It took me long enough to finally get something. I would like you guys to know that your accomplishments allow me to start building with confidence. I went the cheap route with pioneer b20's with a goal of keeping the project at $100.

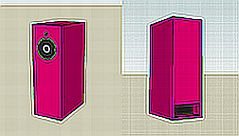

I am going to build some half chang enclosures and maybe crossover with a tweeter. I hooked them up to my main amp while in some cardboard boxes. I played some rap and some album leaf. To let you know album leaf is a band playing mainly instrumental ambient type music that could put anybody to sleep. They were played to get some comparisons to my radio shack mach 3 speakers. The first was to compare the bass with the 15 inch woofer and the other was to hear midrange and treble compared to the horns.

The mid's were slightly muffled and highs very light. When bracing the cardboard box the bass turned out to be impressive even though the box is about .8 cubic feet. The changs will take care of the bass and testing them with some really crappy free tweeters with a 1uF cap make me want to get helper tweeters. I'll wait to finalize that after i build the boxes.

In keeping cheap, i was going to buy 2 sheets of 3/4" mdf. Is there any decent plywood that you could recommend that would be enough and be around $50. What is a cheap tweeter i should get?

If anybody wants to make laying out their cuts on wood easier, you should look at this optimization program. download the free version. http://www.download.com/Sheet-Cutting-Suite/3000-6677_4-10167862.html?tag=lst-1&cdlPid=10285263

I am going to build some half chang enclosures and maybe crossover with a tweeter. I hooked them up to my main amp while in some cardboard boxes. I played some rap and some album leaf. To let you know album leaf is a band playing mainly instrumental ambient type music that could put anybody to sleep. They were played to get some comparisons to my radio shack mach 3 speakers. The first was to compare the bass with the 15 inch woofer and the other was to hear midrange and treble compared to the horns.

The mid's were slightly muffled and highs very light. When bracing the cardboard box the bass turned out to be impressive even though the box is about .8 cubic feet. The changs will take care of the bass and testing them with some really crappy free tweeters with a 1uF cap make me want to get helper tweeters. I'll wait to finalize that after i build the boxes.

In keeping cheap, i was going to buy 2 sheets of 3/4" mdf. Is there any decent plywood that you could recommend that would be enough and be around $50. What is a cheap tweeter i should get?

If anybody wants to make laying out their cuts on wood easier, you should look at this optimization program. download the free version. http://www.download.com/Sheet-Cutting-Suite/3000-6677_4-10167862.html?tag=lst-1&cdlPid=10285263

Attachments

krikus050 said:

Is there any decent plywood that you could recommend that would be enough and be around $50.

None that I'm aware of, at least in the thickness required. If it's in the budget, seal the MDF inside and out with a decent sealer such as this to 'tighten' up its tone a bit: http://www.lowes.com/lowes/lkn?action=productDetail&productId=100757-8-21801&lpage=none

GM

Re: Re: first project, b20's

I would love to send you my address but i am not able to since i have not made enough posts to email people. I am under moderation. Are these the tweeters you bought 200 of?

I figured as much. I will probably go mdf then. I looked into much detail about staining it and some people say it looks decent with certain products. I will post my results and if it was easy or not.

I will look into this, thank you.

I figured if i buy 2 47"x97" sheets of mdf I will be able to make the half changs and the 3.0cu ft boxes. I will keep whichever i like best and give to other set to somebody.

Nelson Pass said:Send me your address and I'll send you a pair of the tweeters

I was giving away for these at Burning Amp.

I would love to send you my address but i am not able to since i have not made enough posts to email people. I am under moderation. Are these the tweeters you bought 200 of?

GM said:

None that I'm aware of, at least in the thickness required. If it's in the budget, seal the MDF inside and out with a decent sealer such as this to 'tighten' up its tone a bit: http://www.lowes.com/lowes/lkn?action=productDetail&productId=100757-8-21801&lpage=none

GM

I figured as much. I will probably go mdf then. I looked into much detail about staining it and some people say it looks decent with certain products. I will post my results and if it was easy or not.

AdamThorne said:If you like cheap and don't care about ugly, I've heard Oriented Strandboard (OSB) can be acoustically acceptable and the stuff is super cheap.

Haven't tried it myself, though.

I will look into this, thank you.

I figured if i buy 2 47"x97" sheets of mdf I will be able to make the half changs and the 3.0cu ft boxes. I will keep whichever i like best and give to other set to somebody.

MDF and all that.

kirkus050:

here's a rant against MDF: don't do it! Almost anything else is better. If you suspect you may try something better in the same cabinet spend some $$$ on Baltic Birch.

as impoverished as some of us may be, the results will be substantially better. OSB or even "chip board" has to better too: better dampening and less of the carcinogen formaldehyde !

in a pinch even use some sonotube (cardboard tube for cement forming columns and footings..)

As a minimum, maybe getting your local Home Depot or lumber yard to cut the MDF may be OK, as they cut it on a large panel saw, in well ventilated areas. If MDF, as suggested earlier, seal both the insides and out with a good primer , and paint . Some loudspeaker makers even take it further and suggest that if an enclosure is veneered on the outside it should be veneered on the inside and finished in exactly the same way.

stew

kirkus050:

here's a rant against MDF: don't do it! Almost anything else is better. If you suspect you may try something better in the same cabinet spend some $$$ on Baltic Birch.

as impoverished as some of us may be, the results will be substantially better. OSB or even "chip board" has to better too: better dampening and less of the carcinogen formaldehyde !

in a pinch even use some sonotube (cardboard tube for cement forming columns and footings..)

As a minimum, maybe getting your local Home Depot or lumber yard to cut the MDF may be OK, as they cut it on a large panel saw, in well ventilated areas. If MDF, as suggested earlier, seal both the insides and out with a good primer , and paint . Some loudspeaker makers even take it further and suggest that if an enclosure is veneered on the outside it should be veneered on the inside and finished in exactly the same way.

stew

stranded board...

stranded board might just be what the doctor ordered. dont be too afraid to try weird wood with these. they will sound good anyways.

You are in for a real treat. the b20 is a total overperformer.

I personally had the most luck sonically (and the best looks) with the driver back mounted against the paper gasket on the front of the frame. (screwed in from the inside of the cabinet).

it will require a removable rear panel, but that should not muck up the sound too much.

Nelson: got a link to what those free tweeters were?

I personally went on the super cheap and got the piezos with a .68 cap straight up. that was decent enough for my purposes.

enjoy,

Clark

stranded board might just be what the doctor ordered. dont be too afraid to try weird wood with these. they will sound good anyways.

You are in for a real treat. the b20 is a total overperformer.

I personally had the most luck sonically (and the best looks) with the driver back mounted against the paper gasket on the front of the frame. (screwed in from the inside of the cabinet).

it will require a removable rear panel, but that should not muck up the sound too much.

Nelson: got a link to what those free tweeters were?

I personally went on the super cheap and got the piezos with a .68 cap straight up. that was decent enough for my purposes.

enjoy,

Clark

Re: stranded board...

ANYBODY can find me. Try the passlabs home page.

I bought 2000.

Hi Clark, how many would you like? Do I have to send them all the

way to Japan?

krikus050 said:I would love to send you my address but i am not able to since i have not made enough posts to email people. I am under moderation. Are these the tweeters you bought 200 of?

ANYBODY can find me. Try the passlabs home page.

I bought 2000.

blumenco said:Nelson: got a link to what those free tweeters were?

Hi Clark, how many would you like? Do I have to send them all the

way to Japan?

Become the target of boys, run the risk that a doorbell ring might summon you to a flaming bag of doody on your doorstep.

...

Become the target of audio geeks, the bag is full of tweeters.

OTOH maybe it's your wife that is the target...

"But honey I HAVE to build it, I've got all these tweeters...!"

"... If I ever get my hands on the Pass guy..."

...

Become the target of audio geeks, the bag is full of tweeters.

OTOH maybe it's your wife that is the target...

"But honey I HAVE to build it, I've got all these tweeters...!"

"... If I ever get my hands on the Pass guy..."

B-20 cabinet design

Mr. Pass did a TL (?) design, however I can't find it on his site now....

I wondered how much material it took to produce? Maybe that it's not on his site, but here somewhere.

On the subject of OSB for speaker cabinets, don't let it get wet!, seal it well! Someone built a BIB with these Pioneer B-20"s and the little push in PE tweeter, and was very satisfied, except his distaff half wouldn't let them in the house.

The builders are now using an OSB product that is for subflooring, it looks to be about an Inch thick, and is rated for at least 16" span. This might be worth experimenting with. A builder told me he gets it for ~$25/sh.

John

Mr. Pass did a TL (?) design, however I can't find it on his site now....

I wondered how much material it took to produce? Maybe that it's not on his site, but here somewhere.

On the subject of OSB for speaker cabinets, don't let it get wet!, seal it well! Someone built a BIB with these Pioneer B-20"s and the little push in PE tweeter, and was very satisfied, except his distaff half wouldn't let them in the house.

The builders are now using an OSB product that is for subflooring, it looks to be about an Inch thick, and is rated for at least 16" span. This might be worth experimenting with. A builder told me he gets it for ~$25/sh.

John

Well, if you'd run a search you'd've found it easily enough. Posts 53 - 58.

http://www.diyaudio.com/forums/showthread.php?postid=749237#post749237

http://www.diyaudio.com/forums/showthread.php?postid=749237#post749237

had to do what i had to do

I went to home improvement stores yesterday. The only cheap and readily available thing was mdf so I bought a couple 4'x8' sheets.

I was thinking about doing 45 degree cuts to each side to improve the look of it. I have enough tools to accomplish this but wanted to know your thoughts on the sturdiness of this. Will mdf hold up with 45 degree cuts with screws going through them?

If not, will painting them hide the different edges you would see? I assume this would work with some decent sanding. I did want to stain them and figure that you would be able to notice the edges with that.

I went to home improvement stores yesterday. The only cheap and readily available thing was mdf so I bought a couple 4'x8' sheets.

I was thinking about doing 45 degree cuts to each side to improve the look of it. I have enough tools to accomplish this but wanted to know your thoughts on the sturdiness of this. Will mdf hold up with 45 degree cuts with screws going through them?

If not, will painting them hide the different edges you would see? I assume this would work with some decent sanding. I did want to stain them and figure that you would be able to notice the edges with that.

Krikus050

I don't know about others, there always are several ways to skin the proverbial cat.

I would cut nice square 90's, and glue with either pu ( gorilla ) or something like Titebond. The glue joint will be stronger than the wood.

As to finish, sanding, filling with Bondo works well for MDF ( helps to hide those seams ).

Finish with a coat of primer and more sanding, then a glossy black, white, or any color you desire. I treat this stuff like an auto finish.

There are other ways to do it, I've heard of people staining this stuff too.....

Whatever you do, I would strongly recommend sealing this stuff inside and out to prevent moisture intrusion, and wear a respirator while cutting and sanding, the resins in MDF are not good for your lungs.

John

I don't know about others, there always are several ways to skin the proverbial cat.

I would cut nice square 90's, and glue with either pu ( gorilla ) or something like Titebond. The glue joint will be stronger than the wood.

As to finish, sanding, filling with Bondo works well for MDF ( helps to hide those seams ).

Finish with a coat of primer and more sanding, then a glossy black, white, or any color you desire. I treat this stuff like an auto finish.

There are other ways to do it, I've heard of people staining this stuff too.....

Whatever you do, I would strongly recommend sealing this stuff inside and out to prevent moisture intrusion, and wear a respirator while cutting and sanding, the resins in MDF are not good for your lungs.

John

GM said:Frankly, I wouldn't even use screws since it weakens the glue joint.

GM

I was planning on screwing into the wood while the glue was still setting. Wouldn't that not have that problem?

Screws weaken any joint compared to a properly bonded one. Engineered bonding agents of today are far stronger than the hide glues of yesteryear, so reducing bonding surface area to add a separate component that stresses the materials in 3D is going in the wrong direction.

Of course in a HIFI app it's mostly moot since hopefully they won't be subjected to the type of abuse a prosound/whatever piece of gear gets, so adding them isn't a big deal, just that they aren't necessary anymore for a strong joint.

GM

Of course in a HIFI app it's mostly moot since hopefully they won't be subjected to the type of abuse a prosound/whatever piece of gear gets, so adding them isn't a big deal, just that they aren't necessary anymore for a strong joint.

GM

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Full Range

- first project, b20's