes in inches - used mm and then had to trick the widow and start high and work my way down. [kept losing the response line]

Here's what I can up with two (2) vent/ports (L&R).

4 wood strips = 52mm, 13mm each.

Jeff, went back to WinIsd, found out could not work vent sizes in inches - used mm and then had to trick the widow and start high and work my way down. [kept losing the response line]

Here's what I can up with two (2) vent/ports (L&R).

4 wood strips = 52mm, 13mm each.

Attachments

Last edited:

John, glad you are still here.

The silicon:

(1) Only use RTV112 or RTV118; they are self leveling products

(2) it will give you more bass - easy trick to lower the response

(3) the speaker guru that we used to work with, said it took the ringing out

(4) I think it makes a plastic cone sound more natural

(5) it is easy to take off if you don't like it

The silicon:

(1) Only use RTV112 or RTV118; they are self leveling products

(2) it will give you more bass - easy trick to lower the response

(3) the speaker guru that we used to work with, said it took the ringing out

(4) I think it makes a plastic cone sound more natural

(5) it is easy to take off if you don't like it

yup. easy to do. Don't put too much on, spin around as you work.

Better if speaker is out of box.

Turn upside down to dry; especially if voice coil is "open"

Can find it on ebay OR here - remember 118. Its on the second 1/2 of page:

McMaster-Carr

Better if speaker is out of box.

Turn upside down to dry; especially if voice coil is "open"

Can find it on ebay OR here - remember 118. Its on the second 1/2 of page:

McMaster-Carr

Jeff, went back to WinIsd, found out could not work vent sizes in inches - used mm and then had to trick the widow and start high and work my way down. [kept losing the response line]

Yes, a couple of annoying glitches.

I took grindstone's numbers and ran another sim using your vent sizes. Box is 18.5L @57Hz tuning. You'll notice the vent length is quite a bit less, due to the higher tuning.

jeff

Attachments

Fs is 20hz off? I'll check that here.

Likely that grindstone is just measuring at a different part of the T/S curves. Computer driven measuring kit is often this far off factory measures (my own included -- i always start with the factory numbers).

dave

Picking up speed

Picking up speed, but only have a few hours into this so far. Going to tune it up today.

The white screen is a blocker to keep the damping material from blocking the ports; found it in our last pizza box order. I may have to go order another pizza for the second one.

Will probably just throw the pizza out and keep the white screen - the pizza was terrible

Picking up speed, but only have a few hours into this so far. Going to tune it up today.

The white screen is a blocker to keep the damping material from blocking the ports; found it in our last pizza box order. I may have to go order another pizza for the second one.

Will probably just throw the pizza out and keep the white screen - the pizza was terrible

Attachments

Last edited:

Gaskets

I'd much rather pay an extra dollar for factory gaskets, vs. making them. One resin not to buy less expensive speakers, have to spend more $$ fixing them.

Might put some hard wood on L&R panels (for looks).

So far so good.

I'd much rather pay an extra dollar for factory gaskets, vs. making them. One resin not to buy less expensive speakers, have to spend more $$ fixing them.

Might put some hard wood on L&R panels (for looks).

So far so good.

Attachments

Last edited:

I'd much rather pay an extra dollar for factory gaskets, vs. making them.

Just use draugh eclusion tape (weather strip). Home despot has nice neoprene stuff. THis is what the KEF drivers of yore shipped with.

dave

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Full Range

- W5-1611 SAF - The Sequel