There was a question how I do recessed holes for hex screws.

I use Pilot Point, Twist Drills from DeWalt or from Black&Decker sold under "Bullet" name and available from Home Depot. Those are my favourite drill bits.

For screw head hole size I choose a drill bit next size up and measure the pilot size. I drill a pilot hole first. Then choose the slowest speed on my drill press (which for that purpose is necassary) and drill the big hole for the screw head (adjust the deph of the hole first). Than I drill through the final hole for the screw with a regular bit (because the pilot is smaller than screw size).

I use Pilot Point, Twist Drills from DeWalt or from Black&Decker sold under "Bullet" name and available from Home Depot. Those are my favourite drill bits.

For screw head hole size I choose a drill bit next size up and measure the pilot size. I drill a pilot hole first. Then choose the slowest speed on my drill press (which for that purpose is necassary) and drill the big hole for the screw head (adjust the deph of the hole first). Than I drill through the final hole for the screw with a regular bit (because the pilot is smaller than screw size).

Attachments

an idea

Peter,

Your current picture today in the Aleph X thread give me an idea of how to mount the heatsink to the chassis ... quickier and easier.

- We (because that's how I have seen it done) have always use "L" brackets or some form of small plate bar to "tie" the heatsinks to the chassis.

- How about just built the chassis first (whichever shape it may be) and then cut a big hole on the two side sheet metals to install the heatsinks. The hole on the 2 side sheet metals could be just big enough for the transistors to go through.

- It's much easier to work on the 6 rectangular sheet metals first ... instead of ... concerning of how to align the L brackets (or narrow metal bars), heatsinks and chassis together.

- Once the chassis is done. Cut the big/small rectangular holes on the side plates and bolt on the heatsinks! I believe this will be cleaner and quicker to built.

- Besides, the chassis acts like a huge heatsink too.

- As you know, I have cut rectangular holes with just a jig-saw with metal blades. Holes can be cut quite easily. If you screw up, you won't be able to see the bad cut from outside once the chassis has been put together.

Fellow Diyer's, comments please?

Peter,

Your current picture today in the Aleph X thread give me an idea of how to mount the heatsink to the chassis ... quickier and easier.

- We (because that's how I have seen it done) have always use "L" brackets or some form of small plate bar to "tie" the heatsinks to the chassis.

- How about just built the chassis first (whichever shape it may be) and then cut a big hole on the two side sheet metals to install the heatsinks. The hole on the 2 side sheet metals could be just big enough for the transistors to go through.

- It's much easier to work on the 6 rectangular sheet metals first ... instead of ... concerning of how to align the L brackets (or narrow metal bars), heatsinks and chassis together.

- Once the chassis is done. Cut the big/small rectangular holes on the side plates and bolt on the heatsinks! I believe this will be cleaner and quicker to built.

- Besides, the chassis acts like a huge heatsink too.

- As you know, I have cut rectangular holes with just a jig-saw with metal blades. Holes can be cut quite easily. If you screw up, you won't be able to see the bad cut from outside once the chassis has been put together.

Fellow Diyer's, comments please?

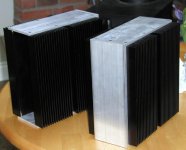

Even easier is to use heat sinks as part of a chassis and mount top and bottom plate directly to the heat sinks as I did here. No brackets required. It doesn't always look good cosmetically but I did it this way here because heat sinks had threaded holes already. Very easy and fast way to build a chassis, 4 plates, 2 heat sinks (or four in my case) and 18 screws. Back panel is mounted through the grooves in heat sink, so no screws were required, front panel uses only 2 screws. That's what I call good engineering.

Attachments

You should be reading introduction section more often. This one's for real.

This one's for real.

http://www.diyaudio.com/forums/showthread.php?s=&threadid=4868

http://www.diyaudio.com/forums/showthread.php?s=&threadid=4868

Building a chassis an aircraft style

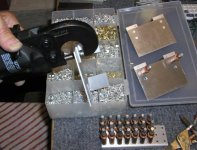

Some people were complaining about countless screws they had to put in when building their amps. Today I decided to use some of my aircraft tools and try riveting.

Today I decided to use some of my aircraft tools and try riveting.

Clecos were used to hold the parts together while drilling. After holes were open with size 40 drill bit and then size 30, I countersunk the holes for flush head rivets with piloted countersink.

Some people were complaining about countless screws they had to put in when building their amps.

Clecos were used to hold the parts together while drilling. After holes were open with size 40 drill bit and then size 30, I countersunk the holes for flush head rivets with piloted countersink.

Attachments

After deburring the holes I used a squeeze gun to install the rivets. It was actually the first time that I tried that technique at home, but I must say that I like the results and I will do it more often For anybody interested in obtaining some of the tools I used here, http://www.yardstore.com/ offers good selection and prices on used aircraft tools an accessories.

For anybody interested in obtaining some of the tools I used here, http://www.yardstore.com/ offers good selection and prices on used aircraft tools an accessories.

Attachments

...some help?

I hate to be a threadjacker, but this is in the same genre...

I'm in the process of making an amp based around ESP P88 preamp and 2 ESP P3A amp boards (passive bi-amp - I would go active but I don't want to kill my lovely B&W 603-S3's).

Anyway the question I had was where to find good heatsinks and cases (pre-made - I don't have time to make) for the amp in the UK?

The sinks need to be about 1deg C/Watt

Also any ideas about cases with heatsinks available in the UK - I was thinking of buying a Maplin (UK electronics distributor) rackmount case and using heatsinks internally, but if anyone can suggest a good distibutor of cases with combined sinks in the UK that would be great.

Also I don't want to spend the earth (I am a student).

I hate to be a threadjacker, but this is in the same genre...

I'm in the process of making an amp based around ESP P88 preamp and 2 ESP P3A amp boards (passive bi-amp - I would go active but I don't want to kill my lovely B&W 603-S3's).

Anyway the question I had was where to find good heatsinks and cases (pre-made - I don't have time to make) for the amp in the UK?

The sinks need to be about 1deg C/Watt

Also any ideas about cases with heatsinks available in the UK - I was thinking of buying a Maplin (UK electronics distributor) rackmount case and using heatsinks internally, but if anyone can suggest a good distibutor of cases with combined sinks in the UK that would be great.

Also I don't want to spend the earth (I am a student).

Peter Daniel said:I'm thinking about building a small aeroplane in my backyard...

There is a company (can't remember who) that makes plane kits!

That has to be the ultimate DIY feat!

The kits are like the ones you may have made as a child - you get a series of flat packs of plywood and literaly just glue them together and source and engine!

Crazy huh

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Design & Build

- Equipment & Tools

- Useful tools and techniques