Hi all,

Well, I got the FE127EN's from Dave, and am starting to plan out a build of the fonkens...I have a couple of questions though:

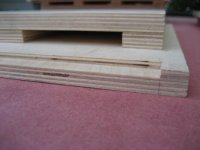

1) What are builders of the fonkens doing in terms of joinery? Are straight butt joints good enough, or are you mitering them, or possibly rabbiting (as Dave the Bass did)?

2) The front baffle - it's designed to be 19mm...but the rest of the cabinet is 12mm...since BB is pretty expensive, what are people doing for this one? Using 19mm for these two pieces and then finding other uses for the leftover?

3) on the BB, it comes in 5x5 sheets AFAIK...I have only quickly looked at the plans, but does it take 2 sheets to make a pair of fonkens?

4) Has anyone done any exotic veneers with the fonkens? I am not a big fan of the look of plywood, and, well, the bamboo stuff is 500$/sheet!

thanks all,

B

p.s - once i get back from vacation I will be hopefully keeping a photo log here on the site.

Well, I got the FE127EN's from Dave, and am starting to plan out a build of the fonkens...I have a couple of questions though:

1) What are builders of the fonkens doing in terms of joinery? Are straight butt joints good enough, or are you mitering them, or possibly rabbiting (as Dave the Bass did)?

2) The front baffle - it's designed to be 19mm...but the rest of the cabinet is 12mm...since BB is pretty expensive, what are people doing for this one? Using 19mm for these two pieces and then finding other uses for the leftover?

3) on the BB, it comes in 5x5 sheets AFAIK...I have only quickly looked at the plans, but does it take 2 sheets to make a pair of fonkens?

4) Has anyone done any exotic veneers with the fonkens? I am not a big fan of the look of plywood, and, well, the bamboo stuff is 500$/sheet!

thanks all,

B

p.s - once i get back from vacation I will be hopefully keeping a photo log here on the site.

I went with butt joints on the outer portions of the cabinet but used an 1/8" dado on all sides of the driver brace as well as the top and bottom of the inner side panel.

For the front baffle I picked up a piece of 12" x 30" x 3/4" BB at my local Woodcraft store. It was ~ $12. For the rest of the cabinet I used natural birch 1/2" ply. Couldn't find a sheet of BB, wasn't looking forward to footing the bill if I did!

You might/should be able to make both cabinets out of one 5x5 piece of stock, but it will be pretty close. From memory, I have just about a half sheet of 4x8 ply left over from my build.

Anyway, have fun and take some pictures!

For the front baffle I picked up a piece of 12" x 30" x 3/4" BB at my local Woodcraft store. It was ~ $12. For the rest of the cabinet I used natural birch 1/2" ply. Couldn't find a sheet of BB, wasn't looking forward to footing the bill if I did!

You might/should be able to make both cabinets out of one 5x5 piece of stock, but it will be pretty close. From memory, I have just about a half sheet of 4x8 ply left over from my build.

Anyway, have fun and take some pictures!

I'm in the middle of a Fonken build right now.

One 5x5 sheet of Baltic Birch ply is more than enough for two cabinets.

I'm doing simple butt joints, 'cause that's all I know how to do.

I cut the front baffles from a sheet of 3/4" 'cabinet grade' ply that was relatively free of voids (based on observation of prior use of that particular sheet of ply.)

Cheers, Jim

One 5x5 sheet of Baltic Birch ply is more than enough for two cabinets.

I'm doing simple butt joints, 'cause that's all I know how to do.

I cut the front baffles from a sheet of 3/4" 'cabinet grade' ply that was relatively free of voids (based on observation of prior use of that particular sheet of ply.)

Cheers, Jim

I am assembling a pair today. With regards to your questions:

1. The joint where the side panels and top/bot meet is naturally a rabbit joint with a huge glue area. Dado slots were made on the baffle and rear using a router with 1/2" mortise to align the brace during glue up. It does not help much with strength, but assures the brace is glued in the right place. Rabbit joints were also made in the side panels where the rear fits into. This again was done mostly to assist in the glue up as everything moves when clamps are applied! Dry assemble everything first. All panes should fit (air tight) with low clamp pressure.

First assume your plywood is not square. I have limited tools and used an MDF sheet as a reference and flush trim bit on two edges of all panels. Mark the 90 degree sides and do not alter it on the table saw. Make all the size cuts at the same time on the table saw for accuracy. For rabbit joints, a trick is to sneak up on a cut using paper shims (.002") on the fence of the table saw. Also, over size some of the panels and trim excess later with a router and flush trim bit.

I find it best to glue up in stages due to having only 10 clamps and limited working time for the glue. However, it is necessary to assemble it as if it were complete, to ensure fit.

2. You can buy 3mm or 6mm Baltic Birch from Ace Hardware or craft stores and glue it to the 12mm baffle. I used two 3mm 12" X 24" sheets glued together, the outer layer was cut with a jig saw for easy flush mounting of the driver. The Fonken cabinet design seems overkill for strength with a driver that has less than 3 grams of moving mass, so I think the thickness on the front baffle has more to do with aesthetics. I actually considered using 6mm for everything except the baffle.

3. I purchased two BB 30" by 60" sheets at $55 total. Accounting for mistakes, I used about 1.5 sheets.

4. Danish oil with a cherry stain looks good on BB. Good veneer is expensive and time consuming.

I have some left over 3/4" Sonic Barrier constrained layer mass loaded vinyl damping material. I would like to use it on the side panel walls only. Would the slight reduction in apparent volume and extra damping be a disadvantage in the Fonken?

1. The joint where the side panels and top/bot meet is naturally a rabbit joint with a huge glue area. Dado slots were made on the baffle and rear using a router with 1/2" mortise to align the brace during glue up. It does not help much with strength, but assures the brace is glued in the right place. Rabbit joints were also made in the side panels where the rear fits into. This again was done mostly to assist in the glue up as everything moves when clamps are applied! Dry assemble everything first. All panes should fit (air tight) with low clamp pressure.

First assume your plywood is not square. I have limited tools and used an MDF sheet as a reference and flush trim bit on two edges of all panels. Mark the 90 degree sides and do not alter it on the table saw. Make all the size cuts at the same time on the table saw for accuracy. For rabbit joints, a trick is to sneak up on a cut using paper shims (.002") on the fence of the table saw. Also, over size some of the panels and trim excess later with a router and flush trim bit.

I find it best to glue up in stages due to having only 10 clamps and limited working time for the glue. However, it is necessary to assemble it as if it were complete, to ensure fit.

2. You can buy 3mm or 6mm Baltic Birch from Ace Hardware or craft stores and glue it to the 12mm baffle. I used two 3mm 12" X 24" sheets glued together, the outer layer was cut with a jig saw for easy flush mounting of the driver. The Fonken cabinet design seems overkill for strength with a driver that has less than 3 grams of moving mass, so I think the thickness on the front baffle has more to do with aesthetics. I actually considered using 6mm for everything except the baffle.

3. I purchased two BB 30" by 60" sheets at $55 total. Accounting for mistakes, I used about 1.5 sheets.

4. Danish oil with a cherry stain looks good on BB. Good veneer is expensive and time consuming.

I have some left over 3/4" Sonic Barrier constrained layer mass loaded vinyl damping material. I would like to use it on the side panel walls only. Would the slight reduction in apparent volume and extra damping be a disadvantage in the Fonken?

Attachments

I find the 'clear' polyurethane gives a nice yellowish cast to the birch. On Birch I have tried:

--clear urethane - makes nice yellowish color

--clear Minwax polycrylic - no added color, has an albino sort of look

-- Minwax classic oak urethane/stain - adds a slight red tint to the yellowish urethane which I like

-- Minwax golden oak stain covered with clear polycrylic - OK, but not as appealing as the classic oak urethane/stain; somehow it just looks dull

-- Minwax red chestnut stain covered with clear polycrylic - nice dark reddish finish, but a bit blotchy on the birch.

Cheers, Jim

--clear urethane - makes nice yellowish color

--clear Minwax polycrylic - no added color, has an albino sort of look

-- Minwax classic oak urethane/stain - adds a slight red tint to the yellowish urethane which I like

-- Minwax golden oak stain covered with clear polycrylic - OK, but not as appealing as the classic oak urethane/stain; somehow it just looks dull

-- Minwax red chestnut stain covered with clear polycrylic - nice dark reddish finish, but a bit blotchy on the birch.

Cheers, Jim

I prefer wood in its most natural organic state. Unfortunately, oil based polyurethane does give a slight "golden glow". I used this purely due to already having it on hand from another project. Water based polycrylics are very clear and do not yellow with age. They are easier to clean up, but more difficult to apply due to fast dry time and more layers to build a durable finish.

schn0354 said:Polyurethane oil based varnish will turn the birch a little darker with a slight "golden tint". Always test the finish on a scrap piece.

to each his own, but I would certainly prefer the slightly warmer look to something like a water-white clear poly/acrylic on maple or birch

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Full Range

- fonken build