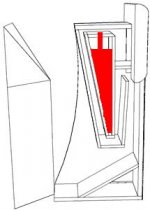

Inspired by Denis' thread about his Little Big Horn I decided to experiment with some stuffing in my frugelhorns. Here are the results.

Graph1: Near field response taken at the driver and at the mouth for reference

Graph2: Difference at mouth caused by a small handful of pillow stuffing placed up the mouth.

Graph3: Difference at listening position

Overall listening impressions. The bass sounds a little tighter but less dominating. If anything I would say it is less hollow sounding. The graph shows less than 1db difference below 80Hz but a 6db difference at 127Hz. I'd call that a success as I've always wondered why the 120-250 range was so peaky.

Any thoughts on what else I should try?

Graph1: Near field response taken at the driver and at the mouth for reference

An externally hosted image should be here but it was not working when we last tested it.

Graph2: Difference at mouth caused by a small handful of pillow stuffing placed up the mouth.

An externally hosted image should be here but it was not working when we last tested it.

Graph3: Difference at listening position

An externally hosted image should be here but it was not working when we last tested it.

Overall listening impressions. The bass sounds a little tighter but less dominating. If anything I would say it is less hollow sounding. The graph shows less than 1db difference below 80Hz but a 6db difference at 127Hz. I'd call that a success as I've always wondered why the 120-250 range was so peaky.

Any thoughts on what else I should try?

The horns are peaky in that range because certain compromises had to be made to make such a low response in a limited size package.

I pulled my frugal horns back out of the closet recently and I've been using them exclusively. I was planning on doing exactly what you are doing now but haven't got to it yet.

For now, the cure I'm implementing is mating them to an OB woofer w/ a high crossover point. The frugal horns are currently high passed at 230 hz, 42 db/oct slope and no further signal processing except the "loud" button on the (cheap) amp activated to plump up what's left of the midbass and sweeten up the highs. This high crossover point essentially cuts out the horn action completely, so the box is currently doing little more than holding up the driver. Regardless, above 230 hz, these little things are stunning.

I'm glad to see your measurements of stuffing applied to the mouth (saves me the work of doing my own experimenting). You can also try some stuffing in the throat, but you should probably tack it in so it doesn't get lost in there forever. Take care to not completely block the throat.

Before I put these speakers in storage a few months ago, the last thing I tried was opening up the full potential area for the back chamber. It did reduce the peaks noticably but not enough, and it's not something I would recommend - unless you plan to go further yet - since IIRC the larger chamber will negatively affect excursion, which is already taxed enough, being a 4 inch driver.

By going further, what I mean is that I plan to experiment with small 1/4 wave resonators in the back chamber. This concept has been discussed recently in the subwoofer forum, and consists of installing 1 or more thin empty tubes (open on one end, closed on the other). Length is determined by 1/4 wavelength of the frequency you wish to notch out - in my case the one at ~220 hz bothers me much more than the one an octave lower - so IIRC the length would be ~17 inches. The diameter is determined by whatever will fit in there and get around the bend, so maybe some type of (unkinked) hose or bendable pipe with an elbow, capped on one end and with the open end near the driver. That should seriously impact the strength of the higher of the peaks (imo the one that can make the frugal horn sound hollow and boxy). The back chamber will still be unusually large even with the resonators in place, so a bit of back fill may be desired. Anyway, I only mention this in case you felt like trying it and evaluating it and measuring it and posting the measurements. If this works it should be a much better option than stuffing, since as you found out, stuffing does not attack peaks specifically, it pulls down the whole bass range.

I'm determined to make these work if at all possible without a high xo point, but I'm doubly challenged since I have severe room modes that correspond almost exactly the the horn's peaks.

I pulled my frugal horns back out of the closet recently and I've been using them exclusively. I was planning on doing exactly what you are doing now but haven't got to it yet.

For now, the cure I'm implementing is mating them to an OB woofer w/ a high crossover point. The frugal horns are currently high passed at 230 hz, 42 db/oct slope and no further signal processing except the "loud" button on the (cheap) amp activated to plump up what's left of the midbass and sweeten up the highs. This high crossover point essentially cuts out the horn action completely, so the box is currently doing little more than holding up the driver. Regardless, above 230 hz, these little things are stunning.

I'm glad to see your measurements of stuffing applied to the mouth (saves me the work of doing my own experimenting). You can also try some stuffing in the throat, but you should probably tack it in so it doesn't get lost in there forever. Take care to not completely block the throat.

Before I put these speakers in storage a few months ago, the last thing I tried was opening up the full potential area for the back chamber. It did reduce the peaks noticably but not enough, and it's not something I would recommend - unless you plan to go further yet - since IIRC the larger chamber will negatively affect excursion, which is already taxed enough, being a 4 inch driver.

By going further, what I mean is that I plan to experiment with small 1/4 wave resonators in the back chamber. This concept has been discussed recently in the subwoofer forum, and consists of installing 1 or more thin empty tubes (open on one end, closed on the other). Length is determined by 1/4 wavelength of the frequency you wish to notch out - in my case the one at ~220 hz bothers me much more than the one an octave lower - so IIRC the length would be ~17 inches. The diameter is determined by whatever will fit in there and get around the bend, so maybe some type of (unkinked) hose or bendable pipe with an elbow, capped on one end and with the open end near the driver. That should seriously impact the strength of the higher of the peaks (imo the one that can make the frugal horn sound hollow and boxy). The back chamber will still be unusually large even with the resonators in place, so a bit of back fill may be desired. Anyway, I only mention this in case you felt like trying it and evaluating it and measuring it and posting the measurements. If this works it should be a much better option than stuffing, since as you found out, stuffing does not attack peaks specifically, it pulls down the whole bass range.

I'm determined to make these work if at all possible without a high xo point, but I'm doubly challenged since I have severe room modes that correspond almost exactly the the horn's peaks.

Hmm, that is an interesting idea. So length is the only thing that matters? Not volume or diameter? 17" would be tough to fit in but it could be done. Do you have any links to discussions about this approach?

After some more listening last night and this morning I have decided to keep the stuffing in. It allows me to turn it up louder without the 'boominess' taking over.

After some more listening last night and this morning I have decided to keep the stuffing in. It allows me to turn it up louder without the 'boominess' taking over.

I'm no expert on this subject but AFAIK the concept is very similar to a helmholtz resonator bass trap - in the way that a ported box is similar to a transmission line.

If we were using a helmholtz trap the volume of enclosed space along with the size and length of the opening (port) would be incredibly important. Technically, you might be able to just add a port to the enclosed space inside the horn and tune it to the desired notch frequency by lengthening or shortening the port. I'm pretty sure something like that should work, but other than selecting the notch frequency there's nothing more that can be adjusted.

OTOH, a 1/4 wave resonator is different than a helmholtz resonator in that the length (and shape - which we can disregard since it's a uniform csa) determines the tuning. These are tuned in the same manner, adding or reducing length to obtain the desired notch frequency tuning. These (in my mind) are more flexible, in that I'm imagining a 1 inch diameter hose length (capped on one end). If the one hose isn't enough, add another, and another, until the notch is big enough.

The q of the notch (sharp deep notch vs shallow wide notch) can be adjusted in both a helmholtz and 1/4 wave resonator by playing with stuffing.

PLEASE note that I have no experience with this type of mechanical notch to date, but most recently it has been discussed somewhere in the tapped horn thread as a result of it's use in a commercial product, so I'm assuming the concept works well when needed.

If we were using a helmholtz trap the volume of enclosed space along with the size and length of the opening (port) would be incredibly important. Technically, you might be able to just add a port to the enclosed space inside the horn and tune it to the desired notch frequency by lengthening or shortening the port. I'm pretty sure something like that should work, but other than selecting the notch frequency there's nothing more that can be adjusted.

OTOH, a 1/4 wave resonator is different than a helmholtz resonator in that the length (and shape - which we can disregard since it's a uniform csa) determines the tuning. These are tuned in the same manner, adding or reducing length to obtain the desired notch frequency tuning. These (in my mind) are more flexible, in that I'm imagining a 1 inch diameter hose length (capped on one end). If the one hose isn't enough, add another, and another, until the notch is big enough.

The q of the notch (sharp deep notch vs shallow wide notch) can be adjusted in both a helmholtz and 1/4 wave resonator by playing with stuffing.

PLEASE note that I have no experience with this type of mechanical notch to date, but most recently it has been discussed somewhere in the tapped horn thread as a result of it's use in a commercial product, so I'm assuming the concept works well when needed.

You're interested in one or more band stop filters and yes, they reduce the filter (rear) chamber's net Vb if you don't locate them somewhere else with a duct back to it like I've seen done on some Lowther horns: http://paws.kettering.edu/~drussell/GMI-Acoustics/Filters-Frame.html

GM

GM

The diagrams remind me alot of how auto manufacturers design their intake systems. Everyone rips them off to install straight pipe cold-air-intakes but quite a bit of R&D goes into those labrinths of plastic to reduce engine noise.GM said:You're interested in one or more band stop filters and yes, they reduce the filter (rear) chamber's net Vb if you don't locate them somewhere else with a duct back to it like I've seen done on some Lowther horns: http://paws.kettering.edu/~drussell/GMI-Acoustics/Filters-Frame.html

GM

Edit: Doh, how about I read the introduction before i open my mouth.

Anyway, I've been giving this some thought. I'm not sure I want to make any more changes to my frugels, but I'd be interested in experimenting with the concept on a future design.

For example, how about attaching some 1/2"x1/2" square rods to the front of a design like the frugel, separated by 1/2" and then placing a new baffle over them, creating channels that run the height of the enclosure. Then you can insert more 1/2"x1/2" square rods into the bottom to adjust the length of the channels until the desired freq response is achieved. Cut off the extra that sticks out the bottom and glue in place.

Do you follow or should I draw a crude picture with mspaint?

chuyler1 said:

.........but quite a bit of R&D goes into those labrinths of plastic to reduce engine noise.

And to make the motor more efficient. Racing was my primary hobby, so learned TL, horn, etc. design primarily to design high performance intake/exhaust systems.

Square rods or square tubes? Best to draw a picture, I guess.

GM

Square closed-ended tubes.

After reading the entire link, it sounds like chambers are the best way to create band-pass filters, but the example graphs show the filters as very efficient in cutting out a band...i wonder if it would do more harm than good trying to tame say 220Hz with a chamber.

Other questions I have after reading...

Does the chamber have to be branched off the throat of our horn system or could it be branched from the compression chamber and have the same effect?

To begin calculations, you need "a neck with radius a". How would I start with a square neck, say 12mm x 12mm.

Or maybe I don't need a square neck, perhaps just drilling a hole to the center chamber in the frugel horn would be enough. Give the right size hole, and filling the chamber to the right volume might work, maybe???

After reading the entire link, it sounds like chambers are the best way to create band-pass filters, but the example graphs show the filters as very efficient in cutting out a band...i wonder if it would do more harm than good trying to tame say 220Hz with a chamber.

Other questions I have after reading...

Does the chamber have to be branched off the throat of our horn system or could it be branched from the compression chamber and have the same effect?

To begin calculations, you need "a neck with radius a". How would I start with a square neck, say 12mm x 12mm.

Or maybe I don't need a square neck, perhaps just drilling a hole to the center chamber in the frugel horn would be enough. Give the right size hole, and filling the chamber to the right volume might work, maybe???

GM said:AFAIK it would have to be tapped into the throat.

GM

I've thought about it a bit and I'm not sure how I can do that without cutting off the top of the box. If the opening of the helmholtz port is placed right near the throat opening (directly undernearth the throat opening at the top front of the filter chamber) is that maybe close enough? That would be about as close as I can get without major surgery.

I'll be working on this soon, and I'm hoping to eliminate things that won't work since it's such a tight spot to work in. If I have to cut the top of the box off I might end up doing that but I'd like to avoid it if possible.

Dunno. I mean to get the best vent measurement accuracy requires the mic be placed inside it a bit, so it seems reasonable to me that porting the trap near the throat may not (won't?) yield good results since to some extent it will be converting the filter chamber to a double bass reflex (DBR) one, at least to my way of thinking. Maybe you could use MJK's DBR WS to get an idea. I'm not hopeful though.

GM

GM

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Full Range

- Experimenting with Stuffing