Hi to all!

Has anyone tried "Rehdeko cone treatment" or other similar (NOT "EnABL") cone treatments with 8 inches fullrangers?

here is Weber Rehde's patent description:

http://www.freepatentsonline.com/4100992.html

I have Fostex FE206E. This particular driver suits my needs very well, almost perfectly BUT it has a big problem

it is sharp nasty ringing (=howling) resonance at around 2.8 kHz. I know that it is a break-up resonance of the main cone - not of the whizzer

I wonder how it could be effectively treated.

best regards,

graaf

Has anyone tried "Rehdeko cone treatment" or other similar (NOT "EnABL") cone treatments with 8 inches fullrangers?

here is Weber Rehde's patent description:

http://www.freepatentsonline.com/4100992.html

I have Fostex FE206E. This particular driver suits my needs very well, almost perfectly BUT it has a big problem

it is sharp nasty ringing (=howling) resonance at around 2.8 kHz. I know that it is a break-up resonance of the main cone - not of the whizzer

I wonder how it could be effectively treated.

best regards,

graaf

Attachments

graaf said:

here is Weber Rehde's patent description: http://www.freepatentsonline.com/4100992.html

I recommend using a mechanic's stethoscope to isolate it, then decide on a course of action rather than using the 'sawed off shotgun' approach, though I've found variations of Fig. 7 to work well if it's a broadband problem.

GM

Hi,

i used "Ponal" as coating for paper cones with good results.

Another possibility is to use a small aluminium pipe, bend it

as a ring to stabilize the cone along a certain radius.

Use an appropriate glue, not too hard and only very little

amount . You can use a piece of a toothpick e.g. to close the

ring tightly.

In both cases it is useful to know, how the breakup mode

looks like. I have used cork powder to visualise it with some

success so far ...

The "Ponal" wood glue applied to the whole cone ia a good

broadband "quietener" but to do selective damping or bracing

to save moved mass is preferable.

If the picture you have posted shows the breakup mode

correctly, maybe an alu ring stabilizer placed slightly outside the

phase coherent center of the cone would work -

just a gut feeling ...

Cheers

i used "Ponal" as coating for paper cones with good results.

Another possibility is to use a small aluminium pipe, bend it

as a ring to stabilize the cone along a certain radius.

Use an appropriate glue, not too hard and only very little

amount . You can use a piece of a toothpick e.g. to close the

ring tightly.

In both cases it is useful to know, how the breakup mode

looks like. I have used cork powder to visualise it with some

success so far ...

The "Ponal" wood glue applied to the whole cone ia a good

broadband "quietener" but to do selective damping or bracing

to save moved mass is preferable.

If the picture you have posted shows the breakup mode

correctly, maybe an alu ring stabilizer placed slightly outside the

phase coherent center of the cone would work -

just a gut feeling ...

Cheers

thanks You GM and LineArray for Your interest and suggestions

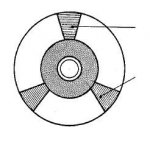

a qui pro quo - the picture shows one of the cone coating patterns that can be found in Rehde's patent

what I found most interesting is that He recommended coating of only part of cone area, sometime only a small part

I have made some tries with Fostexes and the posted pattern is mostly similar to the one I used

mine looks more like the "radioactivity symbol" and coated cone surface area more or less equals the uncoated

I chosed it because I wanted an asymmetric pattern - I read somewhere that it is good to break the symmetry of the cone because most harmful are axis-symmetric modes

I have also used a kind of glue but cyanoacrylic

I chose it after some tries on sheets of paper. The cyanoacrylic glue seemed to penetrate the paper best and to stiffened it most

Weber Rehde recommended "varnish of cellulose type" (nitrocellulose)

I have tried nitrocellulose based nail varnish on sheet of paper and it seemed to work less effective than cyanoacrylic glue

Unfortunately I cannot do any genuine measurements but a "measurement" I did using DEQ2496 RTA function and ECM8000 showed that after the treatment of the FE206E resonant frequency response peak got a bit smaller and shifted from around 2.8 to around 4 kHz

audibly it certainly became less offensive but not enough, therefore I think what can be done next/better

what do You think of applying the treatment only to a part of the cone - like in Rehde patent?

Have You tried Stabilon and Vinylflex paper cone treatments offered by Intertechnik Deutschland?

they are both polyvinylacetate based but the first is said to be a stiffener and the second to be a dampener

what about treating of half of the cone surface with stiffener and the rest with dampener? what do You think?

best,

graaf

LineArray said:

If the picture you have posted shows the breakup mode

correctly,

a qui pro quo - the picture shows one of the cone coating patterns that can be found in Rehde's patent

what I found most interesting is that He recommended coating of only part of cone area, sometime only a small part

I have made some tries with Fostexes and the posted pattern is mostly similar to the one I used

mine looks more like the "radioactivity symbol" and coated cone surface area more or less equals the uncoated

I chosed it because I wanted an asymmetric pattern - I read somewhere that it is good to break the symmetry of the cone because most harmful are axis-symmetric modes

LineArray said:

i used "Ponal" as coating for paper cones with good results.

I have also used a kind of glue but cyanoacrylic

I chose it after some tries on sheets of paper. The cyanoacrylic glue seemed to penetrate the paper best and to stiffened it most

Weber Rehde recommended "varnish of cellulose type" (nitrocellulose)

I have tried nitrocellulose based nail varnish on sheet of paper and it seemed to work less effective than cyanoacrylic glue

Unfortunately I cannot do any genuine measurements but a "measurement" I did using DEQ2496 RTA function and ECM8000 showed that after the treatment of the FE206E resonant frequency response peak got a bit smaller and shifted from around 2.8 to around 4 kHz

audibly it certainly became less offensive but not enough, therefore I think what can be done next/better

LineArray said:

The "Ponal" wood glue applied to the whole cone ia a good

broadband "quietener" but to do selective damping or bracing

to save moved mass is preferable.

what do You think of applying the treatment only to a part of the cone - like in Rehde patent?

Have You tried Stabilon and Vinylflex paper cone treatments offered by Intertechnik Deutschland?

they are both polyvinylacetate based but the first is said to be a stiffener and the second to be a dampener

what about treating of half of the cone surface with stiffener and the rest with dampener? what do You think?

best,

graaf

graaf said:

what about treating of half of the cone surface with stiffener and the rest with dampener? what do You think?

best,

graaf

Hi,

i found that thinking too much about cone treatment,

breakup modes and coating drives me mad.

I modified lots of drivers and basically i think that someday

you will end up with building drivers by yourself.

An 8 inch fullrange will inevitably suffer from breakup to

a certain extent. I basically think you cannot win using

a stiffener. With a paper cone, a dampener is the way to go.

Most paper is stiff and has little damping, you have to add

what is missing to get a composite material with better

habits.

"Ponal" introduces some stiffness but is mainly a dampener.

If you bend a sheet of coated paper and watch how it

goes back into its shape, you get a feeling how much damping

is introduced by the coating.

One way might be to make a foam of the coating material

to increase the thickness of the coat and keeping mass low ...

When moved mass is an issue, i think it is preferable to

coat only near the surround, but i have litte experience with

fullrangers. For most bass and midrangers a total area coating

will give best results IMO.

With some drivers i had good results introducing slots into

the cone and then closing them with a dampener ...

Very expensive experiments, maybe get some cheap and

evil sounding drivers to practice ...

At present i do not want to spend much time in modifying

drivers anymore, i think it is better to use drivers of smaller

size. Unsufficiently damped breakup modes are worst in the

nasal to precence region from 1-6 Khz, if you find a driver

which behaves well in that range one can tolerate some

uncontrolled breakup at higher frequenies.

Since you cannot supress breakup totally in my present

fullrange design i use multple drivers and balance them

taking advantage of the tolerances of individual drivers.

Using that method i obtained the best results ever, thereby

keeping the need for compensation in the XO at minimum.

Cheers

Attachments

LineArray said:

An 8 inch fullrange will inevitably suffer from breakup to

a certain extent. I basically think you cannot win using

a stiffener. With a paper cone, a dampener is the way to go.

Most paper is stiff and has little damping, you have to add

what is missing to get a composite material with better

habits.

stiffener moves break-up resonance higher in frequency

isn't it reasonable to move it higher? in case of my FE206E moving it from around 2.8 kHz to around 4 kHz was certainly beneficial to the sound quality

LineArray said:

Since you cannot supress breakup totally in my present

fullrange design i use multple drivers and balance them

taking advantage of the tolerances of individual drivers.

for conventional front firing speakers it would be also my choice

but I need one fullrange driver to fulfill my "room/loudspeaker interface" design priorities

best regards,

graaf

ps.

any more experience with coating of fullrangers anyone?

help please!

I use liquid bitumen

With a very thin cone you may have to stiffen it first with something hard first

But be aware of likely loss of sensitivity

Also such FR drivers usually have very small voicecoil with short Xmax which may not be able to deal with the exstra weight and new lower Fs

With a very thin cone you may have to stiffen it first with something hard first

But be aware of likely loss of sensitivity

Also such FR drivers usually have very small voicecoil with short Xmax which may not be able to deal with the exstra weight and new lower Fs

graaf said:

stiffener moves break-up resonance higher in frequency

isn't it reasonable to move it higher? in case of my FE206E moving it from around 2.8 kHz to around 4 kHz was certainly beneficial to the sound quality

Hi graaf,

i think it is a success to move the breakup from 2.8 to 4 Khz,

if it was a midranger then the difference would be between

nasty and perfect.

But i think in your case the resonance must have become less

prominent too, otherwise you would not feel it sounds better

now.

Moving resonance up in frequency is a way to go for midrangers

but what to do with a fullranger ? If it is a whizzer cone design,

maybe moving a resonance above the mechanical XO of the

whizzer works well ... so in some cases stiffener would be

in the race again, don't know.

LineArray said:

I basically think you cannot win using

a stiffener. With a paper cone, a dampener is the way to go.

Most paper is stiff and has little damping, you have to add

what is missing to get a composite material with better

habits.

paper is not that stiff

fortunately it has "some" damping

interesting papers on physical properties of diaphragms:

http://www.fostexusa.com/support/pdf/fostex/nf1/nf1_tech_white_paper.pdf

www.infinitysystems.com/home/technology/whitepapers/cmmd.pdf

these are manufacturer information brochures of course, nevetheless presented facts and measurements are interesting (especially in the Fostex brochure))

LineArray said:

i think it is a success to move the breakup from 2.8 to 4 Khz,

if it was a midranger then the difference would be between

nasty and perfect.

yes indeed, therefore I think that this modification is worth to be further researched and perfected

this seems to be "the way to go" with a fullranger

LineArray said:

But i think in your case the resonance must have become less

prominent too, otherwise you would not feel it sounds better

now.

I agree

on the other hand I wonder why it has become less prominent. Is it a matter of added damping? or perhaps the diaphragm itself has more damping at this higher frequency? or perhaps this is a benefit of introducing of an assymetrical pattern in the diaphragm?

best,

graaf

tinitus said:I use liquid bitumen

With a very thin cone you may have to stiffen it first with something hard first

what do You think of treating some parts of the cone with stiffener and some with dampener?

taking the image attached to the first post as an example - treating the grey coloured parts with stiffener and the rest with dampener? or the other way round?

or yet different - treating the grey coloured part in the center with stiffener and the radial coloured parts with dampener leaving the rest untreated? or the other way round?

so many options

does the theory of cone diaphragm suggest best/optimal one?

has anybody tried such an approach?

best,

graaf

Hi graaf,

Single circular drivers tend to generate much more noticeable 'dissonances' (than elliptical) at frequencies related to radial symmetry.

Circular drivers offset on a baffle, or those mounted in line with others can sound better as the symmetry of transverse wave motion at the driver perimeter becomes less 'focussed' with respect to the cone and its centre.

I have found that modifying mounting arrangemets or interfering with transverse wave symmetry can do much to improve reproduction without anything being done to the cone itself.

To me, LineArray's spacing inconstancy will have a significant effect in randomising frequency dependent transverse wave pressure effects upon circular cone apertures, and thus sound less dissonant than a single circular driver or a conventional close spaced line.

Try foam fingers (off mini paint rollers) to reduce air-side wave symmetry within the driver perimeter. Here in front of a B200.

Cheers ......... Graham.

Single circular drivers tend to generate much more noticeable 'dissonances' (than elliptical) at frequencies related to radial symmetry.

Circular drivers offset on a baffle, or those mounted in line with others can sound better as the symmetry of transverse wave motion at the driver perimeter becomes less 'focussed' with respect to the cone and its centre.

I have found that modifying mounting arrangemets or interfering with transverse wave symmetry can do much to improve reproduction without anything being done to the cone itself.

To me, LineArray's spacing inconstancy will have a significant effect in randomising frequency dependent transverse wave pressure effects upon circular cone apertures, and thus sound less dissonant than a single circular driver or a conventional close spaced line.

Try foam fingers (off mini paint rollers) to reduce air-side wave symmetry within the driver perimeter. Here in front of a B200.

Cheers ......... Graham.

Attachments

graaf said:

does the theory of cone diaphragm suggest best/optimal one?

has anybody tried such an approach?

best,

graaf

I remember some studies from Celestion / UK concerning

the bass midrange unit of the SL6 bookshelf speaker.

They did lots of analysis with laser holographics on

that diaphragm. As far as i know they ended up with a

material which has high damping, but they varied thickness

of the diaghragm in radial direction. This way they obtained

a cone which shrinks in a "non breakup" or at least

rather smooth manner with increasing frequency.

To mimikry such behaviour with a thin paper cone, i would

suggest to treat with dampener at the outer area near the

surround. If it is a fullranger maybe introduce a small ring

near the surround and then make it successively wider to

see what happens with every step.

Leave a middle ring untreated and start again from the

center using a stiffener.

I think, a whizzer design has to be looked at differently than

a single cone.

But one has to deal with the real object, we will not find an

all purpose method - just by discussion - which fits to all

diaphragms.

graaf said:

what do You think of treating some parts of the cone with stiffener and some with dampener?

so many options

does the theory of cone diaphragm suggest best/optimal one?

has anybody tried such an approach?

best,

graaf

Liquid bitumen is quite effective, but the problem is that it is quite heavy

I have had some luck with polyurethane glue, it is very light but leaves a rugged surface so it was applied to the backside

From time to time Dammar Harz has been mentioned fore light paper cones

Natural harz lacquer like shellac can be altered to soft hardening by a drop of oil or very little amount of bees propolis ... maybe it gives a more natural tone

Graham Maynard said:Hi graaf,

Single circular drivers tend to generate much more noticeable 'dissonances' (than elliptical) at frequencies related to radial symmetry.

Hi Graham,

since i am playing with drivers, i feel the tendency, that

oval shaped ones - especially fullrangers - tend to a more

benign behavoiur than comparable circular ones.

I agree with you that even without breakup modes, the

concentric radiation of the air wave and reflection from the

border of the diaphragm is not very beneficial to uncoloured

reproduction due to interference effects ...

Also the distribution of bending waves along the cone,

may be more smooth in an oval shaped diaphragm.

Of cause there are fewer oval high quality drivers than

circular ones, so a fair comparation is difficult ...

Graham Maynard said:

Circular drivers offset on a baffle, or those mounted in line with others can sound better as the symmetry of transverse wave motion at the driver perimeter becomes less 'focussed' with respect to the cone and its centre.

...

To me, LineArray's spacing inconstancy will have a significant effect in randomising frequency dependent transverse wave pressure effects upon circular cone apertures, and thus sound less dissonant than a single circular driver or a conventional close spaced line.

Cheers ......... Graham.

Briefly, this is exactly what the upper section of "Dipol 08"

is optimized to.

Especially the arrangement of the upper 3 drivers on the

baffle was chosen, to have the least possible disturbing

impact of interference on the response.

---

Do you think that breakup modes and airwave interferences

are interconnected to a significant extent, when assuming a

thin paper cone e.g. ?

@graaf: I was thinking about your suggestions. Why not

use the alu pipe ring stabilizer in the center - which i mentioned

before - and a dampener as coating near the outer suspension ?

Will be tricky to find the best diameter of the ring stabilizer, and

the best witdh and thickness of the damping coat, but i

think this combined techniques could have some potential.

A friend of mine was experimenting with those ring stabilizers

some years ago and we tweaked some cheap fullrangers

in an astonishing way using that. This way you get real stiffness

you know, it is not comparable to a coating using stiffener ...

Cheers

Hi LineArray,

I too made a tall (6ft) 'line' with uneven spacing, and it sounded better than a minimum spaced regular line using more of the same drivers. Your picture reminds me of this finding, though I did not take my own construction any further.

I can understand the benefits you report because the line does not detract from individual driver quality by imposing a regular 'spacing' dependent characteristic.

You ask

>>Do you think that breakup modes and airwave interferences

are interconnected to a significant extent, when assuming a

thin paper cone e.g. ?<<

YES!

Thinking about this further makes me wonder if it would be possible to use foam rolls or pieces behind a single driver, very close to the cone though clear of its X.lim, in order to prevent symmetrical surface pressure pattern induced break-up. This to prevent an avalanche mode into break-up by modifying pressures acting upon the cone.

Behind the cone would be less 'odd' looking too.

and YES again.

If only the LS driver manfacturers would come up with a high quality widerange elliptical.

The best I feel we can do is keep the air length paths from being symmetrical all around.

Cheers ....... Graham.

I too made a tall (6ft) 'line' with uneven spacing, and it sounded better than a minimum spaced regular line using more of the same drivers. Your picture reminds me of this finding, though I did not take my own construction any further.

I can understand the benefits you report because the line does not detract from individual driver quality by imposing a regular 'spacing' dependent characteristic.

You ask

>>Do you think that breakup modes and airwave interferences

are interconnected to a significant extent, when assuming a

thin paper cone e.g. ?<<

YES!

Thinking about this further makes me wonder if it would be possible to use foam rolls or pieces behind a single driver, very close to the cone though clear of its X.lim, in order to prevent symmetrical surface pressure pattern induced break-up. This to prevent an avalanche mode into break-up by modifying pressures acting upon the cone.

Behind the cone would be less 'odd' looking too.

and YES again.

If only the LS driver manfacturers would come up with a high quality widerange elliptical.

The best I feel we can do is keep the air length paths from being symmetrical all around.

Cheers ....... Graham.

Graham Maynard said:Hi LineArray,

You ask

>>Do you think that breakup modes and airwave interferences

are interconnected to a significant extent, when assuming a

thin paper cone e.g. ?<<

YES!

Thinking about this further makes me wonder if it would be possible to use foam rolls or pieces behind a single driver, very close to the cone though clear of its X.lim, in order to prevent symmetrical surface pressure pattern induced break-up. This to prevent an avalanche mode into break-up by modifying pressures acting upon the cone.

Behind the cone would be less 'odd' looking too.

Hi,

when thinking on closed box designs

(also backloaded horns etc.) , one might think whether

standing waves inside the box behind the driver influence

cone breakup modes too. With large area thin paper cones

this might be a serious issue.

To build an absorbent jacket around the drivers at the rear

side is of advantage in many cases.

I use such a jacket in my OB design to get the rollof from the

rear more smooth, so i can XO it in a more definite manner to

the tweeter panel, without using an electrical lowpass.

The jacket changes midrange to high distribution into a more

cardioid shape too ...

In my street is a hatmaker, i talked to her on friday last week

and maybe she will make some more beautiful jackets for my

drivers ... on the pic posted before the jackets were taken off.

This is not quite what you thought about, but your idea is worth

thinking.

Cheers

Attachments

Graham Maynard said:

Try foam fingers (off mini paint rollers) to reduce air-side wave symmetry within the driver perimeter. Here in front of a B200.

very interesting!

does it work (is it needed?) also if one listens extremely off axis?

(my Fostexes work in a Carlsson type omnidirectional setup)

are there any measurements showing how the rollers work?

best,

graaf

LineArray said:

Of cause there are fewer oval high quality drivers than

circular ones...

I wonder why?

LineArray said:

Why not

use the alu pipe ring stabilizer in the center - which i mentioned

before - and a dampener as coating near the outer suspension ?

yeah, why not?

but I am not sure I understand well what to do

can You post a diagram, a simple schematic of this modification?

best regards,

graaf

hi graaf,

here we go ...

1.) Get an aluminium pipe from a model building shop.

2.) Bend a piece of pipe into a ring using a cylindrical object,

of somewhat smaller diameter than your desired.

3.) Close the ring by inserting a little piece of a toothpick,

tay stick or similar material with some glue into both

ends of the open ring to get it close tightly.

4.) Glue the ring onto the cone.

5.) Apply your preferred dampener using a rotating device

(turntable) and a brush to the outer ring.

6.) Let it dry.

7.) Listen.

Some schematics: Dark area is inside the ring, white area is

untreated, grey area is treated with dampener.

Dimensions and relative size of the areas and the ring have to

be identified by your own research on the particular driver ...

here we go ...

1.) Get an aluminium pipe from a model building shop.

2.) Bend a piece of pipe into a ring using a cylindrical object,

of somewhat smaller diameter than your desired.

3.) Close the ring by inserting a little piece of a toothpick,

tay stick or similar material with some glue into both

ends of the open ring to get it close tightly.

4.) Glue the ring onto the cone.

5.) Apply your preferred dampener using a rotating device

(turntable) and a brush to the outer ring.

6.) Let it dry.

7.) Listen.

Some schematics: Dark area is inside the ring, white area is

untreated, grey area is treated with dampener.

Dimensions and relative size of the areas and the ring have to

be identified by your own research on the particular driver ...

Attachments

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Full Range

- 8 inches paper cone treatments