I'm planning a horn derived from the Frugel horn but taller and refolded. See the attached pdf (sorry - no CAD here). One goal is to get the driver to ear level. The internal width is the same as the frugel (14cm = 5.5") and the foot print will be the same as the frugel with wings. Not shown, but planned is a frugel like deflector.

I've kept the frugel horn expansion but I've modified the folding to get a square cross section at the throat and to better proportion the mouth- the top half of the frugel mouth is pretty skinny and probably not totally effective. To get the throat square, I've made the first meter of the horn a constant 2" and I will be using a wedge to make the curve. I've calculated the frugal throat at about 4 square inches so this will give me a 2 X 2 inch throat. The wedge will be to one side rather than centered. Like the frugel, the CC is configurable.

I've drawn it with 3/4" front, top, bottom and partitions. Right now it looks like I'll make the the front and top out of maple, the sides plywood and the partitions and bottom out of poplar. 1 X 6" poplar from a big box store is exactly the right size - it's actually 3/4 X 5 1/2.

I know I could build the frugal and tilt it back but half the fun of this hobby for me is designing something. This is totally derivative so many thanks to Dave and the frugel horn originators for doing the heavy lifting on the design.

Comments are welcome.

I've kept the frugel horn expansion but I've modified the folding to get a square cross section at the throat and to better proportion the mouth- the top half of the frugel mouth is pretty skinny and probably not totally effective. To get the throat square, I've made the first meter of the horn a constant 2" and I will be using a wedge to make the curve. I've calculated the frugal throat at about 4 square inches so this will give me a 2 X 2 inch throat. The wedge will be to one side rather than centered. Like the frugel, the CC is configurable.

I've drawn it with 3/4" front, top, bottom and partitions. Right now it looks like I'll make the the front and top out of maple, the sides plywood and the partitions and bottom out of poplar. 1 X 6" poplar from a big box store is exactly the right size - it's actually 3/4 X 5 1/2.

I know I could build the frugal and tilt it back but half the fun of this hobby for me is designing something. This is totally derivative so many thanks to Dave and the frugel horn originators for doing the heavy lifting on the design.

Comments are welcome.

Attachments

I can not give you any feedback on the viability but I like the simplicity of the shape and the increased height of the driver would obviate the need for tilting the speaker.

I don't have any experience with either driver, but from reading posts here, the 126-eNabled is significantly better than the 108-sigma. And if you're willing to eNable the 126 yourself, it's cheaper to boot.

I don't have any experience with either driver, but from reading posts here, the 126-eNabled is significantly better than the 108-sigma. And if you're willing to eNable the 126 yourself, it's cheaper to boot.

don't have any experience with either driver, but from reading posts here, the 126-eNabled is significantly better than the 108-sigma. And if you're willing to eNable the 126 yourself, it's cheaper to boot.

Regarding this comparison, the way I interpret the posts from experienced users and people that have listened to both drivers is:

FE108ESig still rules the midrange and has a more finely resolved, distant, and 'relaxed' way with the tunes.

FE126eN is more efficient, dynamic, extended at both ends, and upfront. However, even with treatment the FE126eN still has a smidge of the untreated 126's aggressive (upper?)mids.

There are a few people who prefer the untreated 108 over the treated FE126eN, so I'd hesitate to state that the FE126eN is "significantly better" in a general sense. Different might be more appropriate. What I would like to know is how Dave's treatments for the 108 have worked out.

Considering my preferences and constraints, in the context of FAST system I'd likely prefer the straight 108 in Aiko over a fully worked 126 in 'most anything. That said, this is all guesstimation, as I have heard neither.

Cheers

Raymond

rcdaniel said:What I would like to know is how Dave's treatments for the 108 have worked out.

The 1st set of uneblemished 108eS are on the bench (along with 3 206eSR.

dave

Dear D Henry,

As a complete non tech person I do thank for your Bugel Horn PDF. I'd come to a similar conclusion about the listening height, I do prefer the soundstage just above my ears.

I will soon have a small room 7ft x 10ft to use as a listening room and these will be able to take advantage of the corner positions perfectly.

Regards - Jem

As a complete non tech person I do thank for your Bugel Horn PDF. I'd come to a similar conclusion about the listening height, I do prefer the soundstage just above my ears.

I will soon have a small room 7ft x 10ft to use as a listening room and these will be able to take advantage of the corner positions perfectly.

Regards - Jem

Bugel Horn Taper

Dear D Henry,

I have been thinking about the taper in the Bugel Horn and wondered if doing it this way would work. Using two pieces per speaker of 1/2" x 2" following the folds in the 2" part of the to make the taper.

I hope this sketch explains it beter than my words;

Regards - Jem

Dear D Henry,

I have been thinking about the taper in the Bugel Horn and wondered if doing it this way would work. Using two pieces per speaker of 1/2" x 2" following the folds in the 2" part of the to make the taper.

I hope this sketch explains it beter than my words;

An externally hosted image should be here but it was not working when we last tested it.

Regards - Jem

Jem,

I think that could work. The problem I would have is figuring out how to affix it to the sides of the partitions.

What I was thinking was to create a solid wedge out of two inch thick material. I would make the two inch material by gluing together two pieces of .75" MDF and one piece of .5" MDF. Think of it as a 39" long pie slice shape that is 2" thick and starts at 3.5" wide and tapers to a point. Of course it has to bend in two places to fit the folding but that just makes it interesting to construct. The wedge would be pushed to one side so that the 2 X 2" throat would start at the opposite side. I don't think the asymmetry is important.

I don't know if my description makes sense but I don't have the technology to create a 3d drawing that shows it.

Denis

I think that could work. The problem I would have is figuring out how to affix it to the sides of the partitions.

What I was thinking was to create a solid wedge out of two inch thick material. I would make the two inch material by gluing together two pieces of .75" MDF and one piece of .5" MDF. Think of it as a 39" long pie slice shape that is 2" thick and starts at 3.5" wide and tapers to a point. Of course it has to bend in two places to fit the folding but that just makes it interesting to construct. The wedge would be pushed to one side so that the 2 X 2" throat would start at the opposite side. I don't think the asymmetry is important.

I don't know if my description makes sense but I don't have the technology to create a 3d drawing that shows it.

Denis

Dear Denis,

Here in the UK MDF is either 12mm or 18mm, well the stuff I can get is and it would be a lot for me to cut to a taper only having a handsaw.

I can get the rest of the MDF for the cabinets cut into parallel strips by B&Q (a DIY shed) and they can easily cut me some 2" wide strips as well.

I thought of making one side and the front and glueing in the first two internal baffles and then attaching the tapers (hatched lines) and proceed from there, as you say it will be 'interesting' at the bends, but a bit of packing will soon sort it out

Looking at the design as I do quite often it looks to be the most elegant I've ever seen.

Kind regards - Jem

Here in the UK MDF is either 12mm or 18mm, well the stuff I can get is and it would be a lot for me to cut to a taper only having a handsaw.

I can get the rest of the MDF for the cabinets cut into parallel strips by B&Q (a DIY shed) and they can easily cut me some 2" wide strips as well.

I thought of making one side and the front and glueing in the first two internal baffles and then attaching the tapers (hatched lines) and proceed from there, as you say it will be 'interesting' at the bends, but a bit of packing will soon sort it out

An externally hosted image should be here but it was not working when we last tested it.

Looking at the design as I do quite often it looks to be the most elegant I've ever seen.

Kind regards - Jem

I can see where a handsaw would limit your options. I plan to use a band saw, although a jigsaw with a longish blade would also work.

This may be a dumb idea but, what about making the wedge out of 2" rigid foam insulation? It really isn't very compressible and it's certainly easy to cut.

Veteran horn builders; what do you think?

This may be a dumb idea but, what about making the wedge out of 2" rigid foam insulation? It really isn't very compressible and it's certainly easy to cut.

Veteran horn builders; what do you think?

Dear Denis,

It occured to me whilst digging at the allotment this afternoon that I'd done that taper thing entirely wrong, there's not enough volume in it.

It should be as you suggested, just the one 'wedge' I will still make it from 2" x 1/2" MDF.

As per this drawing;

I've no idea about the foam stuff I've never used it.

Regards - Jem

It occured to me whilst digging at the allotment this afternoon that I'd done that taper thing entirely wrong, there's not enough volume in it.

It should be as you suggested, just the one 'wedge' I will still make it from 2" x 1/2" MDF.

As per this drawing;

I've no idea about the foam stuff I've never used it.

Regards - Jem

Jem - I think the two tapers are equivalent area. The advantage to the second is that you only have to fit one board instead of two.

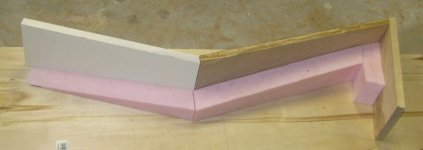

In the interest of saving a thousand words, I've attached a picture of a mockup of the wedge done with scrap wood and Styrofoam.

In the interest of saving a thousand words, I've attached a picture of a mockup of the wedge done with scrap wood and Styrofoam.

Attachments

dhenryp said:I'm planning a horn derived from the Frugel horn but taller ... internal width is the same as the frugel

These dimensions will actually make it a tiny bit smaller than Frugel-Horn MkII.

dave

The wedge in the mockup went together really quickly; no more than 20 minutes. Granted it's Styrofoam, but I cut it with the same power tools I would use for a solid; a miter saw for the short angles and a bandsaw for the major slope. The bandsaw is a luxury but as I mentioned before,a jigsaw should work nicely too

I think this wedge has some advantages over the original frugel "wedgie"; The short angles are 30 and 15 degrees - easy to set up and the the major slope is only on one side which is easier to cut and fit.

WRT to FH2; it look like it will be an interesting comparison. I can't wait to see it. Have you refolded it or kept basically the old design? Do you have an ETA?

It occurs to me that the Bugelhorn name might be seen as an attempt to "horn in" (irresistible pun) on the fugel-horn lineage, especially now that I know the the legitimate heir is in the works. If this is the case I apologize - it wasn't my intention. I've been fiddling with this basic design since the original fugel came out years ago. If anyone sees this as a cause for confusion, please comment or send a PM and I will happily change the name of the horn and thread.

Denis

I think this wedge has some advantages over the original frugel "wedgie"; The short angles are 30 and 15 degrees - easy to set up and the the major slope is only on one side which is easier to cut and fit.

WRT to FH2; it look like it will be an interesting comparison. I can't wait to see it. Have you refolded it or kept basically the old design? Do you have an ETA?

It occurs to me that the Bugelhorn name might be seen as an attempt to "horn in" (irresistible pun) on the fugel-horn lineage, especially now that I know the the legitimate heir is in the works. If this is the case I apologize - it wasn't my intention. I've been fiddling with this basic design since the original fugel came out years ago. If anyone sees this as a cause for confusion, please comment or send a PM and I will happily change the name of the horn and thread.

Denis

Can somebody help me with a hornresp question? I'm trying to simulate the bugelhorn and have a problem with CMS for a Fostex FE126E.

The data sheet lists CMS at 0.0017mm/Newton while hornresp is looking for meter Newton. That is 1.7E-06 meter Newton (I think).

When hornresp calculates CMS based on an SD of 6.5 square cm and a VAS of 9.95 liter it gives me 1.65E-01 meter Newton.

Which is correct?

The 1.7E-06 meter Newton causes RMS to calculate out to 400+ while the 1.65E-01 meter Newton causes RMS to be calculated at less than .01 (fs = 70, QMS = 2.96).

Thanks!

The data sheet lists CMS at 0.0017mm/Newton while hornresp is looking for meter Newton. That is 1.7E-06 meter Newton (I think).

When hornresp calculates CMS based on an SD of 6.5 square cm and a VAS of 9.95 liter it gives me 1.65E-01 meter Newton.

Which is correct?

The 1.7E-06 meter Newton causes RMS to calculate out to 400+ while the 1.65E-01 meter Newton causes RMS to be calculated at less than .01 (fs = 70, QMS = 2.96).

Thanks!

dhenryp said:The data sheet lists CMS at 0.0017mm/Newton while hornresp is looking for meter Newton.

When hornresp calculates CMS based on an SD of 6.5 square cm and a VAS of 9.95 liter it gives me 1.65E-01 meter Newton.

The 1.7E-06 meter Newton causes RMS to calculate out to 400+ while the 1.65E-01 meter Newton causes RMS to be calculated at less than .01 (fs = 70, QMS = 2.96).

Hi dhenryp,

The Fostex FE126E specification sheet contains a typograhical error. The units shown for Cms should read m/N not mm/N. Also, your value of Sd should be 65cm^2 not 6.5cm^2.

Cms = 0.0017m/N = 1.70E-03m/N

Sd = 0.0065m^2 = 65cm^2

For Sd = 65cm^2 and Vas = 9.95 litres, Hornresp calculates Cms to be 1.65E-03, which is close to the 1.70E-03 value specified by Fostex.

Using the Fostex value of 1.70E-03 for Cms, Hornresp calculates Mmd to be 2.74 and Rms to be 0.45. Mmd seems about right given that Mms (which includes the air load) is quoted by Fostex as having a value of 2.9grams.

Hope this helps.

Kind regards,

David

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Full Range

- Bigger Frugel horn (Bugelhorn?)