Hi there,

It is an idea I toyed with for a long time, but this time, I actually made it.

I need a very small tinning bath, because my "complex" digital prototypes are wired using the émafil technique:

Until now, I was tinning the wire ends with a soldering iron, but a bath is much more practical.

Here is a description of my build.

I started with a 82Ω 7W vitrified WW resistor, heat-resistant cable and tubing, a bit of non-woven fiberglass sheet, a 6mm metric bolt made of stainless steel (important), a piece of thin-walled stainless steel tube and a stand.

The end of the bolt has its diameter reduced to 5mm for a 7mm length, to allow the insertion into the resistor.

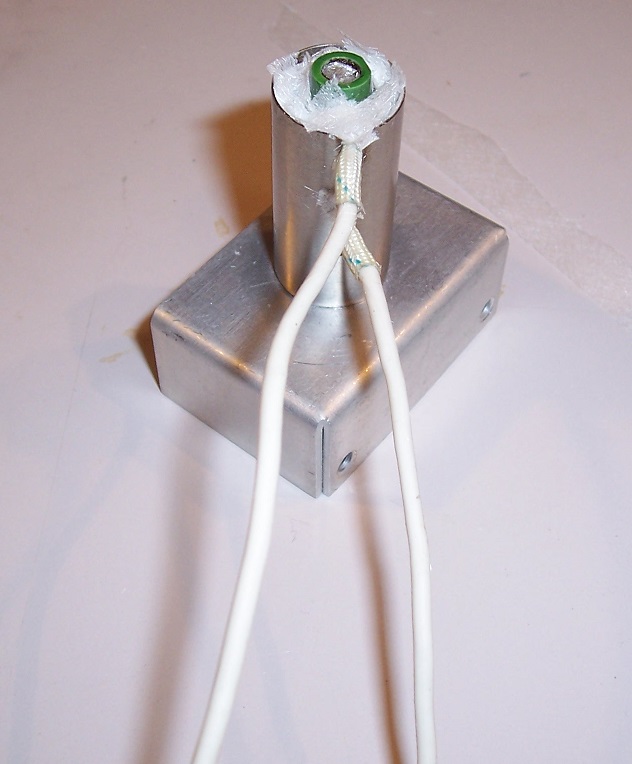

The assembled thing looks like this:

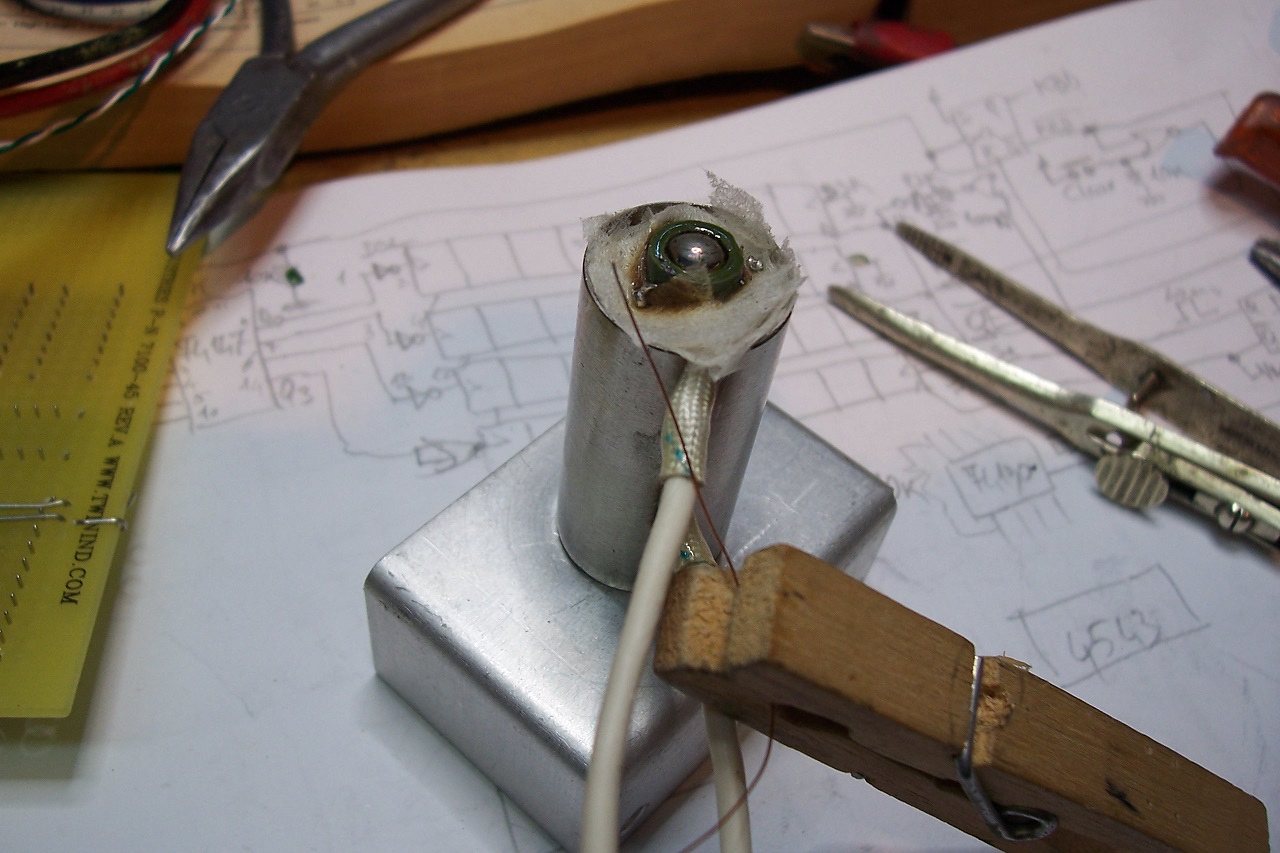

Here it is in action, fed by a 30V DC supply:

Afterwards, I found that I could protect the solder surface from oxidation using a mix of sodium borate and boric acid: they form a brittle and crumbly crust that is easily penetrated by a wire, even a thin one.

There are probably more suitable compounds, but it is a good beginning

It is an idea I toyed with for a long time, but this time, I actually made it.

I need a very small tinning bath, because my "complex" digital prototypes are wired using the émafil technique:

Until now, I was tinning the wire ends with a soldering iron, but a bath is much more practical.

Here is a description of my build.

I started with a 82Ω 7W vitrified WW resistor, heat-resistant cable and tubing, a bit of non-woven fiberglass sheet, a 6mm metric bolt made of stainless steel (important), a piece of thin-walled stainless steel tube and a stand.

The end of the bolt has its diameter reduced to 5mm for a 7mm length, to allow the insertion into the resistor.

The assembled thing looks like this:

Here it is in action, fed by a 30V DC supply:

Afterwards, I found that I could protect the solder surface from oxidation using a mix of sodium borate and boric acid: they form a brittle and crumbly crust that is easily penetrated by a wire, even a thin one.

There are probably more suitable compounds, but it is a good beginning

Attachments

Last edited:

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.