Just looked over a previous thread discussing the merits and issues with these speakers. I have a pair that will need to be repaired if I plan to use them. I'm currently using the SFB/3 baffles they came on with other drivers and I'm pretty happy with the sounds I'm getting. I'm using Eminence Alpha 12s in the the 12" hole where these were. I'm mulling over sending these for a recone and trying them out, but not sure its worth the effort. On the down side, these apparently only can handle about 10 watts, have some bad reviews, and will cost some money to have reconed. On the up side, they have large Alnico magnets and will fit in the hole perfectly. They won't need to handle lots of power, and they'll only be getting signal between about 100 and 700 Hz (active crossover). I may recone them anyway for use as guitar drivers, but the low power handling and nonstandard mounting holes makes that problematic as well.

Anybody have any specs on these or advice? Think they have any shot at sounding better than the Eminences? Thanks!

Anybody have any specs on these or advice? Think they have any shot at sounding better than the Eminences? Thanks!

I'll just keep on thinking in public here, maybe someone will chime in soon.

First thing I'm wondering (related to my original question) is - for hi-fi is there any advantage of alnico over ceramic or other magnet material? In the guitar speaker world, alnico is prized as the "musical magnet" partly since it seems to "compress" in a pleasing fashion - in hi-fi we call that "distortion" and don't appreciate it as much. I know that there are a number of current drivers (especially in the full-range world) that still use alnico at a hefty upcharge - obviously somebody buys them.

Second thing to add is - I looked more closely at the speakers, and tried playing one a bit at low volume. The other has a spider that has come completely loose from the metal, and probably has bits of gunk down in the voice coil space. The one I played sounds pretty okay in free air. If I could figure out how to go about cleaning the messed up one out, then realigning the voice coil, I could probably just refoam them myself if I could find an appropriate refoaming kit. These have the slight flat edge on the cones. Any suggestions for instructions or a kit, or should I just put 'em in the closet and not waste more of my time?

First thing I'm wondering (related to my original question) is - for hi-fi is there any advantage of alnico over ceramic or other magnet material? In the guitar speaker world, alnico is prized as the "musical magnet" partly since it seems to "compress" in a pleasing fashion - in hi-fi we call that "distortion" and don't appreciate it as much. I know that there are a number of current drivers (especially in the full-range world) that still use alnico at a hefty upcharge - obviously somebody buys them.

Second thing to add is - I looked more closely at the speakers, and tried playing one a bit at low volume. The other has a spider that has come completely loose from the metal, and probably has bits of gunk down in the voice coil space. The one I played sounds pretty okay in free air. If I could figure out how to go about cleaning the messed up one out, then realigning the voice coil, I could probably just refoam them myself if I could find an appropriate refoaming kit. These have the slight flat edge on the cones. Any suggestions for instructions or a kit, or should I just put 'em in the closet and not waste more of my time?

(some) specs:

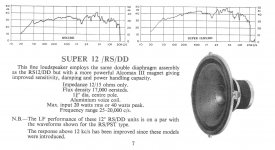

Here is a clip from the Wharfedale General Catalogue 1962, showing their specs. for the Super 12/RS/DD. Do yours match the description? From what I know, the "RS" refers to "Roll Surround", which was a half-roll formed of fine cloth. Cloth surrounds generally tended to be a lot more durable than the ubiquitous foam type. You mentioned you are considering "refoaming" yours, and it makes me wonder why.

Another question for you: do you know of a place that will re-cone these or supply parts for that job, and if so, how close to original would the parts be? I myself have a Super 8/RS/DD with a broken (aluminum) voice coil, that I've been unable to repair, and would dearly like to restore the speaker to it's original performance, but so far have not found a source for suitable repair parts. Personally, I think the Super 8 in the right system would have great potential - the Super 12 even more so.

Wilf

Here is a clip from the Wharfedale General Catalogue 1962, showing their specs. for the Super 12/RS/DD. Do yours match the description? From what I know, the "RS" refers to "Roll Surround", which was a half-roll formed of fine cloth. Cloth surrounds generally tended to be a lot more durable than the ubiquitous foam type. You mentioned you are considering "refoaming" yours, and it makes me wonder why.

Another question for you: do you know of a place that will re-cone these or supply parts for that job, and if so, how close to original would the parts be? I myself have a Super 8/RS/DD with a broken (aluminum) voice coil, that I've been unable to repair, and would dearly like to restore the speaker to it's original performance, but so far have not found a source for suitable repair parts. Personally, I think the Super 8 in the right system would have great potential - the Super 12 even more so.

Wilf

Attachments

Mine look just like that except that one looks like it has a small whizzer - mine doesn't have one. I don't know what type surround it had as the surround is now completely gone.

I was going to check with Orange County Speaker or Simply Speakers about repair, but I don't know that they have the right parts.

I was going to check with Orange County Speaker or Simply Speakers about repair, but I don't know that they have the right parts.

The SFB/3 was fitted with the Wharfedale W12/FS speaker in conjunction with the Golden/FSB 10" and a Super3 tweeter(facing upwards).Original cones are not available and the best recourse if the cones are intact is to have a skilled person fit new foam surrounds which can be fabricated from foam plastic sheets.My prefered colour is grey.

Wharfedale fullrange 12s

This is my first post here and while in the process of rewinding two speech coils for a pair of Wharfedale Coaxial 12s, I looked in here for a break. About your full range 12s; if there is any nostalgia attached to them, then they are probably worth repairing. To clean the speech coil gap, the diaphragm will have to be removed. You mentioned that one spider is already loose which implies the glue has deteriorated; the other might be removed easily. If not, pure acetone will do the trick. By pure, I mean the commercial kind available at hardware stores, NOT nail polish remover as that's only about 6% acetone.

Oh, this can get lengthy. I'll try to make it short and if you're really willing to see this through, I'll send piccies of the process. I've had more than a casual experience repairing loudspeakers not to mention helping a fella in the Philippines build a horn system. At 69, I've got a collection of Wharfedales dating back to the 50's and most work. Still in use is a Briggs' 3 way an uncle built in '57, complete with the EICO HF61 preamp, HF30 power amp and his old Rek-O-Kut turntable. The 15 incher has been refoamed. There is also a pair of corner cabinets built for the Coaxial 12s but the speech coils unwound due to aged glue, ergo the rewinding, by hand. They have a concentric tweeter which, fortunately, is OK. The cabinets now temporarily house a Super 12 FS/AL and an upfiring Super 8 FS/AL and a Super 3 tweeter. All three have aluminum speech coils. I'll refrain from expounding on the aluminum coils vs copper or bronze. Yes, bronze. Wharfedale did make a 10 inch, the W10 FS/B, foam surround, bronze speech coil. I have 3, two of which await foam annuli.

For the repair, you'll need shim stock, plastic, of thicknesses ranging from 0.010 to 0.003 inches. Airplane kit type glue will work for the spider to frame but DON'T use it on the foam annulus regardless what the manufacturer of the glue says. Use white or yellow wood glue. It takes much longer to set but won't affect the foam and becomes close to invisible after setting so any that leaks out won't show. The longer setting time is also advantageous for centering the annulus.

To clean the gap, invert the speaker, protect your eyes and use a compressed air can. Follow this with masking tape. Take about 2 inches of tape, reverse wind it (sticky side out) to make a loop about 0.75 inch diameter. Flatten it and wiggle it into the gap; it'll remove that which is adhering to the pole piece and inner top plate, including anything metallic held by the magnet.

After all cleaning is done, place tape over the gap. Next, measure and cut the annulus. If using foam, 0.125 inch is adequate. If using a half roll surround which can be obtained in kits from various places, keep in mind that Wharfedale speakers from that era DON'T necessarily measure the same as their non British equivalents. Fir example, the W15 FS is called a 15 inch but has a diaphragm measuring 11 inches at the flange to where the annulus is glued. Most 15s measure 12.5 inches across the flange. This oversight cost me a lot of work in the 70's building a pair of Klipsch type corner horns for a W15 FS. They came out unnecessarily larger than expected as the smaller diaphragm area required a longer horn path. MEASURE carefully; the folks that sell these kits provide the needed dimensions of the annuli in their kits, which come with white glue, applicator brush, instructions, the annulus of course and if my memory serves me well, a dustcap.

After affixing the annulus, the assembly has to be shimmed to the pole piece and very snugly. If using the same spider and hopewfully it's still affixed to the apex of the cone, it's probably flat so when shimming the coil, the spider should be flat, not raised or cupped. Earlier Wharfedales used a phenolic material comprised of two concentric discs connected with 3 or 4 S shaped radial spokes. It looked just like a spider from the top, hence the name. Usually, on these older speakers, especially full ranges, the gap between the inner speech coil and the pole piece will be about 0.010 inch, +/- a few thousandths. To lock the coil in place, after shimming with a circular band of shim stock, a few strips about 0.25 inch wide and an inch long can be inserted with tweezers between the inner coil and pole piece. These small shims are usually about 0.005 inch to 0.007 inch, depending on the gap. The initial shims should hold the diaphragm in place until the smaller ones are inserted. Keep them evenly spaced around the coil. Three is minimun but I've used as many as 9. If these shims are not evenly spaced, the coil may be out of round and might rub. Oh, tweezers are metallic and attracted by a magnet. It'll take practice as that magnetic field, especially in a full range from that era is of an intensity of about 13000 gauss (1.3 T/m) To get an idea of how strong that is, a 15 inch screwdriver shaft, if placed across the gap, will allow one to lift a 22 pound speaker.

My apologies for the lengthy jib/jab. I didn't mention suppliers names here as I'm uncertain of the policy in that regard.

I'm going to bookmark this message somehow so I can follow up. Hopefully, diyaudio has made that provision.

Robert.

This is my first post here and while in the process of rewinding two speech coils for a pair of Wharfedale Coaxial 12s, I looked in here for a break. About your full range 12s; if there is any nostalgia attached to them, then they are probably worth repairing. To clean the speech coil gap, the diaphragm will have to be removed. You mentioned that one spider is already loose which implies the glue has deteriorated; the other might be removed easily. If not, pure acetone will do the trick. By pure, I mean the commercial kind available at hardware stores, NOT nail polish remover as that's only about 6% acetone.

Oh, this can get lengthy. I'll try to make it short and if you're really willing to see this through, I'll send piccies of the process. I've had more than a casual experience repairing loudspeakers not to mention helping a fella in the Philippines build a horn system. At 69, I've got a collection of Wharfedales dating back to the 50's and most work. Still in use is a Briggs' 3 way an uncle built in '57, complete with the EICO HF61 preamp, HF30 power amp and his old Rek-O-Kut turntable. The 15 incher has been refoamed. There is also a pair of corner cabinets built for the Coaxial 12s but the speech coils unwound due to aged glue, ergo the rewinding, by hand. They have a concentric tweeter which, fortunately, is OK. The cabinets now temporarily house a Super 12 FS/AL and an upfiring Super 8 FS/AL and a Super 3 tweeter. All three have aluminum speech coils. I'll refrain from expounding on the aluminum coils vs copper or bronze. Yes, bronze. Wharfedale did make a 10 inch, the W10 FS/B, foam surround, bronze speech coil. I have 3, two of which await foam annuli.

For the repair, you'll need shim stock, plastic, of thicknesses ranging from 0.010 to 0.003 inches. Airplane kit type glue will work for the spider to frame but DON'T use it on the foam annulus regardless what the manufacturer of the glue says. Use white or yellow wood glue. It takes much longer to set but won't affect the foam and becomes close to invisible after setting so any that leaks out won't show. The longer setting time is also advantageous for centering the annulus.

To clean the gap, invert the speaker, protect your eyes and use a compressed air can. Follow this with masking tape. Take about 2 inches of tape, reverse wind it (sticky side out) to make a loop about 0.75 inch diameter. Flatten it and wiggle it into the gap; it'll remove that which is adhering to the pole piece and inner top plate, including anything metallic held by the magnet.

After all cleaning is done, place tape over the gap. Next, measure and cut the annulus. If using foam, 0.125 inch is adequate. If using a half roll surround which can be obtained in kits from various places, keep in mind that Wharfedale speakers from that era DON'T necessarily measure the same as their non British equivalents. Fir example, the W15 FS is called a 15 inch but has a diaphragm measuring 11 inches at the flange to where the annulus is glued. Most 15s measure 12.5 inches across the flange. This oversight cost me a lot of work in the 70's building a pair of Klipsch type corner horns for a W15 FS. They came out unnecessarily larger than expected as the smaller diaphragm area required a longer horn path. MEASURE carefully; the folks that sell these kits provide the needed dimensions of the annuli in their kits, which come with white glue, applicator brush, instructions, the annulus of course and if my memory serves me well, a dustcap.

After affixing the annulus, the assembly has to be shimmed to the pole piece and very snugly. If using the same spider and hopewfully it's still affixed to the apex of the cone, it's probably flat so when shimming the coil, the spider should be flat, not raised or cupped. Earlier Wharfedales used a phenolic material comprised of two concentric discs connected with 3 or 4 S shaped radial spokes. It looked just like a spider from the top, hence the name. Usually, on these older speakers, especially full ranges, the gap between the inner speech coil and the pole piece will be about 0.010 inch, +/- a few thousandths. To lock the coil in place, after shimming with a circular band of shim stock, a few strips about 0.25 inch wide and an inch long can be inserted with tweezers between the inner coil and pole piece. These small shims are usually about 0.005 inch to 0.007 inch, depending on the gap. The initial shims should hold the diaphragm in place until the smaller ones are inserted. Keep them evenly spaced around the coil. Three is minimun but I've used as many as 9. If these shims are not evenly spaced, the coil may be out of round and might rub. Oh, tweezers are metallic and attracted by a magnet. It'll take practice as that magnetic field, especially in a full range from that era is of an intensity of about 13000 gauss (1.3 T/m) To get an idea of how strong that is, a 15 inch screwdriver shaft, if placed across the gap, will allow one to lift a 22 pound speaker.

My apologies for the lengthy jib/jab. I didn't mention suppliers names here as I'm uncertain of the policy in that regard.

I'm going to bookmark this message somehow so I can follow up. Hopefully, diyaudio has made that provision.

Robert.

Just looked over a previous thread discussing the merits and issues with these speakers. I have a pair that will need to be repaired if I plan to use them. I'm currently using the SFB/3 baffles they came on with other drivers and I'm pretty happy with the sounds I'm getting. I'm using Eminence Alpha 12s in the the 12" hole where these were. I'm mulling over sending these for a recone and trying them out, but not sure its worth the effort. On the down side, these apparently only can handle about 10 watts, have some bad reviews, and will cost some money to have reconed. On the up side, they have large Alnico magnets and will fit in the hole perfectly. They won't need to handle lots of power, and they'll only be getting signal between about 100 and 700 Hz (active crossover). I may recone them anyway for use as guitar drivers, but the low power handling and nonstandard mounting holes makes that problematic as well.

Anybody have any specs on these or advice? Think they have any shot at sounding better than the Eminences? Thanks!

Klipschorn,I have seen all the models you have mentioned from that early era and your repair methods are correct.All the coils were bonded with a cellulose cement and this needs re-coating with model aeroplane dope to avoid the unravelling problem.It might be possible to use an impact resistant instant adhesive to coat the coil as an alternative to the cellulose dope.I always thought that the"B" in the designation stood for a bakelised cone apex and in the coil for the W10FSB is wound with copper wire.The bakelite spiders in the Super 12FS/AL caused fatigue problems in the cone neck that made the lead out wires go o/c.Sometimes other creasing is evident at a point roughly midway up the cone where the ribbing starts.

I used to own a pair of NOS Super 8/RS/DD which I sold on to a fellow in Italy who needed a pair for a Wharfedale speaker restoration project he was working on..

My real reason for posting is I think posting the pictures here of the restoration process on a pair of (Super) Nn RS/DD Wharfedale drivers would be informative.. You can post these directly to the forum by going to "Advanced" and clicking on "Manage Attachments" - that way they'll be hosted here.. (Apologies if you already know this)

My real reason for posting is I think posting the pictures here of the restoration process on a pair of (Super) Nn RS/DD Wharfedale drivers would be informative.. You can post these directly to the forum by going to "Advanced" and clicking on "Manage Attachments" - that way they'll be hosted here.. (Apologies if you already know this)

Bronze voice coils and phenolic spiders

Thanks for the info on the cellulose cement. That made sense to me as I recalled that early movies were filmed on cellulose triacetate which discoloured and crystallised with age. As for the designation "B", we have a problem. A Briggs' three way system an uncle built in 1957, which I acquired in 1972, is all original with exception of the woofer and midrange annuli. They were foam which rotted over time. The ten inch was used in lieu of the recommended 8 inch as the dealer who sold Louis the components had no eights. The ten has a flat currugated spider and the label says, W10FS/B. My uncle told me then that the speech coil was bronze. Why bronze and not copper? Only Wharfedale can possibly answer that one. The reason given for the aluminum coils was that it was lighter than copper but considering the mass of the cone & coil assembly in a Super 12FS/AL, that difference would be of little consequence. Also consider that an original Super 12FS/AL, one of which I have, is equipped with a phenolic (Bakelite) spider, yet no "B" appears in the model number. Admittedly, bronze is less prone to corrosion than pure copper but the magnet wire is enameled.

On the phenolic spiders. I can understand their use on a midrange driver which has negligable excursion as the stiffer spider would increase transient response. The same would appear to be true for a full range but that would limit low distortion low frequency output due limited excursion ability and nonlinearity.

The thermal conductivity of aluminum is about 63% that of copper and the electrical conductivity is about 61%. The only advantage left seems to be weight as stated earlier. I have no figures on bronze and there are several alloys but copper is scaled as 100% electrical conductivity and any metal added to make an alloy such as bronze, decreases that conductivity. By the way, silver is scaled at 105%. I doubt that thermal conductivity was a consideration for what should be obvious reasons. Ahhhhh, inconsistencies and Englysshe is loaded with them. One comes to mind. Consider the word soap. All other phonetically similar words in the English language are spelled thus, cope, dope, hope, mope, nope, pope, and rope. It would logically follow that the cleaning agent be spelled sope. And also consider the rule, I before E except after C. I'm led to believe that some 40% of words violate that rule and one comes to mind, WEIRD. Yes, indeed, weird is a weird word.

Thanks for the info on the cellulose cement. That made sense to me as I recalled that early movies were filmed on cellulose triacetate which discoloured and crystallised with age. As for the designation "B", we have a problem. A Briggs' three way system an uncle built in 1957, which I acquired in 1972, is all original with exception of the woofer and midrange annuli. They were foam which rotted over time. The ten inch was used in lieu of the recommended 8 inch as the dealer who sold Louis the components had no eights. The ten has a flat currugated spider and the label says, W10FS/B. My uncle told me then that the speech coil was bronze. Why bronze and not copper? Only Wharfedale can possibly answer that one. The reason given for the aluminum coils was that it was lighter than copper but considering the mass of the cone & coil assembly in a Super 12FS/AL, that difference would be of little consequence. Also consider that an original Super 12FS/AL, one of which I have, is equipped with a phenolic (Bakelite) spider, yet no "B" appears in the model number. Admittedly, bronze is less prone to corrosion than pure copper but the magnet wire is enameled.

On the phenolic spiders. I can understand their use on a midrange driver which has negligable excursion as the stiffer spider would increase transient response. The same would appear to be true for a full range but that would limit low distortion low frequency output due limited excursion ability and nonlinearity.

The thermal conductivity of aluminum is about 63% that of copper and the electrical conductivity is about 61%. The only advantage left seems to be weight as stated earlier. I have no figures on bronze and there are several alloys but copper is scaled as 100% electrical conductivity and any metal added to make an alloy such as bronze, decreases that conductivity. By the way, silver is scaled at 105%. I doubt that thermal conductivity was a consideration for what should be obvious reasons. Ahhhhh, inconsistencies and Englysshe is loaded with them. One comes to mind. Consider the word soap. All other phonetically similar words in the English language are spelled thus, cope, dope, hope, mope, nope, pope, and rope. It would logically follow that the cleaning agent be spelled sope. And also consider the rule, I before E except after C. I'm led to believe that some 40% of words violate that rule and one comes to mind, WEIRD. Yes, indeed, weird is a weird word.

Klipschorn,I have seen all the models you have mentioned from that early era and your repair methods are correct.All the coils were bonded with a cellulose cement and this needs re-coating with model aeroplane dope to avoid the unravelling problem.It might be possible to use an impact resistant instant adhesive to coat the coil as an alternative to the cellulose dope.I always thought that the"B" in the designation stood for a bakelised cone apex and in the coil for the W10FSB is wound with copper wire.The bakelite spiders in the Super 12FS/AL caused fatigue problems in the cone neck that made the lead out wires go o/c.Sometimes other creasing is evident at a point roughly midway up the cone where the ribbing starts.

The only mention of bronze in the Wharfedale nomenclature,had to do with the rectangular magnet used for the lesser models.The voice coil wire on the W10 FSB is copper and if you remove the cone you will find the winding height to be 0.325". The corrugated disc spider was made of an impregnated black cloth.Interestingly the 1.6T magnet on the W10 is more powerful(in terms of total flux) than the famous Axiom 80 and it was not until the introduction of the Super 10 RS/DD that a full range unit was manufactured.

I Have a pair of the SFB/3s as well and can tell you without a doubt that the 12" , 10" and Super 3s were driver designs specifically for this loudspeaker utilizing longer voice coils for the two larger drivers and a metal dustcap on the Super 3 variant that extended HF response,

All the original SFB literature I have, as well as several of Gilbert Brigg's books on the subject repeatedly stress these drivers were not utilized previously or after on any of his other loudspeaker designs.

These units were designed and engineered specifically in response to the introduction of the Quad ESL57s. There was some fear among manufacturers as the time that the ES design might make electrodynamic loudspeakers obsolete unless a credible response was mounted. Briggs along with the Leak compnay mounted a number of public "is it real or SFB/3?" demonstrations.

I've seen a number of the SFB/3s where subsequent owners have substituted various non-stock Wharfedale drivers rather than attempt a re-cone of the plastic foam surround of the original 12" and 10" SFB drivers as well as utilizing the non metal dustcap version of the Super 3. These hybrids have none of the sound quality of the originals.

What is truly amazing to me is that this 55-year-old design sounds spectacular today and even with spending significant significant dollars on new production esoteric drivers can't be bested by any significant margin that could possibly justify such a large expense.

When one sees the pictures of how Gilbert Briggs field tested each element of the design of these particular speakers and the manufacture of the drivers I would be highly skeptical of any inference that any other Wharfedale 10" or 12" drivers, or for that matter other Super 3s could be substituted.

Briggs repeatedly references that he used both the Klipschorn and ESL57 as side by side reference points for what he was zeroing in on with his SFB/3 (two radically different loudspeaker designs and approaches), so I for one am prepared to grant great credence to Mr. Briggs assertions that the SFB/3 drivers were unique to that particular model alone

All the original SFB literature I have, as well as several of Gilbert Brigg's books on the subject repeatedly stress these drivers were not utilized previously or after on any of his other loudspeaker designs.

These units were designed and engineered specifically in response to the introduction of the Quad ESL57s. There was some fear among manufacturers as the time that the ES design might make electrodynamic loudspeakers obsolete unless a credible response was mounted. Briggs along with the Leak compnay mounted a number of public "is it real or SFB/3?" demonstrations.

I've seen a number of the SFB/3s where subsequent owners have substituted various non-stock Wharfedale drivers rather than attempt a re-cone of the plastic foam surround of the original 12" and 10" SFB drivers as well as utilizing the non metal dustcap version of the Super 3. These hybrids have none of the sound quality of the originals.

What is truly amazing to me is that this 55-year-old design sounds spectacular today and even with spending significant significant dollars on new production esoteric drivers can't be bested by any significant margin that could possibly justify such a large expense.

When one sees the pictures of how Gilbert Briggs field tested each element of the design of these particular speakers and the manufacture of the drivers I would be highly skeptical of any inference that any other Wharfedale 10" or 12" drivers, or for that matter other Super 3s could be substituted.

Briggs repeatedly references that he used both the Klipschorn and ESL57 as side by side reference points for what he was zeroing in on with his SFB/3 (two radically different loudspeaker designs and approaches), so I for one am prepared to grant great credence to Mr. Briggs assertions that the SFB/3 drivers were unique to that particular model alone

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Full Range

- Wharfedale Super 12s - recone or not?