Hi Andy,

That looks better.

Hi Mark,

It also means less heat generated everywhere in the machine.

-Chris

That looks better.

Hi Mark,

Yes, absolutely!The rotation/read speed is about keeping the FIFO buffer approximately half full. Low mass means faster/low power servo control.

It also means less heat generated everywhere in the machine.

-Chris

I will have to trust my ears on this matter, and right now don't have two different machines to compare.

I'm not giving into marketing as I've been absent from the hobby for a couple of years. Perhaps responding to what I see as trends in the designs and in the asking prices. If that's responding to marketing, then I'm guilty as charged. So be it, I can live with it.

Are we no longer poo-pooing light weight boombox motors, spindle shafts and bearings then?

How about light weight computer CD drives/readers, no longer easy targets?

I'm getting confused.

I'm not giving into marketing as I've been absent from the hobby for a couple of years. Perhaps responding to what I see as trends in the designs and in the asking prices. If that's responding to marketing, then I'm guilty as charged. So be it, I can live with it.

Are we no longer poo-pooing light weight boombox motors, spindle shafts and bearings then?

How about light weight computer CD drives/readers, no longer easy targets?

I'm getting confused.

Hi Andy,

That looks better ......

-Chris

I have 2 of these.

The build quality is outstanding.

2x transformers

Separate analog and digital boards

etc...

‚j‚d‚m‚v‚n‚n‚c�EƒPƒ“ƒEƒbƒh�@‚c‚o�|‚P‚P‚O‚O‚r‚f�@‚a‹‰ƒI�[ƒfƒBƒI�Eƒtƒ@ƒ“

More pictures.

Andy

Frankly, (and on first sight) the 47 Labs player looks to me like a plastic cheapo

in an expensive box. Platter looks like Sanyo.

Vrds is ok to me if this design lasts forever.

Remember the rubber mats people put on the CD?

Impossible to center them. But the sound was soooo

analogue!

in an expensive box. Platter looks like Sanyo.

Vrds is ok to me if this design lasts forever.

Remember the rubber mats people put on the CD?

Impossible to center them. But the sound was soooo

analogue!

Last edited:

Hi kach22i,

Hi Mark,

Remember that with analog you get once chance at a read and that's it. With computer drives, they read multiple times to try and recover the data. Next time you try to copy a music CD, set the software for no errors and see how much extra time it takes! Only with the error correction used for data can they read enough correctly to work. The error correction used for audio CDs isn't robust enough to make that claim about reading at 52X the red book rate. It can, but not error free, not even close.

Trying this with a decent audio transport would be interesting. You would have to change all the servo settings for high speed operation. That is probably the only thing holding back CD transports from reading at those high rates, although a stable platter transport would probably gut itself trying. That would be a horrible and smoky death.

-Chris

Why not use the better components when available. They add many more years to the unit before repair is required. Don't go cheap just because you can!Are we no longer poo-pooing light weight boombox motors, spindle shafts and bearings then?

Hi Mark,

Easy. They are junk. Cheap, high volume junk.How can you Poo-poo a player that can read up to 52 times faster than red book?

Remember that with analog you get once chance at a read and that's it. With computer drives, they read multiple times to try and recover the data. Next time you try to copy a music CD, set the software for no errors and see how much extra time it takes! Only with the error correction used for data can they read enough correctly to work. The error correction used for audio CDs isn't robust enough to make that claim about reading at 52X the red book rate. It can, but not error free, not even close.

Trying this with a decent audio transport would be interesting. You would have to change all the servo settings for high speed operation. That is probably the only thing holding back CD transports from reading at those high rates, although a stable platter transport would probably gut itself trying. That would be a horrible and smoky death.

-Chris

The Stan Curtis article I linked to is interesting because he was one of the first to design a high-end CD player and did it on his own... was considered either better or on a par with Sony's own 552/702 combo effort.

He was much focused on read errors and designed a read error counter box which would show the differences in read errors between mechanical and also CD pressing methods.

Reducing vibration seemed to be key in his designs (although the affordable players used standard CDM mechs).

And so it is interesting that his cost-no-object design from the 90s used a vacuum pump to flatten the CD onto a lightweight platter, used a powerful motor, suspension and, presumably for practical purposes with the vacuum, turned the CD upside down.

Making it more like a turntable is practical, not a marketing ploy. Means you can use techniques which would otherwise get in the way of the laser if the normal way up.

When I talk of using a platter it would not be for the purposes of speed stability but vibration reduction of spinning bit of polycarbonate . Air pressure from the spinning CD can lift the CD depending on tray design so becomes less stable, oscillations from the air pressure.. Not to mention the thing not sitting flat in the first place.

Not seen a study on CDs in that regard but definitely in regard to general fast spinning discs in free air.

He was much focused on read errors and designed a read error counter box which would show the differences in read errors between mechanical and also CD pressing methods.

Reducing vibration seemed to be key in his designs (although the affordable players used standard CDM mechs).

And so it is interesting that his cost-no-object design from the 90s used a vacuum pump to flatten the CD onto a lightweight platter, used a powerful motor, suspension and, presumably for practical purposes with the vacuum, turned the CD upside down.

Making it more like a turntable is practical, not a marketing ploy. Means you can use techniques which would otherwise get in the way of the laser if the normal way up.

When I talk of using a platter it would not be for the purposes of speed stability but vibration reduction of spinning bit of polycarbonate . Air pressure from the spinning CD can lift the CD depending on tray design so becomes less stable, oscillations from the air pressure.. Not to mention the thing not sitting flat in the first place.

Not seen a study on CDs in that regard but definitely in regard to general fast spinning discs in free air.

When your warped and vibrating discs play with a BLER less than 5, what do you need to improve? With new discs, the main source of errors is the glass-mastering and stamper making. Error counts of stamper and the discs replicated from it are almost identical.

If all players had an error counter, you would see that most players give the same results.

If all players had an error counter, you would see that most players give the same results.

Is that an assumption on your part? Or you're speaking from a position of having tested different mech designs and their implementation e.g vibration control, external vibration isolation?

I'm guessing an assumption based on not having examined the question. At least Stan Curtis has albeit 20 years ago and found differently to your assertion.

His writings on it are hard to find and anecdotal - sadly never seen a paper or anything more formal.

I'm guessing an assumption based on not having examined the question. At least Stan Curtis has albeit 20 years ago and found differently to your assertion.

His writings on it are hard to find and anecdotal - sadly never seen a paper or anything more formal.

Last edited:

Hi Mark,

I used to have a counter that hung on the C1 and 2 flag test points. You are being extremely optimistic there my friend. That stayed at my shop when I sold it. Same as the jitter meter.

You have no idea how much I wish your information was correct. It ain't. Those computer CDROM drives are not as good as a decent CD mech at getting the information off the disc either. They are cheap to service though (fork lift the mech). No matter how hard you wish those cheap little drives would out perform a standard CD transport that was half decent, they just don't. If they did, they would be put in a different form factor, but the heart of the transport would be the same.

-Chris

I used to have a counter that hung on the C1 and 2 flag test points. You are being extremely optimistic there my friend. That stayed at my shop when I sold it. Same as the jitter meter.

You have no idea how much I wish your information was correct. It ain't. Those computer CDROM drives are not as good as a decent CD mech at getting the information off the disc either. They are cheap to service though (fork lift the mech). No matter how hard you wish those cheap little drives would out perform a standard CD transport that was half decent, they just don't. If they did, they would be put in a different form factor, but the heart of the transport would be the same.

-Chris

Hi NATDBERG,

Normal mechanisms clamp the CD in the center only. No vibration problems. If it were to vibrate, it would make the RF/eye pattern look unfocused or fuzzy. I guess a motor with bad bearings would do the same, make it vibrate. Normally there is not a vibration problem with a small rotating system.

-Chris

Normal mechanisms clamp the CD in the center only. No vibration problems. If it were to vibrate, it would make the RF/eye pattern look unfocused or fuzzy. I guess a motor with bad bearings would do the same, make it vibrate. Normally there is not a vibration problem with a small rotating system.

-Chris

Reducing vibration seemed to be key

That's it. Vibration is the main variable that I have tried to address in transport mod. And it is not a factor of the disk alone but integral from the shaft to the table where the box is put (which is often forgotten). Easily the most important issue because it is easily audible.

Thin metal as the top cover and bottom base of the box is imo a terrible vibration generator. The small four springs (or rubber) on the mech is not sufficient to isolate the vibration.

That Kenwood in the link above certainly gives attention to vibration management.

I found this website below to be on-topic, the later part has lots of pictures and examples of former CD drives.

CD_transport_DIY

Re: CD/Rom drives, even they claim to pay attention to vibration.

Unique Vibration Control Mechanism "VACS" Vibration Acoustic Control Structure

PD-501HR | TEAC

While reading signals from a rating disc, vibrations may cause a read error and negatively affect the sound quality by missing some of the original data on the disc. To eliminate vibrations and reach perfect data reading, the PD-501HR employs a unique vibration control mechanism, VACS, for a smooth rotation. After dozens of evalution tests the VACS instrument was chosen and fixed to the drive of the unit in order to achieve the best possible performance.

And that beast which has already been posted, I found more on it.

REVIEW: Esoteric K-07 SACD/CD player/DAC | WORDS AND MUSIC

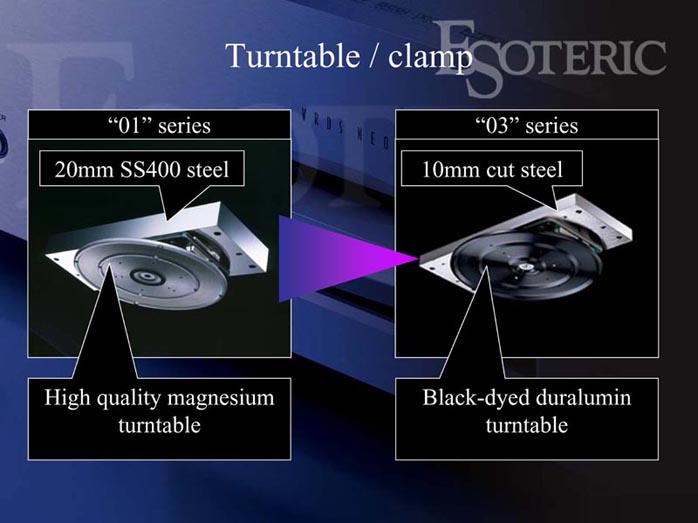

Talking of disc playback, the K-07 uses laser optics from Sony, mounted in an in-house shaft-mounted laser pickup assembly, designed to ensure the optical axis is always at the centre of the data-track on the disc, for the most accurate reading of that data.

It’s the same optical system found in the company’s flagship SA-CD players: Esoteric calls it the Vertically-aligned Optical Stability Platform, or VOSP, and the mechanism is clamped by a large steel plate and an 8mm thick large-diameter steel stabilizer designed to eliminate resonances and vibrations in the disc.

I just found out that Esoteric is part of Teac/Tascam..........the upper, upper end.

From 2005...............more images and info in link.

6moons audio reviews: Esoteric X-03 SACD

Much to my frustration, I have not been able to get more information about the CD-5010B which is in the TASCAM professional broadcast CD players ($1,000 to $4,000 range players).

CD-5010B » TEAC Industrial Products Division

I should note that I am interested in top loaders, which I assume this thread is gravitating towards.

So far products from Rega seem like the most cost effective. I'm open to learning more, and about DIY solutions.

The JVC boombox derived design with the 5-gram weight...............little motor, tiny bearings, does anyone have evidence/experience that 5 grams is too much weight? In too much I mean will shorten motor/bearing service life noticeably.

Last edited:

The only vibration to worry about in a properly running CD mechanism would be external vibration. That would seem to be the target for the high mass clamping systems. But there is another way to do this. Simply make the chassis and covers stiff and highly damped. Not with blu-tac (or whatever that putty was called). That will isolate the CD from vibration.

I was authorized warranty for the Esoteric line along with the Tascam and Teac product. Yes, it was the top of the line. it wasn't magic though and it grew out of the high end Teac line before they decided they had to differentiate those from the budget models. Oddly enough, I also have a piece of equipment from Marantz (before Philips) that was marketed as the "Esoteric" line. Pretty neat stuff as it also represented the top models from their line. Can't keep a great name down I guess.

Back to basics. You do not require a rotating high mass system to control vibration. All you really need to do is isolate the environmental vibration from reaching that system. The actual rotating parts ought to be as light as reasonably possible with as few attachments to the outside world as possible. The "stable platter" design adds a connection to the chassis through the support and bearings for that structure. Normally, the disc motor with it's turntable is the one and only connection to the chassis. The magnetic clamper disconnects from the holder completely so that you only ever have one entry point for vibration to attack the system. That leaves less structure to isolate. Additionally, the stable platter normally requires contact with the holder through bearings, so you are actually adding a vibration source through that design.

Now, about top loading type transports. Again, replicating an LP type of experience for no good reason. What is now introduced is a direct path for FOD to enter the transport, and even the laser head assy. Many people unknowingly abuse the disc motor by using excessive force to set the clamper into place. Although you can design around these problems a little, you are more likely to suffer vibration issues through the top loading port. Its more difficult to make that acoustically dead, and there is a strong desire to make that cover see-through. Damping material tends to be opaque.

The tray offers an easy way to protect the inner workings from people and their fingers. These trays always disconnect from the actual mechanism, so no vibration coupling from that direction.

Vibration isn't the mean nasty monster these marketing firms would have you believe. Don't mistake extraordinary efforts to make certain parts of transports large and heavy for more than they really are. Something to attract your attention so you can talk about anything but the important technical things that really matter. There were problems with the stable platter mechanisms, don't kid yourself. They were a PITA to set up. Solving vibration issues from the transport was the issue. Adding connection points to the outside world will always be problematic. If you want to fight vibration, put a good transport into a vault like structure and leave it alone. Attempts to make the rotating components massive will only end up fighting with what is required to actually play the CD.

The one and only benefit to the "stable platter" is to remind people of a turntable in order to move product. At least they aren't using green LEDs in the bay anymore!

I have a suggestion for all the heavy stable platter people that they can learn from. Take a current hard drive apart. They are far more sensitive to vibration than a CD is. Look at the platters and notice how it is put together, and have a look at the top clamp assy. Notice to how the casing is designed to protect the insides from vibration.

-Chris

I was authorized warranty for the Esoteric line along with the Tascam and Teac product. Yes, it was the top of the line. it wasn't magic though and it grew out of the high end Teac line before they decided they had to differentiate those from the budget models. Oddly enough, I also have a piece of equipment from Marantz (before Philips) that was marketed as the "Esoteric" line. Pretty neat stuff as it also represented the top models from their line. Can't keep a great name down I guess.

Back to basics. You do not require a rotating high mass system to control vibration. All you really need to do is isolate the environmental vibration from reaching that system. The actual rotating parts ought to be as light as reasonably possible with as few attachments to the outside world as possible. The "stable platter" design adds a connection to the chassis through the support and bearings for that structure. Normally, the disc motor with it's turntable is the one and only connection to the chassis. The magnetic clamper disconnects from the holder completely so that you only ever have one entry point for vibration to attack the system. That leaves less structure to isolate. Additionally, the stable platter normally requires contact with the holder through bearings, so you are actually adding a vibration source through that design.

Now, about top loading type transports. Again, replicating an LP type of experience for no good reason. What is now introduced is a direct path for FOD to enter the transport, and even the laser head assy. Many people unknowingly abuse the disc motor by using excessive force to set the clamper into place. Although you can design around these problems a little, you are more likely to suffer vibration issues through the top loading port. Its more difficult to make that acoustically dead, and there is a strong desire to make that cover see-through. Damping material tends to be opaque.

The tray offers an easy way to protect the inner workings from people and their fingers. These trays always disconnect from the actual mechanism, so no vibration coupling from that direction.

Vibration isn't the mean nasty monster these marketing firms would have you believe. Don't mistake extraordinary efforts to make certain parts of transports large and heavy for more than they really are. Something to attract your attention so you can talk about anything but the important technical things that really matter. There were problems with the stable platter mechanisms, don't kid yourself. They were a PITA to set up. Solving vibration issues from the transport was the issue. Adding connection points to the outside world will always be problematic. If you want to fight vibration, put a good transport into a vault like structure and leave it alone. Attempts to make the rotating components massive will only end up fighting with what is required to actually play the CD.

The one and only benefit to the "stable platter" is to remind people of a turntable in order to move product. At least they aren't using green LEDs in the bay anymore!

I have a suggestion for all the heavy stable platter people that they can learn from. Take a current hard drive apart. They are far more sensitive to vibration than a CD is. Look at the platters and notice how it is put together, and have a look at the top clamp assy. Notice to how the casing is designed to protect the insides from vibration.

-Chris

I have tested thousands of discs using CD-Cats sa3 and other expensive CD test equipment (100,000 US$). I also used NERO DiscSpeed and Opti Drive Control (<30 US$) with different CD/DVD(-R) Drives. The results between different players are always very close and disc related. I would even say that a Plextor CD-R drive will read at lower error correction than the CD-Cats. This is maybe partly because it is able to adapt its read strategy. It is like comparing an old LADA with a new MINI. Not saying that you should not prefer the old LADA.

Not saying that you should not prefer the old LADA.

Not saying that you should not prefer the old LADA.

Not saying that you should not prefer the old LADA.Attachments

I was talking to a DJ recently about problems with both CD-R and USB memory when used in clubs. These are extreme conditions and reliability is more important than for us at home. He told me about discs skipping because of the vibrations from the speakers. Here you could imagine that a construction that clamped the whole disc may help. A large, heavy platter would also need to be perfectly balanced and centred or it will be the cause of the vibrations it is trying to prevent.

Much to my frustration, I have not been able to get more information about the CD-5010B which is in the TASCAM professional broadcast CD players ($1,000 to $4,000 range players).

It is no longer produced any more and as replaced by the CD-5020A-AT

which uses a Sanyo DV11VFGP traverse mechanism with DL-3150-101 laser.

This already happened in 2010, before Sanyo was bought by Pansonic.

No new information after that. This is why I started this thread -

you simply can´t be sure that those mechs will be around in some years beside some clones.

BTW, another goal of this thread is to swap the often used Sharp LT022 laser diodes against present ones from Rohm. Bigges obstacle is the diffraction grating. But I can only start to play around with that when the math is done

on how to adapt the APC. This is beyond my abilities. Can anyone help me with that.

Datasheets are in post #186 in this thread:

http://www.diyaudio.com/forums/digi...et-us-build-one-ourselves-19.html#post4509547

In the area of reasonable mass i did build the prototype of this stabilizer:

Should be be easily adopted to any top loading mech like CD-Pro2 (have to check wether the eight of 71grams is too much for the CDPro2 Motor) , thus first batch will be for the Sony fixed pickup mechs with Ø6mm shaft.

Those are "used" to stabilizers of double weight. But again, those stabilizers are not about addin mass but doing a litle bit of damping while protecting the mech from wear by heavy mass.

http://www.diyaudio.com/forums/digi...ickup-mechanism-first-prototype-finished.html

All the best,

Salar

Last edited:

I have tested thousands of discs using CD-Cats sa3 and other expensive CD test equipment (100,000 US$). I also used NERO DiscSpeed and Opti Drive Control (<30 US$) with different CD/DVD(-R) Drives. The results between different players are always very close and disc related. I would even say that a Plextor CD-R drive will read at lower error correction than the CD-Cats. This is maybe partly because it is able to adapt its read strategy. It is like comparing an old LADA with a new MINI.Not saying that you should not prefer the old LADA.

The Lada Niva doesn't hold the "normally aspirated engine running at altitude" record for nothing! Rumour has it that Lada will make any of their old models for you too - I'd love a new Fiat 124 or 128 Lada clone over a new mini.

I'd also prefer an old, original mini.

Both perform better in important areas than most modern cars and likely last longer AND can be fixed by yourself as opposed to the new mini. If you've ever driven a real mini you'll find nothing modern comes even close to that go-cart feel which is much more satisfying than tending-to-homogeneity-and-mediocrety, modern cars.

Err... there may be some analogies in there which translate to CD mechs

- Home

- Source & Line

- Digital Source

- Quality CD-Mechanisms are long gone - let us build one ourselves!