I am getting to the end of a loudspeaker project using Fostex F200A drivers in spun spherical steel enclosures.

The spheres are about 510mm outer diameter to give about 70 litres of volume (after damping). The wall thickness is 3mm. Modeling the F200A in a sealed box of this volume gives an -3dB point of 74Hz.

So far, the sound has improved as I have added more and more stuffing to the enclosures.

The sound of these speakers is awesome. I've used other Fostex 8" full-rangers before but the F200A has so much more body and depth. It is a great unit for infinite baffle enclosures.

Can anyone offer any advice on the best method of damping the insides of a spherical enclosure? I understand that there will be one main resonance, caused by the consistent diameter of the sphere.

The spheres are about 510mm outer diameter to give about 70 litres of volume (after damping). The wall thickness is 3mm. Modeling the F200A in a sealed box of this volume gives an -3dB point of 74Hz.

So far, the sound has improved as I have added more and more stuffing to the enclosures.

The sound of these speakers is awesome. I've used other Fostex 8" full-rangers before but the F200A has so much more body and depth. It is a great unit for infinite baffle enclosures.

Can anyone offer any advice on the best method of damping the insides of a spherical enclosure? I understand that there will be one main resonance, caused by the consistent diameter of the sphere.

Attachments

sharpi31 said:

Can anyone offer any advice on the best method of damping the insides of a spherical enclosure? I understand that there will be one main resonance, caused by the consistent diameter of the sphere.

remember the driver is not in the centre of a sphere. so there is no one consistent distance from the driver. you have the next best thing to an open baffle.

Awesome enclosures. the eyes follow you around the room..

Google the words Elliot sound and westhost then look at the baffle step article.

Thanks - I had a metal spinner build them to spec.

The two halves of each sphere are spun from flat sheets of steel, then welded together with an additional steel strip on the inside. A flat section cut to match the F200A was welded on to each sphere.

There is also a steel bar running from side to side inside the sphere, to reduce ringing.

As the metal is spun, the thickness of the walls varies slightly. It is thickest around the driver (and at the rear opposite) and thinner towards the middle. This is a nice side-effect of the spinning process that also reduces ringing.

I'll get better photos next week....

The two halves of each sphere are spun from flat sheets of steel, then welded together with an additional steel strip on the inside. A flat section cut to match the F200A was welded on to each sphere.

There is also a steel bar running from side to side inside the sphere, to reduce ringing.

As the metal is spun, the thickness of the walls varies slightly. It is thickest around the driver (and at the rear opposite) and thinner towards the middle. This is a nice side-effect of the spinning process that also reduces ringing.

I'll get better photos next week....

It would seem that the sticky goos that car audio people use might be good. After all , they were made to damp sheetmetal. There have been products mentioned here, some roofing compounds for example, but I need to try and find them. You want something that will remain a bit flexible I believe. Easy to apply- remove driver, pour in goo, cover and rotate! Steel really does ring, so attention to this should pay off big!

I very much like your idea.

I very much like your idea.

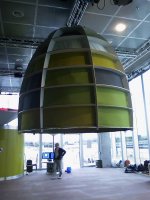

Well these speakers are almost finished and are installed at the new BBC Scotland headquarters. All that remains is for a custom aluminium ring to be installed over the driver to hide the octagonal basket.

The huge bell shaped external frame is designed to create an audio immersion zone with little spillage outside. The HF beaming of the 8" full range driver was advantageous in this instance!

There are two of these 'sound cones' - both have a DEQ2496 upstream.

Not exactly hifi and not exactly DIY, but this forum has been a great resource for me on this project.

The huge bell shaped external frame is designed to create an audio immersion zone with little spillage outside. The HF beaming of the 8" full range driver was advantageous in this instance!

There are two of these 'sound cones' - both have a DEQ2496 upstream.

Not exactly hifi and not exactly DIY, but this forum has been a great resource for me on this project.

Attachments

I buildt In-Wall speaker, using the F200A, integrating a book-shelf to become part of my F200-speaker, thinking that my creation was kind of special.

But, this, this....is just...I can only agree with previous poster - ...Wow! A visit to BBC Scotland Office must be arranged.

Really curious of how it sounds...

Great project!

Thanks for sharing.

LageB

Stockholm

But, this, this....is just...I can only agree with previous poster - ...Wow! A visit to BBC Scotland Office must be arranged.

Really curious of how it sounds...

Great project!

Thanks for sharing.

LageB

Stockholm

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Full Range

- F200A in spherical steel infinite baffle enclosure