The resonant frequency of the RS100-8 is 87.5hz.

That would put the 1/4 wavelength at 38.75".

I read somewhere that you should make the pipe slightly shorter than the 1/4" length and lightly stuff the pipe to dampen & slow the wave.

How short should I make the pipe? 36"? 30" anywhere in between?

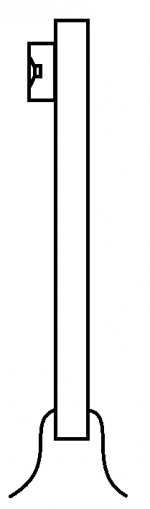

Here is a picture of my design idea.

Any Thoughts?

That would put the 1/4 wavelength at 38.75".

I read somewhere that you should make the pipe slightly shorter than the 1/4" length and lightly stuff the pipe to dampen & slow the wave.

How short should I make the pipe? 36"? 30" anywhere in between?

Here is a picture of my design idea.

Any Thoughts?

Attachments

That length calculation is for an untapered line (as yours looks to be), but does not include the end correction,

A good place to start is with Martin King's free alignment tables. It will generate the appropriate cross-section, length, and driver off-set.

dave

A good place to start is with Martin King's free alignment tables. It will generate the appropriate cross-section, length, and driver off-set.

dave

Make sure to at least check out the the alignment tables and/or horn resp. Many times some kind of taper will result in flatter response. Also with what looks like a compression chamber on the front end it could further mess with the response if not specifically designed. Also a flare at the end will change response, possibly beneficially but its hard to guess.

Not sure exactly about end correction but I believe it is something to do with the pipe resonates, the maximum of air velocity will not occur exactly at the open end of the tube but a little beyond so the tuning will be not quite exactly the length of the pipe. I believe it is worse the larger the pipe is in diameter relative to length

Good luck!

Not sure exactly about end correction but I believe it is something to do with the pipe resonates, the maximum of air velocity will not occur exactly at the open end of the tube but a little beyond so the tuning will be not quite exactly the length of the pipe. I believe it is worse the larger the pipe is in diameter relative to length

Good luck!

A pipe, tube, horn's acoustic length is longer than its physical length, so the end correction is how much the pipe is shortened for a given acoustic length.

Since the end correction is ~0.613x the effective terminus radius, flaring will affect it. In the scheme of things though, even it if alters tuning as much as a few Hz it won't be audible. That said, any line that requires damping won't audibly benefit from flaring unless it has a huge radius.

GM

Since the end correction is ~0.613x the effective terminus radius, flaring will affect it. In the scheme of things though, even it if alters tuning as much as a few Hz it won't be audible. That said, any line that requires damping won't audibly benefit from flaring unless it has a huge radius.

GM

A pipe, tube, horn's acoustic length is longer than its physical length, so the end correction is how much the pipe is shortened for a given acoustic length.

Sounds like I was close

8" driver firing into a 5" pipe

Maybe I'm missing something but isnt it a 4" driver into a 2.5" tube? Same ratio i guess...

This reminds me of when I stuck a new 6.5" driver into a 8 foot carpet tube that was the perfect size for it. If sounded terrible because of all of the resonances but it was quite a bit louder than OB

The ID of the pipe is 5".

The interior radius is 2.5"

Gotca, I was thinking diameter...

So, I'd be looking at approximately a 37" tube lightly stuffed.

How do transmission lines usually behave with the open end is firing ~6" above carpet.

I was planning on building 3 legs for each tube similar to coat rack legs.

This will have the tube terminus be about 6" above the carpet.

Would you think it would help to diffuse high frequencies exiting the terminus?

How do transmission lines usually behave with the open end is firing ~6" above carpet.

I was planning on building 3 legs for each tube similar to coat rack legs.

This will have the tube terminus be about 6" above the carpet.

Would you think it would help to diffuse high frequencies exiting the terminus?

Why? A cardboard tube is already incredibly rigid from an acoustical POV and a little driver isn't capable of stressing it even if the other end was capped off. I mean they use them for concrete forms, so it would take a really powerful compressor to flex it.

GM

GM

Last edited:

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Full Range

- RS100-8 Transmission Line