Thank you for the comments bear.

While I hear what you're saying I really just can't afford the time to do much testing and developing a specific design (as well as the fact I'd be starting from pretty much zero in terms of knowledge about all that stuff).

So the fact that the designs are there, and fairly easy to build, and also the fact that the Lowthers seem to have been mentioned as having been tried in some of the cabinets, is what attracted me to the Frugel-horn website.

I'm aware that this is not going to give me an ideal solution, but am happy to invest a couple of days building the things at the risk of deciding I don't like the sound afterwards.

In terms of positioning I'm pretty much fixed on what's shown in my initial sketch - this layout is determined already by other things.

As for the wider baffles... I'd be fine with wider baffles, especially if it meant the depth of the cabinets could be reduced a bit. So would be interested in any suitable designs that are wider!

While I hear what you're saying I really just can't afford the time to do much testing and developing a specific design (as well as the fact I'd be starting from pretty much zero in terms of knowledge about all that stuff).

So the fact that the designs are there, and fairly easy to build, and also the fact that the Lowthers seem to have been mentioned as having been tried in some of the cabinets, is what attracted me to the Frugel-horn website.

I'm aware that this is not going to give me an ideal solution, but am happy to invest a couple of days building the things at the risk of deciding I don't like the sound afterwards.

In terms of positioning I'm pretty much fixed on what's shown in my initial sketch - this layout is determined already by other things.

As for the wider baffles... I'd be fine with wider baffles, especially if it meant the depth of the cabinets could be reduced a bit. So would be interested in any suitable designs that are wider!

Sachiko was replaced by Haruna when Fostex replaced the FE206E with the FE206En.

I took the opportunity to remove many of the 'generic' aspects included on the site / pdf because as a rule I don't care for stuffing any old driver into a box & hoping for the best. FH3 is an exception since it was deliberately designed to be forgiving & tolerant of a wide range of appropriately sized drive units from the outset. Of course, you can try a Lowther in Haruna, and I would say with a high level of confidence it will do better in that box than in some others since it has sheer size on its side, but I make no promises.

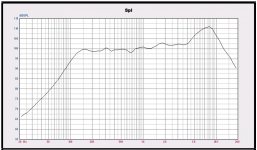

Basically true, but with caveats. Here is the PM5a.

I took the opportunity to remove many of the 'generic' aspects included on the site / pdf because as a rule I don't care for stuffing any old driver into a box & hoping for the best. FH3 is an exception since it was deliberately designed to be forgiving & tolerant of a wide range of appropriately sized drive units from the outset. Of course, you can try a Lowther in Haruna, and I would say with a high level of confidence it will do better in that box than in some others since it has sheer size on its side, but I make no promises.

The basic response of the driver is more or less a response that gently droops from a mid point in the frequency range down to either end.

Basically true, but with caveats. Here is the PM5a.

Attachments

Sachiko was replaced by Haruna when Fostex replaced the FE206E with the FE206En.

I took the opportunity to remove many of the 'generic' aspects included on the site / pdf because as a rule I don't care for stuffing any old driver into a box & hoping for the best. FH3 is an exception since it was deliberately designed to be forgiving & tolerant of a wide range of appropriately sized drive units from the outset. Of course, you can try a Lowther in Haruna, and I would say with a high level of confidence it will do better in that box than in some others since it has sheer size on its side, but I make no promises.

Thanks for the clarification.

Two questions if you don't mind...

1) Are there any of the designs you'd suggest as more suitable for Lowther PM6Cs (including obsolete ones)?

2) The FH3: Any guidance on the closest this can be positioned to a wall at the rear?

2) The FH3: Any guidance on the closest this can be positioned to a wall at the rear?

Designed to be close.

dave

Btw, most of the designs you see are with narrow baffles.

This is done for cosmetic and WAF reasons in the main.

The best sound will be with a WIDE baffle.

If you have no constraints, then look beyond the typical compromises that most designs of necessity embody.

_-_-bear

If you want a wide baffle, consider a wall mount flat panel horn like the Cornu spiral. You get bass enhancement from wall, ceiling and floor, no BSC needed, and the open and expansive sound stage that these things have is wonderful for certain kinds of music. An easy way to build the Cornu spiral horn is being developed at this thread that you may want to check out: http://www.diyaudio.com/forums/construction-tips/223313-foam-core-board-speaker-enclosures.html

Oh, I almost forgot to mention the most important thing: the WAF on these things is through the roof!

Last edited:

Ok - three years on from my first post, I'm finally about to build some speakers.

Going to go with the [FONT=Verdana, Helvetica, Arial, san-serif]Kirishima design from the Frugal-horn site.

I'm going to build it from OSB instead of ply... possibly controversial(?) but having done a little reading others seem to have had OK results with OSB. Main reason is cost - I can always rebuild in more expensive materials in the future if I decide it's worth it.

I'm going to put my Lowther PM6Cs in them to start with, and see what happens. Might decide to change to some Fostex FE206En (that's what's specified for that design) if the Lowthers don't seem to be OK.

The only other modification I'll make to the design will be to smooth out the angled deflecter at the rear of the mouths into a curve. This is mainly for aesthetic reasons as the insides of the horn mouths will be visible. (Unless someone tells me this is a really bad idea for some reason!)

I've got most of the bits cut and will start on putting it together tomorrow.

I'll post some photos as I go along.

[/FONT]

Going to go with the [FONT=Verdana, Helvetica, Arial, san-serif]Kirishima design from the Frugal-horn site.

I'm going to build it from OSB instead of ply... possibly controversial(?) but having done a little reading others seem to have had OK results with OSB. Main reason is cost - I can always rebuild in more expensive materials in the future if I decide it's worth it.

I'm going to put my Lowther PM6Cs in them to start with, and see what happens. Might decide to change to some Fostex FE206En (that's what's specified for that design) if the Lowthers don't seem to be OK.

The only other modification I'll make to the design will be to smooth out the angled deflecter at the rear of the mouths into a curve. This is mainly for aesthetic reasons as the insides of the horn mouths will be visible. (Unless someone tells me this is a really bad idea for some reason!)

I've got most of the bits cut and will start on putting it together tomorrow.

I'll post some photos as I go along.

[/FONT]

Beware OSB is NOT flat! It will be a nightmare trying to fit all those pieces. Particle board is flat and reasonably inexpensive! I have used OSB, not fun and NOT worth the savings.

Larry

Do you mean it's not flat as in it has a slightly uneven surface, or as in it can be warped?

I've used OSB a fair bit for other stuff and haven't had a problem. I've found it to be much less prone to warping than plywood.

As for the slight unevenness of the surface; I'm using a gap-filling adhesive to make sure there aren't any small voids along the joints.

OSB - both irregular surface and I've found prone to warpage - we receive a lot of shipping crates from suppliers made from varying grades of this material type, and I'd consider none to be suitable for an enclosure as elaborate as the Kirishima

I'd certainly not rely on "gap filling adhesives" - if you don't want to spend the bucks on plywood, go for the particle board.

keep the change

I'd certainly not rely on "gap filling adhesives" - if you don't want to spend the bucks on plywood, go for the particle board.

keep the change

OSB - both irregular surface and I've found prone to warpage - we receive a lot of shipping crates from suppliers made from varying grades of this material type, and I'd consider none to be suitable for an enclosure as elaborate as the Kirishima

I'd certainly not rely on "gap filling adhesives" - if you don't want to spend the bucks on plywood, go for the particle board.

keep the change

Thanks for your comments.

The OSB was already ordered and cut, though, so no going back now.

Have been putting it together today and it seems to be fine. Maybe the OSB you see inshipping crates is a different grade to the stuff I use.

Maybe the OSB you see inshipping crates is a different grade to the stuff I use.

certainly likely

it's the results that count - if you're happy, then the naysayers are definitely full of $hite

Here they are partially installed in their final locations.

As you can see it's a slightly unusual arrangement as they are kind of built into a wall/screen. Only the drivers and the horn mouths will be visible once they are properly in. I'm going to paint the insides of the mouths white.

I spent about 5 hours last night listening to them. They sound great and I'm pleased with them. There are a few relatively minor things that could be improved...I might make a slightly more detailed comment on them later.

As you can see it's a slightly unusual arrangement as they are kind of built into a wall/screen. Only the drivers and the horn mouths will be visible once they are properly in. I'm going to paint the insides of the mouths white.

I spent about 5 hours last night listening to them. They sound great and I'm pleased with them. There are a few relatively minor things that could be improved...I might make a slightly more detailed comment on them later.

Attachments

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Full Range

- Building a fullrange horn - any advice for a newbie?