Hello guys

Some decades ago, I built a (very) small electroplating machine to do some casual gold and nickel plating, as well as doing aluminium anodising for my own use.

In recent years, I have used the equipment mostly for anodising but recently, a friend asked me to do some nickel plating on brass stanchions he made for a model loco tender.

Each of the stanchions weighs 1g and there are 34 of them.

Each stanchion was newly machined in brass and I pre-prepped them with degreaser and set the machine up complying with all the correct specs for the chemicals I use.

I keep on getting a sooty, black deposit on the items with very little nickel desposited.

From previous experience 15 years ago, I applied a current feed of .5ampere @ 2Vdc and surmise even this little current is too much hence the black sootiness.

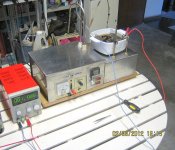

The first pic shows goldplating in progress, hence the muddy colour of the electrolyte.

What do you think?

bulgin

Some decades ago, I built a (very) small electroplating machine to do some casual gold and nickel plating, as well as doing aluminium anodising for my own use.

In recent years, I have used the equipment mostly for anodising but recently, a friend asked me to do some nickel plating on brass stanchions he made for a model loco tender.

Each of the stanchions weighs 1g and there are 34 of them.

Each stanchion was newly machined in brass and I pre-prepped them with degreaser and set the machine up complying with all the correct specs for the chemicals I use.

I keep on getting a sooty, black deposit on the items with very little nickel desposited.

From previous experience 15 years ago, I applied a current feed of .5ampere @ 2Vdc and surmise even this little current is too much hence the black sootiness.

The first pic shows goldplating in progress, hence the muddy colour of the electrolyte.

What do you think?

bulgin

Attachments

Last edited:

Hi,

I'm no expert (at all) but know that really good plating can require intermediate

layers from the main substrate to the final layer, good iron chromium plating

has little to do with the chromium thickness and everything to do with the

intermediate layers used to stabilise the overall crystal structure layers.

As far as I know in my limited knowledge, Brass as an alloy of Copper and

Zinc, is not a good substrate for electroplating, I've never come across

an application where it is plated (for good effect, rather than bling).

In my limited knowledge I think all alloys won't be good for plating as

you can only plate one element at a time. You might find though

for Nickel on Brass it can be done some with intermediate layers.

As far as I know good chromium plating has a copper, then nickel, then

chromium layer, so I'm assuming you might need to copper plate first.

rgds, sreten.

I haven't checked out good procedures for silver or gold plating brass.

I'm no expert (at all) but know that really good plating can require intermediate

layers from the main substrate to the final layer, good iron chromium plating

has little to do with the chromium thickness and everything to do with the

intermediate layers used to stabilise the overall crystal structure layers.

As far as I know in my limited knowledge, Brass as an alloy of Copper and

Zinc, is not a good substrate for electroplating, I've never come across

an application where it is plated (for good effect, rather than bling).

In my limited knowledge I think all alloys won't be good for plating as

you can only plate one element at a time. You might find though

for Nickel on Brass it can be done some with intermediate layers.

As far as I know good chromium plating has a copper, then nickel, then

chromium layer, so I'm assuming you might need to copper plate first.

rgds, sreten.

I haven't checked out good procedures for silver or gold plating brass.

Last edited:

Hi Guys

Thanks for your kind responses.

@ sreten

Merry Christmas and all the best for 2013

You may be right about the copper first. I have never done this on brass and it is very long ago that I plated nickel which I used mostly on antique watch cases before goldplating them.

I have some copper bits here which I will try to nickel plate tomorrow and see how it goes.

If I find a solution to the current problem, I will post here.

Regards

bulgin/ba

Thanks for your kind responses.

@ sreten

Merry Christmas and all the best for 2013

You may be right about the copper first. I have never done this on brass and it is very long ago that I plated nickel which I used mostly on antique watch cases before goldplating them.

I have some copper bits here which I will try to nickel plate tomorrow and see how it goes.

If I find a solution to the current problem, I will post here.

Regards

bulgin/ba

nickel likes to go over copper.

There are resources online that tell you all the tricks.

I am not near where I have it, but I have a book that outlines standard electroplating methods. I think the zinc is a problem...

Usually for chromium plating they go with copper first, then nickel then chromium...

_-_-bear

There are resources online that tell you all the tricks.

I am not near where I have it, but I have a book that outlines standard electroplating methods. I think the zinc is a problem...

Usually for chromium plating they go with copper first, then nickel then chromium...

_-_-bear

Hello guys

Prosperous, peaceful and happy New Year to you all.

I finally got the problem sorted and the job delivered.

It seems my original stock of nickel electrolyte was no good/contaminated or whatever after storing it for 15 years.

I found a recipe for nickel electrolyte on the web which works perfectly.

1litre of white vinegar, a teaspoon of salt and the same of sugar. And of course a few pieces of nickel and a bench powersupply.

The powersupply is pre-set to 12Vdc and the + terminal is attached to 1 piece of nickel and immersed in the vinegar solution.

The - terminal is attached to the other piece of nickel and the solution is aerated with eg a fish tank pump.

After a few hours with the current connected, the electrolyte will turn green and will be suitable to plate whatever you want with nickel.

bulgin

Prosperous, peaceful and happy New Year to you all.

I finally got the problem sorted and the job delivered.

It seems my original stock of nickel electrolyte was no good/contaminated or whatever after storing it for 15 years.

I found a recipe for nickel electrolyte on the web which works perfectly.

1litre of white vinegar, a teaspoon of salt and the same of sugar. And of course a few pieces of nickel and a bench powersupply.

The powersupply is pre-set to 12Vdc and the + terminal is attached to 1 piece of nickel and immersed in the vinegar solution.

The - terminal is attached to the other piece of nickel and the solution is aerated with eg a fish tank pump.

After a few hours with the current connected, the electrolyte will turn green and will be suitable to plate whatever you want with nickel.

bulgin

Looks like the nickel donor is actually "a nickel".

I'm amazed that such a crude solution works, although it's not impossible.

I set up my own galvanizing system for my raw speaker frames, but after 2 (successful) tries I dismounted everything and sold it.

***VERY*** nasty chemicals (and that's an understatement), many baths containing cyanide (which happens to improve the action) .... acid vapors and fumes ... forget it.

I usually get 50 12" speaker frames galvanized for around U$100 , or 2 bucks each ... not worth risking my life to save peanuts.

Let "them" breath those fumes.

I'm amazed that such a crude solution works, although it's not impossible.

I set up my own galvanizing system for my raw speaker frames, but after 2 (successful) tries I dismounted everything and sold it.

***VERY*** nasty chemicals (and that's an understatement), many baths containing cyanide (which happens to improve the action) .... acid vapors and fumes ... forget it.

I usually get 50 12" speaker frames galvanized for around U$100 , or 2 bucks each ... not worth risking my life to save peanuts.

Let "them" breath those fumes.

Hello guys

I finally got the problem sorted and the job delivered.

It seems my original stock of nickel electrolyte was no good/contaminated or whatever after storing it for 15 years.

I found a recipe for nickel electrolyte on the web which works perfectly.

bulgin

Hello

Where did you find this recipe on the internet ?

Thank

Bye

Gaetan

Usually just an acid for electroplating... there is somewhere on the web a neat site where a guy does "benchtop" anodizing, gets great results too... made me want to do it.

Hello

Can we use bulgin recipe's for copper electroplating (replacing nickel donor by copper) ?

And can we use bulgin recipe's for gold electroplating (replacing nickel donor by gold) ?

Thank

Bye

Gaetan

Last edited:

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Design & Build

- Equipment & Tools

- Electroplating Nickel on Brass