Re. coating or damper pads

First let me say that I have not studied the EnABL process.

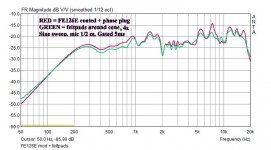

Some weeks ago I did however do some simple measurements of the Fostex FE-126e. This driver has some nasty peaks around 7 kHz.

First I compared a new driver with a coated driver: The coated driver is unanimously reported to sound considerably better than stock. It did however not show any noticeablel change in the measured response (at leat not at higher frequencies).

Based on hints from MarkMck regarding location of resonant modes, I tried to add small felt and cork pads around the perimeter of the driver, 10 mm from edge. This did show results. It seemed that many small pads were better than a few larger ones.

Attached is a measurement I saved. This is with only 4 felt pads. 8 small cork pads (10mm dia) were even better in flattening the HF peaks. I show this only as example of measurement. I did not have the time for a proper listening comparison.

NB: The coating, using ModPodge, is important before doing these experiments as it will allow self adhesive pads to be applied and removed without damaging the cone.

SveinB

First let me say that I have not studied the EnABL process.

Some weeks ago I did however do some simple measurements of the Fostex FE-126e. This driver has some nasty peaks around 7 kHz.

First I compared a new driver with a coated driver: The coated driver is unanimously reported to sound considerably better than stock. It did however not show any noticeablel change in the measured response (at leat not at higher frequencies).

Based on hints from MarkMck regarding location of resonant modes, I tried to add small felt and cork pads around the perimeter of the driver, 10 mm from edge. This did show results. It seemed that many small pads were better than a few larger ones.

Attached is a measurement I saved. This is with only 4 felt pads. 8 small cork pads (10mm dia) were even better in flattening the HF peaks. I show this only as example of measurement. I did not have the time for a proper listening comparison.

NB: The coating, using ModPodge, is important before doing these experiments as it will allow self adhesive pads to be applied and removed without damaging the cone.

SveinB

Attachments

I wondn't really expect the mod-podge treatment to show up in the FR -- its job is to reduce cone self-noise....

In my mod the damar pattern is an attempt to help quell the resonances Mark pointed out... i know they aren't totally effective, because i can still see them in the impedance plot (i have to get a laptop assembled to put FR measure kit into place)... we are just about to go another round of experimenting on the cones, i'll give this a try.

dave

In my mod the damar pattern is an attempt to help quell the resonances Mark pointed out... i know they aren't totally effective, because i can still see them in the impedance plot (i have to get a laptop assembled to put FR measure kit into place)... we are just about to go another round of experimenting on the cones, i'll give this a try.

dave

The 2.7 kHz peak was bothering me the most. I tried the felt pads on the cone about 5/8" in from the edge. This did reduce the peak, but also tended to reduce the upper treble and I think it caused new dips and peaks. I did not want to lose the upper treble so I removed the felt pads. I got a large piece of some heavy felt, about 1/2" thick, and cut a hole for the driver with triangles that projected past the point where this 2.7 kHz resonance came off the cone. I taped this to the speaker baffle. It looks a lot like what Bert Doppenberg did on one of his speakers. If you go to http://www.t-linespeakers.org/FALL/bd-pipes.html and then go down 1 screen you will see what this looks like. It sounded horrible. I reduced the BSC resistor to about half and it now sounds better than ever. The 2.7 kHz peak is gone. While it now sounded very good the 5kHz peak was much obvious. The 5kHz peak seems to come from a resonance well down the cone. I tried the "98 cent tweak", speaker stuffing wrapped between the whizzer and the cone, and this calmed it down some. I have to take better measurements and refine these but hopefully this may be of some help.

Jim

Jim

Hi Bob,

I missed your excellent challenge ot the EnABL process a week ago. When thread posts are collected into one spot, as they were in the EnABL + Mamboni thread, my link and email notification for the original threads disappeared. This is the first 1000 words or so of my answers to your questions from a week ago. It is also posted in the EnABL thread and all of the rest of my answers will only be posted there.

You may think in anyway that you wish to, we all do so. Please have another look at the paper posted on the Positive Feedback site.

http://www.positive-feedback.com/Issue21/standingwaves.htm

Scroll to the last graph, right at the end of the paper. Look carefully at the graph and notice that the untreated cone shows evidence of energy that is still radiating from the cone surface. It is still radiating in discreet peaks and troughs, within the time period that our correlator uses for placement of and distance from threat analysis.

Then notice that the untreated cone has ceased to have energy in the same format. There are still some peaks of emitting energy but most has dropped below the test sheets limit. You may think that all of the activity is still going on and I deliberately cut off the chart scale, to prevent you from seeing it. If you were to run this test on your own, you might prove to yourself that I am indeed attempting to hood wink you.

In actuality, the processed cone has just gotten more energy into the air, in a shorter period of time, than the untreated cone was able to. You can see evidence of this in the graphs. Look at the comparison of the first curve sets. Notice that in some discreet frequency points, the treated cone is 9 dB more efficient than the untreated cone. No question in my mind that the conformal coating, used as a boundary layer enhancement is effecting this event.

Now look at the middle graph from the Positive Feedback site. The two cones are emitting energy at about the same rate, at the same point in time. Different frequency points in this decaying energy plot show differences in storage between the two, for differing frequencies, but the amount of power being emitted is within an equivalent level. If the coating was the only effector here, then this graph should also show a noticeable difference in level, everywhere across the frequency band, because a more efficient emitter surface should work more efficiently, regardless of energy levels being worked with.

Something else must be at play here. This is the same tweeter in both sets of tests. The same test set up, same microphone, same computer etc. etc. One day later though. All that seems left is that the pattern is enforcing an increase in energy transfer into the air during this middle graph period and having done so, ceases to allow energy to return in the boundary layer and provide the same “ringing” emission that the untreated cone is producing. There are no other differences between the two test points. So, more efficient emission into the air from a combination of pattern and boundary layer enhancement is the answer, for the paper cone tweeter.

Change the diaphragm materials to poly carbonate, aluminum, titanium and suddenly things are quite different. Same pattern performs the same function, but the conformal coating is reduced to just the area where the pattern blocks are applied or not used at all. Here is where the effectiveness of the pattern shows up. Certainly this pattern increases the boundary layer impedance. Just as certainly, the materials with less boundary layer and higher internal longitudinal wave speed do not require the conformal coating, but do respond to the pattern with the same “character” as found in a drivers where the conformal coating is required.

Bud

I missed your excellent challenge ot the EnABL process a week ago. When thread posts are collected into one spot, as they were in the EnABL + Mamboni thread, my link and email notification for the original threads disappeared. This is the first 1000 words or so of my answers to your questions from a week ago. It is also posted in the EnABL thread and all of the rest of my answers will only be posted there.

I have never tried it or even heard about it before, but I'm just not convinced from the information given that the EnABL process (just the blocks), is actually having any audible effect on the driver. I'm sure it will have a minor effect, just not audible. Bear in mind I am not a scientist of any fashion, so maybe my pea brain just can't handle the data, but I don't understand the following:

quote:

"An effective solution to the problem of transient standing waves on transducers is to apply a low mass pattern of diffraction blocks to the skin effect surface.

quote:

This pattern must allow relatively free passage to a transverse wave in any direction. When placed near a terminus the EnABL pattern eliminates reflections from the terminus back through the pattern, due to the skin effect energy density within the pattern openings."

I just think that if the returning reflection is of such low amplitude to be arrested by these blocks, it wouldn't really be a problem in the first place. Why does the high compliance surround not absorb the wave? At what frequencies is the pattern supposed to be effective?

You may think in anyway that you wish to, we all do so. Please have another look at the paper posted on the Positive Feedback site.

http://www.positive-feedback.com/Issue21/standingwaves.htm

Scroll to the last graph, right at the end of the paper. Look carefully at the graph and notice that the untreated cone shows evidence of energy that is still radiating from the cone surface. It is still radiating in discreet peaks and troughs, within the time period that our correlator uses for placement of and distance from threat analysis.

Then notice that the untreated cone has ceased to have energy in the same format. There are still some peaks of emitting energy but most has dropped below the test sheets limit. You may think that all of the activity is still going on and I deliberately cut off the chart scale, to prevent you from seeing it. If you were to run this test on your own, you might prove to yourself that I am indeed attempting to hood wink you.

In actuality, the processed cone has just gotten more energy into the air, in a shorter period of time, than the untreated cone was able to. You can see evidence of this in the graphs. Look at the comparison of the first curve sets. Notice that in some discreet frequency points, the treated cone is 9 dB more efficient than the untreated cone. No question in my mind that the conformal coating, used as a boundary layer enhancement is effecting this event.

Now look at the middle graph from the Positive Feedback site. The two cones are emitting energy at about the same rate, at the same point in time. Different frequency points in this decaying energy plot show differences in storage between the two, for differing frequencies, but the amount of power being emitted is within an equivalent level. If the coating was the only effector here, then this graph should also show a noticeable difference in level, everywhere across the frequency band, because a more efficient emitter surface should work more efficiently, regardless of energy levels being worked with.

Something else must be at play here. This is the same tweeter in both sets of tests. The same test set up, same microphone, same computer etc. etc. One day later though. All that seems left is that the pattern is enforcing an increase in energy transfer into the air during this middle graph period and having done so, ceases to allow energy to return in the boundary layer and provide the same “ringing” emission that the untreated cone is producing. There are no other differences between the two test points. So, more efficient emission into the air from a combination of pattern and boundary layer enhancement is the answer, for the paper cone tweeter.

Change the diaphragm materials to poly carbonate, aluminum, titanium and suddenly things are quite different. Same pattern performs the same function, but the conformal coating is reduced to just the area where the pattern blocks are applied or not used at all. Here is where the effectiveness of the pattern shows up. Certainly this pattern increases the boundary layer impedance. Just as certainly, the materials with less boundary layer and higher internal longitudinal wave speed do not require the conformal coating, but do respond to the pattern with the same “character” as found in a drivers where the conformal coating is required.

Bud

JimT said:It looks a lot like what Bert Doppenberg did on one of his speakers. If you go to BD-Pipes and then go down 1 screen you will see what this looks like.

The felt star is mine, shown installed on my set of Bert Doppenburg ML-V. The star was adapted from something that GM came up with (for the 40-1354?)

A prime number of points (13) with the edge of the star cut at ~ 45 degrees so that the shape is opening up, and there are no 90 degree surfaces.

dave

How come a company like Fostex doesn't bother to enable itself with the enabling process and benefit from the resultant performance boost at what would to them be a trifling cost, or is it that they just don't understand the loudspeaker business.

Until such time as the exact nature of how EnABL works - ie what combinations of materials, painted /embossed/or engraved patterns,etc, - and production engineers can develop the required process(es) to be incorporated during the fabrication of the cones, it's a bit presumptuous to assert that the cost(s) would be trifling.

Notwithstanding the very expensive limited production / custom series drivers, considering how many years Fostex has retained some of the stamped basket assemblies in drivers with which the average NA or European DIYer is most familiar, it's probably safe to say that the bean-counters are highly involved in the mass market products.

Further, considering how long the parent company has been in business, and the volume of all types of OEM drivers they produce, the provenance of which the average consumer is never aware, I'd dare say they have a pretty good understanding of the "loudspeaker business."

Do they care if some painted polka dots do something special for some listeners? - have you heard a pair of FE138ESRs?

Are you saying that no one knows how it works? How do the people who apply the process do so? Is it an intuitive thing or do they have some special gift like Witch Doctors? Fostex need to hire these people whatever the cost, they wouldn't need to bother with limited production runs of fancy speakers, all there products would make a quantum leap in quality and they would dominate the market.

Someone tell them.

Someone tell them.

One person's opinion: in my very limited experience, it's an audible, but ultimately I'd say subtle, tweak which (apparently) alters the time domain behavior, rather than the frequency response.

It's not going to transform a $40 Fostex into a $3,000 Feastrex (not that price means quality -- it certainly doesn't). If you want a tweak that will make a -huge- difference immediately, try digital EQ (e.g., using your computer as a source -- it's free, it's infinitely customizable, and it's fun). After that, improve your system's source as much as possible. Then try room treatments and positioning. Get some measurement gear, deal with room modes, etc. And after that, if you are so inclined, try whatever tweaks which may now (finally) be audible.

It's important, in my limited experience, to try things in order of greatest to least significance. Once you have a system which is dialed in "grossly," you might try the subtler tweaks. But trying the subtler tweaks first makes no sense and will have little impact (in my opinion).

It's not going to transform a $40 Fostex into a $3,000 Feastrex (not that price means quality -- it certainly doesn't). If you want a tweak that will make a -huge- difference immediately, try digital EQ (e.g., using your computer as a source -- it's free, it's infinitely customizable, and it's fun). After that, improve your system's source as much as possible. Then try room treatments and positioning. Get some measurement gear, deal with room modes, etc. And after that, if you are so inclined, try whatever tweaks which may now (finally) be audible.

It's important, in my limited experience, to try things in order of greatest to least significance. Once you have a system which is dialed in "grossly," you might try the subtler tweaks. But trying the subtler tweaks first makes no sense and will have little impact (in my opinion).

Are you saying that no one knows how it works? How do the people who apply the process do so? Is it an intuitive thing or do they have some special gift like Witch Doctors?

Try reading the EnABL Listening impressions & techniques thread.

This will give you the 'how to' information.

Cheers,

Alex

Why would they care? And besides, they already stuck En on the end of their driver names, I'm sure the marketing department felt that was all that was needed. If you get those engineer guys involved there is just no telling how much money they would waste. Marketeers all know that specs are meaningless and BS is what sells, along with striking women with scant clothing. Been proven time after time after time.

Bud

Bud

Are you saying that no one knows how it works? How do the people who apply the process do so? Is it an intuitive thing or do they have some special gift like Witch Doctors? Fostex need to hire these people whatever the cost, they wouldn't need to bother with limited production runs of fancy speakers, all there products would make a quantum leap in quality and they would dominate the market.

Someone tell them.

Perhaps you focused too much on the sardonic quip in the first part of my prior post, and missed the overarching sentiment.

My points were that -

1) it could be that the costs of any manufacturer implementing EnABL techniques in production would be more than "trifling"

2) does Fostex ( a division of a pretty big company that manufactures a lot of audio transducers, and obviously "understands the loudspeaker business" ) actually pay attention to or care about what its customers outside of the domestic Japanense market think of the sound of its products?

All that said, I'm still quite fond of many of their speakers - hell if it wasn't for the FE126/7 and FE167, I'd probably have long ago been enticed back to the "fine" commercial mainstream offerings available my area, and missed out on the most fun 10 years in over 45yrs in this hobby (I was a very late bloomer to DIY) . Of course, like a lot of new addicts to this life-style, I could (actually, have) build(t) more than a few pairs of very nice systems for myself and siblings for the cost of sales tax on anything that I'd even care to borrow from the local dealer for an in-home demo.

oh, the humanity

One person's opinion: in my very limited experience, it's an audible, but ultimately I'd say subtle, tweak which (apparently) alters the time domain behavior, rather than the frequency response.

It's not going to transform a $40 Fostex into a $3,000 Feastrex (not that price means quality -- it certainly doesn't). If you want a tweak that will make a -huge- difference immediately, try digital EQ (e.g., using your computer as a source -- it's free, it's infinitely customizable, and it's fun). After that, improve your system's source as much as possible. Then try room treatments and positioning. Get some measurement gear, deal with room modes, etc. And after that, if you are so inclined, try whatever tweaks which may now (finally) be audible.

It's important, in my limited experience, to try things in order of greatest to least significance. Once you have a system which is dialed in "grossly," you might try the subtler tweaks. But trying the subtler tweaks first makes no sense and will have little impact (in my opinion).

This makes a lot of sense to me. What in your opinion is a good digital EQ program?

"If you get those engineer guys involved there is just no telling how much money they would waste." Just wow.

Would somebody please give me the definition of "skin effect energy density". This phrase was used in this thread, and I am sure it is too fancy to be just made up gibberish...

Would somebody please give me the definition of "skin effect energy density". This phrase was used in this thread, and I am sure it is too fancy to be just made up gibberish...

"If you get those engineer guys involved there is just no telling how much money they would waste." Just wow.

Would somebody please give me the definition of "skin effect energy density". This phrase was used in this thread, and I am sure it is too fancy to be just made up gibberish...

So you believe it because you don't understand it, or are you making a joke?

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Full Range

- Help me kill a fostex artifact.