Hi all,

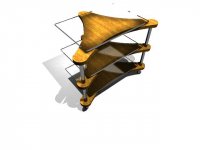

Here's a project I've been thinking about for some months. A basic drawing with some dimentions was laying on my desktop, untill I discovered the Povray software and and wanted to have a preview of my project.

Here's the description:

Every stage is made of a wood plate and a glass plate(you can use granite too!). They will certainly be deboupled with squash balls (not shown on the picture)

Like TNT's Flexy Rack, the stages are fastened with threaded steel bars.

I'll try to post a better picture, when I'll be able to render something more realistic.

Any Povray experts here? www.povray.org if you're interested.

Do you like it?

Alex

Here's a project I've been thinking about for some months. A basic drawing with some dimentions was laying on my desktop, untill I discovered the Povray software and and wanted to have a preview of my project.

Here's the description:

Every stage is made of a wood plate and a glass plate(you can use granite too!). They will certainly be deboupled with squash balls (not shown on the picture)

Like TNT's Flexy Rack, the stages are fastened with threaded steel bars.

I'll try to post a better picture, when I'll be able to render something more realistic.

Any Povray experts here? www.povray.org if you're interested.

Do you like it?

Alex

Attachments

wuffwaff said:Hi Bricolo,

looks are really nice but I wouldn´t use glass to put the equipment on. There´s almost no damping and many components tend to react to this (no I won´t say that they sound some way "glassy")

Maybe you could use macrolon or acrylic plates for this?

William

Is granite better?

Is granite better?

Hi Bricolo

IME experience granite is as bad as it gets. Most stones have a strong intrinsic sound due to resonance, high mass and parallel sides. The only exception i can think of is slate but it also requires attention. Some people absolutely love the strong resonating bass which granite imposes upon everything so it's pterry much a question of taste.

There is some truth in the claim that the best stand is shelfless as it deals well with air-borne vibrations but structural vibrations affect it as much as normal stands and you still need some way of isolating components.

Without criticising your design it appears to provide good coupling between shelves and supporting pillars but minimal isolation. In this case you need to individually isolate each component which works but is quite painful to achieve.

A simple, yet effective shelf design is a constrained layer sandwich, similar to Simposium. Central to this is polyethylene closed cell foam in the mid layer which behaves similarly to an air bladder. I use foam with 45kg/m3 which appears suitable for medium heavy loads. On both sides of the 15mm foam core i have layers of baltic birch/pvc and thin (1mm) alu. This platform provides very good isolation, comparable to an air bladder without the bladder annoyances. Combining materials with different density and resonances pretty much removes any audible signature. Even reducing the number of layers to three still provides most of the benefits.

To use a constrained layer platform with a stand of your design you have to make sure that the vertical pillars are only bolted to the bottom layer of the platform, otherwise you'll lose most of the isolation.

Hi,

You're right, there's a strong coupling between the metal pillars and the wood shelves. But the wood and glass shelves are decoupled with squash balls. Isn't this ok?

Bolting the shelves only under them would lead to a unstable rack, except if I strongly bold the top and bottom shelves at both sides.

Your "sandwich" would replace the wood, wouldn't it? And what would you advice in place of the glass?

Thanks

Alex

You're right, there's a strong coupling between the metal pillars and the wood shelves. But the wood and glass shelves are decoupled with squash balls. Isn't this ok?

Bolting the shelves only under them would lead to a unstable rack, except if I strongly bold the top and bottom shelves at both sides.

Your "sandwich" would replace the wood, wouldn't it? And what would you advice in place of the glass?

Thanks

Alex

But the wood and glass shelves are decoupled with squash balls.

It's ok. But not great. The balls provide a lossy coupling in a few points but still leave a large surface area open to collect air-borne vibrations. The constrained layer dissipates vibrations evenly accross the surface.

Bolting the shelves only under them would lead to a unstable rack

Sorry, i wasn't clear. Bolting 'under' is not really bolting, isn't it? What i meant was only the lower board of the sandwich to be firmly (top and bottom) bolted. This obviously means larger holes through the other layers so that the top nut can be fastened to the bottom layer.

And what would you advice in place of the glass?

If you use the constrained layer approach there is no need for glass. In fact adding glass will destroy most of the sonic benefits.

After all this approach may not really be appropriate for your design. It's really difficult to make something which sounds good and looks gorgeous. If you are dead-set on the gorgeous looks using maple for wood and acrylic for glass is probably the best compromise. Where would the ugly balls fit though?

On second thought, if i were to build a brand new rack i might follow this concept.

It offers a lot of flexibility regarding matrials and has interesting ideas regarding vibration control. I think it's really cool.

And if you really must use those

Attachments

little thing i found usefull when i built my flexy rack was to use a few layers of that thin teflon tape used for sealing with air compressors under the nuts and washers you use to clamp the boards to the threaded rods, same purose as those nylock nuts but easier to work with

"Now I've seen everything. After viewing the rack link above we need to get racks that have adjustments so we can tweak the rack for the best sound too."

Best I've read in a long time.

First off, if you make the rack for solid state amps, go with looks. Solid state amps aren't affected by vibrations. For valves and mechanical stuff (turntables, CD players) go with mass. If that doesn't help, move further away from the airport.

Best I've read in a long time.

First off, if you make the rack for solid state amps, go with looks. Solid state amps aren't affected by vibrations. For valves and mechanical stuff (turntables, CD players) go with mass. If that doesn't help, move further away from the airport.

Solid state amps aren't affected by vibrations.

Really? Wish i had known this 20 years ago. Would have saved me lots of trouble and auditions. I guess i'm just a sucker for snake oil. Even if it's home-brewed.

It appears so for "normal" vibrations.

You probably know about the site already, so take this as info for the newbies.

<<"Microphony is an important factor in the sound of an amplifier, so any attempt at vibration-damping is a good idea."

Microphony is essentially something that happens in sensitive valve preamplifiers. If it happens in solid-state power amplifiers the level is so far below the noise it is effectively non-existent.

Experiments on this sort of thing are rare (if not unheard of) and so I offer the only scrap of evidence I have. Take a microphone preamp operating at a gain of +70 dB, and tap the input capacitors (assumed electrolytic) sharply with a screwdriver; the preamp output will be dull thump, at low level. The physical impact on the electrolytics (the only components that show this effect) is hugely greater than that of any acoustic vibration; and I think the effect in power amps, if any, must be so vanishingly small that it could never be found under the inherent circuit noise.>>

http://www.dself.dsl.pipex.com/ampins/pseudo/subjectv.htm

Having that said, don't we all go that extra mile? I wouldn't know if I could hear any difference between Teflon and PVC isolated cable. I seriously doubt I could. Yet I will never know. Paying a $100 extra for that power cord is a low price to pay for a good night's sleep.

You probably know about the site already, so take this as info for the newbies.

<<"Microphony is an important factor in the sound of an amplifier, so any attempt at vibration-damping is a good idea."

Microphony is essentially something that happens in sensitive valve preamplifiers. If it happens in solid-state power amplifiers the level is so far below the noise it is effectively non-existent.

Experiments on this sort of thing are rare (if not unheard of) and so I offer the only scrap of evidence I have. Take a microphone preamp operating at a gain of +70 dB, and tap the input capacitors (assumed electrolytic) sharply with a screwdriver; the preamp output will be dull thump, at low level. The physical impact on the electrolytics (the only components that show this effect) is hugely greater than that of any acoustic vibration; and I think the effect in power amps, if any, must be so vanishingly small that it could never be found under the inherent circuit noise.>>

http://www.dself.dsl.pipex.com/ampins/pseudo/subjectv.htm

Having that said, don't we all go that extra mile? I wouldn't know if I could hear any difference between Teflon and PVC isolated cable. I seriously doubt I could. Yet I will never know. Paying a $100 extra for that power cord is a low price to pay for a good night's sleep.

Yet I will never know

But why? It's neither expensive nor time consuming. I wouldn't be suggesting the same to Mr Self as his inner ears were sadly amputated in a childhood accident.

I guess I was sort of cheating. I was talking about long-time degradation of PVC. There's no short-time degradation. And I do use PVC, 2.5 sqmm solid core in my diy distributor box. But much of my preference of Teflon (or similar type of compounds; Teflon is, after all, just a brand name) is about being safe rather than sorry. If I'm to spend $2,000 on my Garrard 301 I'm not going to be stingy about a couple of feet of internal wiring.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- General Interest

- Everything Else

- My DIY Rack project