Hello all,

I am not sure that this trhead is in the proper forum ...

I am looking for all your knowledge on how to twist wires together without by hand in order to make long run of proper twisted wire for audio cables.

I have found this

www.aircraftspruce.com/menus/to/safetywiretools.html

and this

www.amazon.com/Bon-Tool-Co-Wire-Twister/dp/B00067T9OA

but I do not know how this work.

I have found that too

http://www.twistechnology.com/?go=3...82f9b18335616af351affc954366f6be70084a751273a

but this is out of my budget !

Give to this forum your ideas, diy tools or machines, tips and so on.

I think this will help many of cable builders.

Thank you

I am not sure that this trhead is in the proper forum ...

I am looking for all your knowledge on how to twist wires together without by hand in order to make long run of proper twisted wire for audio cables.

I have found this

www.aircraftspruce.com/menus/to/safetywiretools.html

and this

www.amazon.com/Bon-Tool-Co-Wire-Twister/dp/B00067T9OA

but I do not know how this work.

I have found that too

http://www.twistechnology.com/?go=3...82f9b18335616af351affc954366f6be70084a751273a

but this is out of my budget !

Give to this forum your ideas, diy tools or machines, tips and so on.

I think this will help many of cable builders.

Thank you

SY said:Use a variable speed drill. Either a helper or a vise on the other end. Keep things taut, and after twisting, release the tension slowly.

I find gently warming the cable with a heat gun before releasing the tension helps set the twist with more flexible stranded cables.

i have a thin, 50mm diameter circle of lexan, it has holes spaced equally around the centre of various diameters,and each one is slightly flared.

just thread the wires through, vice one end and rotate to twist.

pretty much stress free and easier to get accurate twist per distance unit than with a drill.

just thread the wires through, vice one end and rotate to twist.

pretty much stress free and easier to get accurate twist per distance unit than with a drill.

Shorter lengths, use the advise as per any above ( or your own choise: www.aircraftspruce.com/menus/to/safetywiretools.html ) ... longer lengths, 10+ feet, best consult with a rope maker or learn about braiding.

phn said:I don't quite agree with the drill technique. I don't know if it's bad, but it does put stress on the wires. If you twist two individual wires loosely by hand, they will stay twisted. No force is needed.

Of course, twisting long wires this way isn't easy.

With solid copper or tinned solid copper, I've never had a failure in, oh, 30 years of doing it this way. They do stay twisted. Silver wire will break using this method, though.

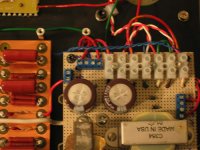

Attachments

I too use a power drill, but I leave the other ends of the wires loose and separated. As the drill spins the two wires together on one end, I let the other ends of the wires spin and rotate. This allows the wires to twist while being spun and gives a much tighter winding that will maintain its integrity when moved and handled. This works best with stranded wire with reasonably flexible insulation. I’ve never used silver wire, so I can’t comment on its breakage.

I’ve used this method for twisting copper varieties of wires in lengths from 6-inches to 30-feet with excellent results and zero failures.

I’ve used this method for twisting copper varieties of wires in lengths from 6-inches to 30-feet with excellent results and zero failures.

If twisting small amounts/thin (7/0.2 etc) of wire, I do them directly in the chuck of a hand drill, tied off the other end. Then before taking the twisted wires out of the chuck give them a firm pull, you should feel the wires stretch slightly. The stretching action really does help the the twist set in the wires.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- General Interest

- Everything Else

- Twisting wires || METHOD, TOOLS, TIPS ... ||