Most definitely. The laser can provide accurate focus by moving up or down; there's no multi-element lens assembly inside the laser for "internal focusing". If I understood your post correctly, the laser servo will be stressed to keep the laser pickup at lower position (5mm !!) at all times. You can observe the laser pick-up movement if you pick a CD with a lot of tracks, and then select the last track. This will force the laser pickup to move to the edge of the CD, and then you can observe the movement. Event though the laser pickup moves in all directions very quickly, it should not be sent to its lower position; most definitely it should not be at its lower position at all times - this will saturate the servo.

On a side note, long time ago when I was playing with laser pickups and CD reflectivities, I found a CD that has an outstanding reflectivity. This guaranties a high RF signal amplitude - it can be useful to know this for testing...The Nightfly by Donald Fagen. There are CD pressings that have very low reflectivity... The Nightfly is NOT one of those.

On a side note, long time ago when I was playing with laser pickups and CD reflectivities, I found a CD that has an outstanding reflectivity. This guaranties a high RF signal amplitude - it can be useful to know this for testing...The Nightfly by Donald Fagen. There are CD pressings that have very low reflectivity... The Nightfly is NOT one of those.

I did the test and observed the movement of the lens. It is only moving up to about 0.5-0.75mm from rest position.

But there is obviously something wrong with transport pcb. Positive line (+13V) transistor in power supply gets hot. When I disconnect power from transport pcb it stays relatively cool.

It is very difficult to troubleshoot that pcb, it is underneath the transport drawer.

I tested various CD for reflectivity levels but it doesn't help. Cd-player still breaks spindle motor when changing tracks.

But there is obviously something wrong with transport pcb. Positive line (+13V) transistor in power supply gets hot. When I disconnect power from transport pcb it stays relatively cool.

It is very difficult to troubleshoot that pcb, it is underneath the transport drawer.

I tested various CD for reflectivity levels but it doesn't help. Cd-player still breaks spindle motor when changing tracks.

Unfortunatelly I don't have spare motor to test. I only compared resistance with working one and all the values are the same (16.5 ohms). I did the test with battery. The motor was running easily and fast.

The transistor will get hot even when cd-player is idle (motor not spinning).

I start to wonder if the problem is not related to cd-player not being able to lock to system clock. I discovered that when I touch the varactor diode SVC211 (D501) - I believe it's part of the VCO circuit - with oscilloscope probe, exactly the same time spindle motor brakes and stops.

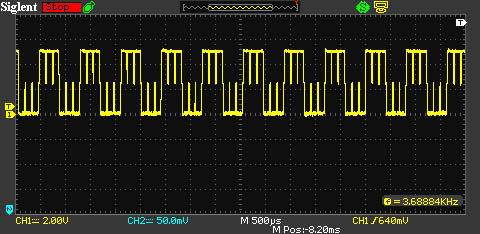

DM signal changes immediately and it look like this:

I marked with yellow where I touch the diode with probe if that is of any help.

The transistor will get hot even when cd-player is idle (motor not spinning).

I start to wonder if the problem is not related to cd-player not being able to lock to system clock. I discovered that when I touch the varactor diode SVC211 (D501) - I believe it's part of the VCO circuit - with oscilloscope probe, exactly the same time spindle motor brakes and stops.

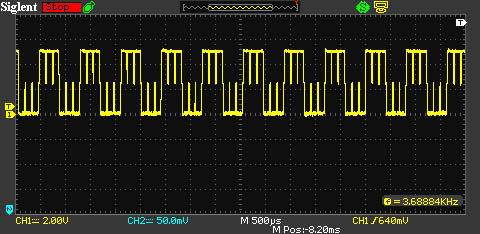

DM signal changes immediately and it look like this:

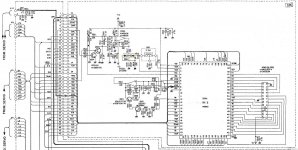

I marked with yellow where I touch the diode with probe if that is of any help.

I was also under impression from the start that the issue was related to clock signal.

Touching the yellow point with the probe is not a proper test, especially if the multiplier was set to X1. That part of circuitry will be very sensitive to any loading.

I’d look at signals at R522 and R523 while the CD player is working, and then observe what happens when in stop / play/ disk loading / laser obtaining valid focus, track change / ff and frev.

Re spindle motor, the way I clean the graphite, that comes of the brushes and short the commutators, is by injecting methylated spirits into tiny holes on the motor case with syringe – under “pressure”; this worked many times for me with great success. Note that the commutators can become dirty and cause the electrical short…. just enough to cause trouble. 16.5 ohms might be okay, but it may not…

Touching the yellow point with the probe is not a proper test, especially if the multiplier was set to X1. That part of circuitry will be very sensitive to any loading.

I’d look at signals at R522 and R523 while the CD player is working, and then observe what happens when in stop / play/ disk loading / laser obtaining valid focus, track change / ff and frev.

Re spindle motor, the way I clean the graphite, that comes of the brushes and short the commutators, is by injecting methylated spirits into tiny holes on the motor case with syringe – under “pressure”; this worked many times for me with great success. Note that the commutators can become dirty and cause the electrical short…. just enough to cause trouble. 16.5 ohms might be okay, but it may not…

My intension to probe yellow point wasn't clock signal observation. It was rather curiosity and I wanted to understand the circuit better. There is dedicated point on digital pcb to observe clock signal that I've used.

However there is no lock confirmation signal as far as I know. I will try with R522 and R523.

Do you think I can use isopropyl alcohol instead of methylated?

I agree that it still can be a motor problem. It is controlled by two signals and the problem starts always when switching from one to another.

After swichitng to DM signal motor should spin up and then slow down to lock on clock.

Maybe this locking system is very sensitive to rotation speed?

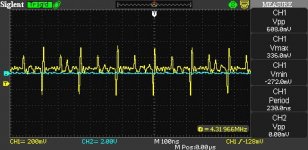

There is also one strange thing with 5v line. I can observe noise (small peaks) of 4.32MHz (clock) frequency.

However there is no lock confirmation signal as far as I know. I will try with R522 and R523.

Do you think I can use isopropyl alcohol instead of methylated?

I agree that it still can be a motor problem. It is controlled by two signals and the problem starts always when switching from one to another.

After swichitng to DM signal motor should spin up and then slow down to lock on clock.

Maybe this locking system is very sensitive to rotation speed?

There is also one strange thing with 5v line. I can observe noise (small peaks) of 4.32MHz (clock) frequency.

Do you think I can use isopropyl alcohol instead of methylated?

Yes.

You could also try vodka, šljivovica (double distilled)...

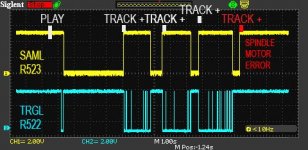

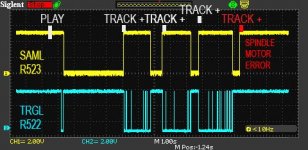

I did measurements on R522 and R523

After pressing 'play'

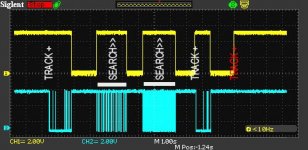

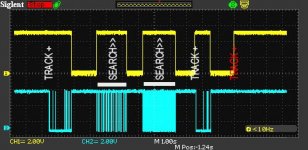

When changing track (going up or down)

(I moved channels aside to be easier to see)

Yellow idle = 5V, Play = 0V

Blue idle = 5V, drops to 0V when changing tracks, search etc

When spindle motor brakes yellow signal stays 5V and blue signal doesn't drop.

During search

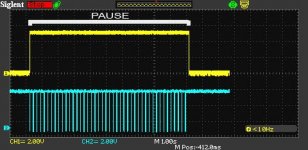

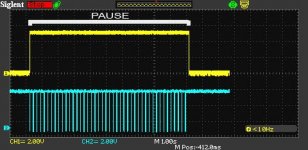

Pause

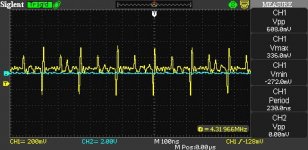

Zoom in to signal on R523

How to interpret these readings?

Good I can use isopropyl alcohol. I can save vodka for better occasion

After pressing 'play'

When changing track (going up or down)

(I moved channels aside to be easier to see)

Yellow idle = 5V, Play = 0V

Blue idle = 5V, drops to 0V when changing tracks, search etc

When spindle motor brakes yellow signal stays 5V and blue signal doesn't drop.

During search

Pause

Zoom in to signal on R523

How to interpret these readings?

Good I can use isopropyl alcohol. I can save vodka for better occasion

When spindle motor brakes yellow signal stays 5V and blue signal doesn't drop.

Ok, so you are not pressing any commands, signals at R522 and R523 look stable -> and then the spindle motor stops spinning (and starts to spin in opposite direction?)

If above is correct, then:

1. Wash the motor, or try to get a new motor. They are quite cheap and easy to obtain.

2. If motor still behaves erratically, confirm that signals don’t change on IC501, pins 1 through 12 when the motor stops to spin correctly during play.

If all signals stay stable on pins 1 – 12, when the motor starts to behave erratically, then the whole section we are talking about at the moment is okay.

Nick

The spindle motor only stops spinning after pressing buttons (selecting new track, changing tracks >, <.

If I am not pressing I can continue to listen the whole cd without a single problem.

I was not accurate. Yellow signal goes high 5V after pressing and drops down to 0V when cd-player lock on track successfully.

If I am not pressing I can continue to listen the whole cd without a single problem.

I was not accurate. Yellow signal goes high 5V after pressing and drops down to 0V when cd-player lock on track successfully.

Where can I obtain the new motor? I searched for it for a very long time with no success  I know the part number VE403100 or VE406400

I know the part number VE403100 or VE406400

An externally hosted image should be here but it was not working when we last tested it.

the original part:

YAMAHA VC406400 DISC MOTOR (CDX1100) (Last of suppy) ? Tap Electronics Co.

YAMAHA VC406400 DISC MOTOR (CDX1100) (Last of suppy) ? Tap Electronics Co.

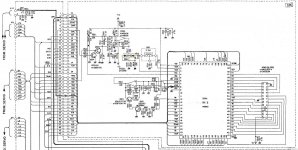

I have just checked the service manual very quickly, and figured out two things:

1. The motor part details are listed on mechanism parts page, part number is: vc406400. This is how I managed to find the original part

2. The mechanism requires adjustments - see the beginning of the user manual.

I can e-mail you the manual if you don't have it.

1. The motor part details are listed on mechanism parts page, part number is: vc406400. This is how I managed to find the original part

2. The mechanism requires adjustments - see the beginning of the user manual.

I can e-mail you the manual if you don't have it.

Big thank you Extreme_Boky.

Last weekend I tried with cleaning the motor with alcohol. I noticed an improvement so I was reassured to try with new motor.

I swapped the motors. I took one from working CDX-700 and installed it in CDX-1100.

And then again the one from CDX-700 went to CDX-1100.

To my surprise CDX-700 still works great.

CDX-1100 struggles but it is again a bit better. Now it is only difficult to read TOC, if succesful cd-player works quite good - I can now change tracks easly.

I hope it is only a matter of making some adjustemnt (FOS, FOG, TRG, TRB etc).

Last weekend I tried with cleaning the motor with alcohol. I noticed an improvement so I was reassured to try with new motor.

I swapped the motors. I took one from working CDX-700 and installed it in CDX-1100.

And then again the one from CDX-700 went to CDX-1100.

To my surprise CDX-700 still works great.

CDX-1100 struggles but it is again a bit better. Now it is only difficult to read TOC, if succesful cd-player works quite good - I can now change tracks easly.

I hope it is only a matter of making some adjustemnt (FOS, FOG, TRG, TRB etc).

I was to optimistic. I followed service manual with all the adjustments. No success.

Motor still breaks and rotates anticlockwise but not so often as previously.

I had a problem with Focus Gain and Tracking Gain adjustment as this needs double channel ACVM. I tried with double channel oscilloscope and multimeter but how can I measure the ratings?

Focus Gain

E(TE) - E[Q] = 15dB

Reference E[Q] = 30mV, E[TE]=131mV

Tracking Gain

E[FO] - E[R] = 10dB

Reference E[FO] = 160mV, E[R]=50mV

I got the impression that the broken motor is the result not the cuase of the failure

Motor still breaks and rotates anticlockwise but not so often as previously.

I had a problem with Focus Gain and Tracking Gain adjustment as this needs double channel ACVM. I tried with double channel oscilloscope and multimeter but how can I measure the ratings?

Focus Gain

E(TE) - E[Q] = 15dB

Reference E[Q] = 30mV, E[TE]=131mV

Tracking Gain

E[FO] - E[R] = 10dB

Reference E[FO] = 160mV, E[R]=50mV

I got the impression that the broken motor is the result not the cuase of the failure

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Source & Line

- Digital Source

- Yamaha CDX-1100 spindle motor driver problem?