I'm rebuilding some old amplifiers and need to figure out which devices are within spec or failing. There are a lot of units available for decent prices and I don't want to end up regretting a purchase.

Are any of these transistor testers better than the others?

Heathkit IT-18

BK 520B

Sencore TR-15a

BK 162

regards and thanks for the help

Are any of these transistor testers better than the others?

Heathkit IT-18

BK 520B

Sencore TR-15a

BK 162

regards and thanks for the help

If the devices are silicon (as opposed to germanium) then they will either be faulty or OK rather than "OK but out of spec". Transistors don't deteriorate or age in that sense.

As to your specific question... well, I've never felt the need for a purpose designed tester tbh.

Maybe that's not much help

As to your specific question... well, I've never felt the need for a purpose designed tester tbh.

Maybe that's not much help

If the devices are silicon (as opposed to germanium) then they will either be faulty or OK rather than "OK but out of spec". Transistors don't deteriorate or age in that sense.

As to your specific question... well, I've never felt the need for a purpose designed tester tbh.

Maybe that's not much help

I guess that helps ;-)

Can you check a transistor in-circuit with a multi-meter and tell if it's good or bad?

I guess that helps ;-)

Can you check a transistor in-circuit with a multi-meter and tell if it's good or bad?

They either fail shorted or open. You can check for shorts with most meters. The notable exception is a Simpson Model 260.

For in circuit testing you are really looking to detect shorts or near shorts across the junctions. You really need to isolate two of the three leads to check for leakage and so on. I used to find (working in a service environment) that the real evidence of a faulty transistor was always in the interpretation of voltage/scope readings. Power devices always (99%) fail either short circuit or occasionally going open between base and emitter. Small signal circuitry is where it got interesting because failure is almost always non-destructive to the surrounding circuitry and the real fun of the chase was making informed decisions based on all the evidence of the activity around the device. The evidence is always there... its interpreting it

For general repair, basic checks with a meter suffice for most instances.

For general repair, basic checks with a meter suffice for most instances.

They either fail shorted or open. You can check for shorts with most meters. The notable exception is a Simpson Model 260.

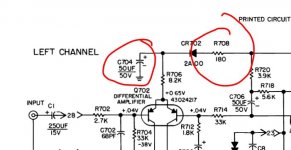

I've got a Citation Twelve with a faulty right channel. There's a burnt resistor and I'm trying to isolate the cause. The circuit uses a transistor to set the bias and I'm guessing that transistor (a 2N5232) is the source of my problem. With the amp plugged in, I'm reading 43 volts across that resistor.

I think I've found a manual. What's the resistor that's burning ?

R707

Last edited:

R707 other channelThere is only the cap that could cause that.

Thanks for the help.

The cap is the only low impedance path to draw the current that would damage the 180 ohm. The diode may have suffered with the overload though and should be replaced.

Have to leave it there for today, but if you get stuck or if there are other problems then there are ways and means of powering it all up safely (using a bulb tester). Confirm the output is at zero volts DC before connecting speakers.

Have to leave it there for today, but if you get stuck or if there are other problems then there are ways and means of powering it all up safely (using a bulb tester). Confirm the output is at zero volts DC before connecting speakers.

The cap is the only low impedance path to draw the current that would damage the 180 ohm. The diode may have suffered with the overload though and should be replaced.

Have to leave it there for today, but if you get stuck or if there are other problems then there are ways and means of powering it all up safely (using a bulb tester). Confirm the output is at zero volts DC before connecting speakers.

Thanks for the help. I have some components to order. The white caps look like cheap generics. I'm going to replace all of the electrolytics and diodes on the board. On the other channel, someone wired two 100uf 25v caps in series to get the 50uf called for in the schematic. The schematic, however, called for 50v caps.

I'm also going to replace the power supply caps as well. Someone replaced one cap out of four so the caps are mismatched.

May I suggest this: before you wholesale replace most of the parts on the thing, make it work first. Your resistor burnt up, and it appears the cap is at fault, so replace that. But see that the amp is stable and functions before changing all that stuff. Reason is this: if you change out 25 caps and a dozen diodes, that is close to 75 joints that must first be cleared of an old part then soldered under a new part. That is 75 more opportunities for some little error or mis-step to confuse repairing the amp.

Right now you know it is not working, but if you replace a bunch of stuff and then see if it works, and it doesn't, how can you be sure that the issue is not now something you did while changing parts. Believe me, we all have made bonehead moves with a soldering iron.

I am not telling you not to renew the circuit, just wait. The old caps may well be tired, but other than the out and put bad ones, right now all they will do is allow extra hum or diminished decoupling or some such. When the amp runs, then upgrade away.

Unless I missed something, why would you change out all the diodes?

Right now you know it is not working, but if you replace a bunch of stuff and then see if it works, and it doesn't, how can you be sure that the issue is not now something you did while changing parts. Believe me, we all have made bonehead moves with a soldering iron.

I am not telling you not to renew the circuit, just wait. The old caps may well be tired, but other than the out and put bad ones, right now all they will do is allow extra hum or diminished decoupling or some such. When the amp runs, then upgrade away.

Unless I missed something, why would you change out all the diodes?

I'm rebuilding some old amplifiers and need to figure out which devices are within spec or failing. There are a lot of units available for decent prices and I don't want to end up regretting a purchase.

Are any of these transistor testers better than the others?

Heathkit IT-18

BK 520B

Sencore TR-15a

BK 162

regards and thanks for the help

I usually start by checking in the pcb.

You can check for low/ high readings in different directions between BC and BE.

I usually find transistors shorted CE.

If you are not certain you could pull the transistors and check the HFE on a DMM.

Someone really caught me out once when the previous owner had stuck in a pnp instead of an npn !! HAd me scratching my head for a good half an hour.

May I suggest this: before you wholesale replace most of the parts on the thing, make it work first. Your resistor burnt up, and it appears the cap is at fault, so replace that. But see that the amp is stable and functions before changing all that stuff. Reason is this: if you change out 25 caps and a dozen diodes, that is close to 75 joints that must first be cleared of an old part then soldered under a new part. That is 75 more opportunities for some little error or mis-step to confuse repairing the amp.

Right now you know it is not working, but if you replace a bunch of stuff and then see if it works, and it doesn't, how can you be sure that the issue is not now something you did while changing parts. Believe me, we all have made bonehead moves with a soldering iron.

I am not telling you not to renew the circuit, just wait. The old caps may well be tired, but other than the out and put bad ones, right now all they will do is allow extra hum or diminished decoupling or some such. When the amp runs, then upgrade away.

Unless I missed something, why would you change out all the diodes?

A sensible aproach as you will know if anything has caused an error.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Design & Build

- Equipment & Tools

- vintage transistor testers