You can easily fill the spaces with acrylic. Chloroform can be used to dissolve small pieces of acrylic.

I have a cdm1 too, so its worth a try, but the acrylate will not dissolve easy i think. And be aware not to hang around above those vapours for too long, chloroform can be used as an aneastetic drug, when you wake up, there will be a huge headache!

Hi Boky & Lourens

QUOTE]1. Did you actually carry out this mod yourself?[/QUOTE]

I haven't tried this mod yet, as I'm still experimenting with woods under the transport. I have tried a solid piece of acrylic under the transport and it did offer some improvements in the sound (ie soundstage). To my ears wood offers a better soundstage.

However, if the CDM is resting on the acrylic/perxpex I assume that there can be some vibrations. These vibrations can be attenuated with very little bluetac (actually I prefer UHU yellowtac it's a bit softer), or by actually clamping the CDM to its base to facilitate damping.

I noticed that there was more detail when a little blutac was added, probably attenuated those vibrations.

[

Lourens, the acrylic/chloroform will not bond to the metal but you may consider bolting the top plate to the CDM1 via its 4 holes.

If the glue hardens it will not offer adequate attenuation. Ideally you will need a very little something soft ie blutac or bitumen (for deadening car panels)

Cheers

Richard

QUOTE]1. Did you actually carry out this mod yourself?[/QUOTE]

I haven't tried this mod yet, as I'm still experimenting with woods under the transport. I have tried a solid piece of acrylic under the transport and it did offer some improvements in the sound (ie soundstage). To my ears wood offers a better soundstage.

However, if the CDM is resting on the acrylic/perxpex I assume that there can be some vibrations. These vibrations can be attenuated with very little bluetac (actually I prefer UHU yellowtac it's a bit softer), or by actually clamping the CDM to its base to facilitate damping.

I noticed that there was more detail when a little blutac was added, probably attenuated those vibrations.

[

You say you can lift the moulded inserts off easily. So it does not bond with the metal surface?

Lourens, the acrylic/chloroform will not bond to the metal but you may consider bolting the top plate to the CDM1 via its 4 holes.

Some glue will prevent unwanted resonances then, contributing to the dead silence we are aiming at, mechanically speaking, won't it?

If the glue hardens it will not offer adequate attenuation. Ideally you will need a very little something soft ie blutac or bitumen (for deadening car panels)

Cheers

Richard

Hi Tubee

It does take a while for the acrylic to dissolve, the process is sped up by using small pieces or even shavings of the acrylic.

The things we do for better sound

Cheers

Richard

but the acrylate will not dissolve easy i think.

It does take a while for the acrylic to dissolve, the process is sped up by using small pieces or even shavings of the acrylic.

chloroform can be used as an aneastetic drug, when you wake up, there will be a huge headache!

The things we do for better sound

Cheers

Richard

Well if increasing mass is important, then perhaps epoxy (Araldite), filled with lead shot might be an easier, less dangerous approach.

I cannot see what advantage the melted acrylic sheet would give, once its structural integrity has been modified with the chloroform solvent.

By the way, I also think the CDM1 is quite heavy on its own, certainly around 150 grams if I remember rightly. Much more than a disk – this is what is important here – the mass difference between the pickup and the disk.

Also, if the analogue sound is what is sought, try a 14 bit machine…That’s the other common point with the CDM1.

Cheers

Philippe

I cannot see what advantage the melted acrylic sheet would give, once its structural integrity has been modified with the chloroform solvent.

By the way, I also think the CDM1 is quite heavy on its own, certainly around 150 grams if I remember rightly. Much more than a disk – this is what is important here – the mass difference between the pickup and the disk.

Also, if the analogue sound is what is sought, try a 14 bit machine…That’s the other common point with the CDM1.

Cheers

Philippe

acrylic base

here is the first step of my current project , the mechanical part .

Not so amazing since it's too sensitive with shocks or vibrations

(there's NO suspension for the moment) , and as the metrology theory states , three feets are sufficient in a plane , so the stuff is balancing on it's four feets , but the sound is here .

So next step is obvious ...

here is the first step of my current project , the mechanical part .

Not so amazing since it's too sensitive with shocks or vibrations

(there's NO suspension for the moment) , and as the metrology theory states , three feets are sufficient in a plane , so the stuff is balancing on it's four feets , but the sound is here .

So next step is obvious ...

Attachments

Well if increasing mass is important, then perhaps epoxy (Araldite), filled with lead shot might be an easier, less dangerous approach

Phimor you posted this just before i wanted, few days ago i glued something with epoxy 2 component glue. A day later had thoughts about it of aplying it to the cdm-1. Epoxy glue bought cheap here from a Lidl. Hardens quickly and has problably almost the same soundcaracteristics as acrylate.

Indeed filling the hollows spaces is only for mass adding and dampening, to reduce air circulations in CDM-1 from the spinning disc, this filling is problably not very usefull i think, because the cd platter gets on the spaces when a cd is loaded (with a standard front loader)

Yes Phimor, my 14 bit CD300 gives a very analog feeling to sound...and a real bass.....Also, if the analogue sound is what is sought, try a 14 bit machine…That’s the other common point with the CDM1.

Thanks Lourens ,it's not the same ,this time it's a KSS 210 I salvaged with the motherboard from a cheapo chinese combo I found in the street . The DAC is a LC 7881 what is not so bad , but I have to re-do all the supplies, cheapest implementation .

Otherwise , I used to fill the holes in the plastic mechanism with mold paste (!!!) I used to steal from my daughter . Stay smooth , don(t turn grease or liquid ,very useful & efficient .

Good mods .

Otherwise , I used to fill the holes in the plastic mechanism with mold paste (!!!) I used to steal from my daughter . Stay smooth , don(t turn grease or liquid ,very useful & efficient .

Good mods .

Well if increasing mass is important, then perhaps epoxy (Araldite), filled with lead shot might be an easier, less dangerous approach.

hi Philip,

I second your and Tubees view that filling the gaps with melted acryllic is not the only way. Thank you for describing a less dangerous approach!

By the way, I also think the CDM1 is quite heavy on its own, certainly around 150 grams if I remember rightly. Much more than a disk – this is what is important here – the mass difference between the pickup and the disk.

If we try to implement the René Boonen/Pierre Lurné recipe on how to eliminate any vibrations caused by a cd mechanism -- and that's a promising way to go as we understand from the Audiomeca website -- there is one relevant objective if you want to modify a Philips cdm1: prevent or reduce disc vibrations due to the high speed spinning just above a very irregular surface.

A second objective (prevent or reduce mechanical vibrations in the cdm construction itself) is rather superfluous given the solid zamac construction, imho.

If you compare top surfaces of cdm0 (see attached picture) and cdm1 (see post #11), the differences are obvious.

There could very well be some explanation for perceived and valued sonic differences between these two otherwise rather identical mechanisms...

That's the only reason for me to follow Boonens footsteps in creating a new smooth surface. With any useful material that does the job.

To my ears 14 bit does not sound analogue per se. My best sounding (=less digital, or most analogueAlso, if the analogue sound is what is sought, try a 14 bit machine…That’s the other common point with the CDM1.

BTW Philips used cdm0 as well as cdm1 in their early machines. The picture of the cdm0 was actually scanned from a 1985 Marantz CD-84 mkII brochure, while my 1984 CD74 has a cdm1... Unfortunately all my 14 bit cd players are fitted with cdm1, but it would be a nice experiment to compare a cdm0 and cdm 1 in two otherwise identical cdp's, i guess.

groeten

Lourens

Attachments

Hi Lourens, the difference in the smooth surface you noticed may well be due to a cover plate. You can just make out the edge of what looks like a sheet metal cover in your photo. I say this because I’ve become very familiar with CDM0 and CDM1 differences. In the CD200 and 202 (CDM0) and MCD (CDM1), all top loaders, there is a plastic cover over the pick up, so the surface of the mechanism is not exposed to the disk (or the user). This may well be different with tray loading players which would not need the ‘embellishment’.

By the way, a CDM0 will work very well in place of a CDM1, notwithstanding the hall motor (this is the other difference between the two pick ups, and probably accounts for any sonic performance variation). I successfully tested my repaired CDM1 in a Meridian MCD. It may suggest that the servo board can cope with different pick up spindle motors. This could this open the possibility of using later CDMs in those earlier machine, or (more usefully) CDM1 in later machines.

Hi Tubee, yes 14 bit is ‘different’, interesting also that all three players mentioned above have distinctly different sounds, though similar topologies. The difference with the 200 and 202 is especially puzzling since they have similar chip sets (SoPhi board) and transport. The MCD, with its alum chassis is in a class of its own…(as is the Meridian rats nest I/V section ;-)

As this machine is based on the CD100, it indicates Philips knew something of the benefits of ‘heavy engineering’, so it would confirm your idea Lourens.

Cheers

Philippe

By the way, a CDM0 will work very well in place of a CDM1, notwithstanding the hall motor (this is the other difference between the two pick ups, and probably accounts for any sonic performance variation). I successfully tested my repaired CDM1 in a Meridian MCD. It may suggest that the servo board can cope with different pick up spindle motors. This could this open the possibility of using later CDMs in those earlier machine, or (more usefully) CDM1 in later machines.

Hi Tubee, yes 14 bit is ‘different’, interesting also that all three players mentioned above have distinctly different sounds, though similar topologies. The difference with the 200 and 202 is especially puzzling since they have similar chip sets (SoPhi board) and transport. The MCD, with its alum chassis is in a class of its own…(as is the Meridian rats nest I/V section ;-)

As this machine is based on the CD100, it indicates Philips knew something of the benefits of ‘heavy engineering’, so it would confirm your idea Lourens.

Cheers

Philippe

Mephisto II

I found an interesting review of this ultimate transport; http://www.tnt-audio.com/sorgenti/mephisto_e.html

With some more back ground information and a nice picture of the impressive cdm....

I want to hear this thing

Lourens

Extreme_Boky said:(...)

Back to Audiomeca's mechanism

(...)

There's no doubt in my mind (especially now - a week after I sent the unit back to Melbourne when all the impressions and thoughts have settled in my head) that the plastics used extensively in Audiomeca Mephisto II transport are to blame for analog - like sound.

I found an interesting review of this ultimate transport; http://www.tnt-audio.com/sorgenti/mephisto_e.html

With some more back ground information and a nice picture of the impressive cdm....

I want to hear this thing

Lourens

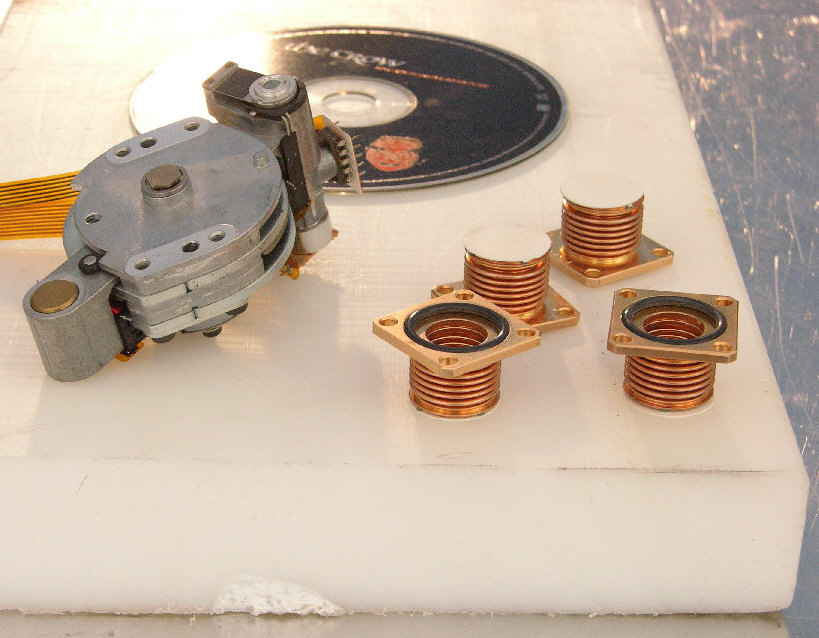

Bernhard are you fishing?

After all you are the one proposing the image, so you must know the objects.

I admit they look like they really belong in a Bugatti engine, but they are probably the suspension for the mechanism. Is this part of a kit?

Personally I find the rubber o-ring intriguing, somehow surperfluous, especially if intended to be fitted against a plastic surface (Corian).

Philippe

PS nice looking CDM1

After all you are the one proposing the image, so you must know the objects.

I admit they look like they really belong in a Bugatti engine, but they are probably the suspension for the mechanism. Is this part of a kit?

Personally I find the rubber o-ring intriguing, somehow surperfluous, especially if intended to be fitted against a plastic surface (Corian).

Philippe

PS nice looking CDM1

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Source & Line

- Digital Source

- Analog sound from Digital source. Possible?