Member

Joined 2009

Paid Member

Hey nkolisnyk - I might take you up on the listen offer. At the moment my project is stalled while I try to decide between buying an old pair of second hand speakers (Wharfedale W60s - $40) or to build a pair of Nelson Pass enclosures with Pioneer BOFUs ($150) or whether to go all out and build BIBs with Fostex FE206ens...(Probably about $300)

I remember when I was an undergrad, a guy 3 floors down had some floorstanding wharfdales. They had bass that I still dream about, solid bass it was, felt like there was a crew digging up the concrete sidewalk when they were working hard.

So why not do both - get the W60's and build you own, you can always use an extra pair in the basement, garage etc.

Last thing I would mention, and it's a personal choice thing - but I would recommend using good materials right from the get-go. Forget particle board. With all the hard work you are going to put into your DIY speakers you will feel a lot better knowing you are crafting something that should last and you will feel proud at the end of it. I know some people will knock up prototypes out of lesser materials, but these guys are semi-pro's with all the gear and it ain't so much heartache for them when their prototypes go on the bonfire. In my case, even if the job done isn't perfect, I want to feel good about what I build and know that it might well turn out to be a keeper. Good materials also means using good tools and good drivers (within your budget of course).

Hope that helps.

At the end of the day (so to speak) - what is one looking for in a speaker enclosure material? I figure consistency and void-free composition (e.g. quality plywood or particle board) but to what extent is the material meant to resonate (or not) and to what extent is it meant to be dead and stop sound?

I've been thinking of using cement fibre board - it has good consistency and higher density than wood. I reckon that combined with damping materials where required it would make good front, back and internal baffle materials. I'm thinking of using baltic birch for the sides.

Thoughts??

I've been thinking of using cement fibre board - it has good consistency and higher density than wood. I reckon that combined with damping materials where required it would make good front, back and internal baffle materials. I'm thinking of using baltic birch for the sides.

Thoughts??

Member

Joined 2009

Paid Member

I would recommend good quality plywood and stick to one material - it'll keep things simple in terms of tools, joints, finishing etc. I use the Birch Plywood from my local Home Depot.

There's a lot that could be said about the choice of materials - I'm not an expert but the choice of plywood is based on the school of thought that you want a stiff enclosure that has low energy storage - damping is not as critical as making it stiff so resonances are minimized and those that remain are pushed above the audio range. Use plenty of internal bracing to stiffen things up.

Heavy materials will provide more damping, but for a BIB this makes for one very awkward project because it will be too darn heavy. Cement board must be heavy, hard to cut neatly and certainly heavy. Dave of planet10 fame started me off right with the Plywood - he's built more speakers than I'll ever listen to.

For the baffles you can double up on the plywood thickness to add considerably more stiffness.

There's a lot that could be said about the choice of materials - I'm not an expert but the choice of plywood is based on the school of thought that you want a stiff enclosure that has low energy storage - damping is not as critical as making it stiff so resonances are minimized and those that remain are pushed above the audio range. Use plenty of internal bracing to stiffen things up.

Heavy materials will provide more damping, but for a BIB this makes for one very awkward project because it will be too darn heavy. Cement board must be heavy, hard to cut neatly and certainly heavy. Dave of planet10 fame started me off right with the Plywood - he's built more speakers than I'll ever listen to.

For the baffles you can double up on the plywood thickness to add considerably more stiffness.

Dave of planet10 fame started me off right with the Plywood - he's built more speakers than I'll ever listen to.

slight correction - drawn, yes - but the building is left to others

Yes, i am no longer allowed to build boxes. Chris is WAY better than i would ever hope to be and he has access to a wet dream of woodwoorking equipment. And he is getting better all the time.

I spend my time designing, drawing, & doing drivers. (and packing, shipping, and so on)

Chris & i are symbiots.

dave

I spend my time designing, drawing, & doing drivers. (and packing, shipping, and so on)

Chris & i are symbiots.

dave

Hey Everyone - well, if all goes according to plan I should be buying my plywood today and getting the speakers some time this week. I am building BIB enclosures.

Some more questions though!

- Is damping material required for BIBs? And if so, where and how much?

- I am going to use CAT 5 for the cables from my Miniwatt tube amp (3.5wpc) to the speakers. I've seen all sorts of types - braided, bundled, 2 cables, 3 cables, etc. What is the best option? It sounds like some here recommend a single Cat5 cable? striped wires to one terminal and solid colour wires to the other terminal?

- Somewhat unrelated: For the interconnect cables from my DAC to the Miniwatt - I'm wondering what type of cable and where the best value for money is?

Thanks as always...

Some more questions though!

- Is damping material required for BIBs? And if so, where and how much?

- I am going to use CAT 5 for the cables from my Miniwatt tube amp (3.5wpc) to the speakers. I've seen all sorts of types - braided, bundled, 2 cables, 3 cables, etc. What is the best option? It sounds like some here recommend a single Cat5 cable? striped wires to one terminal and solid colour wires to the other terminal?

- Somewhat unrelated: For the interconnect cables from my DAC to the Miniwatt - I'm wondering what type of cable and where the best value for money is?

Thanks as always...

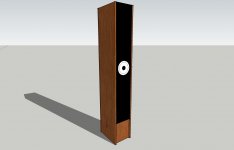

Picture

Here is a picture showing what I'm going for...I plan to install black phase plugs later on.

I am doubling up the plywood on the front face (the black part) - with the scrap plywood - should I also double up the back faces? Don't think I would have enough to double other faces.

Regarding bracing - I'm thinking of running 2" strips of vertical plywood inside the corners to lend some rigidity to the structure. Would this compromise the sound in any way?

Here is a picture showing what I'm going for...I plan to install black phase plugs later on.

I am doubling up the plywood on the front face (the black part) - with the scrap plywood - should I also double up the back faces? Don't think I would have enough to double other faces.

Regarding bracing - I'm thinking of running 2" strips of vertical plywood inside the corners to lend some rigidity to the structure. Would this compromise the sound in any way?

Attachments

As to cables - that´s cheap&easy. Cat5, cheapest doorbell wire...as long as it´s solid core instead of litz it´s better than any megabuck crap.

Connects...depends on where you live and how much radio noise you get off the air. (My personal record: Radio Vatican on my turntable´s connects).

If needed, the most brutal way is microphone cable, with the shield connected to ground on BOTH sides via a ~100ohms resistor.

Doubling the front of your boxes always is a good idea. At the back, where nobody looks, you can do something even more efficient. Cut your wood into ~2" wide strips and glue them on not flat but edge on. Not symmetrically but at odd angles and distances.

Connects...depends on where you live and how much radio noise you get off the air. (My personal record: Radio Vatican on my turntable´s connects).

If needed, the most brutal way is microphone cable, with the shield connected to ground on BOTH sides via a ~100ohms resistor.

Doubling the front of your boxes always is a good idea. At the back, where nobody looks, you can do something even more efficient. Cut your wood into ~2" wide strips and glue them on not flat but edge on. Not symmetrically but at odd angles and distances.

Last edited:

It sounds like some here recommend a single Cat5 cable? striped wires to one terminal and solid colour wires to the other terminal?

That's what i use. Cable is system dependent.

dave

YOWWEEE - it is done.

I can positively say that I have never ever heard sound as complete, nuanced, detailed, clear, etc. etc. in my life.

I have tested Pablo Cassals on Cello Suites, Peter Hurford on Organ (e.g. intro to Passacaglia and Fugue in C minor) and there is no lack at bass. I can't conceive that a sub would ever be necessary unless these moved to a significantly bigger room.

Mid range is gorgeous and detailed, I am hearing details I haven't heard before - even on good quality headphones. Sounds are extremely "real". I am really very impressed.

As I mentioned in an earlier post, I have higher frequency hearing deficiency, so I won't comment on whether a tweeter might be necessary. As far as I can hear, there is more than enough.

I have no stuffing in the cabinets and don't feel the need to add. I expect the system to get better as the tubes and the speakers wear in. They are still comparatively new.

For reference, the amplifier is a miniwatt N3 - 3.5w per channel. Sovtek EL84 with Tung Sol 12AX7. I am streaming music from my Imac through a Nuforce udac2. Cables are all single pair solid 24ga from cat5e.

Everyone reading this: I highly recommend the FE206en in BIBs. I suspect that these are mated well to my room, so that is one variable for others.

I'll post pictures soon.

I can positively say that I have never ever heard sound as complete, nuanced, detailed, clear, etc. etc. in my life.

I have tested Pablo Cassals on Cello Suites, Peter Hurford on Organ (e.g. intro to Passacaglia and Fugue in C minor) and there is no lack at bass. I can't conceive that a sub would ever be necessary unless these moved to a significantly bigger room.

Mid range is gorgeous and detailed, I am hearing details I haven't heard before - even on good quality headphones. Sounds are extremely "real". I am really very impressed.

As I mentioned in an earlier post, I have higher frequency hearing deficiency, so I won't comment on whether a tweeter might be necessary. As far as I can hear, there is more than enough.

I have no stuffing in the cabinets and don't feel the need to add. I expect the system to get better as the tubes and the speakers wear in. They are still comparatively new.

For reference, the amplifier is a miniwatt N3 - 3.5w per channel. Sovtek EL84 with Tung Sol 12AX7. I am streaming music from my Imac through a Nuforce udac2. Cables are all single pair solid 24ga from cat5e.

Everyone reading this: I highly recommend the FE206en in BIBs. I suspect that these are mated well to my room, so that is one variable for others.

I'll post pictures soon.

Always pleased to hear a good DIY experience. You have become a Maker. Recently I was reading about the culture of Steampunk in science fiction-- specifically introductions and non fiction pieces in an anthology on this form. Though it is never mentioned in DIY, speaker building and handcrafted audio fall into the Maker category. DIY is fashionable again. Enjoy your new build and looking forward to seeing the pictures.

Here are the pictures...

Apartments a mess...now its cleanup time!

Cabinets have not yet been stained and varnished, but you'll get the idea

looks good, bass should be more than adequate since BIB, wonder about the higher freq response on this 8"...

gychang

I've experimented with stuffing after all:

Placed high density wool batt behind the speaker and up to the start of the line at the top of the cabinet. (Apex of the triangle.)

I also placed some wool batt at the bottom of the box (where the line folds and reverses).

After listening for a while I felt that I had lost something. I removed the batts at the bottom of the cabinets - resulting in a more rounded low to mid range response. I like it more this way.

So...batt behind the speaker, but none where the line folds. Sound is clear and punchy but still 'full'.

Placed high density wool batt behind the speaker and up to the start of the line at the top of the cabinet. (Apex of the triangle.)

I also placed some wool batt at the bottom of the box (where the line folds and reverses).

After listening for a while I felt that I had lost something. I removed the batts at the bottom of the cabinets - resulting in a more rounded low to mid range response. I like it more this way.

So...batt behind the speaker, but none where the line folds. Sound is clear and punchy but still 'full'.

Final Version

After getting used to the speakers and tuning the bass:

I have run 4' of tapered insulation from the apex of the Z-driver down past the speaker. I tapered the top insulation in the narrower portions of the apex so that it isn't too densely stuffed.

I have placed mineral board at bottom of the box - i.e. the fold. The mineral board is a sample from my office for sound control panels used in gymnasiums. (Absorbs high frequencies well but not lower frequencies.)

When I stick my head in the top of the BIB boxes (which elicits a laugh from my wife) I hear only lower frequencies coming out of the box. This leads me to think that the higher frequencies are successfully eliminated.

After getting used to the speakers and tuning the bass:

I have run 4' of tapered insulation from the apex of the Z-driver down past the speaker. I tapered the top insulation in the narrower portions of the apex so that it isn't too densely stuffed.

I have placed mineral board at bottom of the box - i.e. the fold. The mineral board is a sample from my office for sound control panels used in gymnasiums. (Absorbs high frequencies well but not lower frequencies.)

When I stick my head in the top of the BIB boxes (which elicits a laugh from my wife) I hear only lower frequencies coming out of the box. This leads me to think that the higher frequencies are successfully eliminated.

Cut sheet

I am attaching the cut sheet for those that are interested. Note that some of the dimensions (side panels) are larger than the dimensions on the calculator. This is to accommodate for the space lost when mounting the front and rear panels within the width of the side panels, similarly for the bottom panel.

Note that this design doubles up the front panel with two smaller half pieces.

I've added phase plugs to mine - new picture!

Good luck!

I am attaching the cut sheet for those that are interested. Note that some of the dimensions (side panels) are larger than the dimensions on the calculator. This is to accommodate for the space lost when mounting the front and rear panels within the width of the side panels, similarly for the bottom panel.

Note that this design doubles up the front panel with two smaller half pieces.

I've added phase plugs to mine - new picture!

Good luck!

Attachments

Platplaas, congratulations on your build!

Very useful thread, wish I had found this earlier. I've been posting my share of newbie questions in other posts, where it looks you have got a lot of them answered here.

I am going to try a BIB with Fe166En later this week. My amp now is also a Miniwatt N3 (same as yours).

Some questions for you:

1. For adjusting stuffing, how are you doing it? Removable (screwed on) side?

2. It's a big cabinet - glude together only, or you have screws nails?

3. How many layers is your ply?

Very useful thread, wish I had found this earlier. I've been posting my share of newbie questions in other posts, where it looks you have got a lot of them answered here.

I am going to try a BIB with Fe166En later this week. My amp now is also a Miniwatt N3 (same as yours).

Some questions for you:

1. For adjusting stuffing, how are you doing it? Removable (screwed on) side?

2. It's a big cabinet - glude together only, or you have screws nails?

3. How many layers is your ply?

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Full Range

- First timer - desperately confused with the options...