Can I use the grey 100nf capacitor I have soldered from the power supply? and have replaced by a PIO.

Regards,

Rudy

No, it's too big, the leads will be long and his size will affect mechanic operation.

Regards,

Tibi

A proper sized 10nF silver-mica could be best noise killer.

If you can verify that 10nF is making a difference or works as intended, I have some very nice quality Cornell Dubilier silver micas I can try.

They are big though.

By the way, since we are gaining the 3-4mm on the pcb by soldering the cap on the solder blubs there and not on the pads, don t we have some slack to use a bit bigger leads?

Unless soldering it even closer makes some difference as well

You may test and let us know.

This 100nF cap is there to kill any kind of noise, not only from power supply, but also from and induced RF trough ribbon cable.

The main rule is that whatever you put there, must be connected as close as possible to laser diode.

Regards,

Tibi

This 100nF cap is there to kill any kind of noise, not only from power supply, but also from and induced RF trough ribbon cable.

The main rule is that whatever you put there, must be connected as close as possible to laser diode.

Regards,

Tibi

You may test and let us know.

This 100nF cap is there to kill any kind of noise, not only from power supply, but also from and induced RF trough ribbon cable.

The main rule is that whatever you put there, must be connected as close as possible to laser diode.

Regards,

Tibi

In that case, replacing the ribbon cable with tightly twisted and shielded pairs of wire should further reduce RF interference and/or inductance.

We may even not use the plastic clips on the pcbs, but solder the laser wires directly as close as possible to the relevant inputs/outputs.

In that case, replacing the ribbon cable with tightly twisted and shielded pairs of wire should further reduce RF interference and/or inductance.

We may even not use the plastic clips on the pcbs, but solder the laser wires directly as close as possible to the relevant inputs/outputs.

Yes and no.

Current signal collected by pin diodes can be affected by parasitic capacitance of shielding. Ribbon flat cable is constructed in such way to keep this parasitic capacitance at minimum between pin diodes and also between each pin diode and ground.

On other hand, cable to laser and monitor diode can be shielded and may improve performance.

I totally agree with soldering the clips to ribbon cable.

Regards,

Tibi

As I said the cap is 100nF X5R.

Almost any capacitor will be better, but must be small enough do not affect mechanic operation. Also big caps with long leads are out discussion here. The cap must be as close as possible to laser.

My choice is Arcotronics MKT. It is good, cheap, have exceptionally low ESR, and small enough to be soldered directly on laser pins.

Another candidate could be VISHAY-RODERSTEIN MKP-1837.

Here is the cap in his new job.

Regards,

Tibi

Tibi,

Is this mod part of the high grade kit, or will I still have to do this? My Shiga should be here soon. So I like to know so I can order part if needed. Thank you.

Tony G

+1 for C11

But I do not consider it icingI consider it a significant part of the main course. It makes a huge difference. Possibly as big as C8.

Oh and moving from a cheap 1euro noname cap to a Cornell Dubilier also had a quite audible impact.

I hope to try the miniregs very soon. I will post back...

Hi Tibi ,

what value you used for C11 ?

Tibi,

Is this mod part of the high grade kit, or will I still have to do this? My Shiga should be here soon. So I like to know so I can order part if needed. Thank you.

Tony G

I plan to include this mod in the high-grade kit.

Unfortunately your Shiga MKII HG will come without this mod. I suggest you to go for Arcotronics cap.

Regards,

Tibi

Hi Tibi ,

what value you used for C11 ?

C11 is 1nF silver-mica.

CD19FD102JO3F - CORNELL DUBILIER - CAP, SILVER MICA, 1NF, 500V, RAD | element14 Singapore

Regards,

Tibi

Thank you Tibi,As I said the cap is 100nF X5R.

Almost any capacitor will be better, but must be small enough do not affect mechanic operation. Also big caps with long leads are out discussion here. The cap must be as close as possible to laser.

My choice is Arcotronics MKT. It is good, cheap, have exceptionally low ESR, and small enough to be soldered directly on laser pins.

Another candidate could be VISHAY-RODERSTEIN MKP-1837.

Here is the cap in his new job.

Regards,

Tibi

5 minutes work and here it is the MKP1837 on laser board .

Sounds really good ,there is more control of everything but the most is the better control of sound stage,a more sharp image.

its deffinitely worth this mod

All the best

Nicu

Attachments

Now, I'm very tempted to replace another two small X5R caps.

One is Vcc decoupling on photo-detector and another one is Vref decoupling for the same photo-detector. Unfortunately these must be small enough to fit the space and as close as possible to photo-detector chip. I'm looking for a solution ... will see.

Regards,

Tibi

Your talking about the two at the bottom of the eye near that small ribbon cable right? Yeah they are pretty small with very small space around them. Perhaps if they are soldered on the chip's leads directly? Although it should be VERY sensitive to heat...

I did the test today and did some fast listening before going to work.

Definitely an improvement, although I still have to pinpoint it. The system did not play for a week and might have been a bit numb.

TOC reading was definitely faster and smoother, and cdr playback was also with less skips in my mk1. There was some new skips on a plain cd though.

The sound gave me an idea that there was more low volume details. Spatial microsounds, drum tickles, bass string plucking etc.

Bass and mid lows seem a bit thinner, but I will give it a bit more time.

A minor problem, the cap is thick and when the sled goes to the end of its travel it slightly touches the plastic wall (sanyo mecha)

By the way on my sanyo mecha the original cap was soldered even further away on the pcb. There was about 10mm distance from the solder joints

Definitely an improvement, although I still have to pinpoint it. The system did not play for a week and might have been a bit numb.

TOC reading was definitely faster and smoother, and cdr playback was also with less skips in my mk1. There was some new skips on a plain cd though.

The sound gave me an idea that there was more low volume details. Spatial microsounds, drum tickles, bass string plucking etc.

Bass and mid lows seem a bit thinner, but I will give it a bit more time.

A minor problem, the cap is thick and when the sled goes to the end of its travel it slightly touches the plastic wall (sanyo mecha)

By the way on my sanyo mecha the original cap was soldered even further away on the pcb. There was about 10mm distance from the solder joints

Your talking about the two at the bottom of the eye near that small ribbon cable right? Yeah they are pretty small with very small space around them. Perhaps if they are soldered on the chip's leads directly? Although it should be VERY sensitive to heat...

Yep, hope to get a solution to replace these as well.

Regards,

Tibi

I did the test today and did some fast listening before going to work.

Definitely an improvement, although I still have to pinpoint it. The system did not play for a week and might have been a bit numb.

TOC reading was definitely faster and smoother, and cdr playback was also with less skips in my mk1. There was some new skips on a plain cd though.

The sound gave me an idea that there was more low volume details. Spatial microsounds, drum tickles, bass string plucking etc.

Bass and mid lows seem a bit thinner, but I will give it a bit more time.

A minor problem, the cap is thick and when the sled goes to the end of its travel it slightly touches the plastic wall (sanyo mecha)

By the way on my sanyo mecha the original cap was soldered even further away on the pcb. There was about 10mm distance from the solder joints

Please, test on MKII.

Regards,

Tibi

I just finished building it.

First audition in moderate levels and I must admit that I am impressed. MK2 sounds wonderful.

Tracking is through the roof accurate. It managed to even read and play a few tracks on a Verbatim CDR that not even my PC reads.

Something that I do not like is that the LCD's light flickers while it accelerates or breaks the spindle motor, indicating that I am having some voltage drop. This probably also causes it to have to scan twice to read the TOC. This could be because of the Sanyo mecha. I think I had the same issue on the MK1 initially. Do you guys have something like that using the standard mecha?

Sonically the thing is superb. Even unmodified I am getting new stuff in the music. Granted it is a bit mid-frequency centered, but still I am getting more resolution in that area. And without any of the standard mods.

Next stop: C11, C8 and mini-regs.... but that is tomorrow

Tibi where should I try the two miniregs? V3-V4?

First audition in moderate levels and I must admit that I am impressed. MK2 sounds wonderful.

Tracking is through the roof accurate. It managed to even read and play a few tracks on a Verbatim CDR that not even my PC reads.

Something that I do not like is that the LCD's light flickers while it accelerates or breaks the spindle motor, indicating that I am having some voltage drop. This probably also causes it to have to scan twice to read the TOC. This could be because of the Sanyo mecha. I think I had the same issue on the MK1 initially. Do you guys have something like that using the standard mecha?

Sonically the thing is superb. Even unmodified I am getting new stuff in the music. Granted it is a bit mid-frequency centered, but still I am getting more resolution in that area. And without any of the standard mods.

Next stop: C11, C8 and mini-regs.... but that is tomorrow

Tibi where should I try the two miniregs? V3-V4?

Last edited:

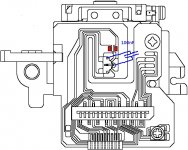

I am not sure where you are attaching cap from picture, I have 3 solder pins below removed cap (triangle, 2 vertical one to the right) are 2 of these what are being used?

Thanks!?

Steve

Hi Steve,

See below picture. Solder pins are top and middle right.

Regards,

Tibi

Attachments

- Home

- Source & Line

- Digital Source

- Shigaclone MKII Black - The builders Thread