I've been talking to a guy who makes a piece of test equipment that keeps quoting the accuracy specification of his device when I'm really interested in repeatability.

He seems to be saying that each measurement of a component stands on its own and if it is within the quoted accuracy of the test gear then it is ok.

My contention is that if (for example) a 1k ohm resistor measures differently every time it is measured, it is not helpful even if it is within the stated accuracy. It does no good to measure two identical resistors and get two different readings even if they are within the stated accuracy.

Am I asking for too much?

He seems to be saying that each measurement of a component stands on its own and if it is within the quoted accuracy of the test gear then it is ok.

My contention is that if (for example) a 1k ohm resistor measures differently every time it is measured, it is not helpful even if it is within the stated accuracy. It does no good to measure two identical resistors and get two different readings even if they are within the stated accuracy.

Am I asking for too much?

My contention is that if (for example) a 1k ohm resistor measures differently every time it is measured,

it is not helpful even if it is within the stated accuracy.

Repeatability is usually better than the absolute accuracy for most typical test equipment, but you'll seldom find an actual spec on it.

Sounds like you want something with the tighter tolerance that you really want.

Last edited:

Are we talking about the difference between precision and accuracy?

I don't think so. For example, in my line of work (controls for refineries and chemical plants), absolute accuracy is not nearly as important as repeatability.

For example, if a pressure in a line is actually 100 psig but the transmitter shows 99.5 and always shows 99.5 when it is 100, then it is a good thing.

If sometimes is shows 99.6 and sometimes 100.5, it may be within its stated accuracy but the process is not going to have very good control.

I've been talking to a guy who makes a piece of test equipment that keeps quoting the accuracy specification of his device when I'm really interested in repeatability.

He seems to be saying that each measurement of a component stands on its own and if it is within the quoted accuracy of the test gear then it is ok.

My contention is that if (for example) a 1k ohm resistor measures differently every time it is measured, it is not helpful even if it is within the stated accuracy. It does no good to measure two identical resistors and get two different readings even if they are within the stated accuracy.

Am I asking for too much?

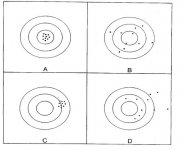

What you are asking for is the precision of the instrument. Precision is how close reads on identical values are. See the following image:

There is a reason that precision is not discussed for most, if not all instruments. Precision on most instruments is VERY VERY high, within one count or less if measured near in time to each other. This is due to the nature of the measurement system on the devices. Most use a dual-slope or multi-slope converter (though delta-sigma devices are slowly getting more common). Most systems find a way to test the voltage of a system, whether it be voltage drop across a resistor, current is turned to voltage using a shunt resistor or voltage is measured directly. The reason for this is the dual/multi-slope converters measure voltage. The benefits of the slope-converter system is that most of the errors can be compensated for during calibration, as a result the reading basically depends on the timing constant and the device under test. The one caveat is that some parts of the system are temperature sensitive and can drift a bit during operation. This is why I said that devices tested near in time to each other.

I've been talking to a guy who makes a piece of test equipment that keeps quoting the accuracy specification of his device when I'm really interested in repeatability.

He seems to be saying that each measurement of a component stands on its own and if it is within the quoted accuracy of the test gear then it is ok.

My contention is that if (for example) a 1k ohm resistor measures differently every time it is measured, it is not helpful even if it is within the stated accuracy. It does no good to measure two identical resistors and get two different readings even if they are within the stated accuracy.

Am I asking for too much?

What you want is actually more accuracy. You want a test equipment to make same/near mistake at each measure which will be a calibration matter for the equipment.

ıf the manufacturer could make it as you want, they would sell it with higher accuracy specification in its manual only after making a new calibration.

What you want is actually more accuracy. You want a test equipment to make same/near mistake at each measure which will be a calibration matter for the equipment.

ıf the manufacturer could make it as you want, they would sell it with higher accuracy specification in its manual only after making a new calibration.

Then how would you explain these specs of a Voltcraft BL-10 Luxmeter:

Accuracy:

± 5% ± 10 lx/fc (< 10,000 lx/fc)

± 10% ± 10 lx/fc (> 10,000 lx/fc)`

Repeatability:

± 2%

I'd compare these specs with the target practise image in the upper right corner: not particularly accurate, but each measurement yields the same result, so despite the poor accuracy it is repeatable. That contradicts your premise that accuracy is necessary for repeatability.

Edit: here's a document on repeatability that graphically shows that repeatability is a function of precision rather than accuracy. No surprise it shows some similarities with PedroDaGr8's images.

Analogue to measurements: a bad accuracy is the result of an offset, or something, but the results are repeatable. If the results were not repeatable, then that would probably be the result of a drifting reference value.

Last edited:

If the results were not repeatable, then that would probably be the result of a drifting reference value.

Lets start using the right term: precision. Precision is how close the measurements are of an identical value under test. Precision can be affected by a variety of things, temperature drift, aging, noise, device warm-up (related to temperature drift), instability, etc.

Then how would you explain these specs of a Voltcraft BL-10 Luxmeter:

Accuracy:

± 5% ± 10 lx/fc (< 10,000 lx/fc)

± 10% ± 10 lx/fc (> 10,000 lx/fc)`

Repeatability:

± 2%

I'd compare these specs with the target practise image in the upper right corner: not particularly accurate, but each measurement yields the same result, so despite the poor accuracy it is repeatable. That contradicts your premise that accuracy is necessary for repeatability.

Edit: here's a document on repeatability that graphically shows that repeatability is a function of precision rather than accuracy. No surprise it shows some similarities with PedroDaGr8's images.

Analogue to measurements: a bad accuracy is the result of an offset, or something, but the results are repeatable. If the results were not repeatable, then that would probably be the result of a drifting reference value.

Good link it is.

Maybe we should keep this in mind: Repeatibility is something inside the borders of "accuracy" which we dont know at each measurement how far from the real value but never outside of accuracy borders.

Attachments

It might be helpful if you explained your measurement application a bit further.

For most reputable manufacturers of measurement equipment- if it is not explicitly stated- the repeatability parameter is cooked into the accuracy.

If you want really high repeatability, you could keep a reference resistor on hand and just do a differential measurement. A reference resistor would give you a pretty stable baseline.

Sent from my iPhone using Tapatalk

For most reputable manufacturers of measurement equipment- if it is not explicitly stated- the repeatability parameter is cooked into the accuracy.

If you want really high repeatability, you could keep a reference resistor on hand and just do a differential measurement. A reference resistor would give you a pretty stable baseline.

Sent from my iPhone using Tapatalk

What is the duration over which these measurements are being taken?

The term "repeatability" usually only applies to successive measurements; beyond that, you're actually talking about "drift" or "stability".

And why are you measuring the same resistor multiple times? The resistor will likely be more stable than your meter.

Sent from my iPhone using Tapatalk

The term "repeatability" usually only applies to successive measurements; beyond that, you're actually talking about "drift" or "stability".

And why are you measuring the same resistor multiple times? The resistor will likely be more stable than your meter.

Sent from my iPhone using Tapatalk

After reading through the thread, I'd say yes, and the only way to get what you want is to characterize the test equipment yourself: repeatedly measure something with a fixed value such as the "resistor" you mentioned, and do statistics on the measurements. This could be a series of tests/characterizations - one for varying line voltage (while, of course, keeping all other possible variables constant), one for varying temperature, one where everything is kept the same as much as possible, etc.I've been talking to a guy who makes a piece of test equipment that keeps quoting the accuracy specification of his device when I'm really interested in repeatability.

...

Am I asking for too much?

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Design & Build

- Equipment & Tools

- Repeatability?