Exhaust builders and tuners claim that the exhaust sound has no influence on the gas velocity, but we know that any pipe can be tuned to match a sound wave, is it possible to tune an exhaust to match the engines exhaust ports sound wave?

What kind of calculations would one need to use?

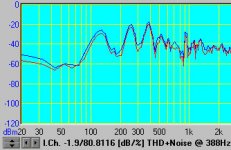

If this is the sound waves from the engines headers.

What kind of calculations would one need to use?

If this is the sound waves from the engines headers.

Attachments

This probably doesn't help you very much, but I know the speaker end of Jensen was experimenting with "speaker mufflers" on automobiles about 15 years back. Family member who I don't come into contact with much was working there. Goal was to eliminate traditional mufflers, gaining extra hp output out of the engine while keeping noise levels the same.

Who knows, you might be able to contact someone there who recalls some of the results.

Who knows, you might be able to contact someone there who recalls some of the results.

Actually that does help, I 'm trying to make an exhaust pipe that has the same resonance as the headers, the idea being to get the lowest impedance in the exhaust, I do not know how Pipe Organ makers or tuners build pipes to vent certain frequencies like 80hz, I am looking to have an exhaust that will resonate at 120Hz 240Hz and 440Hz as these are the main sound waves from my engines headers, I know this sound crazy but I have time and I have never found an acoustically tuned exhaust on a car.

Not crazy at all...."It's the cracked people of the world who let the light in!"

Not quite sure what you have in mind and there may be some confusion about terminology. Are you trying to generate an out of phase resonance that will cancell the existing noise? Or are you looking to reinforce the sound? There is a well developed science of the waves in both exhaust and inlet manifolds. (There are probably entire websites devoted to it.) By exploiting resonances designers can get more gas into and out of a cylinder than would first seem possible. When well done I understand that you can get greater than one atmosphere in the combustion chamber which is a bit "counter intuitive". It is linked with valve timing too and engine spped and only works over a relatively narrow rev' band. That is why they now try to have variable valve timing, variable inlet manifolds etc (Mercedes-Benz sports racers in the 1950'.) The serious texts will sometimes speculate about varyng the length of the exhaust pipe but I can't recall seeing one produced yet. But perhaps you know all this already.....in which case I'm sorry to chat away needlessly.

I am uncertain what you mean by the frequencies generated by the headers...... won't they change as soon as you fit an exhaust pipe to the end of them? Sorry, I'm a little in the dark here but good luck and I hope to learn more.

Not quite sure what you have in mind and there may be some confusion about terminology. Are you trying to generate an out of phase resonance that will cancell the existing noise? Or are you looking to reinforce the sound? There is a well developed science of the waves in both exhaust and inlet manifolds. (There are probably entire websites devoted to it.) By exploiting resonances designers can get more gas into and out of a cylinder than would first seem possible. When well done I understand that you can get greater than one atmosphere in the combustion chamber which is a bit "counter intuitive". It is linked with valve timing too and engine spped and only works over a relatively narrow rev' band. That is why they now try to have variable valve timing, variable inlet manifolds etc (Mercedes-Benz sports racers in the 1950'.) The serious texts will sometimes speculate about varyng the length of the exhaust pipe but I can't recall seeing one produced yet. But perhaps you know all this already.....in which case I'm sorry to chat away needlessly.

I am uncertain what you mean by the frequencies generated by the headers...... won't they change as soon as you fit an exhaust pipe to the end of them? Sorry, I'm a little in the dark here but good luck and I hope to learn more.

This isn’t going to help you any, but typically for highest performance the diameter of the pipe is selected based on the cubic inch displacement of the engine (the bigger the engine, the larger the diameter). The operating RPM range determines the optimal length of the pipe, the higher the RPM range the shorter the pipe. This is why you see very short pipes (zoomies) on dragsters. A proper length of pipe results in a reflected rarefaction at the port when the exhaust valve is open during over-lap, maximizing volumetric efficiency. Calculations can be used to get you in the ballpark, but the only way to really find the best combo for a given vehicle is dyno testing. I’ve seen guys actually place restrictions on the end of an exhaust pipe and pick up a few horsepower on the dyno because their exhaust system was too large. Sorry but I’m not enough of a geek to have any formulas for you (so without formulas why am I bothering to post?).

It is done and has been done for years.

It depends if you want maximum performance or maximum volume.

Also if you wish to improve performance at a particular engine speed.

The method I heard of someone using was to paint the exhaust in stripes of heat sensitive paint and run the engine with the exhaust at the desired speed and load on an engine dyno.

The exhaust system was 4 into 1 headers on a V8.

I cant remember if the pipe was cut at temp maximum or minimum, I do know the vehicle could be heard from nearly 20km away in the right weather. The driver and navigator wore earplugs and well padded helmets and still suffered hearing loss for several days.

No idea if the performance advantage.

Another concept is to construct headers with acoustic reflectors in the collector, the idea being to encourage resonance in the pipes to cause a pulse to bounce off the back of the exhaust valve of the next cylinder to open. Such a construction will most likely not fit under a car but would be excellent in a boat. the reinforcement will be most effective at certain engine speeds where you need the boost or if you are going for narrow bandwidth power.

There has been other discussion on here about intake tuning as well, do some searching.

It depends if you want maximum performance or maximum volume.

Also if you wish to improve performance at a particular engine speed.

The method I heard of someone using was to paint the exhaust in stripes of heat sensitive paint and run the engine with the exhaust at the desired speed and load on an engine dyno.

The exhaust system was 4 into 1 headers on a V8.

I cant remember if the pipe was cut at temp maximum or minimum, I do know the vehicle could be heard from nearly 20km away in the right weather. The driver and navigator wore earplugs and well padded helmets and still suffered hearing loss for several days.

No idea if the performance advantage.

Another concept is to construct headers with acoustic reflectors in the collector, the idea being to encourage resonance in the pipes to cause a pulse to bounce off the back of the exhaust valve of the next cylinder to open. Such a construction will most likely not fit under a car but would be excellent in a boat. the reinforcement will be most effective at certain engine speeds where you need the boost or if you are going for narrow bandwidth power.

There has been other discussion on here about intake tuning as well, do some searching.

kaos said:Calculations can be used to get you in the ballpark, but the only way to really find the best combo for a given vehicle is dyno testing. I’ve seen guys actually place restrictions on the end of an exhaust pipe and pick up a few horsepower on the dyno because their exhaust system was too large. Sorry but I’m not enough of a geek to have any formulas for you (so without formulas why am I bothering to post?).

Yours is the only really on topic post here, as far as I see. There are sort of competing requirements - least flow restriction requires large diameter, but making a very large pipe will affect low RPM horsepower because flow velocity (inertia) is too low to fully scavenge the charge. So you need to balance the requirements of restriction and minimum flow velocity with length. I am not sure how much of an effect exhaust tuning has, but intake tuning can have a 20% or so effect on volumetric efficiency in a specific narrow RPM range, IIRC. I have seen some dyno runs of different after market exhausts on 4 cylinders and they don't make that much difference, although the best are nearly as good (and as loud) as just taking the muffler off.

Active exhaust systems would probably be used to augment passive systems to reduce low frequency noise, since passive systems are best at the high frequency stuff. it basically works like a noise cancelling headset.

Good post. Also the 'tuning potential' of exhaust length, based on scavenging, is rather less than the benefits of getting the induction design right (which is also based on tuned lengths and helmholz resonators...)

Something that works against exhaust tuning by length is the high (and variable) temperature of the exhaust gases. This means the effective speed of sound inside the pipe (often 1000-1300m/s) and therefore the 'tuned length' required, varies somewhat. Many performance-orientated manufacturer's exhaust designs incorporate resonators which are actually quite deliberate in decoupling the exhaust length from the powerband; when sized for peak flow, the overall result is quieter, yet flows almost like a short open pipe at the top end ...

Finally, do you really want an engine which has a 'peaky' response ? Two-strokes are the exemplars of the drivability problems that can raise...

Something that works against exhaust tuning by length is the high (and variable) temperature of the exhaust gases. This means the effective speed of sound inside the pipe (often 1000-1300m/s) and therefore the 'tuned length' required, varies somewhat. Many performance-orientated manufacturer's exhaust designs incorporate resonators which are actually quite deliberate in decoupling the exhaust length from the powerband; when sized for peak flow, the overall result is quieter, yet flows almost like a short open pipe at the top end ...

Finally, do you really want an engine which has a 'peaky' response ? Two-strokes are the exemplars of the drivability problems that can raise...

Thank you for all the responses, the engine in question is turbo charged so the scavenge effect is different from a naturally aspirated engine I think?

The strange thing is the engines main resonance in the headers does not change with an RPM speed increase, it gets louder and quicker for sure, but the 120Hz 240 and 440Hz are are still the main sounds regardless of engine speed, this is what confused me and lead me to ask the question, can I tuned a length of pipe to this wave lengths.

I drove the car with the turbo vented to the atmosphere in the engine bay, no turbo flange cover or down pipe of any sort, this made the turbo spool up very quickly but the actual power was down in the high rpm range, I then weld on a 3 inch down pipe and the longer I made the pipe the more power the engine developed until I connected up the rear back box, it sapped the life from turbo spool up time and dropped the power under boost, I know the silencer function is to reduce sound pressure but it removed so much power in the process, I though there must be a better way.

The strange thing is the engines main resonance in the headers does not change with an RPM speed increase, it gets louder and quicker for sure, but the 120Hz 240 and 440Hz are are still the main sounds regardless of engine speed, this is what confused me and lead me to ask the question, can I tuned a length of pipe to this wave lengths.

I drove the car with the turbo vented to the atmosphere in the engine bay, no turbo flange cover or down pipe of any sort, this made the turbo spool up very quickly but the actual power was down in the high rpm range, I then weld on a 3 inch down pipe and the longer I made the pipe the more power the engine developed until I connected up the rear back box, it sapped the life from turbo spool up time and dropped the power under boost, I know the silencer function is to reduce sound pressure but it removed so much power in the process, I though there must be a better way.

If the engine is turbocharged, the exhaust length has NO bearing at all. All that is required is as low back-pressure as possible, because the turbine is driven by the difference in pressures across it.

I've had a succession of tuned turbo Saabs, amongts othe rtoys, and what seems to work well is a downpipe that expands smoothly from the turbo exhaust flange to a diameter appropriate to the target HP flow (eg 2.5- 3") - hint, smoothly.

After that, the rest of the exhaust system - providing only that it is not actively restrictive in terms of peak flow - has *very* little effect. HTH

I've had a succession of tuned turbo Saabs, amongts othe rtoys, and what seems to work well is a downpipe that expands smoothly from the turbo exhaust flange to a diameter appropriate to the target HP flow (eg 2.5- 3") - hint, smoothly.

After that, the rest of the exhaust system - providing only that it is not actively restrictive in terms of peak flow - has *very* little effect. HTH

martin clark said:If the engine is turbocharged, the exhaust length has NO bearing at all. All that is required is as low back-pressure as possible, because the turbine is driven by the difference in pressures across it.

I understand this theory well and agree with it in theory, but in reality cold air in the engine bay slows the exhaust turbine, this is why I was losing power without any pipe.

Originally posted by martin clark I've had a succession of tuned turbo Saabs, amongts othe rtoys, and what seems to work well is a downpipe that expands smoothly from the turbo exhaust flange to a diameter appropriate to the target HP flow (eg 2.5- 3") - hint, smoothly.

The car is also a Saab using the B202 turbo engines, I fabricated a very smooth flowing stainless steel 3 inch turbo down pipe all the way to the back box, but as soon as I connected the box it reduces or delayed throttle response and power at the top end of the engine.

The whole point is to experiment with this theory, I just want to find out if I can match the resonance of the engine by tuning the exhaust, I sampled the sound from the engine exhaust ports, then the headers and then the down pipe, I'm not sure how I could make an exhaust that would have a resonance of 120Hz 240 and 440hz, these are the fundamental harmonics from the engine.

Does anybody know about pipe organs? can a flip or lip be added inside the exhaust at various lengths for tuning?

Maybe your issue is the back box and not the piping. I thought turbos were less loud than NA on the exhaust side. Could you get away with a glasspack or two?

A link I found that might help?

http://www.fiatforum.com/cinquecento-seicento/44817-turbo-exhaust-design-theory-garrett.html

A link I found that might help?

http://www.fiatforum.com/cinquecento-seicento/44817-turbo-exhaust-design-theory-garrett.html

the exhaust and inlet are tuned to assist with cylinder filling.

The pressure pulse or hydraulic hammer is used to reflect off the first major change in pipe geometry.

The reflected wave has opposite pressure. This opposite pressure can suck more exhaust gases out of the cylinder and squeeze more inlet charge into the cylinders. This effect only works effectively over a narrow range of rpm variation, but it also gives some advantage at the harmonics.

The biggest effects tend to be seen when both inlet and exhaust are tuned for the same RPM, whether this be maximum power, or maximum torque, or very low end torque. This double tuning gives a very peaky power/torque curve that seems to flat spot either side of optimum RPM. It also suffers from odd flat spots lower down the rev range, it's them harmonics again.

Stagger tuning can give a wider spread of the desired characteristic.

Adjustable lengths can widen the usable range even further, but due to cost and reliability are often banned in competition.

The pressure pulse or hydraulic hammer is used to reflect off the first major change in pipe geometry.

The reflected wave has opposite pressure. This opposite pressure can suck more exhaust gases out of the cylinder and squeeze more inlet charge into the cylinders. This effect only works effectively over a narrow range of rpm variation, but it also gives some advantage at the harmonics.

The biggest effects tend to be seen when both inlet and exhaust are tuned for the same RPM, whether this be maximum power, or maximum torque, or very low end torque. This double tuning gives a very peaky power/torque curve that seems to flat spot either side of optimum RPM. It also suffers from odd flat spots lower down the rev range, it's them harmonics again.

Stagger tuning can give a wider spread of the desired characteristic.

Adjustable lengths can widen the usable range even further, but due to cost and reliability are often banned in competition.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- General Interest

- Everything Else

- Engine Exhaust tuning Question?