My experience is that the A7 is marginal on 18mm material and the A10 is unacceptable. I use 24mm material for the baffle in either case.

Bob

So far we've had no major issues when using A7 sans the extra ring on the Murphy Multi-ply (slightly thicker at 18.65mm) but would definitely concur on the 10s and 12s - either 2 layers of 12mm, or 18+6, whatever I happen to have on hand.

Definitely use Mark's supplied gaskets, and to Dave's constant consternation, I really like the supplied screws as well. Take a look at the shanks, these are not standard tapered wood screws.

fe126en

I had the pleasure of listening to the frugalhorn mk3 today in a pretty good

room with a couple of small tube amps and a good source with good recordings.

My very first impression was that of a hollow sound. Stuffing the speakers more

into the corners and toeing them in in front of the listeners helped a good bit to

get some bass going and to lessen the 7k peak. I thought they were a bit bass light but the room was

fairly big, maybe 13 by 15 and well-damped.

He had minimal stuffing in the speakers, only felt and poly in the throat and

the V section stuffed with poly. I understand that more stuffing would mean

less bass. Would it also mean less hollowness to the sound though?

I suggested hogging out a chamfer behind the driver, a supra baffle, and

some dammar on the cone.

My ears did adjust to the sound and I did very much enjoy the listening, but

what could be down to ameliorate the singing-from- the -bottom-of-a-well

sound? thanks

I had the pleasure of listening to the frugalhorn mk3 today in a pretty good

room with a couple of small tube amps and a good source with good recordings.

My very first impression was that of a hollow sound. Stuffing the speakers more

into the corners and toeing them in in front of the listeners helped a good bit to

get some bass going and to lessen the 7k peak. I thought they were a bit bass light but the room was

fairly big, maybe 13 by 15 and well-damped.

He had minimal stuffing in the speakers, only felt and poly in the throat and

the V section stuffed with poly. I understand that more stuffing would mean

less bass. Would it also mean less hollowness to the sound though?

I suggested hogging out a chamfer behind the driver, a supra baffle, and

some dammar on the cone.

My ears did adjust to the sound and I did very much enjoy the listening, but

what could be down to ameliorate the singing-from- the -bottom-of-a-well

sound? thanks

Having not heard your speakers I'm shooting in the dark a bit. So what I say should be taken with a grain of salt.

It seems that the suffing really needs work. It actually takes a fair amount of stuffing to kill the bass. Just stuff away and listen as you go. Just make sure that you can extract stuffing if you overdo it and need to back up. The "holloness" is probably due to a lack of damping as you suggest.

Be sure to do a lot of listening as you go and carefully document each step in case you overdo it and need to back up.

As for "hogging" out the chamber, that's probably a really poor idea. It may be better to just start anew.

Best Regards,

TerryO

It seems that the suffing really needs work. It actually takes a fair amount of stuffing to kill the bass. Just stuff away and listen as you go. Just make sure that you can extract stuffing if you overdo it and need to back up. The "holloness" is probably due to a lack of damping as you suggest.

Be sure to do a lot of listening as you go and carefully document each step in case you overdo it and need to back up.

As for "hogging" out the chamber, that's probably a really poor idea. It may be better to just start anew.

Best Regards,

TerryO

Last edited:

chamfer

chamber

Patience Grasshopper.

Patience Grasshopper.

One must study the Master's wisdom and learn to read.

(Cal, I'm still getting words confused once in a while when reading.)

Best Regards,

Terry

my  :

:

the FE126 in FH3 (for that matter any rear mouth BLH ) certainly benefits from symmetrical corner/boundary loading, full chamfering of rear side of driver through hole, as well as the famous Fostex extended break in period

if the top or one side panel is not removable, adjusting stuffing fill levels in the closed taper "above" the driver, (behind the divider panel) will be "rather tricky"

additional fiber fill below the driver will would tame the bass -necessary for Alpair 7 and EL70 for example, but generally not found so for the FE126

how thick is the felt, and are side walls, top and divider panel in the immediate vicinity of driver lined?

:

: the FE126 in FH3 (for that matter any rear mouth BLH ) certainly benefits from symmetrical corner/boundary loading, full chamfering of rear side of driver through hole, as well as the famous Fostex extended break in period

if the top or one side panel is not removable, adjusting stuffing fill levels in the closed taper "above" the driver, (behind the divider panel) will be "rather tricky"

additional fiber fill below the driver will would tame the bass -necessary for Alpair 7 and EL70 for example, but generally not found so for the FE126

how thick is the felt, and are side walls, top and divider panel in the immediate vicinity of driver lined?

1st section, the smallest v shaped one behind the driver was not even stuffed.

That very much needs careful stuffing. And very difficult to do after the 2nd side goes on.

dave

1st section, the smallest v shaped one behind the driver was not even stuffed.

I heard it , and you called it. Progress..............thanks

fairly well detailed on page 13 of the full plan set

http://www.p10hifi.net/FH/downloads/frugel-hornMk3-1v0-250212.pdf

I've chatted with Dave about trying to fix the broken link for the Sketch-up model, including revision to show damping scheme - an orbital 3D drawing is worth a bazillion of either of our words.

fairly well detailed on page 13 of the full plan set

http://www.p10hifi.net/FH/downloads/frugel-hornMk3-1v0-250212.pdf

I've chatted with Dave about trying to fix the broken link for the Sketch-up model, including revision to show damping scheme - an orbital 3D drawing is worth a bazillion of either of our words.

Looking at page 13 and still need some help. I am finishing up my FH with Fostex Fe126en and have a question to the amount of poly in each "zone".

Am I to put 30g of poly in each zone (green and orange) for a total of 60g? OR spread the 30g out over both zones? if it is the later does that mean that each zone should have 15g?

lastly, if the 30g is wrong please advise to the right amount.

Thanks for the help in advance. Can't wait to hear these things today.

Frugel-horn and sub

Ok, bit of a strange question.

Having built a pair of FH Mk3 and very much enjoying them my only issue is not being able to take them a little louder without "hitting the stops". So looking at adding a sub and powering with one of these amps Hifimediy DDX320v2 2.1 Digital Amplifier

I am planning to build the sub as a sealed box into an existing window seat. There are 2 options as to where the driver is situated but my favoured one would have the 15" sub driver in the wall behind one of the FH cabinets (thus sub driver facing the rear of the FH). So question is, how would this effect the sound of the FH given proximity of the horn mouth to the sub driver? I am thinking not too great an effect but would be interested in peoples thoughts.

Cheers,

Chris

Ok, bit of a strange question.

Having built a pair of FH Mk3 and very much enjoying them my only issue is not being able to take them a little louder without "hitting the stops". So looking at adding a sub and powering with one of these amps Hifimediy DDX320v2 2.1 Digital Amplifier

I am planning to build the sub as a sealed box into an existing window seat. There are 2 options as to where the driver is situated but my favoured one would have the 15" sub driver in the wall behind one of the FH cabinets (thus sub driver facing the rear of the FH). So question is, how would this effect the sound of the FH given proximity of the horn mouth to the sub driver? I am thinking not too great an effect but would be interested in peoples thoughts.

Cheers,

Chris

Looking at page 13 and still need some help. I am finishing up my FH with Fostex Fe126en and have a question to the amount of poly in each "zone".

Am I to put 30g of poly in each zone (green and orange) for a total of 60g? OR spread the 30g out over both zones? if it is the later does that mean that each zone should have 15g?

In all builds you put 30 g in thepoint to the top of the box. Depending on the driver (toom, taste) you put up to 40g below the driver in the front fold. FE126 usually needs none below the driver.

dave

So question is, how would this effect the sound of the FH given proximity of the horn mouth to the sub driver?

I wouldn't face the woofer driver right at the back of the horn.

Optimal sonic placement of the woofer is not often the perfect spot for your decor.

dave

FH3 stuffing

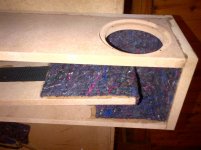

Hi Dave please help, I have attached some pics of my attempt to stuffing the FH3's. You mention carefull stuffing...does the stuffing in the V look OK (see pic1) or do I need to fluff it more. I found it quite difficult to not get those clumps of stuffing. Also, the felt I'm using is not quite as thick as 12mm, prob 8-10mm (see pic2), is this OK or should I put another layer over the existing?

BTW - I have 30g in the V and 20g in the throat as you see it. I also stuck valcro down the side panels of the throat (see pic3) to prevent the stuffing from falling to the bottom.

Thanks!

That very much needs careful stuffing. And very difficult to do after the 2nd side goes on.

dave

Hi Dave please help, I have attached some pics of my attempt to stuffing the FH3's. You mention carefull stuffing...does the stuffing in the V look OK (see pic1) or do I need to fluff it more. I found it quite difficult to not get those clumps of stuffing. Also, the felt I'm using is not quite as thick as 12mm, prob 8-10mm (see pic2), is this OK or should I put another layer over the existing?

BTW - I have 30g in the V and 20g in the throat as you see it. I also stuck valcro down the side panels of the throat (see pic3) to prevent the stuffing from falling to the bottom.

Thanks!

Attachments

- Home

- Loudspeakers

- Full Range

- Frugel-Horn Mk3 Builds & Build Questions