Hi,

I just bought a el-cheapo drill press. A 'kinzo'. Is costed about 79 euro. I have a little question which I could not find (strangely) an answer to in google and diyaudio;

What is the best speed to drill 4.2mm and 5.2mm holes in 16mm thick aluminium??? I want to use the black&decker bullet drills.

I have a choice between 600rpm and 2600rpm...

Thanks,

Edwin

I just bought a el-cheapo drill press. A 'kinzo'. Is costed about 79 euro. I have a little question which I could not find (strangely) an answer to in google and diyaudio;

What is the best speed to drill 4.2mm and 5.2mm holes in 16mm thick aluminium??? I want to use the black&decker bullet drills.

I have a choice between 600rpm and 2600rpm...

Thanks,

Edwin

Any respectable drillpress will have pulleys on top to adjust the speed besides the two main speed settings.

The general rule is that speed is inversely proportional to the drill diameter.

In your particular case I would stick to the 600 setting and a nice and sharp drill bit.

You can always tell when you are doing good you need a minimum push and long Al curls (7-8cm) are generated during drilling. If the stuff looks chunky the drillbit is dull or you're going too slow.

The general rule is that speed is inversely proportional to the drill diameter.

In your particular case I would stick to the 600 setting and a nice and sharp drill bit.

You can always tell when you are doing good you need a minimum push and long Al curls (7-8cm) are generated during drilling. If the stuff looks chunky the drillbit is dull or you're going too slow.

grataku said:Any respectable drillpress will have pulleys on top to adjust the speed besides the two main speed settings.

The general rule is that speed is inversely proportional to the drill diameter.

I meant I can choose between; 600 900 1250 1750 2600 -rpm indeed with pulleys!

So what is the best speed from these 5?

Tnanks in advance!

Edwin

Generally for aluminum, the higher the speed you can get away with, the better. Up to 3/8" diameter you should be OK with 2600 rpm and up to 1/2" diameter 1750 rpm is still safe. But if for some reason you don't feel comfortable with higher speed, just reduce it. 600 rpm is way to slow for 5mm drill bit, but I like to use that speed when boring large holes for recessed screws (Allen type) with B&D bullet drill bits (and for mixing concrete )

)

1" is about 24.5mm.

1" is about 24.5mm.

Ik zeg het, Gamma!

I have a "Quantum", costing about 90 euros, but I think they are all from the same (used 2 be east) German factory.

It weighs about 23 kilos. Still wished I spend a few extra euros to buy me a Proxxon drill press.

Something like this:

I have a "Quantum", costing about 90 euros, but I think they are all from the same (used 2 be east) German factory.

It weighs about 23 kilos. Still wished I spend a few extra euros to buy me a Proxxon drill press.

Something like this:

An externally hosted image should be here but it was not working when we last tested it.

From the man that taps with a drill...

...and you know what happened when you tried that at home...

If you like to try that 1/2 an inch at 1750rpm make sure the piece is well fastened to the drill table!

Well make sure that's the case anyways!

...and you know what happened when you tried that at home...

Peter Daniel said:Generally for aluminum, the higher the speed you can get away with, the better. Up to 3/8" diameter you should be OK with 2600 rpm and up to 1/2" diameter 1750 rpm is still safe. But if for some reason you don't feel comfortable with higher speed, just reduce it. 600 rpm is way to slow for 5mm drill bit, but I like to use that speed when boring large holes for recessed screws (Allen type) with B&D bullet drill bits (and for mixing concrete)

1" is about 24.5mm.

If you like to try that 1/2 an inch at 1750rpm make sure the piece is well fastened to the drill table!

Well make sure that's the case anyways!

grataku said:From the man that taps with a drill...

...and you know what happened when you tried that at home...

If you like to try that 1/2 an inch at 1750rpm make sure the piece is well fastened to the drill table!

Well make sure that's the case anyways!

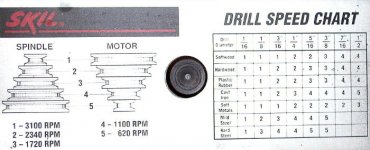

Those numbers are taken directly from the cover of my drill press

However anything like 5mm you can drill at any speed you feel comfortable, even 3200 rpm

Attachments

I've been reading messages on this forum for many months and have learned a great deal about all aspects of DIY audio (I haven't touched on the tube forum yet, though). I've never registered because I haven't felt I had anything to contribute, until I saw this thread. One thing I know a lot about is cutting metal. For what it's worth, my suggestions:

Cutting speed is typically measured in surface feet per minute (probably meters per minute for the rest of the world). To determine the SFM from RPM for a given size drill or other rotating cutting tool (or the workpiece, if it's being turned in a lathe), determine the circumference of the tool (pi*diameter (in feet)). Multiplying the result by the RPM gives surface feet per minute. To find the required RPM when the SFM is known, use a little algebra.

Typical cutting speeds for common materials include 500 SFM for aluminum, 100 SFM for mild steel, and 50 SFM for Stainless Steel. If you do the math, you end up with around 7500 RPM for a 6mm drill in aluminum. The point is, you'll probably not run your drill press too fast for drilling small holes in aluminum.

More important for drilling clean holes in aluminum is using a decent cutting fluid and clearing the chips out of the hole often. Aluminum tends to dissolve into the steel of the drill bit, gradually building up until the drill quits cutting and you a have an oversize, ragged hole (or broken drill bit). Lubrication prevents this. If you're drilling a lot of holes, find an industrial supplier and buy a cutting fluid made for aluminum. They're usually sold in small quantities. Common materials that work well include kerosene (almost as good as commercial products), beeswax, WD-40, and lard. Lubricating oils typically don't work as well. Back the bit out of the hole often to clear the chips and get the lubricant to the cutting edge.

Another important point, especially with materials like Stainless Steel, is to use enough pressure to make the bit cut. If it's not cutting, it's rubbing and getting dull. Push hard enough to produce chips (but not too hard with small bits).

Clamping the workpiece is important. A piece of aluminum spinning around at 3000 RPM is scary if you're sober.

Hopes this helps.

Joe

Cutting speed is typically measured in surface feet per minute (probably meters per minute for the rest of the world). To determine the SFM from RPM for a given size drill or other rotating cutting tool (or the workpiece, if it's being turned in a lathe), determine the circumference of the tool (pi*diameter (in feet)). Multiplying the result by the RPM gives surface feet per minute. To find the required RPM when the SFM is known, use a little algebra.

Typical cutting speeds for common materials include 500 SFM for aluminum, 100 SFM for mild steel, and 50 SFM for Stainless Steel. If you do the math, you end up with around 7500 RPM for a 6mm drill in aluminum. The point is, you'll probably not run your drill press too fast for drilling small holes in aluminum.

More important for drilling clean holes in aluminum is using a decent cutting fluid and clearing the chips out of the hole often. Aluminum tends to dissolve into the steel of the drill bit, gradually building up until the drill quits cutting and you a have an oversize, ragged hole (or broken drill bit). Lubrication prevents this. If you're drilling a lot of holes, find an industrial supplier and buy a cutting fluid made for aluminum. They're usually sold in small quantities. Common materials that work well include kerosene (almost as good as commercial products), beeswax, WD-40, and lard. Lubricating oils typically don't work as well. Back the bit out of the hole often to clear the chips and get the lubricant to the cutting edge.

Another important point, especially with materials like Stainless Steel, is to use enough pressure to make the bit cut. If it's not cutting, it's rubbing and getting dull. Push hard enough to produce chips (but not too hard with small bits).

Clamping the workpiece is important. A piece of aluminum spinning around at 3000 RPM is scary if you're sober.

Hopes this helps.

Joe

Here's another chart that you can print out:

http://www.woodmagazine.com/compstor/speedchart.pdf

http://www.woodmagazine.com/compstor/speedchart.pdf

Peter Daniel said:

1" is about 24.5mm.

Almost right 1" = 25.4 mm

http://www.wihatools.com/conversion.htm

Tazzy said:Duck, I should have known you had a drillpress... I kinda fubar-ed one of the zen heatsinks

Yes, I just red your post on hifi.nl.

Tazzy said:Duck, I should have known you had a drillpress... I kinda fubar-ed one of the zen heatsinks

Hi Tazzy,

pity about the heatsink, can you fix it or work around it? Was looking at the heatsink diagram on your website. Interesting use of the U bracket on top for additional heatsinking. Was wondering if you had considered two L shapes - one on the bottom as you have shown and one above where you now have the U. This would give twice as much coupling to the heatsink. However, the top surface is plastic so not as much heat can be transferred through this surface but it still might be worth it.

The top L bracket would need to be accurately drilled to get a tight sandwich of the FET. This accuracy could be reduced by bolting the upper L to the heatsink using a slot rather than a hole. This gives an adjustment mechanism. Slots are easy to cut in aluminium - just drill two holes side by side and file out.

James

vpharris said:Here's another chart that you can print out:

http://www.woodmagazine.com/compstor/speedchart.pdf

Thanks guys!

This was just the info I needed. I tried drilling om 1750 rpm with a 4.2mm hole and it went great! I messed up a piece of 16mm x 16mm aluminium bar by trying but I will get some new ones saturday... no problem. I will practice a bit more before I put the drill on my heatsinks though!

I surely beats using a normal drill machine and a shaky press holder for it. And it wins hands down from drilling out of hand!

Edwin

Hi,

In addition to what already is said. When drilling aluminium lubricate it with alcohol or spirit (just spiritus in Dutch ). But clean up your drilling machine and oil it after work done otherwise your drilling machine get very rusty. Use new standard HSS drills for best results and don’t use these drills for anything else. If you do a lot of drilling aluminium it is worth buying drills special designed for aluminium. But these are usually not available at a general DIY shop. You have to go to professional tool suppliers for these.

). But clean up your drilling machine and oil it after work done otherwise your drilling machine get very rusty. Use new standard HSS drills for best results and don’t use these drills for anything else. If you do a lot of drilling aluminium it is worth buying drills special designed for aluminium. But these are usually not available at a general DIY shop. You have to go to professional tool suppliers for these.

Cheers

In addition to what already is said. When drilling aluminium lubricate it with alcohol or spirit (just spiritus in Dutch

Cheers

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- General Interest

- Everything Else

- Drill aluminium