Will the W3-881SI be a good speaker for the tabaq box design on http://coolcat.dk/bjoern/TABAQ_TL_for_TB.pdf

I tried modeling the specs but I am very new to this and was less then successful at gaining any real info.

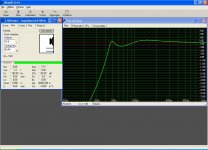

I did do a ported box tuned to 49.5hz and it looks good to me but I will post so someone can correct me. I put in all the specs I could find for the speaker.

I tried modeling the specs but I am very new to this and was less then successful at gaining any real info.

I did do a ported box tuned to 49.5hz and it looks good to me but I will post so someone can correct me. I put in all the specs I could find for the speaker.

Attachments

Hi,

Consider an upgrade to winISD Pro. You get other features such as an excursion chart for the power input, which is very useful for small drivers.

However, this software can't model transmission lines. You're going to either need a different piece of software, or take your chances with the design: the author suggests using drivers with a high Fs and Qts, so you'll be okay there.

Chris

Consider an upgrade to winISD Pro. You get other features such as an excursion chart for the power input, which is very useful for small drivers.

However, this software can't model transmission lines. You're going to either need a different piece of software, or take your chances with the design: the author suggests using drivers with a high Fs and Qts, so you'll be okay there.

Chris

I realize that this thread is a bit stale, but I just completed a TABAQ build using the w3-881sjf with amazing results. I cannot recommend highly enough. Previously I had Acoustat electrostatics and klipsch rf-52 mkii on this system, but these TABAQs are by far the most fun to listen to. Effortless bass that seems to roll off perfectly, very natural sounding with awesome imaging.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

Thanks for the kind words everyone!

This was my first time working with MDF and the second pair of speakers I ever built.

Definitely learned a lot that will make future builds easier.

Zman,

First thing I did to MDF was give it a skim coat of drywall joint compound and then sand with 220 sandpaper to make smooth, followed by 2 coats of oil based primer again sanded with 220 when dry to make smooth, now for the labor intensive part...I used rustoleum oil based paint mixed 50:50 with mineral spirits to thin it down.

Then this was my paint sequence:

2 coats of paint, sand with 220

2 coats of paint, sand with 400

1 coat of paint, sand with 800

1 coat of paint, wait 1 week, sand with 2000, rubbing compound and then polish.

I am going to wax them after a month when I am sure paint is fully cured.

I never listened to the speakers before I applied the finish, I was really concerned I would have all this work in them and not like the sound, thankfully that wasn't the case, and now I'm proud of my first attempt at MDF finishing. Also, I recommend the filter after listening both ways.

Next build I am going to use wood veneer! Should make life easier. Hoping to build a project called the flat5 TL using the w5-1611. Although Bjorn's TABAQ for the W5 looks tempting, the flat5 is visually appealing to me with the wide baffle

This was my first time working with MDF and the second pair of speakers I ever built.

Definitely learned a lot that will make future builds easier.

Zman,

First thing I did to MDF was give it a skim coat of drywall joint compound and then sand with 220 sandpaper to make smooth, followed by 2 coats of oil based primer again sanded with 220 when dry to make smooth, now for the labor intensive part...I used rustoleum oil based paint mixed 50:50 with mineral spirits to thin it down.

Then this was my paint sequence:

2 coats of paint, sand with 220

2 coats of paint, sand with 400

1 coat of paint, sand with 800

1 coat of paint, wait 1 week, sand with 2000, rubbing compound and then polish.

I am going to wax them after a month when I am sure paint is fully cured.

I never listened to the speakers before I applied the finish, I was really concerned I would have all this work in them and not like the sound, thankfully that wasn't the case, and now I'm proud of my first attempt at MDF finishing. Also, I recommend the filter after listening both ways.

Next build I am going to use wood veneer! Should make life easier. Hoping to build a project called the flat5 TL using the w5-1611. Although Bjorn's TABAQ for the W5 looks tempting, the flat5 is visually appealing to me with the wide baffle

Nice build!

I have buit the Flat5 in Br. Nice that no baffle step compensation is need. So the signal goes straight to the W5-1611, no "circuitry" in the way. And the high waf, girlfriend was thrilled that the speakers are only ~10cm thick and stand flat on the wall

Have fun building!

... Hoping to build a project called the flat5 TL using the w5-1611. Although Bjorn's TABAQ for the W5 looks tempting, the flat5 is visually appealing to me with the wide baffle

I have buit the Flat5 in Br. Nice that no baffle step compensation is need. So the signal goes straight to the W5-1611, no "circuitry" in the way. And the high waf, girlfriend was thrilled that the speakers are only ~10cm thick and stand flat on the wall

Have fun building!

ChairmanMAO,

Lot of hard work and it is evident from the finish.

Btw, big risk you too by not having a listen first... but at least you got the speakers finished... sometimes if the sound is too good, then the final finishing tends to get delayed and WCF (Wife Complaining Factor) can go up fast!

Veneering is much easier.

Lot of hard work and it is evident from the finish.

Btw, big risk you too by not having a listen first... but at least you got the speakers finished... sometimes if the sound is too good, then the final finishing tends to get delayed and WCF (Wife Complaining Factor) can go up fast!

Veneering is much easier.

XRK971,

This project can be viewed at the blue plant acoustic website under loudspeaker DIY kits.

Lautsprechershop von blue planet acoustic

This project can be viewed at the blue plant acoustic website under loudspeaker DIY kits.

Lautsprechershop von blue planet acoustic

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Full Range

- W3-881SI tabaq