Hi,

Same experience with my CD platform,the CD is kind of wobbling and it is a bit lose. I spent the whole last night adjusting the gap and try to read different CDs again, finally found that most CD reads ok except the LPCD45 which generates some digital along with the digital signal that doesn't appear with regular CD. Sometime read error and re-seeking occur near the end of the CD or the last 2 tracks. I ordered another Laser mechanic locally for comparison. Any suggestion ?

Same experience with my CD platform,the CD is kind of wobbling and it is a bit lose. I spent the whole last night adjusting the gap and try to read different CDs again, finally found that most CD reads ok except the LPCD45 which generates some digital along with the digital signal that doesn't appear with regular CD. Sometime read error and re-seeking occur near the end of the CD or the last 2 tracks. I ordered another Laser mechanic locally for comparison. Any suggestion ?

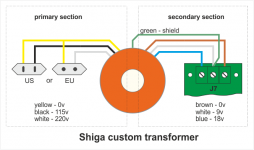

Transformer Secondary to J7 Connector

Tibi or anyone else...

Referencing the User Manual, I just want to make sure I am wiring the transformer to the Power Supply Module correctly.

Viewing the actual Power Supply Module in that SAME orientation as the Diagram, the silk screening marking AC2 is to the left of J7 and the the Blue wire is connected to the J7 input nearest the AC2 marking and the Brown wire goes to the input nearest AC1 to the right of J7...is this correct?

I have the Green/Yellow and White wires going to the center input on J7.

Hope to get this thing fired up this week and fine turn the CD Turntable height as needed.

Tibi or anyone else...

Referencing the User Manual, I just want to make sure I am wiring the transformer to the Power Supply Module correctly.

Viewing the actual Power Supply Module in that SAME orientation as the Diagram, the silk screening marking AC2 is to the left of J7 and the the Blue wire is connected to the J7 input nearest the AC2 marking and the Brown wire goes to the input nearest AC1 to the right of J7...is this correct?

I have the Green/Yellow and White wires going to the center input on J7.

Hope to get this thing fired up this week and fine turn the CD Turntable height as needed.

Tibi I have just hooked up my kit and it seems to act strangely.

When I power it up, the motor that returns the eye to the center seems to work continuously making the plastic suspension thingy go ticktcitckitck and nothing more happens. LCD shows only the dashes flash.

Have I connected something wrong?

thanks again for a wonderful kit

Dim

Could you please send me some pictures with your connections and while working via email ?

Regards,

Tibi

Tibi,

The Shiga arrived! Other than to unwrap everything, I have not wired it up and I hope to do that soon.

On inspecting the Sanyo Transport, I noticed that the CD Turntable had been moved down on the motor shaft to the point it that a mounted CD will not clear the Laser Sled. The motor shaft was not bent.

Since this was reported by at least one other person, I decided to take some measurement off 2 spare Sanyo Transports for reference. Measured with a dial caliber from the top edge of the CD Turntable where the CD will rest on, to the top of the stamped metal "chassis", both of my samples measure 19.58 mm.

What I found in adjusting the CD Turntable that came with the kit is that the CD Turntable is not very tight on the motor shaft at all, or for that matter the 2 spare units. All of them are tight enough not to spin on the shaft on motor start up.

I am going to set the CD Turntable to the measured height 19.58 mm and actually test it to ensure it reads a good sampling of CD's and fine tune the height so that the laser head is close to its static position as possible when reading a perfectly flat CD. That will allow it the maximum amount of +/- laser servo travel for reading disc that are not perfectly flat. After that I will create an epoxy step on the shaft so that the CD Turntable remains at the optimal height to the shaft. You could superglue it in place as well.

Anyway, I hope this helps other folks who run into this problem.

Thanks for this information.

Even I take extremely care to pack everything very well, some packages are reaching destination not a very good shape. :-(

Regards,

Tibi

Oh and some times the laser eye seems to click. I noticed that is hits the surface of the disc. I guess this is not normal right?

No. This is not normal and I suspect the CD Turntable had been moved down.

Please try to adjust as per Sean advice.

Regards,

Tibi

In the attached vid (just unzip it) I think it s obvious that the problem is with the offcenter wobbling puck.

Tibi please advise what should I do

Hi dimkasta,

I´ll send you another CD puck as soon the new batch is ready. However, please check CD turntable.

Regards,

Tibi

Last edited by a moderator:

Tibi or anyone else...

Referencing the User Manual, I just want to make sure I am wiring the transformer to the Power Supply Module correctly.

Viewing the actual Power Supply Module in that SAME orientation as the Diagram, the silk screening marking AC2 is to the left of J7 and the the Blue wire is connected to the J7 input nearest the AC2 marking and the Brown wire goes to the input nearest AC1 to the right of J7...is this correct?

I have the Green/Yellow and White wires going to the center input on J7.

Hope to get this thing fired up this week and fine turn the CD Turntable height as needed.

Hello Sean,

As per https://docs.google.com/document/d/1vlabZc_1If3x12ox2A5ECZxC0HLGnuOWdM-j9X4b7Q0/edit

Page 12 you have a primary and a secondary.

For 110-120V on the primary you may use yellow with black or black with white. It is symetric.

On the secondary you need to have grey and green connected together on the center point. Brown and blue does no matter how to connect them.

Regards,

Tibi

Attachments

Hi,Since this was reported by at least one other person, I decided to take some measurement off 2 spare Sanyo Transports for reference. Measured with a dial caliber from the top edge of the CD Turntable where the CD will rest on, to the top of the stamped metal "chassis", both of my samples measure 19.58 mm.

Is the 19.58mm measured between point A and B of the picture below?

Thanks

Hi,

Is the 19.58mm measured between point A and B of the picture below?

Thanks

syklab,

Looks like you have some space between puck and mechanic., or is just a picture illusion ...

Regards,

Tibi

Shiga case project and CD puck dimensions are available in PNG and CDR - Corel Draw format.

You can download them from vicol audio : shiga CD transport

With these files you can build your own CD puck and Shiga case.

Please note, some files have big resolution and may overload your PC.

Be patient till files are opened.

Regards,

Tibi

You can download them from vicol audio : shiga CD transport

With these files you can build your own CD puck and Shiga case.

Please note, some files have big resolution and may overload your PC.

Be patient till files are opened.

Regards,

Tibi

Last edited by a moderator:

Hi Tibi,

Very good eye you have, I taped a thin piece of cloth under the puck to see if it can damp out some of the vibration from disk wobbling but not much of improvement.

Regards

Well this will make things even worse.

Seems like I need to send to you another CD puck as well.

Regards,

Tibi

syklab,

The 19.58 mm was measured from the TOP of the CD Turntable, point A, without a CD or the Clamp resting on it...to the top of the chassis, or point B in your photo.

If it is easier to measure this way...from the Bottom of the CD Turntable to the top of the chassis, or point B in your photo, the measurement is 17.34 mm. For reference, the thickness of my CD Turntable samples is 2.24 mm.

The 19.58 mm was measured from the TOP of the CD Turntable, point A, without a CD or the Clamp resting on it...to the top of the chassis, or point B in your photo.

If it is easier to measure this way...from the Bottom of the CD Turntable to the top of the chassis, or point B in your photo, the measurement is 17.34 mm. For reference, the thickness of my CD Turntable samples is 2.24 mm.

Hi,

Is the 19.58mm measured between point A and B of the picture below?

Thanks

Hi Tibi,

Seems to have problem trying to download the full image on the SHIGA case drawing and Corel Draw file, I am using IE8 and the screen just go blank. Can you provide a zip version?

Thanks

Right click and save as. PNG file is not big but have very high resolution.

Anyhow, corel draw is what you need.

Regards,

Tibi

I tried today with a self-made puck made out of 4 CDs glued on top of each other. The wobling was reduced significantly (some remained probably because I glued the CDs in a harry and they are not identical), although the motor was obviously coping to move the weight. I tried with 3 and it seems to behave nicely. Now I am looking for a way to keep them centered. I m thinking of some plastic pieces glued to their edge.

With this change it managed to read some more CDs. However it still refuses to read the Metallica - Metallica CD. It simply quits after a second or two and the CD keeps spinning with inertia until it halts after slowing down but by bit by friction.

I tried to move the plastic head a bit further from the metal plate to match the measurements given above (needs less than half a mm), but it just won t move. I have applied some significant force to it including some self-devised levers to try to move it from its inner plastic and not stress the disc base, but it just won t move... I m scared I might break it if I try any harder.

With this change it managed to read some more CDs. However it still refuses to read the Metallica - Metallica CD. It simply quits after a second or two and the CD keeps spinning with inertia until it halts after slowing down but by bit by friction.

I tried to move the plastic head a bit further from the metal plate to match the measurements given above (needs less than half a mm), but it just won t move. I have applied some significant force to it including some self-devised levers to try to move it from its inner plastic and not stress the disc base, but it just won t move... I m scared I might break it if I try any harder.

Last edited:

- Home

- Source & Line

- Digital Source

- Finally, an affordable CD Transport: the Shigaclone story