In my search for a true Full Range driver I did not find any drivers that was satisfying..

First I designed a 8" driver, but it could not do more than 10kHz.

To be true this driver could have been a full range unit with 20kHz or more bandwidth, but due to I managed to reduce resonances and breakups to virtually zero it was 10kHz I got.

Most or possibly all full range drivers are possibly not able to deliver much bandwidth if resonances and breakups are controlled.

My investigation shoved that most drivers have an addition of 6 - 12 dB of their true output witch are resonances and breakups.

This starts from the frequency where the voicecoil assembly and the cone assembly have their resonance - typically between 600Hz and 1200Hz.

This are seen as a dip in level and a bump on the impedance curve.

Above this resonance the whole system are unstable and a rising level vs frequency can often be seen.

If the added resonances and breakups are severe the level drops at closer to 18dB/oct when the response falls towards the highs.

So my quest for the perfect full range driver in sense of a 8" dynamic driver ended there...

Then I designed a AMT driver with full range in mind.

After a lot of investigations regarding materials and physical sizes I was limited to a maximum size of the diaphragm.

I designed a diaphragm that was 1mm below the maximum size that could be produced.

Neodym N52 magnets was the strongest I could source and settled for that.

The poleplates was the next issue to be solved and I tried laser cutting first but got problems with warping, and I ended up with ordering some special stamping tools.. Due to limitations with the stamping process both the back and the front plate are made of two 3mm plates that are stacked.

One AMT driver (front plate) measures 240mm x 90mm and have a diaphragm that are 560 cm2 in area, and the Xmax are 1mm.

Compared to a 8" driver with 220 cm2 this AMT have (560/220x1) a calculated Xmax of 2.5mm. The impedance of the AMT are 8.2 ohm.

The AMT measures "flat" from 100Hz to 18kHz and drops of controlled in both ends.

Due to this I will be using five AMT with a crossover at 125 - 250Hz.

One AMT above the crossover frequency and four below.

In a horn enclosure I expect a resonse down to possibly 25Hz.

Due to this I have made a version of the AMT with five diaphragms (front plate measures 240mm x 300mm).

So fare I have finished the cabinets and finished the first AMT driver, the four remaining AMT elements in each driver will be finished shortly, but the combination of the enormous resolution of the AMT and the slow fall in level downwards gives an impression of a system that have nearly all the bass needed.

Due to this I will soon make a system with four or eight AMT´s in a line source with a wave-guide for a truly full range AMT without any components (crossover).

I will post some pictures and measurements shortly...

First I designed a 8" driver, but it could not do more than 10kHz.

To be true this driver could have been a full range unit with 20kHz or more bandwidth, but due to I managed to reduce resonances and breakups to virtually zero it was 10kHz I got.

Most or possibly all full range drivers are possibly not able to deliver much bandwidth if resonances and breakups are controlled.

My investigation shoved that most drivers have an addition of 6 - 12 dB of their true output witch are resonances and breakups.

This starts from the frequency where the voicecoil assembly and the cone assembly have their resonance - typically between 600Hz and 1200Hz.

This are seen as a dip in level and a bump on the impedance curve.

Above this resonance the whole system are unstable and a rising level vs frequency can often be seen.

If the added resonances and breakups are severe the level drops at closer to 18dB/oct when the response falls towards the highs.

So my quest for the perfect full range driver in sense of a 8" dynamic driver ended there...

Then I designed a AMT driver with full range in mind.

After a lot of investigations regarding materials and physical sizes I was limited to a maximum size of the diaphragm.

I designed a diaphragm that was 1mm below the maximum size that could be produced.

Neodym N52 magnets was the strongest I could source and settled for that.

The poleplates was the next issue to be solved and I tried laser cutting first but got problems with warping, and I ended up with ordering some special stamping tools.. Due to limitations with the stamping process both the back and the front plate are made of two 3mm plates that are stacked.

One AMT driver (front plate) measures 240mm x 90mm and have a diaphragm that are 560 cm2 in area, and the Xmax are 1mm.

Compared to a 8" driver with 220 cm2 this AMT have (560/220x1) a calculated Xmax of 2.5mm. The impedance of the AMT are 8.2 ohm.

The AMT measures "flat" from 100Hz to 18kHz and drops of controlled in both ends.

Due to this I will be using five AMT with a crossover at 125 - 250Hz.

One AMT above the crossover frequency and four below.

In a horn enclosure I expect a resonse down to possibly 25Hz.

Due to this I have made a version of the AMT with five diaphragms (front plate measures 240mm x 300mm).

So fare I have finished the cabinets and finished the first AMT driver, the four remaining AMT elements in each driver will be finished shortly, but the combination of the enormous resolution of the AMT and the slow fall in level downwards gives an impression of a system that have nearly all the bass needed.

Due to this I will soon make a system with four or eight AMT´s in a line source with a wave-guide for a truly full range AMT without any components (crossover).

I will post some pictures and measurements shortly...

Some photos..

Front and back of the one element AMT,

and the five element AMT (on element mounted) in the horn cabinet (down firing horn).

NB! this was the first prototypes so please do not look to closely on the finish..

The folding of the diaphragms have been improved in several steps...

Front and back of the one element AMT,

and the five element AMT (on element mounted) in the horn cabinet (down firing horn).

NB! this was the first prototypes so please do not look to closely on the finish..

The folding of the diaphragms have been improved in several steps...

Attachments

Last edited:

Awesome!!! SoCal Surfers would say "Duuuuuuude - U R outa-sight" or as we would say here in the "south" (southern states) "Shieeeeeeeet"

or as we would say here in the "south" (southern states) "Shieeeeeeeet"

I have my ESS AMT1's - but this is something even the best minds have not been able to accomplish in the 40 years I have been around - so Incredible!

We of course await photo's and info. To be valid you will need independent confirmation and testing of the device so I am putting myself on the list of people you should provide some "test units" to!!!

Crazy Serb will try to beat me to 'em though - I know I can count on that!

or as we would say here in the "south" (southern states) "Shieeeeeeeet"

or as we would say here in the "south" (southern states) "Shieeeeeeeet"

I have my ESS AMT1's - but this is something even the best minds have not been able to accomplish in the 40 years I have been around - so Incredible!

We of course await photo's and info. To be valid you will need independent confirmation and testing of the device so I am putting myself on the list of people you should provide some "test units" to!!!

Crazy Serb will try to beat me to 'em though - I know I can count on that!

Fantastic, Ray, I wasn't aware that you had built these yourself - I thought that the AMT's were a commercial driver that you had mounted into horns!

This is DIY par excellence! A viable new DIY driver based on AMT theory is not something trivial - I commend your technical prowess

Looking forward to the details of this build

PS Your complete system would appear to be as resolving as can be achieved with current technology - SDTrans192 SD card player -> Sabre DAC (to be decided) -> Balanced JFET LU1014D poweramp -> AMT speakers - Awesome !!!!!

This is DIY par excellence! A viable new DIY driver based on AMT theory is not something trivial - I commend your technical prowess

Looking forward to the details of this build

PS Your complete system would appear to be as resolving as can be achieved with current technology - SDTrans192 SD card player -> Sabre DAC (to be decided) -> Balanced JFET LU1014D poweramp -> AMT speakers - Awesome !!!!!

Wow

There usually isn`t any "news" in the loudspeaker world, be it commercial or DIY, that catches my interest for more than 5 minutes .....but.....an AMT capable to play from 150Hz upwards would be really something very, very special.

Can`t wait to see some more details about the construction, data and hopefully measurements eventually.

I`ll definitely follow this thread closely!

In my search for a true Full Range driver I did not find any drivers that was satisfying..

Then I designed a AMT driver with full range in mind.

There usually isn`t any "news" in the loudspeaker world, be it commercial or DIY, that catches my interest for more than 5 minutes .....but.....an AMT capable to play from 150Hz upwards would be really something very, very special.

Can`t wait to see some more details about the construction, data and hopefully measurements eventually.

I`ll definitely follow this thread closely!

Is there a paper on the web with diagrams and schematics on the theory and design of this type of speaker. Things such as the diaphragm makeup, circuit layout, magnet placement would be helpful. I'm thinking of trying a diy amt as well.

Thanks

The patents Oskar Heil issued are easy to find and are possibly the only help you will get...

When I was searching for someone that could manufacture my diaphragms I was amused time after time..

I got some samples of AMT diaphragms, and when I compared those with the patent papers - they was bluecopies of the drawings in the patents.

Due to my implementation of AMT´s are my own and I have used my own "head" - my AMT´s are more different then like all other implementations.

The layout of the diaphragms are so different from the patents that the manufacturer of the diaphragms was sure they could not work.

And as I am using materials that never have been used in AMT´s before, the manufacturer had to implement a new production process and both the film and the conducting materials had to be special ordered.

As my diaphragms only are 12.5 micron thick I was told time after time that a AMT could not be made, and certainly not a 560 cm2 diaphragm that was intended for playing bass. I was also told that it was not possible to use so strong magnets as the neodym N52 magnets I use either together with the thin diaphragms.

All this may be true if I had copied the patents.

But the diaphragms are the easiest part.

The holding/folding container for the diaphragms was also very difficult to find someone to manufacture.

They are made of good old "pertinax" and are 3D CNC machined by a company in Germany.

I have two other AMT´s finished as designs - a 2000 cm2 bass transducer with Xmax of 2mm, and a complementary midrange / treble AMT with a expected bandwith of 50kHz or more.

As the AMT´s I have now are extremely difficult to assemble they are not yet suitable for DIY.

There usually isn`t any "news" in the loudspeaker world, be it commercial or DIY, that catches my interest for more than 5 minutes .....but.....an AMT capable to play from 150Hz upwards would be really something very, very special.

Can`t wait to see some more details about the construction, data and hopefully measurements eventually.

I`ll definitely follow this thread closely!

I will post measurements later this evening.

Fantastic, Ray, I wasn't aware that you had built these yourself - I thought that the AMT's were a commercial driver that you had mounted into horns!

This is DIY par excellence! A viable new DIY driver based on AMT theory is not something trivial - I commend your technical prowess

Looking forward to the details of this build

PS Your complete system would appear to be as resolving as can be achieved with current technology - SDTrans192 SD card player -> Sabre DAC (to be decided) -> Balanced JFET LU1014D poweramp -> AMT speakers - Awesome !!!!!

Thanks John, and thanks to you everything will be running from LiFePo4 batteries very soon...

The patents Oskar Heil issued are easy to find and are possibly the only help you will get...

When I was searching for someone that could manufacture my diaphragms I was amused time after time..

I got some samples of AMT diaphragms, and when I compared those with the patent papers - they was bluecopies of the drawings in the patents.

Due to my implementation of AMT´s are my own and I have used my own "head" - my AMT´s are more different then like all other implementations.

The layout of the diaphragms are so different from the patents that the manufacturer of the diaphragms was sure they could not work.

And as I am using materials that never have been used in AMT´s before, the manufacturer had to implement a new production process and both the film and the conducting materials had to be special ordered.

As my diaphragms only are 12.5 micron thick I was told time after time that a AMT could not be made, and certainly not a 560 cm2 diaphragm that was intended for playing bass. I was also told that it was not possible to use so strong magnets as the neodym N52 magnets I use either together with the thin diaphragms.

All this may be true if I had copied the patents.

But the diaphragms are the easiest part.

The holding/folding container for the diaphragms was also very difficult to find someone to manufacture.

They are made of good old "pertinax" and are 3D CNC machined by a company in Germany.

I have two other AMT´s finished as designs - a 2000 cm2 bass transducer with Xmax of 2mm, and a complementary midrange / treble AMT with a expected bandwith of 50kHz or more.

As the AMT´s I have now are extremely difficult to assemble they are not yet suitable for DIY.

Wow sounds like a lot of engineering on your part went into your design! It never ceases to amaze me the level of expertise that can be found here on this forum.

I will check out the patents. I really love to explore the DIY aspects of these things. I have done planars, ribbons, and esl's. Mostly just for fun and testing and I would really love to attempt something like this. Thanks for the input.

Thanks John, and thanks to you everything will be running from LiFePo4 batteries very soon...

I'm glad I was able to help in some small way - going off grid will hopefully prove to be another significant improvement? Let us know your findings - should be interesting in such a resolving system!

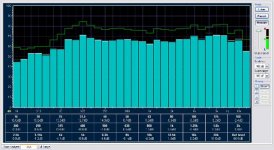

Here is a measurement i did now with XTZ room analyzer.

It is measured with one AMT in a horn cabinet designed for five AMT drivers.

The measured driver have not the latest and most linear diaphragm.

I will come back with better measurements when I get the proper measuring equipment running again, and I have prepared drivers with the final diaphragms..

It is measured with one AMT in a horn cabinet designed for five AMT drivers.

The measured driver have not the latest and most linear diaphragm.

I will come back with better measurements when I get the proper measuring equipment running again, and I have prepared drivers with the final diaphragms..

Attachments

I have received some questions regarding the availability of the AMTs and 8" drivers.

Both the AMTs and 8" drivers was originally designed to be commercial products.

I will now finish some of the drivers as demo units and investigate if there are some companies that will take over the concepts.

The sound quality are remarkable and those that have heard them have never heard anything close.

The "strangest" with the AMTs are how good they play bass - this was my worry, but when I solved the resonances at lower frequencies bass was suddenly the best part...

Even if they drop in level above 18kHz (due to cancelations due the size) there is no distortion and they play the highs better than AMTs that goes to 35kHz.

More detail, more soundstage, more dynamic etc..

Both the AMTs and 8" drivers was originally designed to be commercial products.

I will now finish some of the drivers as demo units and investigate if there are some companies that will take over the concepts.

The sound quality are remarkable and those that have heard them have never heard anything close.

The "strangest" with the AMTs are how good they play bass - this was my worry, but when I solved the resonances at lower frequencies bass was suddenly the best part...

Even if they drop in level above 18kHz (due to cancelations due the size) there is no distortion and they play the highs better than AMTs that goes to 35kHz.

More detail, more soundstage, more dynamic etc..

Wow sounds like a lot of engineering on your part went into your design! It never ceases to amaze me the level of expertise that can be found here on this forum.

I will check out the patents. I really love to explore the DIY aspects of these things. I have done planars, ribbons, and esl's. Mostly just for fun and testing and I would really love to attempt something like this. Thanks for the input.

3832499 + 6205228 + 6111970 + PAT2PDF - Free PDF copies of patents: Download and print!

"Wow sounds like a lot of engineering on your part" - This much more than that

However, this claim still needs independent verification and long term reliability testing in it's intended environment - and I have a great place in mind for that.

Last edited:

I will now finish some of the drivers as demo units and investigate if there are some companies that will take over the concepts.

This is more easily said than done. You will face the "not invented here" syndrome or some companies that might buy it just to kill it so that it will not be around to compete with their devices.

You seem to be very experienced in the area of design though so it is most likely that I am telling you something that you already know.

There is one aspect with the AMT that might make it even more interesting..

There are four "voicecoils" - each of 8 ohm.

The AMT can be configured as a 2 ohm, 8 ohm or 32 ohm device.

Pure resistive in all three configurations.

Four AMTs would be needed to get full level down to 20Hz.

If configured for 32 ohm and four AMTs connected in series - you then have a 128 ohm pure resistive speaker, and if you use eight AMTs in a line source you have a 256 ohm pure resistive speaker.

Connected to a valve / tube OTL amplifier able to deliver 100 - 200 Volt and you have something interesting...

There are four "voicecoils" - each of 8 ohm.

The AMT can be configured as a 2 ohm, 8 ohm or 32 ohm device.

Pure resistive in all three configurations.

Four AMTs would be needed to get full level down to 20Hz.

If configured for 32 ohm and four AMTs connected in series - you then have a 128 ohm pure resistive speaker, and if you use eight AMTs in a line source you have a 256 ohm pure resistive speaker.

Connected to a valve / tube OTL amplifier able to deliver 100 - 200 Volt and you have something interesting...

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Full Range

- The One and Only Full Range AMT