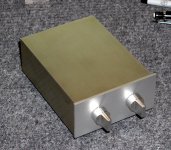

And this is how it's done. I used 2 x 4 rectangular aluminum extrusion cut to 5.5" length. Front and rear panel is done out of clear anodized aluminum angles. The chassis body is brushed and alodined, that's where the gold color comes from. Took me 4 hours to completely make 2 boxes and put preamp in one of them.

I figured it out today and I have to say that it's pretty simple and smart way to do a smaller box (crossover, preamp, phono stage). I guess I'll be using that technique more often. I remeber some guys complaining about using countless screws for a chassis. This one needs only four.

I figured it out today and I have to say that it's pretty simple and smart way to do a smaller box (crossover, preamp, phono stage). I guess I'll be using that technique more often. I remeber some guys complaining about using countless screws for a chassis. This one needs only four.

Attachments

er, ... thats "cute little thang"  I have to say that this is a real contribution. Did you do all the cuts with your trusty metal cutting circular say? My local surplus aluminum supply place is very pricey, but has a great stock of rectangular tube.

I have to say that this is a real contribution. Did you do all the cuts with your trusty metal cutting circular say? My local surplus aluminum supply place is very pricey, but has a great stock of rectangular tube.

For a gain card amp or some such, it might be adaquate heatsink

For a gain card amp or some such, it might be adaquate heatsink

Dave:

>My NAIM NAIT 2 has a very similar chassis. The only difference is that instead of 2 aluminum Ls, it has a steel U. Same 4 screws hold it together.<

Some of the Spectral preamps used this same type of chassis for their remote transformer box. Rectangular tube aluminum extrusion, aluminum U, and 4 screws serving double-duty as feet. The sliding U-part carried all of the electronics and made servicing and repair extremely easy.

jonathan carr

>My NAIM NAIT 2 has a very similar chassis. The only difference is that instead of 2 aluminum Ls, it has a steel U. Same 4 screws hold it together.<

Some of the Spectral preamps used this same type of chassis for their remote transformer box. Rectangular tube aluminum extrusion, aluminum U, and 4 screws serving double-duty as feet. The sliding U-part carried all of the electronics and made servicing and repair extremely easy.

jonathan carr

Peter,

good idea, will copy it . One hint, the tube bottom edge of the front side becomes visible as the L-profile acting as frontplate only covers 3 of the 4 edges.

. One hint, the tube bottom edge of the front side becomes visible as the L-profile acting as frontplate only covers 3 of the 4 edges.

If you file or mill or saw a 60° chamfer on this bottom edge (*almost* but not fully a knife edge) and blacken it afterwards, it becomes fully invisible and the housing looks even slicker.

good idea, will copy it

If you file or mill or saw a 60° chamfer on this bottom edge (*almost* but not fully a knife edge) and blacken it afterwards, it becomes fully invisible and the housing looks even slicker.

filing bottom edge.

This would be a further improvement on a simple idea. I didn't do it, because I was running against the time. One point worth noticing here, is that I used anodized angles from building supplies store, so no additional finish required for front and rear panel.

This would be a further improvement on a simple idea. I didn't do it, because I was running against the time. One point worth noticing here, is that I used anodized angles from building supplies store, so no additional finish required for front and rear panel.

Chassi and surface

Hi,

How do you make the finnish? you mentioned alodine is this a liquid or it is a electrochemical process it sounds that this can dangerous to your health.

A company in my country can make a faceplate wich is cutted and anodized for $20 I think it is the same in US the CNC machine has the advantage that it can make anything with very high precision.

If you had a strategy for enclosures you may only have two or three kind of enclosures drawings following the same design idea.

If you then need a enclosure just mail the file with your drawing and the workshop make the parts you need in a couple of days.

Hi,

How do you make the finnish? you mentioned alodine is this a liquid or it is a electrochemical process it sounds that this can dangerous to your health.

A company in my country can make a faceplate wich is cutted and anodized for $20 I think it is the same in US the CNC machine has the advantage that it can make anything with very high precision.

If you had a strategy for enclosures you may only have two or three kind of enclosures drawings following the same design idea.

If you then need a enclosure just mail the file with your drawing and the workshop make the parts you need in a couple of days.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- General Interest

- Everything Else

- A simple chassis idea