I've googled some more and there seems to be a few sites which sell a lot of different types of plywood. They are just not regular stores so I guess I will have to do a custom order.

I have had the same problem. I ended up getting my birch ply from Halland Audio Design i Kungsbacka when I ordered a speaker kit from them. They had 18mm high quality birch ply available, but this was in 2012/2013 so things might have changed. Custom orders might be tricky, because last time I checked they wanted you to order at least like 10 or 20 boards and most only sell to companies, not home gamers like you and me. But hey, you could always ask Bauhaus, Byggmax, K-Rauta, Beijer, and the other stores if they could do a special order for you but I don't think it will be very cheap.

Thanks for all the answers!

Yeah I noticed that as well. I am looking at this site "calexicowood.se", haven't seen any text about not sending to individuals yet, but maybe that have such a rule anyway. I will send them a message tomorrow.

Okay, then I will try to make it work anyway. Maybe my neighbour can help outLooking pretty is a side-effect. The purpose is for audio quality.

Alternatively to the rebate, you could surface moun tthe driver, and then build-up the baffle around the driver with something easy to cut like cork. 8.5mm without the decorative bezel cover, 10mm with.

Okay, good to knowI must say that I made mine from MDF about 7 years ago and have never regretted it even though I had listened to some made from ply. But then perhaps I am not so fastidious as Dave and friends (sorry Dave

I unfortunately live in Stockholm. Would probably cost a lot to travel there just for some plywood... Will definitely ask the local shops if they can order in some for me if I can't get it from the specialised shops.Frederik, if you are close to Malmo and Copenhagen you might able to pop across for the wood. Don’t know what the Swedish wood prices are like but you can get good quality ply in e.g. XL here at quite reasonable prices. Alternatively you could ask your Home Depot if they can order some for you, as their suppliers might also stock some of the better stuff, the depot just doesn’t have it in shop because few consumers buy it.

I have had the same problem. I ended up getting my birch ply from Halland Audio Design i Kungsbacka when I ordered a speaker kit from them. They had 18mm high quality birch ply available, but this was in 2012/2013 so things might have changed. Custom orders might be tricky, because last time I checked they wanted you to order at least like 10 or 20 boards and most only sell to companies, not home gamers like you and me. But hey, you could always ask Bauhaus, Byggmax, K-Rauta, Beijer, and the other stores if they could do a special order for you but I don't think it will be very cheap.

Yeah I noticed that as well. I am looking at this site "calexicowood.se", haven't seen any text about not sending to individuals yet, but maybe that have such a rule anyway. I will send them a message tomorrow.

Took me a while to decipher this since I haven't understood all the diy language, but I think I got it. I understand that the bezel is wanted/required on the inside. However, the driver cutout on the outside, is this required other than the fact that it looks better when the driver isn't protuding out? I have a feeling it will be difficult to do this cutout with the tools I have at hand.

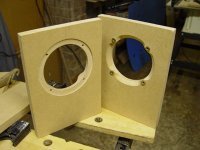

Fredrik, just to help you visualize the terminology - see the attached photo. On the left you see the front of the baffle with a rebate - for the speaker driver to be mounted flush with the front of the baffle. On the right you see the back of the baffle with a chamfer - a 45 degree cutout at the back between the mounting bolts. Both are important for better sound.

Attachments

Jerry - thanks for the picture - says it all

It should be noted that not all “full-range” drivers require the rebate - i.e. those with thinner / tapered flanges such as many of the Fostex, Mark Audio Pluvias and CHN70, and probably other.

However, with the very shallow cones and total mounting depth, I think all should have the chamfer / bevel to rear side of cut-out to avoid cavity resonance.

It should be noted that not all “full-range” drivers require the rebate - i.e. those with thinner / tapered flanges such as many of the Fostex, Mark Audio Pluvias and CHN70, and probably other.

However, with the very shallow cones and total mounting depth, I think all should have the chamfer / bevel to rear side of cut-out to avoid cavity resonance.

Last edited:

Fredrik, just to help you visualize the terminology - see the attached photo. On the left you see the front of the baffle with a rebate - for the speaker driver to be mounted flush with the front of the baffle. On the right you see the back of the baffle with a chamfer - a 45 degree cutout at the back between the mounting bolts. Both are important for better sound.

Thanks, these kind of pictures help

Hello again!

I've decided against going with plywood for a few reasons. Mainly because it was so hard to get in good enough quality. I also figured that MDF will be easier for me to work with, and since I've never built anything like this before I think I'll make it as easy as possible for me. I don't think I would notice the difference unless I did an A + B test either. Furthermore, if I do feel like the sound isn't good enough, I can just build a new pair!

However, I noticed another problem. My initial plan was to create it in 15mm with the 18mm baffle. There doesn't seem to be a lot of 15mm MDF around here unfortunately... So my plan now is to use the 16mm plan and modify it to use a 18mm baffle (since I had the Alpair which required 18mm baffle). So extending the side parts by 2mm so that they cover the 18mm baffle piece. So that the enterior volume will remain exactly the same, but the baffle will stick out another 2mm.

What do you think?

I've decided against going with plywood for a few reasons. Mainly because it was so hard to get in good enough quality. I also figured that MDF will be easier for me to work with, and since I've never built anything like this before I think I'll make it as easy as possible for me. I don't think I would notice the difference unless I did an A + B test either. Furthermore, if I do feel like the sound isn't good enough, I can just build a new pair!

However, I noticed another problem. My initial plan was to create it in 15mm with the 18mm baffle. There doesn't seem to be a lot of 15mm MDF around here unfortunately... So my plan now is to use the 16mm plan and modify it to use a 18mm baffle (since I had the Alpair which required 18mm baffle). So extending the side parts by 2mm so that they cover the 18mm baffle piece. So that the enterior volume will remain exactly the same, but the baffle will stick out another 2mm.

What do you think?

Hello again!

I've decided against going with plywood for a few reasons. Mainly because it was so hard to get in good enough quality. I also figured that MDF will be easier for me to work with, and since I've never built anything like this before I think I'll make it as easy as possible for me. I don't think I would notice the difference unless I did an A + B test either. Furthermore, if I do feel like the sound isn't good enough, I can just build a new pair!

However, I noticed another problem. My initial plan was to create it in 15mm with the 18mm baffle. There doesn't seem to be a lot of 15mm MDF around here unfortunately... So my plan now is to use the 16mm plan and modify it to use a 18mm baffle (since I had the Alpair which required 18mm baffle). So extending the side parts by 2mm so that they cover the 18mm baffle piece. So that the enterior volume will remain exactly the same, but the baffle will stick out another 2mm.

What do you think?

If there is only a 2mm difference in the baffle, I can't imagine that would make any audible difference anywhere within the range of human hearing. Some speaker designers go so far as to say anything within 10% of the original design is acceptable. I don't believe I would go the 10% route on the Frugal-horns, but I would be fine with a baffle 2mm thicker than the original design if that was my only good option.

Plus, if that is the only option, they will sound far better than if you abandoned the project entirely.

Mike

Hello Fredrik,

I made mine from 18.0 mm MDF, with the usual precautions, face mask, do the cutting outdoors.

I also had only very basic tools and had to resort to all sorts of little dodges to assemble them, my story is in the link below.

That was errr about 7 years ago I think, they still sound wonderful

Cheers

I made mine from 18.0 mm MDF, with the usual precautions, face mask, do the cutting outdoors.

I also had only very basic tools and had to resort to all sorts of little dodges to assemble them, my story is in the link below.

That was errr about 7 years ago I think, they still sound wonderful

Cheers

Vitorio - perhaps not all OSB is crated equal? The stuff we see around here is barely suitable for packing crates, and certainly not something on which I'd want to attempt any edge profiling or tinting/varnishing

I'm thinking exactly the same. The OSB we have here in northern Sweden is not something I would build a cabinet from. In that case I think fibreboard? (spånskiva in Swedish) would be a better option.

Hi all

I think the best quality is " estructural OSB-3 or 4". The one I told is the same used for roofs and floors. Is much more rigid than chipboard or mdf.

Here in Spain you can find good quality osb in timber stores. I have seen lower quality in brico stores (lighter, softer). Maybe this explain (and my bad english, too)

I think the best quality is " estructural OSB-3 or 4". The one I told is the same used for roofs and floors. Is much more rigid than chipboard or mdf.

Here in Spain you can find good quality osb in timber stores. I have seen lower quality in brico stores (lighter, softer). Maybe this explain (and my bad english, too)

Vitorio - perhaps not all OSB is crated equal? The stuff we see around here is barely suitable for packing crates, and certainly not something on which I'd want to attempt any edge profiling or tinting/varnishing

Miter joints I guess. It is actually a beautiful material on the panel side, it is alive with randomness. It stains or paints just fine, if random variations are your thing.

Hello Fredrik,

I made mine from 18.0 mm MDF, with the usual precautions, face mask, do the cutting outdoors.

I also had only very basic tools and had to resort to all sorts of little dodges to assemble them, my story is in the link below.

That was errr about 7 years ago I think, they still sound wonderful

Cheers

Hey jemraid,

Nice FH3s!

Spotted you went to B&Q Chesterfield - I'm based in Dronfield. Send me a PM if you fancy meeting up and talking shop for a bit.

Cheers,

Chris

Many moons later... driver upgrade?

After many years of newborn-related absence from diyAudio, I am slowly picking things up again.

I had built the Frugel-Horn in November of 2011 using the Fostex FE128eN drivers. Really loved the sound, although the midrange was (and is) very feisty (that's a technical term, I think).

A couple of years later, my (small) kids got really interested about what that little "button" in the middle of the drivers could do... and pushed it.... in.

Granted, I may be a victim of illusion, but they never really sounded the same to me after that.

Now that the kids are old enough to be reasoned with about this kind of thing, I am thinking of replacing the drivers and I am wondering if the past seven years have brought a newer and better sounding driver I could upgrade to.

I don't even know if the FE128eN are still available, so a suitable replacement driver will have to be found that at least matches the performance of the current ones.

Can anyone help guide me to a good decision here?

I appreciate any and all thoughts!

Thanks and happy Friday!

Stefan

After many years of newborn-related absence from diyAudio, I am slowly picking things up again.

I had built the Frugel-Horn in November of 2011 using the Fostex FE128eN drivers. Really loved the sound, although the midrange was (and is) very feisty (that's a technical term, I think).

A couple of years later, my (small) kids got really interested about what that little "button" in the middle of the drivers could do... and pushed it.... in.

Granted, I may be a victim of illusion, but they never really sounded the same to me after that.

Now that the kids are old enough to be reasoned with about this kind of thing, I am thinking of replacing the drivers and I am wondering if the past seven years have brought a newer and better sounding driver I could upgrade to.

I don't even know if the FE128eN are still available, so a suitable replacement driver will have to be found that at least matches the performance of the current ones.

Can anyone help guide me to a good decision here?

I appreciate any and all thoughts!

Thanks and happy Friday!

Stefan

FE128eN? Was that a Japan-only special edition? Or do you mean the FE126En? If the latter, it's a current unit, so if you were happy with the originals, I'd be inclined to stick with it.

Thanks for your response; you are absolutely correct, of course. FE126eN they are. My handwriting sometimes sucks...

Good to know they are still in production.

I liked them enough to replace with the same, but I am also always curious to try something else.

FE128? Haven't heard of that model before - do you perhaps mean either FE126 or FE108Z (Sigma)? I've heard both of those in several enclosure designs, including both FH1 and FH3, Ed Schillings Hornshoppe Horns, and others.

FWIW, if you have the required power - minimum 10w I'd say - there are several models of comparably sized drivers by Mark Audio that for my money outperform the Fostex in the FH3; specifically the Alpair7.3, or Pluvia7. I've also heard some positive field reports about the newly announced Alpair 7 MS, but how soon before they reach the consumer end of the supply pipeline is not yet certain.

FWIW, if you have the required power - minimum 10w I'd say - there are several models of comparably sized drivers by Mark Audio that for my money outperform the Fostex in the FH3; specifically the Alpair7.3, or Pluvia7. I've also heard some positive field reports about the newly announced Alpair 7 MS, but how soon before they reach the consumer end of the supply pipeline is not yet certain.

- Home

- Loudspeakers

- Full Range

- Frugel-Horn Mk3