First of all, thanks to Dave for all his help. This has been an interesting learning experience.

I've diverged from the original thread. http://www.diyaudio.com/forums/full-range/144099-thread-tysen-variations-fast.html. See for original proposals.

Basically, this is my customized version of the Tysen Speaker. I chose it after building a TQWTL that was very good, however it had some short comings for the types of music that I listen to. Low mids and Bass.

I had used the FE167E FR's for that project, and wanted to incorporate them into the Tysen.

I've diverged from the original thread. http://www.diyaudio.com/forums/full-range/144099-thread-tysen-variations-fast.html. See for original proposals.

Basically, this is my customized version of the Tysen Speaker. I chose it after building a TQWTL that was very good, however it had some short comings for the types of music that I listen to. Low mids and Bass.

I had used the FE167E FR's for that project, and wanted to incorporate them into the Tysen.

Design Requirement:

1. Something tall where the centre for the FR is around 40". The height for both me and my wife to listen on axis.

2. Narrow so that It could be placed near the wall beside the fireplace when we needed more space in the living room.

3. FE167E, cause I already have them, and my DIY budget for the year is shrinking

4. More bass. A Biamped system to control the bass in the room based on a specific recording. Effective EQ of lows and highs.

1. Something tall where the centre for the FR is around 40". The height for both me and my wife to listen on axis.

2. Narrow so that It could be placed near the wall beside the fireplace when we needed more space in the living room.

3. FE167E, cause I already have them, and my DIY budget for the year is shrinking

4. More bass. A Biamped system to control the bass in the room based on a specific recording. Effective EQ of lows and highs.

Current Design Ideas:

1. Adjustable Q with sliding shelves to reveal different chambers altering the volume and Q.

2. Adjustable Faceplate: Like what NP does with his open baffles. FR125SR seems to model well in this cabinet. With lower impedance's than the FE167E, and the faceplace may act like a supra baffle as well.

3. Dual CSS or EL70 drivers wired series.

All this in one cabinet. Will it work, don't know.

DIY is fun

1. Adjustable Q with sliding shelves to reveal different chambers altering the volume and Q.

2. Adjustable Faceplate: Like what NP does with his open baffles. FR125SR seems to model well in this cabinet. With lower impedance's than the FE167E, and the faceplace may act like a supra baffle as well.

3. Dual CSS or EL70 drivers wired series.

All this in one cabinet. Will it work, don't know.

DIY is fun

ML TQWTL Side Note:

My original ML TQWTL was based on some proposed design. It didn't suit my needs. However, I'm not bashing it, I just had the wrong cabinet to begin with, and have verified that with Martin King. I'm sure some designs can go low, and I could have built another one.

However, building a Tysen, gives me the opportunity to build something different.

My original ML TQWTL was based on some proposed design. It didn't suit my needs. However, I'm not bashing it, I just had the wrong cabinet to begin with, and have verified that with Martin King. I'm sure some designs can go low, and I could have built another one.

However, building a Tysen, gives me the opportunity to build something different.

What I meant there is: using either the FE167E single FR, or FR125SR single or dual, or EL70 single or dual, or a combination of the smaller FR's

Well if you mostly like the sound of the FE167E, I'd suggest dual EL70s (series wired), and woofer(s) of choice. As you're aware, the SDX 7's huge advantage is the performance available in very low volume sealed enclosures. Like the FR & WR125s, the price paid for this is sensitivity; and in my own experience, less than graceful performance when over-driven - not something I've yet heard from the Mark Audio drivers mentioned, even at high (for me) SPLs - i.e. circa high 90 's

Just to throw another angle at'cha, you might want to consider trying up-firing one of the EL or CHR70's in a dual driver application. Both my wife & I are quite enjoying what this does in terms of soundstage, etc., in the "castle" microtowers.

Last edited:

Current XO designs:

See thread

http://www.diyaudio.com/forums/soli...d-active-crossovers-open-baffle-speakers.html

I'm still thinking about this. It may well be done using dual supplies to get rid of the bypass caps.

See thread

http://www.diyaudio.com/forums/pass-labs/4486-diy-progress-report-212.html

Some info from NP B4.

I currently have a DIY B1 buffer running on the FE167E FR, and it works amazingly well.

See thread

http://www.diyaudio.com/forums/soli...d-active-crossovers-open-baffle-speakers.html

I'm still thinking about this. It may well be done using dual supplies to get rid of the bypass caps.

See thread

http://www.diyaudio.com/forums/pass-labs/4486-diy-progress-report-212.html

Some info from NP B4.

I currently have a DIY B1 buffer running on the FE167E FR, and it works amazingly well.

less than graceful performance when over-driven - not something I've yet heard from the Mark Audio drivers mentioned, even at high (for me) SPLs - i.e. circa high 90 's

Thanks, that's good to know.

Haven't heard the CHR70's but have heard the Alpair7 and Alpair10. To me, they were too bright for my tastes.

I think I just like the paper FR's, compared to aluminum alloys.

I don't think many have heard the Alpair 7, Mark only made the 1st of them a very short while ago (you probably mean Alpair 6).

Given that you have the volume, and you are using drivers that go lower, you might well consider the Trio8 or Trio10 instead of the SDX7.

dave

I bought the SDX7 cause if this design is not sufficient, then I can build a small sealed box with two drivers.

Yes, they were probably Alpair 6's.

I don't think many have heard the Alpair 7

dave

Yes it was an Alpair 6

Given that you have the volume, and you are using drivers that go lower, you might well consider the Trio8 or Trio10 instead of the SDX7.

dave

I got two of the SDX7's for this project. If it doesn't work out, I may use them for a small sub.

tongue and groove shelves for adjustable Q

That shouldn't be too too hard to do. Multiple shelves exposing different volumes to change up the Q point. The seal should be fairly snug and still be removable. Might need a bit of sanding down.

The shelves could be extracted from the rear of the cabinet, and then be covered afterward.

Drawing to come later.

That shouldn't be too too hard to do. Multiple shelves exposing different volumes to change up the Q point. The seal should be fairly snug and still be removable. Might need a bit of sanding down.

The shelves could be extracted from the rear of the cabinet, and then be covered afterward.

Drawing to come later.

Attachments

Latest Prototype

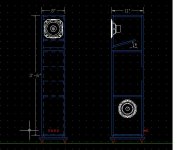

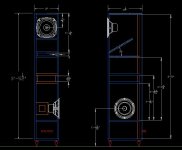

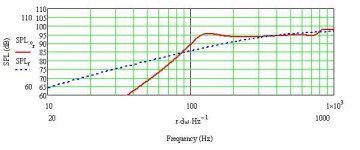

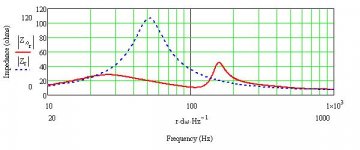

Okay here's the latest drawing and plots. The drawing is still work-in-progress.

I made a few changes.

-Folded aperiodic 12:1 taper fast speaker. I changed it to 12:1 to give a bit more room if I wanted to add a supra baffle later and/or different drivers for this cabinet. I also changed it to move the front port down a bit closer to the middle of the cabinet so it's closer to the sub enclosure.

- The centre of the sub is about 12" from the ground. I looked at other commercial designs (Jamo S606, Polk LSi 15) and they don't have it right to the floor. The cabinet have similar dimension. So I went with it. I don't have a carpeted floor so, I didn't really want it down low.

- I'm still working out the movable shelves. I probably won't use T+G, I'll just use horizontal braces. Much easier. I'm still new to woodworking.

- I'm still working out a back brace for the SDX7.

- The entire back will be removable via screws and sealed with weather stripping. To get access to for stuffing and the BSC/Networks.

- I've moved the cut off frequency up to about 120Hz or so, this was to minimize the impedance down 20 ohms, so perhaps the XO will be higher.

- Material is 1/2" birch from Home depot. Expensive for just a prototype, but I just want to hear how it sounds compared to MDF. Probably could have been 3/4" instead. But we'll see.

Okay here's the latest drawing and plots. The drawing is still work-in-progress.

I made a few changes.

-Folded aperiodic 12:1 taper fast speaker. I changed it to 12:1 to give a bit more room if I wanted to add a supra baffle later and/or different drivers for this cabinet. I also changed it to move the front port down a bit closer to the middle of the cabinet so it's closer to the sub enclosure.

- The centre of the sub is about 12" from the ground. I looked at other commercial designs (Jamo S606, Polk LSi 15) and they don't have it right to the floor. The cabinet have similar dimension. So I went with it. I don't have a carpeted floor so, I didn't really want it down low.

- I'm still working out the movable shelves. I probably won't use T+G, I'll just use horizontal braces. Much easier. I'm still new to woodworking.

- I'm still working out a back brace for the SDX7.

- The entire back will be removable via screws and sealed with weather stripping. To get access to for stuffing and the BSC/Networks.

- I've moved the cut off frequency up to about 120Hz or so, this was to minimize the impedance down 20 ohms, so perhaps the XO will be higher.

- Material is 1/2" birch from Home depot. Expensive for just a prototype, but I just want to hear how it sounds compared to MDF. Probably could have been 3/4" instead. But we'll see.

Attachments

Pics

Here's what it looks like so far. Nothing is glued yet, just clamped together.

- I created a cut sheet list, and got home depot to do the long cuts, and I did the rest myself at home. That's probably the best move I made so far in this construction. Their CNC cutting machine is pretty accurate.

- Still need to file out the speaker holes. I don't have a jig to make 45 degree chamfers, I'm going the old fashioned way. But needs a bit more.

- Higher quality plywood is SOOO much nicer to work with, and there is no MDF dust flying everywhere.

-I'm hoping to get most of this done this week.

Here's what it looks like so far. Nothing is glued yet, just clamped together.

- I created a cut sheet list, and got home depot to do the long cuts, and I did the rest myself at home. That's probably the best move I made so far in this construction. Their CNC cutting machine is pretty accurate.

- Still need to file out the speaker holes. I don't have a jig to make 45 degree chamfers, I'm going the old fashioned way. But needs a bit more.

- Higher quality plywood is SOOO much nicer to work with, and there is no MDF dust flying everywhere.

-I'm hoping to get most of this done this week.

Attachments

- Material is 1/2" birch from Home depot. Expensive for just a prototype, but I just want to hear how it sounds compared to MDF. Probably could have been 3/4" instead. But we'll see.

You will probably have to double up at least the SDX7 part... they can generate a lot of energy.

dave

if you're planning on spending much time in DIY realm, the investment in a cheap router and a few bits will more than pay for themselves.Here's what it looks like so far. Nothing is glued yet, just clamped together.

- I created a cut sheet list, and got home depot to do the long cuts, and I did the rest myself at home. That's probably the best move I made so far in this construction. Their CNC cutting machine is pretty accurate.

- Still need to file out the speaker holes. I don't have a jig to make 45 degree chamfers, I'm going the old fashioned way. But needs a bit more.

preaching to the choir my friend- Higher quality plywood is SOOO much nicer to work with, and there is no MDF dust flying everywhere.

don't be surprised if things take longer than you planned.-I'm hoping to get most of this done this week.

those SDX7 may not be the most efficient driver in the world, but as Dave noted, those are powerful motors - based on some experience, it's pretty hard to over brace an enclosure for them

best of luck, and keep us posted

chris

Last edited:

As per my license agreement:

The previously displayed plots were generated using software created by Martin King and licensed to me for personal DIY purposes only.

MathCad Computer Models : Upgraded Versions

Support MJK

The previously displayed plots were generated using software created by Martin King and licensed to me for personal DIY purposes only.

MathCad Computer Models : Upgraded Versions

Support MJK

You will probably have to double up at least the SDX7 part... they can generate a lot of energy.

dave

Should that be the entire internal area for the SDX7? or will doubling the rear side of the baffle and adding more support.

I only have a bit of 1/2" birch left. I do have some cheap spruce plywood and some MDF (which I'm trying to avoid)

Thanks.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Full Range

- Tysen Variation FE167E with CSS SDX7