Here a link to what I found:

But funny, now there seems to be more pics than there was before. I don't know how that I missed the others.

Front Panel Express: Custom Front Panel Designs & Enclosures - Nameplates - Signs

I'm trying to figure out their price differentials. Chicken - Mid price $44 - $26. Sea Horse - Lower price $23. - $17. Business wall plate - Highest price $109. Laser warning - undisclosed $?????

Jazbo, David

I'd like you guys to be more like

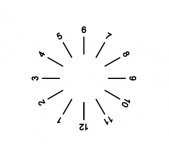

and let me know if there a way using this program to make the numbers around a circle like a knob or switch? Like Terry did in word.

I've played around for a bit in Front Panel Express (FPX) the skirt but it's not a panel. David, yep it does feel like unfinished software.

I hate it when seemingly simple things become a project.

I've made circles and centered, but can't make a circle of text so it doesn' t look obvious.

Any help would be appraciated.

I guess it won't do it. I think FPX people use Corel for that, then import it. If you go to make anything, they want an additional $30.00 for machine programming.

Jazbo,

You cannot create curved text objects with this program w/o extraordinary non-worthwhile effort.

FPX recommends using vectored programs such as COREL, Illustrator etc and importing them. Page 5 of their forum.

Which I had, but then you have to pay almost full price of them again in WIN 7, win 8, etc.

Terry, I'm trying to tweak the text in the file you supplied. Can you check for me the Font name and Size you used?

It doesn't come across in the never version of word.

I have that "special" version of office with word, excel etc, where microsoft crams everything down your throat.

The whole new interface blows and it saves as a .docx.

But funny, now there seems to be more pics than there was before. I don't know how that I missed the others.

Front Panel Express: Custom Front Panel Designs & Enclosures - Nameplates - Signs

I'm trying to figure out their price differentials. Chicken - Mid price $44 - $26. Sea Horse - Lower price $23. - $17. Business wall plate - Highest price $109. Laser warning - undisclosed $?????

Jazbo, David

I'd like you guys to be more like

and let me know if there a way using this program to make the numbers around a circle like a knob or switch? Like Terry did in word.

I've played around for a bit in Front Panel Express (FPX) the skirt but it's not a panel. David, yep it does feel like unfinished software.

I hate it when seemingly simple things become a project.

I've made circles and centered, but can't make a circle of text so it doesn' t look obvious.

Any help would be appraciated.

I guess it won't do it. I think FPX people use Corel for that, then import it. If you go to make anything, they want an additional $30.00 for machine programming.

Jazbo,

You cannot create curved text objects with this program w/o extraordinary non-worthwhile effort.

FPX recommends using vectored programs such as COREL, Illustrator etc and importing them. Page 5 of their forum.

Which I had, but then you have to pay almost full price of them again in WIN 7, win 8, etc.

Terry, I'm trying to tweak the text in the file you supplied. Can you check for me the Font name and Size you used?

It doesn't come across in the never version of word.

I have that "special" version of office with word, excel etc, where microsoft crams everything down your throat.

The whole new interface blows and it saves as a .docx.

Jazbo, David

I'd like you guys to be more like

and let me know if there a way using this program

to make the numbers around a circle like a knob

or switch? Like Terry did in word.

I've played around for a bit in Front Panel Express (FPX)

the skirt but it's not a panel.

David, yep it does feel like unfinished software.

I hate it when seemingly simple things become a project.

I've made circles and centered, but can't make a

circle of text so it doesn' t look obvious.

Any help would be appraciated.

I guess it won't do it. I think FPX people

use Corel for that, then import it. If you go to

make anything, they want an additional $30.00

for machine programming.

Front Designer

Merry Christmas.

Attachments

Rub-on's an some clear coat over it?

-RM

That's that the way I used to do it.

Letter set and clear coat.

Works really well if you have the patients.

Looks professional. Never comes off.

David, Richard,

Yes, that is what I was thinking.

Making the same kind of template that

I can read on the skirt and clear coating.

I figured with a tad more effort, I could

make the concentric rings of numbers that HP did.

the print to decal.

David that looks nice.

Too bad I don't have a Twin T.

Do you know how to rotate the numbers

for the vectors? or Azmith?

Or

How did you do that?

I've got the outside and concentrics done.

Just don't know how to rotate them and place

numerically each individually. They have to be

tanget to the origin, which I placed in the center.

I'll have to find the old XP on my other computer and

try to load it back on and use the software again.

hmmm, the wife cleaned, placed the CD in a bag,

with notes for something else, then placed them in

a box of amplifer parts and tubes, then put non related stuff

with it and put it somewhere I'll find next year.

Two years looking and I found a rehostat (sp) for the sewing

machine with the tools for my rose garden.

I'm still looking for the rehostat for my hand drill,

like a dremel tool but with wheels and bands to

drive it.

In the next month or two my little girl will start walking.

Maybe I don't need to find that other rehostat.

Yes, that is what I was thinking.

Making the same kind of template that

I can read on the skirt and clear coating.

I figured with a tad more effort, I could

make the concentric rings of numbers that HP did.

the print to decal.

David that looks nice.

Too bad I don't have a Twin T.

Do you know how to rotate the numbers

for the vectors? or Azmith?

Or

How did you do that?

I've got the outside and concentrics done.

Just don't know how to rotate them and place

numerically each individually. They have to be

tanget to the origin, which I placed in the center.

I'll have to find the old XP on my other computer and

try to load it back on and use the software again.

hmmm, the wife cleaned, placed the CD in a bag,

with notes for something else, then placed them in

a box of amplifer parts and tubes, then put non related stuff

with it and put it somewhere I'll find next year.

Two years looking and I found a rehostat (sp) for the sewing

machine with the tools for my rose garden.

I'm still looking for the rehostat for my hand drill,

like a dremel tool but with wheels and bands to

drive it.

In the next month or two my little girl will start walking.

Maybe I don't need to find that other rehostat.

David, Richard,

Yes, that is what I was thinking.

Making the same kind of template that

I can read on the skirt and clear coating.

I figured with a tad more effort, I could

make the concentric rings of numbers that HP did.

the print to decal.

David that looks nice.

Too bad I don't have a Twin T.

Do you know how to rotate the numbers

for the vectors? or Azmith?

Or

How did you do that?

I've got the outside and concentrics done.

Just don't know how to rotate them and place

numerically each individually. They have to be

tanget to the origin, which I placed in the center.

I'll have to find the old XP on my other computer and

try to load it back on and use the software again.

hmmm, the wife cleaned, placed the CD in a bag,

with notes for something else, then placed them in

a box of amplifer parts and tubes, then put non related stuff

with it and put it somewhere I'll find next year.

Two years looking and I found a rehostat (sp) for the sewing

machine with the tools for my rose garden.

I'm still looking for the rehostat for my hand drill,

like a dremel tool but with wheels and bands to

drive it.

In the next month or two my little girl will start walking.

Maybe I don't need to find that other rehostat.

I'm not sure what software you have. Front design is not the same software as Front Panel Express.

Front design has a wicked learning curve and it's clumsy.

Last edited:

HP339a Output

David, or Anyone for that matter?

How difficult or easy would it be to have a switch or change

the output impediance of the 339a?

I know there was some discussion about pros and cons of it.

something like three position 50 ohm, 130 ohm, 600 ohm?

Is it possible to make a simple direct out then going into

a impedance box that would switch between the three for

what is needed?

Cheers

David, or Anyone for that matter?

How difficult or easy would it be to have a switch or change

the output impediance of the 339a?

I know there was some discussion about pros and cons of it.

something like three position 50 ohm, 130 ohm, 600 ohm?

Is it possible to make a simple direct out then going into

a impedance box that would switch between the three for

what is needed?

Cheers

Sorry about that, I had it mixed up with Front Designer... But I found another site that does knob scales, please take a look here.Jazbo,

You cannot create curved text objects with

this program w/o extraordinary non-worthwhile effort.

It is very easy to eliminate the 600 ohm series resistor.... doesnt become unstable... but just drive mostly resistive high Z loads and maybe dont short the output for long time.

The 600 ohms comes from a power resistor near the front right pcb... near the big relay. Jumper it out and you have low Z output... or parallel it to get value you want.

Then test to see if distortion increased -- if the DUT is a low Z load (<600 Ohms).

THx-RNMarsh

The 600 ohms comes from a power resistor near the front right pcb... near the big relay. Jumper it out and you have low Z output... or parallel it to get value you want.

Then test to see if distortion increased -- if the DUT is a low Z load (<600 Ohms).

THx-RNMarsh

@Jazbo,

Thanks for trying. That doesn't work though.

If you look at Terry's file you'll understand.

These aren't printed on the surface, but the numbers

are part of the switch which rotates. The numbers need

to be on a radius to the center and tanget to it.

I 'll look and find something figure something out.

I found a back up to CD with some of my legacy

apps on it so all hope isn't lost.

@Richard,

That is simple enough. Just fact finding before opening up the 339A

and starting. Probably be a little bit as I have to put her in the Queue.

Wondering also how the Bruel & Kjaer 1607 Passive/Active works?

Are you using that from HP339a Oscillator-->BK1607-->QA400FFT?

Looking for a sound card that will interface to it simply and

probably try to find and @Juli that Demian says works simply.

I imagine that I would capture that on screen and could also use

that Daydic (sp) software to combine multiple FFT plots?

Thinking this could also be used as a curve tracer for tubes and

ICs, and other ELE gear to match, test, cal etc. Being able to

have the flexibility to dial in a lot of gear for minamal or types

of pleasing distortion if desirable.

I'm starting to get it. Thanks Gentlemen.

Thanks for trying. That doesn't work though.

If you look at Terry's file you'll understand.

These aren't printed on the surface, but the numbers

are part of the switch which rotates. The numbers need

to be on a radius to the center and tanget to it.

I 'll look and find something figure something out.

I found a back up to CD with some of my legacy

apps on it so all hope isn't lost.

@Richard,

That is simple enough. Just fact finding before opening up the 339A

and starting. Probably be a little bit as I have to put her in the Queue.

Wondering also how the Bruel & Kjaer 1607 Passive/Active works?

Are you using that from HP339a Oscillator-->BK1607-->QA400FFT?

Looking for a sound card that will interface to it simply and

probably try to find and @Juli that Demian says works simply.

I imagine that I would capture that on screen and could also use

that Daydic (sp) software to combine multiple FFT plots?

Thinking this could also be used as a curve tracer for tubes and

ICs, and other ELE gear to match, test, cal etc. Being able to

have the flexibility to dial in a lot of gear for minamal or types

of pleasing distortion if desirable.

I'm starting to get it. Thanks Gentlemen.

@Jazbo,

Thanks for trying. That doesn't work though.

If you look at Terry's file you'll understand.

These aren't printed on the surface, but the numbers

are part of the switch which rotates. The numbers need

to be on a radius to the center and tanget to it.

FrontDesigner 3.0 can do something like this.

Larry

Attachments

In Front design you set 'rotating test' to yes.

This will give what you want. Just keep in mind that nothing can be edited after creating an object. If you want to change something you have to start all over again.

@Davada: Does that mean you can save before "creating" an object.

or is the object created for output. I haven't looked at

front designer yet.

Doesn't sound too user friendly, once the thing is object,

then that's it. On larger stuff if you have a typo or something

changes then your screwed eh?

@DDB: Yes, that is it. In that case that would be at 30 degree angles.

It is not user friendly, can be quite frustrating but least expensive SW for simple panels I could find.@Davada: Does that mean you can save before "creating" an object.

or is the object created for output. I haven't looked at

front designer yet.

Doesn't sound too user friendly, once the thing is object,

then that's it. On larger stuff if you have a typo or something

changes then your screwed eh?

@DDB: Yes, that is it. In that case that would be at 30 degree angles.

The scales can be saved and reused or edited before inserting them in a panel. Once in the panel no mods allowed but can delete from panel and reinsert an edited scale if you previously saved it.

The way you need to use, the scales will not be inserted into a panel design so you can save and edit as you like. I havent worked out how the numbers will be transferred to the dial but maybe a clear decal type material with stickum on the front side and pressed onto the rear face of the knob.

Larry

@Davada: Does that mean you can save before "creating" an object.

or is the object created for output. I haven't looked at

front designer yet.

Doesn't sound too user friendly, once the thing is object,

then that's it. On larger stuff if you have a typo or something

changes then your screwed eh?

@DDB: Yes, that is it. In that case that would be at 30 degree angles.

Everything is built from smaller objects. If you want to change some in an object then yes you have to start again. On the TT example label is an object. Once you have it down it doesn't take to long to do. But this is the down fall. No idea why they did it this way. What's wrong with vector graphics?

I think the guy that wrote it didn't know how to do it any other way. Mind you Microsoft did the same with Visio.

Nothing wrong with vector graphics...

...'cept the expense. Vector graphics are scaleable.

Illustrator, Photoshop, corel, and others....

Then the clothing people all use vector graphics

from the custom sewer to monogramers and manufactuers.

I was surprised when I was talking to a lady about sewing

some trouser hems and asked about clothing and other stuff.

I guess she and her crew make clothes from the scratch and

the custom make them until the the "big" order. On the Big

order they then send them out to a pattern person and then

vector them up or down to size by a scaler.

Once those are approved they go over seas to china

for manufacter. That is the process as I recall, not sure

of the exact terminology. I was surprised at the vectoring.

Same with the embroydery (sp) company. They were shut down

because their system guy upgraded the plant to Windows 8.

Nothing worked. Not sure how they worked around it.

I eventually got my shirts in time for our pre-production meeting.

Anyway,

Looks like all the software is about $500 per suite.

Or $299 each.

I"ll have to shop or friend a demo/student program.

or relurn some older back up stuff that can do the job.

Looking for it,

FrontDesigner 3.0 from ABACOM

FrontDesigner

or

Cetina Front Panel Designer

Cetina Front Panel Designer - Free download and software reviews - CNET Download.com

Is there a spell checker with DIY? I thought I found it once,

but recently can't seem to find the right icon any more.

Thanks for your suggestions. I'll figure it out.

It didn't take me long to Max out Front Panel Express.

...'cept the expense. Vector graphics are scaleable.

Illustrator, Photoshop, corel, and others....

Then the clothing people all use vector graphics

from the custom sewer to monogramers and manufactuers.

I was surprised when I was talking to a lady about sewing

some trouser hems and asked about clothing and other stuff.

I guess she and her crew make clothes from the scratch and

the custom make them until the the "big" order. On the Big

order they then send them out to a pattern person and then

vector them up or down to size by a scaler.

Once those are approved they go over seas to china

for manufacter. That is the process as I recall, not sure

of the exact terminology. I was surprised at the vectoring.

Same with the embroydery (sp) company. They were shut down

because their system guy upgraded the plant to Windows 8.

Nothing worked. Not sure how they worked around it.

I eventually got my shirts in time for our pre-production meeting.

Anyway,

Looks like all the software is about $500 per suite.

Or $299 each.

I"ll have to shop or friend a demo/student program.

or relurn some older back up stuff that can do the job.

Looking for it,

FrontDesigner 3.0 from ABACOM

FrontDesigner

or

Cetina Front Panel Designer

Cetina Front Panel Designer - Free download and software reviews - CNET Download.com

Is there a spell checker with DIY? I thought I found it once,

but recently can't seem to find the right icon any more.

Thanks for your suggestions. I'll figure it out.

It didn't take me long to Max out Front Panel Express.

Yes, the 339 output really is 600 Ohms and I should have mentioned that since this is a 339 thread. I thought Gwalters was asking about some other (non-specified) generator). It may also be a true 600 ohm output impedance, but I have seen some that are not, that's why I mentioned it. I don't know how common it is.

Yetty

Hi TerrySt,

I know this is a pretty old topic, but I could use some advice about my HP 339A which I've had for several years. It works fine except for the oscillator, which outputs a sine wave clipped very symmetrically top and bottom. I suspect the output error circuit IC chip may be to blame, but I can't seem to prove it conclusively enough to face the grim prospect of trying to remove the oscillator circuit board to do the work. I have read with great interest your description of your repairs to your 339, and have the following question:

Is there a relatively easy way to remove the Osc circuit board, or a way I can get access to it in order to clip out the old chip, solder in a socket and replace it? I would also replace the amplitude control FET at the same time. Are there any pictures of this process anywhere that you know of?

The manual doesn't say much about some of the waveforms at most of the test points on this board, otherwise I could use my scope to better advantage before I dig into it.

Thanks in advance, I really appreciate any suggestions.

Wade

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Design & Build

- Equipment & Tools

- HP-339A Calibration