You may want to consider starting with a less aggressive solvent, then moving up the food chain:

Start with something like rubbing alcohol, then paint thinner/mineral spirits, degreaser, then on to acetone, etc. Less chance of melting the various adhesives holding things together.

......and don't smoke & stay away from open flames....

Start with something like rubbing alcohol, then paint thinner/mineral spirits, degreaser, then on to acetone, etc. Less chance of melting the various adhesives holding things together.

......and don't smoke & stay away from open flames....

...and don't smoke & stay away from open flames....

And do it outside or under a fume hood.

dave

so to get things "clear" : i must apply IPA on the cloth suspension ? no oil added ? what do yo adice

thanks

Well......I have absolutely no clue as I was unaware that these things could harden up......but I think you have to philosophically decide what you are trying to accomplish.

Adding something:

If you hope to use the rubbing alcohol, acetone, etc as a transport medium/thinner to get oil into the spider & surround, then mix some up and give it a go; the solvent will hopefully evaporate leaving behind the oil, which can also potentially be a solvent to loosen things up.

Removing something:

If you want to remove whatever treatment is already there that has hardened, then just apply solvent and see if it will loosen up/wash out.

If there is no downside to applying just the solvent, why not try that first; you can also apply oil later, ie remove old hardened stuff, wiggle the cone, then apply new softener if req'd.

What are you going to use to apply the various unguents? Artist's paintbrush? Epoxy brush?

that's good advice, i will first give it a try with IPA, and see how things work out.

i'll brush it on the suspension i think.

i'm gonna pass by a friend, he does art restoration, maybe he can help me out a bit more, or give me some advice.

i'll let you know guys,

(got myself already 1l ipa, that should do

i'll brush it on the suspension i think.

i'm gonna pass by a friend, he does art restoration, maybe he can help me out a bit more, or give me some advice.

i'll let you know guys,

(got myself already 1l ipa, that should do

hello guys it has been a while since this tread was started, but i have made some progression.

what did we find out

1)ipa is a bit to aggressive to use, according to the art restaurator, so you should use octane with it, octane gets airborn very fast and so it takes ipa with it. use a 50-50 at max.

using this cleans up the suspension cloth but it stayed stiff.

2)you can use oxgall to get rid of the nicotine

using this made it clear that there was no nicotine on the suspension.

3)the restaurator says that the suspension is treaded with some kind of varnish: i suspect that is was a coating on the suspension to keep it flexible, but after the years it just become hard. he says he can take it off, but we'll have to get to his workshop for that, so that he can try a few tricks on it.

i'll keep you posted.

greetz

ps: planet10, i'm almost done with a fonken fe127, i wanna use felt on the inside of the speaker as damping material, do you approve ?

thanks

what did we find out

1)ipa is a bit to aggressive to use, according to the art restaurator, so you should use octane with it, octane gets airborn very fast and so it takes ipa with it. use a 50-50 at max.

using this cleans up the suspension cloth but it stayed stiff.

2)you can use oxgall to get rid of the nicotine

using this made it clear that there was no nicotine on the suspension.

3)the restaurator says that the suspension is treaded with some kind of varnish: i suspect that is was a coating on the suspension to keep it flexible, but after the years it just become hard. he says he can take it off, but we'll have to get to his workshop for that, so that he can try a few tricks on it.

i'll keep you posted.

greetz

ps: planet10, i'm almost done with a fonken fe127, i wanna use felt on the inside of the speaker as damping material, do you approve ?

thanks

ps: planet10, i'm almost done with a fonken fe127, i wanna use felt on the inside of the speaker as damping material, do you approve ?

thanks

exactly how close to buttoning up the enclosures are you? they are virtually impossible to get into once completed, unless built with removable back panel

we've found 1/2" thick felt (Ultra-touch bonded denim insulation to be precise) to be the most practical thickness - just sure not to occlude the internal openings to the slots

well i have looked around but i have not a rubber suspension, but a cloth. this armor all is used with rubber suspension, and even then, it is much debated.

i'm wondering if i would not recone the suspension, does anyone know a good shop where you can find cloth and not rubber suspension (just in case i cannot get the suspension i good shape)

thanks

i'm wondering if i would not recone the suspension, does anyone know a good shop where you can find cloth and not rubber suspension (just in case i cannot get the suspension i good shape)

thanks

that magic Liquid's Name is ARMOR ALL

Just generic Armourall -- they have quite a few different products?

dave

I'm waiting for an Answer from the Guy, he has applied it on Klein + Hummel B106 (Fostex FE 103), and they were stonedhard

EDIT: it's a Shiny Liquid for deep care treatment- I don't know how to translate it, but that's the Stuff!

http://www.protekk.de/auto-zubehoer/pflege/armor-all-tiefenpfleger-cockpitspray-125ml-2.html

EDIT: it's a Shiny Liquid for deep care treatment- I don't know how to translate it, but that's the Stuff!

http://www.protekk.de/auto-zubehoer/pflege/armor-all-tiefenpfleger-cockpitspray-125ml-2.html

Last edited:

the product you should use is vulpex, it is a well know product in the art restauration business. it is a soap, it is alkain (so ph>7). you should use 5% in water, watch out for you hands and eyes, after use rinse the surface with water.

so for the cloth suspension it should be doable, just watch out cause it burns and also that the paper cone is not getting wet, but it should be a top product. so dilute it, apply a drop and immidiatly start to spread it out, and take it off wit a wet towel.

price in europe : 75 euro/liter.

within a few weeks i'll let you know where i am

so for the cloth suspension it should be doable, just watch out cause it burns and also that the paper cone is not getting wet, but it should be a top product. so dilute it, apply a drop and immidiatly start to spread it out, and take it off wit a wet towel.

price in europe : 75 euro/liter.

within a few weeks i'll let you know where i am

Well I'm about 2 years too late to this thread  but since it popped up I couldn't help commenting on Flat 8 modifications as it's something near and dear to my heart after treating/modding and extensively measuring about 10 different Flat 8 series drivers over the last 8 years, so I wanted to share some insights into tweaks for them, what tweaks work, and more importantly what tweaks NOT to do - the latter found out from painful first hand experience doing modifications that turned out to be ill advised in hindsight.

but since it popped up I couldn't help commenting on Flat 8 modifications as it's something near and dear to my heart after treating/modding and extensively measuring about 10 different Flat 8 series drivers over the last 8 years, so I wanted to share some insights into tweaks for them, what tweaks work, and more importantly what tweaks NOT to do - the latter found out from painful first hand experience doing modifications that turned out to be ill advised in hindsight.

The Flat 8 series IMHO are a fantastic driver that if in pristine condition, and with a few minor tweaks can sound truly outstanding. Although I've heard many other full range drivers, the only other 8" fullrange drivers I own and have extensively measured are the Fostex FE207E/FE206E and a good pair of Flat 8's blows them out of the water. (Much to my disappointment after buying a pair, hoping to find a more modern readily available replacment for the Flat 8's...)

There are quite a few variations of the Flat 8 series - all very similar but slightly different, and they do measure and sound different. Ones I know of are Flat 8, Flat 8A, Flat 8B, Flat 8 Mark II, and 8A-100. Of those I have a pair of 8A, and a pair of Mark II's, and my dad has half a dozen of the 8A-100's.

The first thing before considering any form of tweaking is you really need to measure them first - both Frequency response and CSD waterfall to see what their untreated response is. The free demo version of ARTA is more than sufficient to do this, in fact it's excellent and includes very good CSD waterfall/sonogram plots which are perfect for hunting down resonances.

No two Flat 8 drivers even "matched" pairs measure the same, especially now that they're so old so there is no "one size fits all" tweak that can be applied that will automatically give the best result., Blindly tweaking without measuring before and after can actually make things worse, maybe much worse.

Like any large full range drivers especially of the dual cone variety, the tiniest little variations in production line assembly tolerances such as relative alignment of the two cones, amount and type of glue joining the cones to the voice coil, around the dust cap, and on the surround and spider, surround doping and so on affects the response, often in dramatic and unpredictable ways. Small differences can affect whether specific cone resonances manifest or not.

Quite a number of the Mark II's that are floating around now (such as mine) are hand assembled units - basically around the early 2000's somebody found a large stock of as-new Flat 8 original replacement parts (magnet/basket, cones, surrounds, spiders etc) and started assembling and selling them as new drivers - which was great because at the time they were genuinely as new in condition with pristine cones without the ravages of age, however because they're hand assembled the assembly tolerances are quite loose compared to factory assembled units - the small details like exact positions of the cones, amount of glue used and so on varies significantly from unit to unit, so although they look almost identical the pair matching is quite poor - one unit can have problems with certain resonances whilst another almost identical looking unit can be almost free of resonances.

Original factory assembled units are now also so old that the ravages of time, moisture and damage to the cones all affect the cone damping, and differently for individual drivers, so it's essential to measure first before doing anything - what might be right for one driver may not be for another even though they look the same.

So what are the flaws of a pristine Flat 8 and what can be done about them ? There are 3 main resonance problem areas in the Flat 8 - (1) 2.4Khz, (2) 3-5Khz (3) 8-12Khz. Each has a different cause and solution.

All unmodified Flat 8's exhibit resonance (2) somewhere between 3-5Khz, usually at 4Khz. Sometimes there are two resonances in this range side by side. The cause is cone breakup of the edge of the main cone.

All Flat 8's with unmodified aluminium domes exhibit resonance (3) somewhere between 8-12Khz. The cause is a resonance of the aluminium dome, also slightly exacerbated by the cavity resonance behind the dome which falls at roughly the same frequency. (And modulates with cone excursion as the cavity size changes)

Some Flat 8's exhibit resonance (1) and some do not. The cause seems to be related to the mounting of the whizzer cone and depending on the condition of the whizzer and how it's bonded this resonance may or may not be present. A good pristine Flat 8 generally does not have this resonance, but most less than perfect ones do to some extent. On a few it can be very severe.

Some Flat 8's, like just about any 8" driver, do have a small amount of surround dip resonance at 1Khz as well, but I don't find it noticeable and don't attempt to correct it as doping the surrounds can have unexpected drawbacks and is generally something that can't be undone, as trying to remove the doping agent (assuming it's one that can be removed) tends to remove the original factory applied doping compound from the surround and cause it to permanently stiffen.

There are a number of variations of surround with different Flat 8 models and runs, the ones with thin soft fabric with a wide curvature don't seem to resonate, (one of my Mk II's is like this) while the ones with the narrow curvature do resonate somewhat, causing a dip in the response at 1Khz. (My other Mk II is like this) I wont mention the surround dip further as I don't consider it a significant problem.

So what can we do about the other resonances ? First the things NOT to do, some of them learnt by painful first hand experience with drivers that are permanently and irreparably compromised by doing so.

1) DO NOT coat the whizzer cone with anything - lacquer, damar, shellac, varnish, etc. The whizzer cone of the Flat 8 (when in pristine condition at least) thanks to it's curvilinear 3 laminate design is extremely stiff and light and free from resonances and does not need any treatment. Any coatings will add significant weight, permanently and irrevocably upsetting the original delicate stiffness/weight/damping ratio of the cone, causing it to resonate at 2.4Khz if it was not already doing so.

Water or alcohol based rubber emulsion compounds will also damage the whizzer cone by wetting and dissolving the fibre structure of the paper - which is, as far as I know, made from a laminate of 3 layers of long grain paper where each layer has the grain of the paper rotated 120 degrees from the next. (You can actually see the 3 grain directions with a bright light shone through the cone, and I have seen one water damaged whizzer cone de-laminate into 3 layers) If you wet the cone in any way whether it be water or alcohol etc the grain structure of the paper is permanently damaged.

I can't stress enough how important it is to leave the paper of the whizzer cone alone. Any change you make with coatings cannot be reversed and will result in an edgy sounding resonance at around 2.4Khz which you will never get rid of. Basically the driver is ruined. Don't do it

2) Don't apply coatings to the main cone either. My warning is not so severe here, because the main cone is a much more conventional short grain pulp cone, and harder to ruin, some types of damping coatings on the cone towards the outside may or may not be beneficial, (or bad) however I would recommend against it because I have a better, reversible alternative to coating the main cone. Don't apply any stiffening type coatings like damar either.

3) Don't apply a bead of glue to the joint of the cone and surround on the rear of the cone - this is an often suggested tweak for cone edge breakup of drivers, I've tried it on the Flat 8 and it's not beneficial for this driver. It doesn't ruin the driver either but it does generally make things slightly worse rather than better, and besides I have a better reversible alternative.

4) DO NOT under any circumstances add more glue in the junction between the aluminium dust cap and the whizzer cone. Why would you even try this ? There is a small amount of existing glue in the gap between the dome and whizzer on some drivers, so you might be temped to add a bit more so that it's "glued properly". This will have two bad effects - the 2.4Khz whizzer cone resonance will appear (if not previously present) or get much worse if it was already present. It will also cause a loss of treble in the 5-8Khz range, and make the dust cap resonance at 8-12Khz much worse. Again, impossible to undo, so don't do it. The gap between the dust cap and the whizzer is there for a reason...

The gap between the dust cap and the whizzer is there for a reason...

Ok that's what not to do, now for what can be done.

I'll discuss resonance (2) from 3-5Khz first, as that's the one I first tackled years ago, and the one which IMHO makes the single biggest improvement in midrange clarity and quality. This is a combination of bending and bell modes on the outer part of the main cone starting from about the inner most "decoupling" ring.

The decoupling rings are a blessing and a curse. On the one hand they provide decoupling for radial bending waves at higher frequencies allowing the effective cone diameter to shrink with increasing frequency, and they also provide stiffening against bell modes which travel around the circumference of the cone. The response flatness is improved dramatically compared to a cone with no rings. (Like the FE207E)

On the down side there are 3 rings dividing the outer cone into 3 sections separate from the main cone. The outermost strip of cone receives some damping from the surround, the inner most strip from the inner part of the cone, the strip in between them, (between the 2nd and 3rd line counting from the centre) receives no damping from anywhere, and tends to flap around chaotically at high frequencies...

This is the main source of "random cone breakup sound" in the Flat 8. This is a sound that's not exactly a high Q single frequency resonance, but more a slowly decaying "random noise spectrum" that's excited by any signals in the 3-5Khz range. This random breakup sound is very common on full range drivers (extreme on some) and while it's relatively minimal on the Flat 8 it is audible and the midrange clarity is improved considerably by eliminating it.

There are also radial and bell mode resonances that naturally occur on the outer parts of the cone that can cause a large peak and dip in the 3-5Khz range, and a smaller one at twice that frequency, both of which can also be largely eliminated.

My solution to this is a pattern of small adhesive foam blocks stuck to the rear of the cone. I used a roll of "draught excluder" tape, which is a very soft open cell foam which is sticky on one side, comes in 5 metre rolls and is 3mm thick and 9mm wide.

It's important that the foam is quite sticky so it bonds well to the curvature of the cone and stays put in the long term, and that it's very soft so that it can form to the curve of the cone, and also peel off easily if you want to remove them.

Years ago I spent many weeks trying different lengths, numbers, and combinations of positions to find what worked best (measuring and listening tests with each combination) and found that the exact arrangement that was optimal was different for each driver, however in general this is what I did:

I cut them into strips 15mm long. Around the perimeter of the rear of the cone I placed 8 equally spaced strips parallel to the edge of the cone. The radial position of each strip around the circle is alternated between almost touching the surround (about 2mm clearance) so that it's mostly on the outer most strip of cone but just bridging across the outer ring, to each alternative strip being halfway across the outer most line on the cone. (About 5mm clearance from the surround)

This does three things - it provides a lot of additional edge damping for the cone without modifying the surround, dramatically reducing bending mode standing wave formation, it adds damping to the second strip of cone in from the edge which was previously un-damped and free to flap around chaotically, (eliminating the random cone breakup sound) and it also provides a disruptive interference pattern for bell modes, helping reduce those.

This alone will clean up the 3-6Khz region quite dramatically, but you can go one step further. There may still be a peak and dip around the 4Khz region caused by a single resonance. I took another four 15mm strips and placed them further towards the centre of the cone - where exactly depends on the individual driver, but somewhere near the inner most of the 3 decoupling rings, either inside it, outside it, or straddling it. At some distance from the centre of the cone you'll get a maximally flat response in the 3-6Khz range.

These 4 strips are equally spaced from each other around the cone, but their angular position should be positioned "in between" the existing 8 strips, not in line with them, or they're not as effective.

It's important to not just measure the frequency response, but also to measure the CSD to see when you are really targeting the resonances. On a driver that's large for the frequencies it's producing you can get peaks and dips in the response from non-resonant phenomena, and you can't easily tell these apart on just a FR graph without also referring to the CSD, so you can end up chasing resonances that don't exist, or making the response look flatter (at one point in space) whilst actually making a resonance worse. The CSD always tells the truth.

As I said, of all the tweaks I think this one is the most beneficial, and it really "cleans up" the response of the driver to a very high standard if done right. (It is tedious, time consuming delicate work though, as peeling the strips off to reposition them has to be done very carefully to avoid lifting the surface of the paper...)

Onto resonance (3) at 8-12Khz. This is the dust cap resonance, and you might be tempted to just cut it out, optionally replacing it with a phase plug, and that is one solution, but bear in mind that while you'll get a flatter treble response and eliminate the resonance completely you will loose at least 3-4dB in the treble.

If you're seriously considering cutting the dust cap out, just before you do so, there is a small tweak you can try that largely eliminates the resonance without removing the dust cap or losing more than 1dB or so of treble - put a carefully placed dent in the dust cap

Yes I'm serious. One of my two Flat 8 Mk II's came with a small dent about 8mm long about 1-2mm from and parallel to the edge of the dome, and that driver always had much flatter cleaner treble than the other driver. 8 years later I finally decided what the hell, I'll do the same to the other, so I used a small flat blade screwdriver to very gently push a dent near the edge of the dome the same size and place as the other driver, and voila, the 8-12Khz resonance whilst not eliminated is dramatically improved. If you're going to cut the dust cap out anyway, it may be worth trying.

Finally the resonance at 2.4Khz. This is a very tricky problem. Generally your driver either has this or it doesn't, and there isn't a lot you can do about it. It will show up in the FR graph as a notch around 2.6Khz and a bump around 2.2Khz. This is because the phase rotation of the resonance on the whizzer cone puts it out and in phase with the main cone on either side of the resonance thus leaning towards adding or cancelling.

The resonance is actually between the peak and the notch in the FR, and you need to view a CSD to see the true nature of the resonance.

What I've found is that if the whizzer cone is in pristine crisp, new, unmodified condition, and there is little or no glue bond between the edge of the dust cap and the whizzer cone, this resonance will probably be absent. There will be no notch at 2.6Khz and no peak at 2.2Khz, and no long tail on the CSD graph.

The whizzer cone is supposed to be glued to the junction of the voice coil former and the main cone and not actually touch the dust cap. The dust cap is crimped to the end of the voice coil former and should be about 2-3mm ahead of the whizzer cone junction with the whizzer curving away from it but narrowly missing it. This seems to be key.

If the dust cap and whizzer cone are bonded/glued strongly together this resonance usually forms quite badly, and there doesn't seem to be any way to eliminate it. This also kills the treble response from 5-8Khz and worsens the dust cap resonance at 8-12Khz.

Also, if the whizzer cone is coated/treated, wetted, has moisture damage, has crumple damage, (crushed by kids then straightened out for example) then the resonance will also form, and can't be eliminated.

In the case of the dust cap being glued directly to the whizzer it MAY be possible to get rid of this resonance by removing the dust cap completely, but I have not tried it. The resonance seems to form when there is a direct path for bending waves to travel from one tip of the whizzer cone through the dust cap and up the other side. When the dust cap is not tightly bonded to the whizzer cone or absent that vibrational path is divided in two, pushing the minimal resonant frequency up by a factor of two.

This may in fact be what some people notice when removing the dust cap, that although it also removes the resonance at 8-12Khz, the more audible result may be an improvement to the otherwise problematic resonance around 2.4Khz.

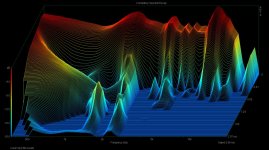

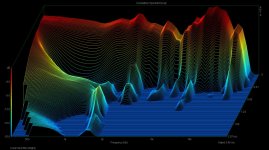

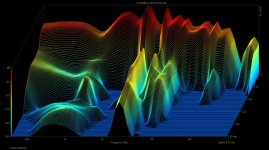

Anyway, that's about all I know about cone tweaking on Flat 8's, so to finish off and provide something quantitative I've attached some CSD plots of my two tweaked Flat 8 MkII's, and to provide a frame of reference I've included the CSD of one of my Fostex FE207E's to show just how much cleaner the Coral's are.

Ignore the humps below 2Khz which are diffraction effects due to mounting the driver on an open baffle during the test. The Right Coral is the better one of the two in every way, there is very little resonance at 2.4Khz or 3-5Khz or 8-12Khz for that matter. It still has the dust cap (albeit dented) fitted.

The Left Coral is not nearly as good and is suffering from a minor(ish) 2.4Khz resonance due to the dust cap being glued directly to the whizzer cone, and it's perfectly obvious on the graph. However to put it into perspective compare that to the severe resonances at 2.8Khz and 4Khz of the Fostex driver....

The Flat 8 series IMHO are a fantastic driver that if in pristine condition, and with a few minor tweaks can sound truly outstanding. Although I've heard many other full range drivers, the only other 8" fullrange drivers I own and have extensively measured are the Fostex FE207E/FE206E and a good pair of Flat 8's blows them out of the water. (Much to my disappointment after buying a pair, hoping to find a more modern readily available replacment for the Flat 8's...)

There are quite a few variations of the Flat 8 series - all very similar but slightly different, and they do measure and sound different. Ones I know of are Flat 8, Flat 8A, Flat 8B, Flat 8 Mark II, and 8A-100. Of those I have a pair of 8A, and a pair of Mark II's, and my dad has half a dozen of the 8A-100's.

The first thing before considering any form of tweaking is you really need to measure them first - both Frequency response and CSD waterfall to see what their untreated response is. The free demo version of ARTA is more than sufficient to do this, in fact it's excellent and includes very good CSD waterfall/sonogram plots which are perfect for hunting down resonances.

No two Flat 8 drivers even "matched" pairs measure the same, especially now that they're so old so there is no "one size fits all" tweak that can be applied that will automatically give the best result., Blindly tweaking without measuring before and after can actually make things worse, maybe much worse.

Like any large full range drivers especially of the dual cone variety, the tiniest little variations in production line assembly tolerances such as relative alignment of the two cones, amount and type of glue joining the cones to the voice coil, around the dust cap, and on the surround and spider, surround doping and so on affects the response, often in dramatic and unpredictable ways. Small differences can affect whether specific cone resonances manifest or not.

Quite a number of the Mark II's that are floating around now (such as mine) are hand assembled units - basically around the early 2000's somebody found a large stock of as-new Flat 8 original replacement parts (magnet/basket, cones, surrounds, spiders etc) and started assembling and selling them as new drivers - which was great because at the time they were genuinely as new in condition with pristine cones without the ravages of age, however because they're hand assembled the assembly tolerances are quite loose compared to factory assembled units - the small details like exact positions of the cones, amount of glue used and so on varies significantly from unit to unit, so although they look almost identical the pair matching is quite poor - one unit can have problems with certain resonances whilst another almost identical looking unit can be almost free of resonances.

Original factory assembled units are now also so old that the ravages of time, moisture and damage to the cones all affect the cone damping, and differently for individual drivers, so it's essential to measure first before doing anything - what might be right for one driver may not be for another even though they look the same.

So what are the flaws of a pristine Flat 8 and what can be done about them ? There are 3 main resonance problem areas in the Flat 8 - (1) 2.4Khz, (2) 3-5Khz (3) 8-12Khz. Each has a different cause and solution.

All unmodified Flat 8's exhibit resonance (2) somewhere between 3-5Khz, usually at 4Khz. Sometimes there are two resonances in this range side by side. The cause is cone breakup of the edge of the main cone.

All Flat 8's with unmodified aluminium domes exhibit resonance (3) somewhere between 8-12Khz. The cause is a resonance of the aluminium dome, also slightly exacerbated by the cavity resonance behind the dome which falls at roughly the same frequency. (And modulates with cone excursion as the cavity size changes)

Some Flat 8's exhibit resonance (1) and some do not. The cause seems to be related to the mounting of the whizzer cone and depending on the condition of the whizzer and how it's bonded this resonance may or may not be present. A good pristine Flat 8 generally does not have this resonance, but most less than perfect ones do to some extent. On a few it can be very severe.

Some Flat 8's, like just about any 8" driver, do have a small amount of surround dip resonance at 1Khz as well, but I don't find it noticeable and don't attempt to correct it as doping the surrounds can have unexpected drawbacks and is generally something that can't be undone, as trying to remove the doping agent (assuming it's one that can be removed) tends to remove the original factory applied doping compound from the surround and cause it to permanently stiffen.

There are a number of variations of surround with different Flat 8 models and runs, the ones with thin soft fabric with a wide curvature don't seem to resonate, (one of my Mk II's is like this) while the ones with the narrow curvature do resonate somewhat, causing a dip in the response at 1Khz. (My other Mk II is like this) I wont mention the surround dip further as I don't consider it a significant problem.

So what can we do about the other resonances ? First the things NOT to do, some of them learnt by painful first hand experience with drivers that are permanently and irreparably compromised by doing so.

1) DO NOT coat the whizzer cone with anything - lacquer, damar, shellac, varnish, etc. The whizzer cone of the Flat 8 (when in pristine condition at least) thanks to it's curvilinear 3 laminate design is extremely stiff and light and free from resonances and does not need any treatment. Any coatings will add significant weight, permanently and irrevocably upsetting the original delicate stiffness/weight/damping ratio of the cone, causing it to resonate at 2.4Khz if it was not already doing so.

Water or alcohol based rubber emulsion compounds will also damage the whizzer cone by wetting and dissolving the fibre structure of the paper - which is, as far as I know, made from a laminate of 3 layers of long grain paper where each layer has the grain of the paper rotated 120 degrees from the next. (You can actually see the 3 grain directions with a bright light shone through the cone, and I have seen one water damaged whizzer cone de-laminate into 3 layers) If you wet the cone in any way whether it be water or alcohol etc the grain structure of the paper is permanently damaged.

I can't stress enough how important it is to leave the paper of the whizzer cone alone. Any change you make with coatings cannot be reversed and will result in an edgy sounding resonance at around 2.4Khz which you will never get rid of. Basically the driver is ruined. Don't do it

2) Don't apply coatings to the main cone either. My warning is not so severe here, because the main cone is a much more conventional short grain pulp cone, and harder to ruin, some types of damping coatings on the cone towards the outside may or may not be beneficial, (or bad) however I would recommend against it because I have a better, reversible alternative to coating the main cone. Don't apply any stiffening type coatings like damar either.

3) Don't apply a bead of glue to the joint of the cone and surround on the rear of the cone - this is an often suggested tweak for cone edge breakup of drivers, I've tried it on the Flat 8 and it's not beneficial for this driver. It doesn't ruin the driver either but it does generally make things slightly worse rather than better, and besides I have a better reversible alternative.

4) DO NOT under any circumstances add more glue in the junction between the aluminium dust cap and the whizzer cone. Why would you even try this ? There is a small amount of existing glue in the gap between the dome and whizzer on some drivers, so you might be temped to add a bit more so that it's "glued properly". This will have two bad effects - the 2.4Khz whizzer cone resonance will appear (if not previously present) or get much worse if it was already present. It will also cause a loss of treble in the 5-8Khz range, and make the dust cap resonance at 8-12Khz much worse. Again, impossible to undo, so don't do it.

Ok that's what not to do, now for what can be done.

I'll discuss resonance (2) from 3-5Khz first, as that's the one I first tackled years ago, and the one which IMHO makes the single biggest improvement in midrange clarity and quality. This is a combination of bending and bell modes on the outer part of the main cone starting from about the inner most "decoupling" ring.

The decoupling rings are a blessing and a curse. On the one hand they provide decoupling for radial bending waves at higher frequencies allowing the effective cone diameter to shrink with increasing frequency, and they also provide stiffening against bell modes which travel around the circumference of the cone. The response flatness is improved dramatically compared to a cone with no rings. (Like the FE207E)

On the down side there are 3 rings dividing the outer cone into 3 sections separate from the main cone. The outermost strip of cone receives some damping from the surround, the inner most strip from the inner part of the cone, the strip in between them, (between the 2nd and 3rd line counting from the centre) receives no damping from anywhere, and tends to flap around chaotically at high frequencies...

This is the main source of "random cone breakup sound" in the Flat 8. This is a sound that's not exactly a high Q single frequency resonance, but more a slowly decaying "random noise spectrum" that's excited by any signals in the 3-5Khz range. This random breakup sound is very common on full range drivers (extreme on some) and while it's relatively minimal on the Flat 8 it is audible and the midrange clarity is improved considerably by eliminating it.

There are also radial and bell mode resonances that naturally occur on the outer parts of the cone that can cause a large peak and dip in the 3-5Khz range, and a smaller one at twice that frequency, both of which can also be largely eliminated.

My solution to this is a pattern of small adhesive foam blocks stuck to the rear of the cone. I used a roll of "draught excluder" tape, which is a very soft open cell foam which is sticky on one side, comes in 5 metre rolls and is 3mm thick and 9mm wide.

It's important that the foam is quite sticky so it bonds well to the curvature of the cone and stays put in the long term, and that it's very soft so that it can form to the curve of the cone, and also peel off easily if you want to remove them.

Years ago I spent many weeks trying different lengths, numbers, and combinations of positions to find what worked best (measuring and listening tests with each combination) and found that the exact arrangement that was optimal was different for each driver, however in general this is what I did:

I cut them into strips 15mm long. Around the perimeter of the rear of the cone I placed 8 equally spaced strips parallel to the edge of the cone. The radial position of each strip around the circle is alternated between almost touching the surround (about 2mm clearance) so that it's mostly on the outer most strip of cone but just bridging across the outer ring, to each alternative strip being halfway across the outer most line on the cone. (About 5mm clearance from the surround)

This does three things - it provides a lot of additional edge damping for the cone without modifying the surround, dramatically reducing bending mode standing wave formation, it adds damping to the second strip of cone in from the edge which was previously un-damped and free to flap around chaotically, (eliminating the random cone breakup sound) and it also provides a disruptive interference pattern for bell modes, helping reduce those.

This alone will clean up the 3-6Khz region quite dramatically, but you can go one step further. There may still be a peak and dip around the 4Khz region caused by a single resonance. I took another four 15mm strips and placed them further towards the centre of the cone - where exactly depends on the individual driver, but somewhere near the inner most of the 3 decoupling rings, either inside it, outside it, or straddling it. At some distance from the centre of the cone you'll get a maximally flat response in the 3-6Khz range.

These 4 strips are equally spaced from each other around the cone, but their angular position should be positioned "in between" the existing 8 strips, not in line with them, or they're not as effective.

It's important to not just measure the frequency response, but also to measure the CSD to see when you are really targeting the resonances. On a driver that's large for the frequencies it's producing you can get peaks and dips in the response from non-resonant phenomena, and you can't easily tell these apart on just a FR graph without also referring to the CSD, so you can end up chasing resonances that don't exist, or making the response look flatter (at one point in space) whilst actually making a resonance worse. The CSD always tells the truth.

As I said, of all the tweaks I think this one is the most beneficial, and it really "cleans up" the response of the driver to a very high standard if done right. (It is tedious, time consuming delicate work though, as peeling the strips off to reposition them has to be done very carefully to avoid lifting the surface of the paper...)

Onto resonance (3) at 8-12Khz. This is the dust cap resonance, and you might be tempted to just cut it out, optionally replacing it with a phase plug, and that is one solution, but bear in mind that while you'll get a flatter treble response and eliminate the resonance completely you will loose at least 3-4dB in the treble.

If you're seriously considering cutting the dust cap out, just before you do so, there is a small tweak you can try that largely eliminates the resonance without removing the dust cap or losing more than 1dB or so of treble - put a carefully placed dent in the dust cap

Yes I'm serious. One of my two Flat 8 Mk II's came with a small dent about 8mm long about 1-2mm from and parallel to the edge of the dome, and that driver always had much flatter cleaner treble than the other driver. 8 years later I finally decided what the hell, I'll do the same to the other, so I used a small flat blade screwdriver to very gently push a dent near the edge of the dome the same size and place as the other driver, and voila, the 8-12Khz resonance whilst not eliminated is dramatically improved. If you're going to cut the dust cap out anyway, it may be worth trying.

Finally the resonance at 2.4Khz. This is a very tricky problem. Generally your driver either has this or it doesn't, and there isn't a lot you can do about it. It will show up in the FR graph as a notch around 2.6Khz and a bump around 2.2Khz. This is because the phase rotation of the resonance on the whizzer cone puts it out and in phase with the main cone on either side of the resonance thus leaning towards adding or cancelling.

The resonance is actually between the peak and the notch in the FR, and you need to view a CSD to see the true nature of the resonance.

What I've found is that if the whizzer cone is in pristine crisp, new, unmodified condition, and there is little or no glue bond between the edge of the dust cap and the whizzer cone, this resonance will probably be absent. There will be no notch at 2.6Khz and no peak at 2.2Khz, and no long tail on the CSD graph.

The whizzer cone is supposed to be glued to the junction of the voice coil former and the main cone and not actually touch the dust cap. The dust cap is crimped to the end of the voice coil former and should be about 2-3mm ahead of the whizzer cone junction with the whizzer curving away from it but narrowly missing it. This seems to be key.

If the dust cap and whizzer cone are bonded/glued strongly together this resonance usually forms quite badly, and there doesn't seem to be any way to eliminate it. This also kills the treble response from 5-8Khz and worsens the dust cap resonance at 8-12Khz.

Also, if the whizzer cone is coated/treated, wetted, has moisture damage, has crumple damage, (crushed by kids then straightened out for example) then the resonance will also form, and can't be eliminated.

In the case of the dust cap being glued directly to the whizzer it MAY be possible to get rid of this resonance by removing the dust cap completely, but I have not tried it. The resonance seems to form when there is a direct path for bending waves to travel from one tip of the whizzer cone through the dust cap and up the other side. When the dust cap is not tightly bonded to the whizzer cone or absent that vibrational path is divided in two, pushing the minimal resonant frequency up by a factor of two.

This may in fact be what some people notice when removing the dust cap, that although it also removes the resonance at 8-12Khz, the more audible result may be an improvement to the otherwise problematic resonance around 2.4Khz.

Anyway, that's about all I know about cone tweaking on Flat 8's, so to finish off and provide something quantitative I've attached some CSD plots of my two tweaked Flat 8 MkII's, and to provide a frame of reference I've included the CSD of one of my Fostex FE207E's to show just how much cleaner the Coral's are.

Ignore the humps below 2Khz which are diffraction effects due to mounting the driver on an open baffle during the test. The Right Coral is the better one of the two in every way, there is very little resonance at 2.4Khz or 3-5Khz or 8-12Khz for that matter. It still has the dust cap (albeit dented) fitted.

The Left Coral is not nearly as good and is suffering from a minor(ish) 2.4Khz resonance due to the dust cap being glued directly to the whizzer cone, and it's perfectly obvious on the graph. However to put it into perspective compare that to the severe resonances at 2.8Khz and 4Khz of the Fostex driver....

Attachments

Last edited:

good lord, that is some information, happy that you joined in with this kind of information.

well, i haven't touched my corals execpt i cutted out one metal dustcap, and it is amazing what it does. that i loose 3-4db in the treble is not noticed by me, but that is because the suspension is stiff and the lows are gone too.

my cone is not white but yellow (no nicotine) and my dustcap looks like it has been at war. so i guess i have a pretty worn out pair. so i continue to get some sound out of it by looking for options.

i wonder why nobody buys the patent of coral and start making these super drivers again. i guess they would sell like belgium chocolate....

thanks for so much info

well, i haven't touched my corals execpt i cutted out one metal dustcap, and it is amazing what it does. that i loose 3-4db in the treble is not noticed by me, but that is because the suspension is stiff and the lows are gone too.

my cone is not white but yellow (no nicotine) and my dustcap looks like it has been at war. so i guess i have a pretty worn out pair. so i continue to get some sound out of it by looking for options.

i wonder why nobody buys the patent of coral and start making these super drivers again. i guess they would sell like belgium chocolate....

thanks for so much info

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Full Range

- fostex new speaker; & treatment of a coral flat 8