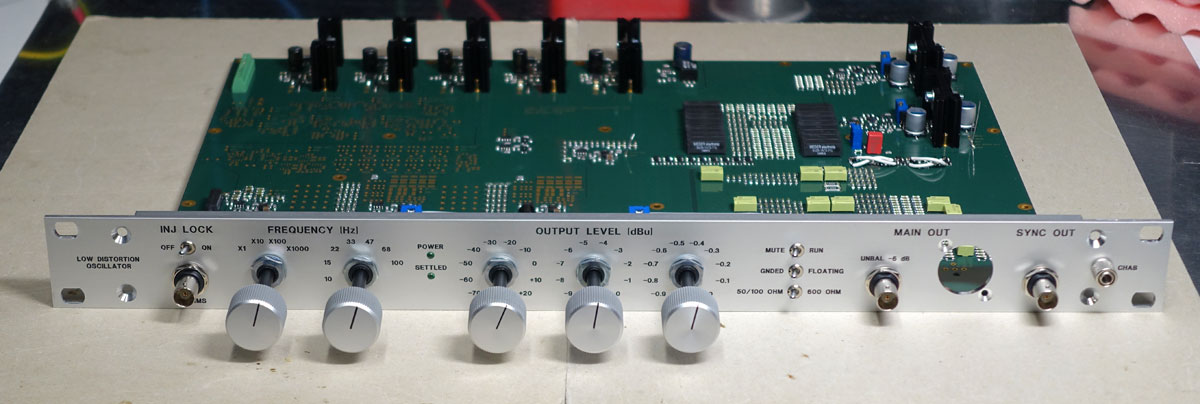

Brief update on my oscillator project: The front panel PCB is fully assembled and, as far as already tested, working as expected (yes, the shafts of the rotary switches will get a cut!):

Samuel

Hi Samuel,

Wow - outstanding!! What are your plans to make this available to purchase? And will it be PCB and a silk-screened front panel?

Thanks!

Brief update on my oscillator project: The front panel PCB is fully assembled and, as far as already tested, working as expected (yes, the shafts of the rotary switches will get a cut!):

Samuel

Very nice work, Samuel. Looks very professional. Such a good oscillator deserves good execution.

Cheers,

Bob

Brief update on my oscillator project: The front panel PCB is fully assembled and, as far as already tested, working as expected (yes, the shafts of the rotary switches will get a cut!):

Samuel

Very nice Samuel.

Best it can be.

Thanks for the update which looks good. I am certainly interested in building one if you make the PCB layout available.Brief update on my oscillator project: The front panel PCB is fully assembled and, as far as already tested, working as expected (yes, the shafts of the rotary switches will get a cut!):

Samuel

Wow That is awesomeBrief update on my oscillator project: The front panel PCB is fully assembled and, as far as already tested, working as expected (yes, the shafts of the rotary switches will get a cut!):

Samuel

Brief update on my oscillator project: The front panel PCB is fully assembled and, as far as already tested, working as expected (yes, the shafts of the rotary switches will get a cut!):

Samuel

Hi Samuel,

Where did you get that front panel and how did you get the lettering on it?

Did you go to Front Panel Express?

Cheers,

Bob

how did you get the lettering on it?

There are a couple of youtube videos on silk-screening metal -- takes different inks.

Thanks very much for your interest and the kind words!

As mentioned previously, I hope to make PCBs available once the design is proven.

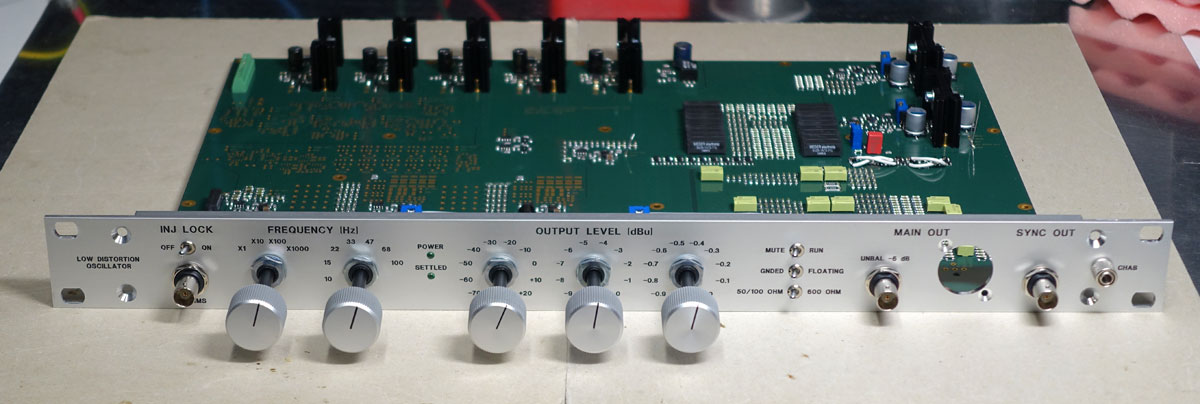

The front panel is engraved by Schaeffer AG (German mother company of Front Panel Express). Likely I can't offer finished front panels, but surely I can make the design file for Front Panel Designer available.

Samuel

As mentioned previously, I hope to make PCBs available once the design is proven.

The front panel is engraved by Schaeffer AG (German mother company of Front Panel Express). Likely I can't offer finished front panels, but surely I can make the design file for Front Panel Designer available.

Samuel

Thanks very much for your interest and the kind words!

As mentioned previously, I hope to make PCBs available once the design is proven.

The front panel is engraved by Schaeffer AG (German mother company of Front Panel Express). Likely I can't offer finished front panels, but surely I can make the design file for Front Panel Designer available.

Samuel

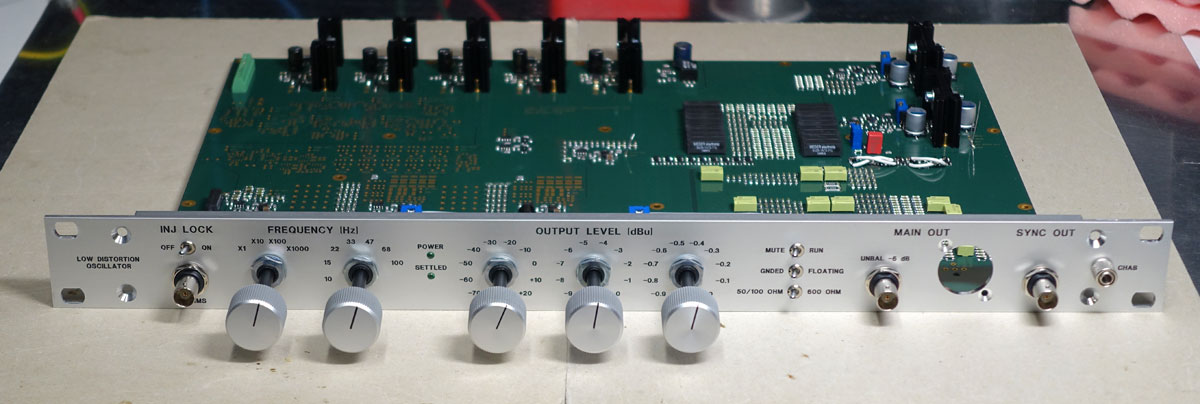

Samuel,

Thank you - I really look forward to it.

That is a beautiful piece.

I am surprised that you couldn't work with Schaeffer AG for a small

production run of the front panel. If it is right, which I think it is,

all the hard work has been done. It's just a matter of cranking them

out with one set up fee.

I would imagine that there might be enough DIYers interested to make

it work. If they want the engraved front panel have them pay upfront.

If not don't.

Or am I missing something?

I am surprised that you couldn't work with Schaeffer AG for a small

production run of the front panel. If it is right, which I think it is,

all the hard work has been done. It's just a matter of cranking them

out with one set up fee.

I would imagine that there might be enough DIYers interested to make

it work. If they want the engraved front panel have them pay upfront.

If not don't.

Or am I missing something?

Thanks very much for your interest and the kind words!

As mentioned previously, I hope to make PCBs available once the design is proven.

The front panel is engraved by Schaeffer AG (German mother company of Front Panel Express). Likely I can't offer finished front panels, but surely I can make the design file for Front Panel Designer available.

Samuel

That is a beautiful piece.

I am surprised that you couldn't work with Schaeffer AG for a small

production run of the front panel. If it is right, which I think it is,

all the hard work has been done. It's just a matter of cranking them

out with one set up fee.

I would imagine that there might be enough DIYers interested to make

it work. If they want the engraved front panel have them pay upfront.

If not don't.

Or am I missing something?

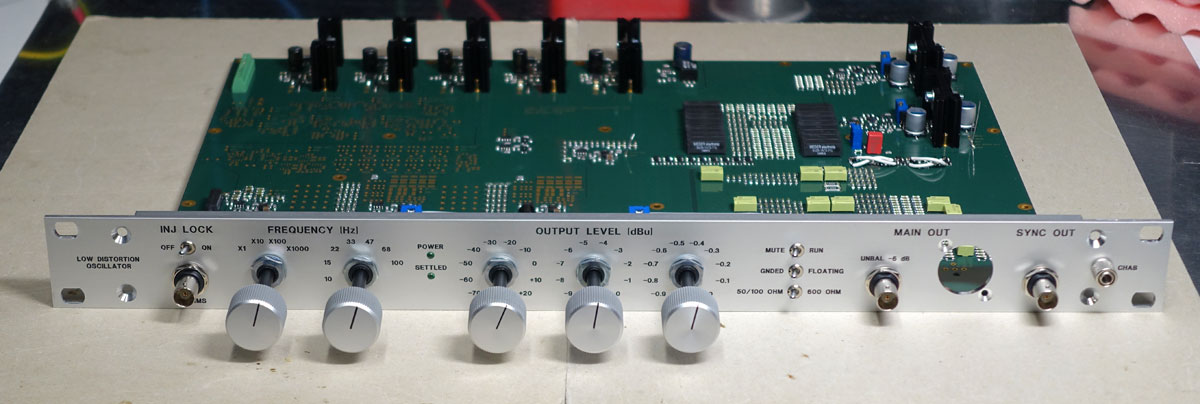

Samuel is smart enough to know that shipping front panels is a thankless task - expensive, time consuming and difficult to pack safely. A PCB drops into a jiffy bag and away it goes.

With an FPD file we can individually order from our nearest FP store, Europe or the U.S., as well as customize color etc. if we want.

Cheers,

Ruairi

Its been quiet here for a while. We will all miss Dick Moore here. I for one, appreciated his contributions.

Back to one of the core questions driving this thread- high performance AGC circuits.

The issue came up for me looking at ways to optimize an oscillator (My Shibasoku). I identified several techniques that have been used and would like to know what has been learned about implementing them.

First is the analog multiplier. Seems to work but has limitations in linearity and is becoming an obsolete electronic part with only a few options available today.

Second is the FET which has well know linearity issues however there are some good tricks for linearizing them but only good to a degree and only really optimum across a narrow range.

Then we have the led-photocell link. Those can be pretty good if the level across it is kept low but they are not real fast to respond to change and the on vs. off is very asymmetrical.

I was also looking at the SSM2018 | datasheet and product info Trimless Voltage Controlled Amplifier | Analog Devices and wondered if anyone has experience using one for an AGC for an oscillator? Its kind of a case of the analog multiplier but possibly easier to use and more linear.

DavidA's light bulb is a great trick but not easy to implement.

Any other ideas?

Back to one of the core questions driving this thread- high performance AGC circuits.

The issue came up for me looking at ways to optimize an oscillator (My Shibasoku). I identified several techniques that have been used and would like to know what has been learned about implementing them.

First is the analog multiplier. Seems to work but has limitations in linearity and is becoming an obsolete electronic part with only a few options available today.

Second is the FET which has well know linearity issues however there are some good tricks for linearizing them but only good to a degree and only really optimum across a narrow range.

Then we have the led-photocell link. Those can be pretty good if the level across it is kept low but they are not real fast to respond to change and the on vs. off is very asymmetrical.

I was also looking at the SSM2018 | datasheet and product info Trimless Voltage Controlled Amplifier | Analog Devices and wondered if anyone has experience using one for an AGC for an oscillator? Its kind of a case of the analog multiplier but possibly easier to use and more linear.

DavidA's light bulb is a great trick but not easy to implement.

Any other ideas?

I was also looking at the SSM2018 | datasheet and product info Trimless Voltage Controlled Amplifier | Analog Devices and wondered if anyone has experience using one for an AGC for an oscillator? Its kind of a case of the analog multiplier but possibly easier to use and more linear.

You will find such an experience in these links to Cyril Bateman's works :

Pro Audio Design Forum • View topic - Cyril Bateman Capacitor Sound Archive

- Home

- Design & Build

- Equipment & Tools

- Low-distortion Audio-range Oscillator