I have always wanted to build a pair of speakers in concrete but I have never find a way to do this in just one casting. The problem has been to get the form out from the finished cabinet. I talked about this with my colleague at work (im a civil engineer) and he suggested to build the form out of polystyrene and then either melting it with heat or chemically with thinner (Toluen) after the concrete has solidified. After testing the methods on a piece of polystyrene I decided to go for the chemical approach in my project.

Since I'm into transmission lines (at the moment) I decided to build a tapered quarter wave tube based on Martin J King Mathcad sheets, that I downloaded back in 2006 or so, but not yet have had the opportunity to try out. I'm sure the new updated (but unavailable to me) sheets are better but since this is more of an experiment in using concrete in the design than building the most optimized TL out there I'm happy that I still had the sheets on my harddrive.

The driver of choice is the Mark Audio CHR-70 that I have heard good things about.

After some hours altering the parameters in Mathcad I was quite satisfied with the teoretical result (as far as I knew with zero experience in designing TL's). So then I jumped on the building. The fun stuff in my opinion 🙂

First of all you need some special tools before the real work can start:

1. Someting to cut the polystyrene with: A simple "hot wire" saw.

2. Something to rotate the 60 kg heavy speaker with under the thinner melting process: A monstrous 3D-Rotator 🙂

Enough speaking, here are the result so far:

Hotwire saw

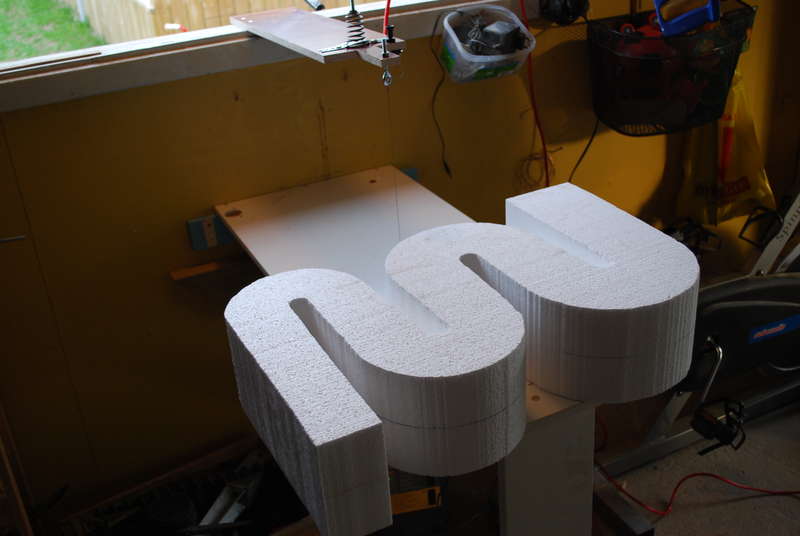

The tube cut out from polystyrene sheet

The edges are rounded a bit to give the concrete structure more strength

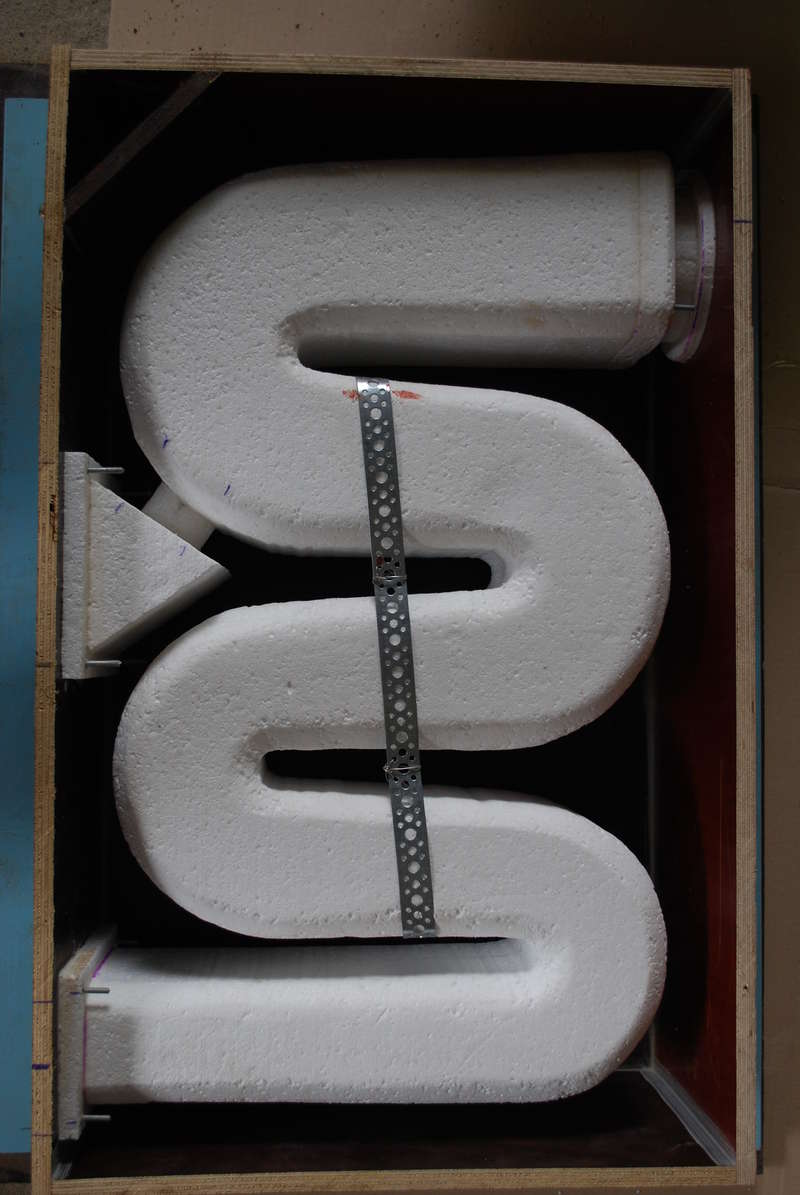

The raw tube form in the plywood form

Some details "shaped" in the polystyrene. Think of the polystyrene as a negative of what will become the cavity inside the concrete. The triangular shape will be a multi purpose cavity serving as terminal and holmholtz resonator or just as terminal depending on the results with the resonator.

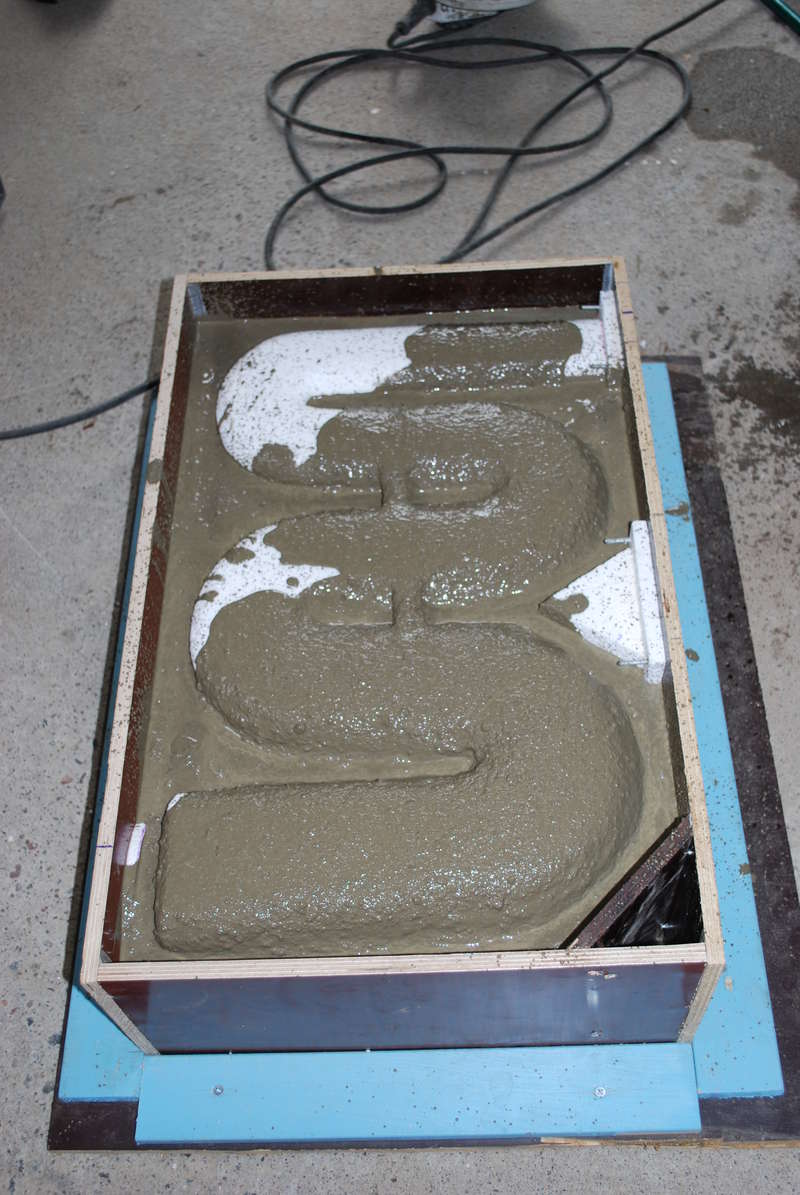

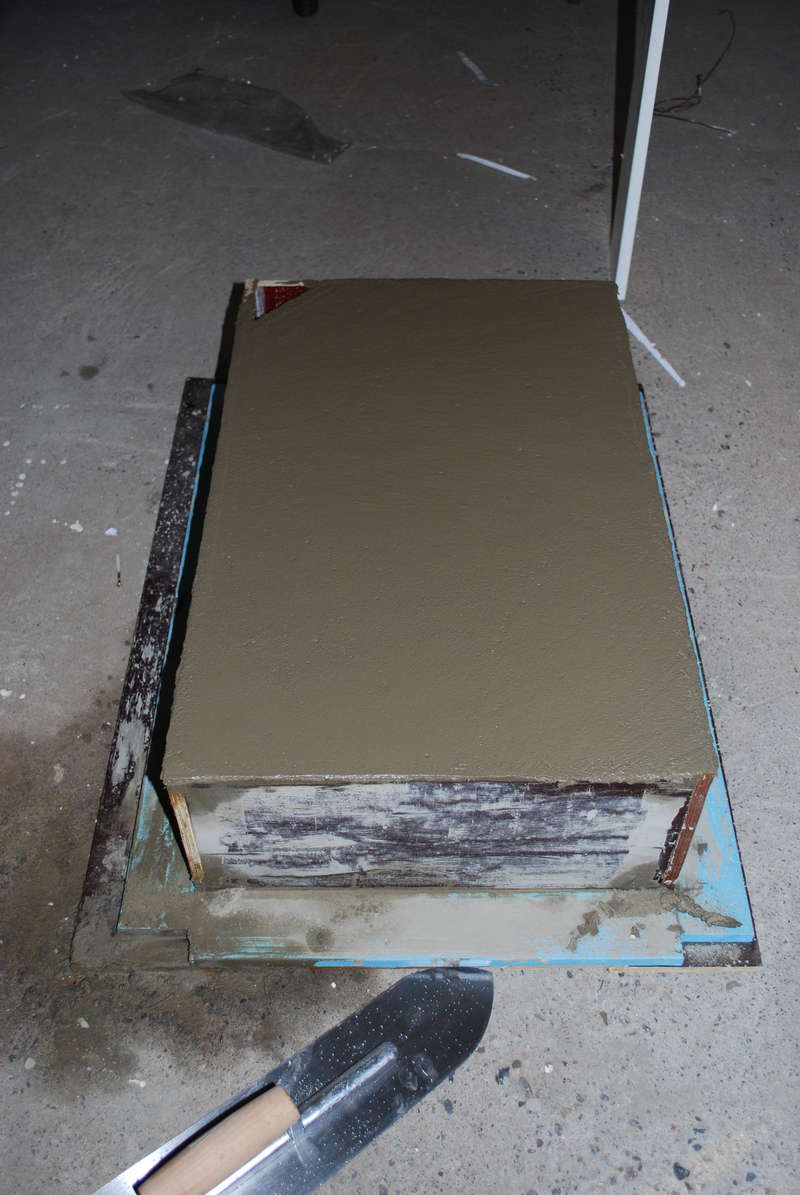

The concrete is vibrated just enough to fill out the form.

Since I'm into transmission lines (at the moment) I decided to build a tapered quarter wave tube based on Martin J King Mathcad sheets, that I downloaded back in 2006 or so, but not yet have had the opportunity to try out. I'm sure the new updated (but unavailable to me) sheets are better but since this is more of an experiment in using concrete in the design than building the most optimized TL out there I'm happy that I still had the sheets on my harddrive.

The driver of choice is the Mark Audio CHR-70 that I have heard good things about.

After some hours altering the parameters in Mathcad I was quite satisfied with the teoretical result (as far as I knew with zero experience in designing TL's). So then I jumped on the building. The fun stuff in my opinion 🙂

First of all you need some special tools before the real work can start:

1. Someting to cut the polystyrene with: A simple "hot wire" saw.

2. Something to rotate the 60 kg heavy speaker with under the thinner melting process: A monstrous 3D-Rotator 🙂

Enough speaking, here are the result so far:

Hotwire saw

The tube cut out from polystyrene sheet

The edges are rounded a bit to give the concrete structure more strength

The raw tube form in the plywood form

Some details "shaped" in the polystyrene. Think of the polystyrene as a negative of what will become the cavity inside the concrete. The triangular shape will be a multi purpose cavity serving as terminal and holmholtz resonator or just as terminal depending on the results with the resonator.

The concrete is vibrated just enough to fill out the form.

The speaker is mounted in the monstrous 3D-Rotator 🙂

I have no pics of the actual thinner melting process while it was quite messy and I did'nt wanna melt my camera aswell.

At this time all the polystyrene was gone, I tested to fill the tube with water to se if all polystyrene was gone and the water volume matched the theoretical volume.

The tube is around 25 liters and to melt the polystyrene I used about 2.5 liters of thinner. Don't try this indoors, the fumes was quite heavy even when working outside a windy day.

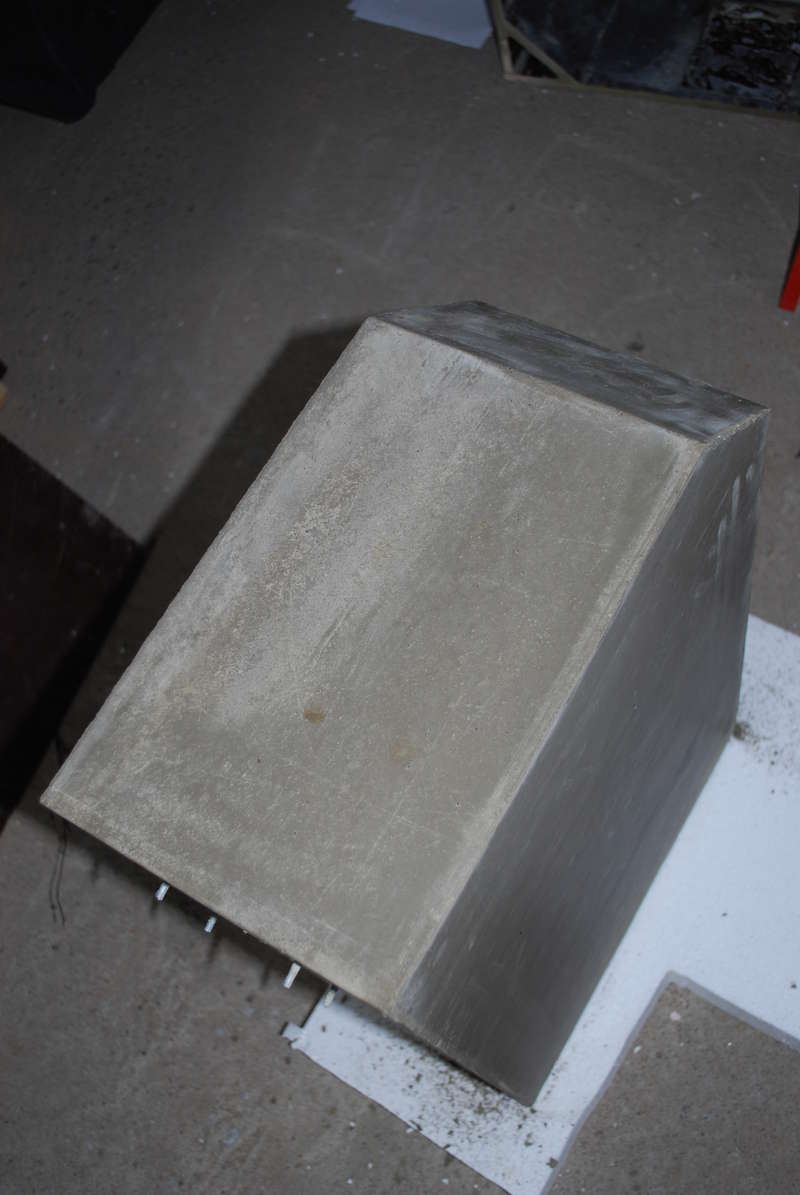

I rounded the edges and rubbed it with cement to get a raw concrete look.

This is where I am so far and I have started to play around with stuffing the pipe and different setups with the helmholtz resonator.

I have done some measurements but I dont know how relevant they are since my equipment is very "diy" (and my knowledge aswell), Panasonic WM-61A mic anf a cheap diy mic preamp.

I will post the graphs later anyway.

I have no pics of the actual thinner melting process while it was quite messy and I did'nt wanna melt my camera aswell.

At this time all the polystyrene was gone, I tested to fill the tube with water to se if all polystyrene was gone and the water volume matched the theoretical volume.

The tube is around 25 liters and to melt the polystyrene I used about 2.5 liters of thinner. Don't try this indoors, the fumes was quite heavy even when working outside a windy day.

I rounded the edges and rubbed it with cement to get a raw concrete look.

An externally hosted image should be here but it was not working when we last tested it.

This is where I am so far and I have started to play around with stuffing the pipe and different setups with the helmholtz resonator.

I have done some measurements but I dont know how relevant they are since my equipment is very "diy" (and my knowledge aswell), Panasonic WM-61A mic anf a cheap diy mic preamp.

I will post the graphs later anyway.

Fascinating!

I'm really interested in your hot wire saw. Did you make it yourself? What kind of wire is it? What voltage?

I'm really interested in your hot wire saw. Did you make it yourself? What kind of wire is it? What voltage?

For those who are attempting this in the future, straight delimonine will dissolve polystyrene. It is a little less volatile than other solvents.

delimonine MSDS http://www.supercoproducts.com/msds/MSDS-FLOAT.PDF

delimonine MSDS http://www.supercoproducts.com/msds/MSDS-FLOAT.PDF

Hi h@kan,

Nice project! Your hot wire saw set-up is genius, I will copy using the closeness of a window to avoid the smell of hot polystyrene.

Do you know that light weight ' EPS cement', http://www.epscement.com/ , have 85% less density than ordinary concrete mix, i.e. the weight could be reduced from 60 kg to about 9 kg without sacrificing good mold stability.

b

Nice project! Your hot wire saw set-up is genius, I will copy using the closeness of a window to avoid the smell of hot polystyrene.

Do you know that light weight ' EPS cement', http://www.epscement.com/ , have 85% less density than ordinary concrete mix, i.e. the weight could be reduced from 60 kg to about 9 kg without sacrificing good mold stability.

b

Way to DIY!!

Very nice idea and congratulations on your idea working! Will follow the thread for your listening impressions.

Uriah

Very nice idea and congratulations on your idea working! Will follow the thread for your listening impressions.

Uriah

I'm not sure on the scale, but I am wondering if the polystyrene could be replaced by plumbing, ie: 4 or 6" sewer pipe. This way you wouldnt have to melt it out and it would be smooth inside. Of course you are then limited to the shape of a circle?

Are these for outdoor use? What kind of driver will you use in them?

Great project! this sure sparked my interest if for outdoor use.

Keep us posted

Are these for outdoor use? What kind of driver will you use in them?

Great project! this sure sparked my interest if for outdoor use.

Keep us posted

The creativity of people on this site never ceases to amaze. Excellent idea brilliantly executed. Looking forward to seeing more pictures and reading how it sounds.

Martin

Martin

johngalt47 said:Fascinating!

I'm really interested in your hot wire saw. Did you make it yourself? What kind of wire is it? What voltage?

Yes it's a diy saw, the wire is 0.65 mm stainless steel wire. The voltage comes from a car battery charger 13V 5A. Im sure 12V 2A is enough.

jackfish said:For those who are attempting this in the future, straight delimonine will dissolve polystyrene. It is a little less volatile than other solvents.

delimonine MSDS http://www.supercoproducts.com/msds/MSDS-FLOAT.PDF

It would definitely be great to find a less intoxicating method to get the polystyrene out. I wonder how much delimonine cost? And most of all I wonder what it's called here in sweden 🙂

I will check into that! I wonder how that product works with thin structures as in mine (25mm)? It's worth investigating because the weight is a bit of a problem.bjorno said:Hi h@kan,

Nice project! Your hot wire saw set-up is genius, I will copy using the closeness of a window to avoid the smell of hot polystyrene.

Do you know that light weight ' EPS cement', http://www.epscement.com/ , have 85% less density than ordinary concrete mix, i.e. the weight could be reduced from 60 kg to about 9 kg without sacrificing good mold stability.

b

starting with 3.2 sd and ending with 1.7 sd. Would a higher ratio be preferable?planet10 said:Well done... not a whole lot of taper in the TQWT?

dave

yan6 said:I'm not sure on the scale, but I am wondering if the polystyrene could be replaced by plumbing, ie: 4 or 6" sewer pipe. This way you wouldnt have to melt it out and it would be smooth inside. Of course you are then limited to the shape of a circle?

Are these for outdoor use? What kind of driver will you use in them?

Great project! this sure sparked my interest if for outdoor use.

Keep us posted

Yes some kind of pipe was my first thaught More specifically this type of formable alu-tube

An externally hosted image should be here but it was not working when we last tested it.

I did'nt manage to taper it in a good way so I skipped it.

I wish I had more experience in loudspeaker measurements.

Feel free to correct me if my measurement setup is incorrect.

The pipe is stuffed (polyester) quite light in the second section and more heavy in the first section (where the driver is placed) I think some more stuffing is required but I post this first result anyway. The helmholtz resonator is tuned to 200 hz.

Audio sector gainclone (quick and dirty) and diy mic-preamp.

I measure in the center of the port and flush the backside of the speaker.

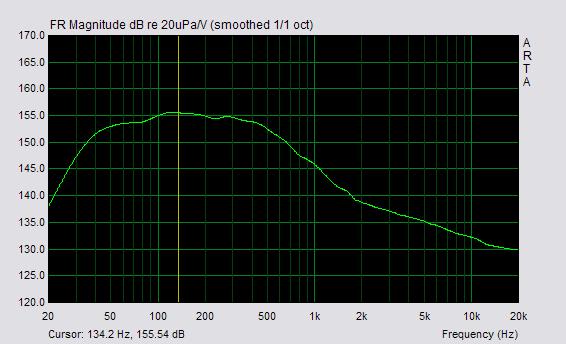

The driver...

The frequency response from the port

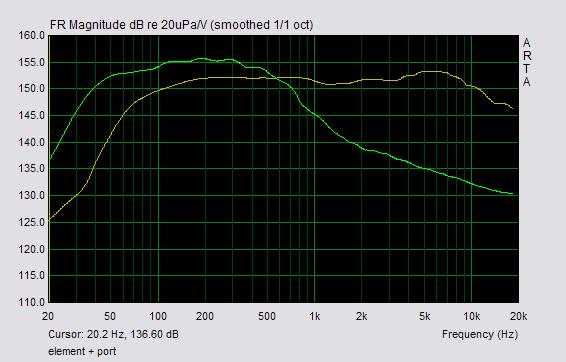

Port and driver in the same graph

If the constant raining will end soon I will measure free field this evening.

Feel free to correct me if my measurement setup is incorrect.

The pipe is stuffed (polyester) quite light in the second section and more heavy in the first section (where the driver is placed) I think some more stuffing is required but I post this first result anyway. The helmholtz resonator is tuned to 200 hz.

Audio sector gainclone (quick and dirty) and diy mic-preamp.

I measure in the center of the port and flush the backside of the speaker.

The driver...

The frequency response from the port

Port and driver in the same graph

If the constant raining will end soon I will measure free field this evening.

h@kan said:starting with 3.2 sd and ending with 1.7 sd. Would a higher ratio be preferable?planet10 said:Well done... not a whole lot of taper in the TQWT?

dave

Closed end is 3.2? Then it is not a TQWT, but a (not quite) 2:1 TL.

As to how it works, i'd have modeled it with MJK tables at least before building. I'm guessing you used Classic techniques which sometimes work, sometimes not.

dave

planet10 said:

starting with 3.2 sd and ending with 1.7 sd. Would a higher ratio be preferable?

Closed end is 3.2? Then it is not a TQWT, but a (not quite) 2:1 TL.

As to how it works, i'd have modeled it with MJK tables at least before building. I'm guessing you used Classic techniques which sometimes work, sometimes not.

dave

Okej! Did not realise there is a breakpoint in tapering ratio and when going under a given ratio it becomes a X:1 TL. Is there any other design differences between a TQWT and a X:1 TL?

Regards H@kan

TL is beginning to have as many meanings as the eskimos have words for snow...

If a line has a taper (closed : open) of n:1, n=>1 then its is typically called a TL. If n<1 it is a TQWT. But TL is also being used for all of those in the sense that they are all quarter-wave resonators.

And then there is a really strict definition of a TL which includes damping.

dave

If a line has a taper (closed : open) of n:1, n=>1 then its is typically called a TL. If n<1 it is a TQWT. But TL is also being used for all of those in the sense that they are all quarter-wave resonators.

And then there is a really strict definition of a TL which includes damping.

dave

planet10 said:TL is beginning to have as many meanings as the eskimos have words for snow...

If a line has a taper (closed : open) of n:1, n=>1 then its is typically called a TL. If n<1 it is a TQWT. But TL is also being used for all of those in the sense that they are all quarter-wave resonators.

And then there is a really strict definition of a TL which includes damping.

dave

Well explained. Thanks!

Regards h@kan

Hmm. For the sake of interest, a TQWT traditionally was in fact a negative taper line, i.e. one that tapers toward the terminus, so strictly speaking, the definition actually holds good. At some point in the past, the definition got flipped, and started being used for a positive taper line, i.e. one that expands toward the terminus. That's what's generally meant when people use the term now, but technically, a positive taper line is a horn.

Sorry. Didn't mean to add confusion. 😉

Sorry. Didn't mean to add confusion. 😉

Scottmoose said:[ For the sake of interest, a TQWT traditionally was in fact a negative taper line, i.e. one that tapers toward the terminus, so strictly speaking, the definition actually holds good. At some point in the past, the definitio

Where did that come from? I've never seen a TQWT that went that way.

I always thot that TQWT was just another acronym for a Voigt pipe?

dave

I can't remember offhand -GM is probably the best man to ask WRT the history of it, but as I understand it, that's what happened. We're going back to the 1930s WRT this I believe, but I've taken to using that definition at least in my own mind, mainly because it makes horn definition easier -as far as I'm concerned, if something is expanding toward the terminus, it's a horn.

Scottmoose said:a TQWT traditionally was in fact a negative taper line

Actually, saying something has a negative taper is a bit meaningless mathematically, so that can lend a lot of confusion. A taper is always >0, it is a question of whether it is greater to, equal to, or greater than 1. (and which end you choose to put as the denominator -- in a 1/4 w/l box, i would suggest the closed end. In a 1/2 w/l it ismore ambiguous.

dave

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Full Range

- TQWT Concrete cabinet attempt, building thread.