I have this soldering iron from Maplin.

It's supposed to be temperature controlled, but I suspect that it's temperature variable. Whatever, it's not a bad iron, it wasn't too expensive and I was able to buy one off-the-shelf and see what it was like in my hand before I paid the money.

Anyway, I've done a lot of work with it, you can turn it up and down and it will do heavy work like turret boards, and pump out a fair bit of heat when required. It's not the same as a Weller, it's got no magnet in the bit for temperature control, but it's OK.

At the time I bought it, I was careful to check that there were spare bits available, in fact I bought a set of three, the only trouble being that I do a lot of surface mount stuff, and I like a very pointy bit so I had to buy 3 to get 1 I liked.

The other day the expected happened, and the solder finally ate the bit I was using. Of course, the next thing was that I couldn't lay my hands on the spare bits.

Never mind, I nipped off down to Maplin's and bought another set of spares. The only trouble, as it turned out, the thin, pointy bit in this set is not a thin and pointy as the original, and all the ones in the shop are the same. Bummer.

After a couple of days of 'making do' with the best of a bad bunch my creativity re-asserted itself. I have a little lathe I bought off a guy at work when he got a better one and this was an obvious use for it.

I had some brass stock in hand, unfortunately no copper, but I figured the brass would do. Here is the result. 2 hand made bits with one of the bought ones for comparison.

It's important to tin the bit immediately when you heat it for the first time, or you have to abrade it to get it to take solder.

I figure that if I hadn't had the lathe I could still have made these with a couple of files and the workpiece chucked in an electric drill.

w

It's supposed to be temperature controlled, but I suspect that it's temperature variable. Whatever, it's not a bad iron, it wasn't too expensive and I was able to buy one off-the-shelf and see what it was like in my hand before I paid the money.

Anyway, I've done a lot of work with it, you can turn it up and down and it will do heavy work like turret boards, and pump out a fair bit of heat when required. It's not the same as a Weller, it's got no magnet in the bit for temperature control, but it's OK.

At the time I bought it, I was careful to check that there were spare bits available, in fact I bought a set of three, the only trouble being that I do a lot of surface mount stuff, and I like a very pointy bit so I had to buy 3 to get 1 I liked.

The other day the expected happened, and the solder finally ate the bit I was using. Of course, the next thing was that I couldn't lay my hands on the spare bits.

Never mind, I nipped off down to Maplin's and bought another set of spares. The only trouble, as it turned out, the thin, pointy bit in this set is not a thin and pointy as the original, and all the ones in the shop are the same. Bummer.

After a couple of days of 'making do' with the best of a bad bunch my creativity re-asserted itself. I have a little lathe I bought off a guy at work when he got a better one and this was an obvious use for it.

I had some brass stock in hand, unfortunately no copper, but I figured the brass would do. Here is the result. 2 hand made bits with one of the bought ones for comparison.

It's important to tin the bit immediately when you heat it for the first time, or you have to abrade it to get it to take solder.

I figure that if I hadn't had the lathe I could still have made these with a couple of files and the workpiece chucked in an electric drill.

w

I did the same routine for years; sharpened my copper or brass bits as needed. They would barely last through a soldering session though. The iron coating on real tips makes a big difference in their longevity.

I just recently purchased a GOOT temp controlled iron and after using it for a few weeks now, it's made me wonder why I waited so long to get one. I can get real HAKKO tips for around $1 each, so I don't see the need to ever have to sharpen one again.

I just recently purchased a GOOT temp controlled iron and after using it for a few weeks now, it's made me wonder why I waited so long to get one. I can get real HAKKO tips for around $1 each, so I don't see the need to ever have to sharpen one again.

Wakybaki

Got a few of those and they last just a few weeks

Trick is to wait for maplin sales and buy them when price is low £ 7 / 9

Given up in the end and foud that one of their £60 + irons was on sale at less than half no bad for the money considering branded stuff sels for over £100.

If you need spares send me PM

Got the bad abit to keep al sort of stuff as it may came handy...

Glad to help if I can

Got a few of those and they last just a few weeks

Trick is to wait for maplin sales and buy them when price is low £ 7 / 9

Given up in the end and foud that one of their £60 + irons was on sale at less than half no bad for the money considering branded stuff sels for over £100.

If you need spares send me PM

Got the bad abit to keep al sort of stuff as it may came handy...

Glad to help if I can

Last edited:

http://www.audioxpress.com/magsdirx/ax/addenda/media/simon2894.pdf

This is the article I did on the US version of this "Tool."

This is the article I did on the US version of this "Tool."

So what do you do with your lathes then? When I fix up the CNC on this one it'll make these for me unattended.

I used lots of different irons professionally, hot air rework stations, some very expensive. Some with RF heating (Metcal I think) took such good care of you, you couldn't get the solder to melt in some circumstances, like if you were trying to rework something built with a higher melting-point solder. I never had one the tip didn't erode through eventually. No soldering iron is perfect, I like one which will deliver some heat when I judge it necessary.

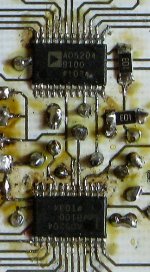

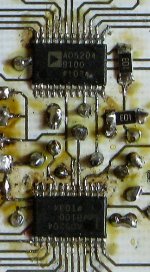

These are hand-worked 1206 and TSSOP24s on a home-made board, done with this iron. I knew a couple of women at Racal I rated as better than me with a soldering iron, but they did it all day, every day.

Now I've got the use back of one that I like when the supplier discontinued the tips I liked. I know why tips are plated, I'm more interested in having something I can fix up myself, although if I could figure a way of plating my own, I'd go for that.

Never mind, I can always melt these down in my flowerpot furnace and recast them.

Or maybe I'll rig up my dremel-alike as a grinder and try cutting some harder stuff.

w

Thanks Bksabath, I've got this one.

I used lots of different irons professionally, hot air rework stations, some very expensive. Some with RF heating (Metcal I think) took such good care of you, you couldn't get the solder to melt in some circumstances, like if you were trying to rework something built with a higher melting-point solder. I never had one the tip didn't erode through eventually. No soldering iron is perfect, I like one which will deliver some heat when I judge it necessary.

These are hand-worked 1206 and TSSOP24s on a home-made board, done with this iron. I knew a couple of women at Racal I rated as better than me with a soldering iron, but they did it all day, every day.

Now I've got the use back of one that I like when the supplier discontinued the tips I liked. I know why tips are plated, I'm more interested in having something I can fix up myself, although if I could figure a way of plating my own, I'd go for that.

Never mind, I can always melt these down in my flowerpot furnace and recast them.

Or maybe I'll rig up my dremel-alike as a grinder and try cutting some harder stuff.

w

Thanks Bksabath, I've got this one.

I can get similar surface mount results with a <$10 iron and a hand sharpened tip (did it for 6 years). Not having to worry about my tip dissolving half way through a project now is a nice thing though.

One thing I noticed from switching from a dumb-iron to temp controlled iron is that I was used to my tip being HOT!!! I had to set the station to at least 370C to be able to solder the way I was used to.

One thing I noticed from switching from a dumb-iron to temp controlled iron is that I was used to my tip being HOT!!! I had to set the station to at least 370C to be able to solder the way I was used to.

http://www.audioxpress.com/magsdirx/ax/addenda/media/simon2894.pdf

This is the article I did on the US version of this "Tool."

Hi, Simon

The Velleman VTSS5V is not a temperature controlled solder station, it just use the usual dimmer triac for variable power. No temperature control feedback action...

Hi, Simon

The Velleman VTSS5V is not a temperature controlled solder station, it just use the usual dimmer triac for variable power. No temperature control feedback action...

And they stopped advertising it as a temperature controlled iron after the article came out!

These are hand-worked 1206 and TSSOP24s on a home-made board, done with this iron. I knew a couple of women at Racal I rated as better than me with a soldering iron, but they did it all day, every day.

Looks like you're ready for a shot of flux cleaner.

~Tom

These are hand-worked 1206 and TSSOP24s on a home-made board, done with this iron. I knew a couple of women at Racal I rated as better than me with a soldering iron, but they did it all day, every day.

I do mean to rain a little on your parade. I wouldn't take a picture of anything that looked like that. Your board is OK and the TSSOP solder is adequate but the through hole is pretty sad. Flux remover and a little action with wick would do wonders for that.

G²

If you can get a Quick soldering station over there it should be cheap, I have their copy of the Hako836A, and it is magnificent, calibrateable, very accurate and repeatable temps, I have left it on overnight many times and over the years I had it I think I replaced one bit. And the iron was just over $30, also comes with a nice cast iron holder.

I just replate mine with heavy pure dull nickel plating... maybe .001" or more (much much heavier than standard plating). They then last for years...

Last for years... you just don't use them enough! Now that bits are hitting $5 ea. I just might start doing it myself. Thanks.

I bought two old soldering stations on bric-a-brac sales, this was a rela discover I won't never go back to temperature unregulated irons. The first one is a Magnastat Weller, the second, even better, is a Pace MBR-200E, which I found incredibly comfortable. However its tip is at the end of its life and despite having spent hours on the net searching for a replacement among various manufacturers, I couldn't find any with the requirement of 1/8" shank (original Pace part numbers : 1121-0130, 1121-0131 and 1121-0132). I will be happy if anyone can help (Europe).

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Design & Build

- Equipment & Tools

- Soldering iron bit rescue