More info about Silan chip, you may find on Product information

Datasheet http://doc.chipfind.ru/pdf/silan/sc7461103.pdf

We are also working on a remote and a CD magnetic puck for this project.

I expect to have both available at the end of August - beginning of September.

Those who ordered now may have the option to get these in one single delivery.

Regards,

Tibi

Datasheet http://doc.chipfind.ru/pdf/silan/sc7461103.pdf

We are also working on a remote and a CD magnetic puck for this project.

I expect to have both available at the end of August - beginning of September.

Those who ordered now may have the option to get these in one single delivery.

Regards,

Tibi

Last edited by a moderator:

We are also working on a remote and a CD magnetic puck for this project.

I expect to have both available at the end of August - beginning of September.

Those who ordered now may have the option to get these in one single delivery.

Regards,

Tibi

Thanks Tibi. Any idea what your pricing will be for each?

Thanks Tibi. Any idea what your pricing will be for each?

At this time I don't have any calculation, but I can give some ideas about what we are designing.

Remote - is just a small PCB with a 3V Lithium battery, push buttons, IC and IR LED on the same side. This will keep cost low and will allow you to dress in any enclosure you like.

CD puck - I'll go for a NAIM stile. Small simple and efficient.

A small round piece of machined Al, who accommodates a small ring magnet.

Regards,

Tibi

Hi Tibi,

First, create or buy a round long rod of Delrin 6cm diameter and drill a hole exactly in the middle.

Create the delrin so thick that he not go skidding on the CD.

Forget the magnet that sounds not good, listen to classical music then you know what I mean.

My 2 cents,

Rudy

First, create or buy a round long rod of Delrin 6cm diameter and drill a hole exactly in the middle.

Create the delrin so thick that he not go skidding on the CD.

Forget the magnet that sounds not good, listen to classical music then you know what I mean.

My 2 cents,

Rudy

Last edited:

Hi Tibi,

First, create or buy a round long rod of Delrin 6cm diameter and drill a hole exactly in the middle.

Create the delrin so thick that he not go skidding on the CD.

Forget the magnet that sounds not good, listen to classical music then you know what I mean.

My 2 cents,

Rudy

Hi Rudy,

Many thanks for your suggestion. I agree with you, any magnet puck will affect focus and tracking performance when paying fist ~5-6 min.

I wonder where I'll get Delrin in Romania.

Till we finish our first magnetic puck, I'll stay open to any CD puck project, which is reproductible, easy to make, use cheap materials and is magnetless.

Regards,

Tibi

I might have a bit, about 30mm but would need to check.

Fwiw, aluminium will look much better unless you're able to cnc machine the delrin to acheive the finish. Another alternative is a non-magentic brass puck that is just heavy enough to stop the CD from spinning on start up.

Fran

Fwiw, aluminium will look much better unless you're able to cnc machine the delrin to acheive the finish. Another alternative is a non-magentic brass puck that is just heavy enough to stop the CD from spinning on start up.

Fran

Tibi,

If you can't find Delrin, try nylon. It is about the same hardness and machines well. Nylon isn't as shiny as Delrin, but it will work. If you do try plastic, you might want to try it in white or a lighter color, if available. As Woodturner says, it is more difficult to get a very smooth surface finish with Delrin and especially with nylon. When its dark, the flaws show more than when light in color.

My two cents. I agree with Woodturner. Aluminum without a magnet would be my choice. It is easy to machine, has a little weight, and is non-magnetic.

Jac

If you can't find Delrin, try nylon. It is about the same hardness and machines well. Nylon isn't as shiny as Delrin, but it will work. If you do try plastic, you might want to try it in white or a lighter color, if available. As Woodturner says, it is more difficult to get a very smooth surface finish with Delrin and especially with nylon. When its dark, the flaws show more than when light in color.

My two cents. I agree with Woodturner. Aluminum without a magnet would be my choice. It is easy to machine, has a little weight, and is non-magnetic.

Jac

CD Clamp...Magnet or a Weight

I like the idea of the brass with sufficient mass to cause minimal slip of the CD at start up. One would need to consider the additional load to the thrust bearing of the CD Turntable drive motor...but I doubt much weight would be needed.

Threading the existing CD Turntable is not something most folks are going to have the means to do.

The magnet CD Clamp does work and is simple to execute. That is what I will start with and then try a brass or other metal weight and see just how much difference it makes in how the thing sounds.

Talking to a friend who has a current ARC CD player, that unit uses a magnet CD Clamp. Being a former ARC dealer, he is now curious and is going to talk to the ARC guys about what they may have experimented with for CD Clamps. The ARC units use the CD-Pro drive units. I will let you folks know what we find out...

I like the idea of the brass with sufficient mass to cause minimal slip of the CD at start up. One would need to consider the additional load to the thrust bearing of the CD Turntable drive motor...but I doubt much weight would be needed.

Threading the existing CD Turntable is not something most folks are going to have the means to do.

The magnet CD Clamp does work and is simple to execute. That is what I will start with and then try a brass or other metal weight and see just how much difference it makes in how the thing sounds.

Talking to a friend who has a current ARC CD player, that unit uses a magnet CD Clamp. Being a former ARC dealer, he is now curious and is going to talk to the ARC guys about what they may have experimented with for CD Clamps. The ARC units use the CD-Pro drive units. I will let you folks know what we find out...

Just my two cents in this nice discussion. Keeping the hole completely centered might not be enough. Just remember that all materials can have slightly different densities on different sides. So balancing the puck might be equally important as centering it.

And just some food for thought, a vid loaned from the RC world to give you some ideas

RC Tire Balancing -- ProLine Minute w/ Squirrel #1 - YouTube

And just some food for thought, a vid loaned from the RC world to give you some ideas

RC Tire Balancing -- ProLine Minute w/ Squirrel #1 - YouTube

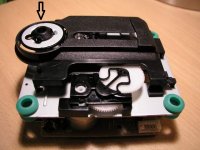

You can create the same form on the lathe as of the original puck.

You see on the picture that there is a hole in the CD Platform.

There than the puck be placed in the hole.

That's more stable also the shiga is placed in horizontale position.

Regards,

Rudy

You see on the picture that there is a hole in the CD Platform.

There than the puck be placed in the hole.

That's more stable also the shiga is placed in horizontale position.

Regards,

Rudy

Attachments

Many thanks to all who paid till now.

I received many messages with different requests.

I´ll do my best to full fill all of them.

Someone requested me to measure original JVC puck. His message was trough forum pm and I lost his name. However, here is a drawing which could be used to make such puck.

Regards,

Tibi

I received many messages with different requests.

I´ll do my best to full fill all of them.

Someone requested me to measure original JVC puck. His message was trough forum pm and I lost his name. However, here is a drawing which could be used to make such puck.

Regards,

Tibi

Attachments

You can create the same form on the lathe as of the original puck.

You see on the picture that there is a hole in the CD Platform.

There than the puck be placed in the hole.

That's more stable also the shiga is placed in horizontale position.

Regards,

Rudy

Interesting pictures. Thank you. I can't wait to see the mechanic in person.

Do I understand correctly that someone has threaded the center hole and uses a puck that screws into the mechanic? When not turned on, doesn't the motor spin easily? I guess that means they use the friction of the CD on the mechanic to hold the base while screwing in the puck.

Do I understand correctly that someone has threaded the center hole and uses a puck that screws into the mechanic? When not turned on, doesn't the motor spin easily? I guess that means they use the friction of the CD on the mechanic to hold the base while screwing in the puck.

That's probably me, and no, it works fine, although not quite as easy as just dropping the puck on.

On the subject of the puck, I think you would need a decent amount of weight to prevent the disc slipping on startup if you are not going to use magnets. I don't think a puck of 25mm dia made from aluminium will be heavy enough. Brass maybe.... anyone tried this yet?

Fran

CD Clamp...Magnet or a Weight

I mention previously that ARC uses a magnetic CD Clamp in all their CD Player and as I suspected, they indeed did spent a great deal of time experimenting with various methods of holding the CD to the CD turntable.

To sum it all up, ARC played with brass, various woods (including Shun Mook), spider-like clamps, magnets, etc, etc. Relative to these materials and methods versus the magnet clamp design ended up with, they summed it up this way..."Some are okay, some are worse, but none are better."

Going back to the need to go to great lengths balancing whatever CD Clamp you use, please realize that the CD is only turning 500 rpm starting at the beginning(inside) of the CD, and is down to 200 rpm on the outside. With a 30mm Clamp being at the center of rotation, it would need to be a poor design and grossly off center to cause any noticeable vibration. Again, with the typical manufacturing tolerance variations in CD's, which includes center holes that are overly large, the CD's are by far the biggest potential contributor to vibration in the system...and there is nothing you can do about that. Fortunately, the CD tracking system handles the latter pretty well.

For those who want to use a screw down clamp, or something else that you concluded "sounds" better, have at it. Likewise, if you want to go to the effort of "balancing" your CD Clamp, well, go for it. That is afterall the beauty of this hobby!

I mention previously that ARC uses a magnetic CD Clamp in all their CD Player and as I suspected, they indeed did spent a great deal of time experimenting with various methods of holding the CD to the CD turntable.

To sum it all up, ARC played with brass, various woods (including Shun Mook), spider-like clamps, magnets, etc, etc. Relative to these materials and methods versus the magnet clamp design ended up with, they summed it up this way..."Some are okay, some are worse, but none are better."

Going back to the need to go to great lengths balancing whatever CD Clamp you use, please realize that the CD is only turning 500 rpm starting at the beginning(inside) of the CD, and is down to 200 rpm on the outside. With a 30mm Clamp being at the center of rotation, it would need to be a poor design and grossly off center to cause any noticeable vibration. Again, with the typical manufacturing tolerance variations in CD's, which includes center holes that are overly large, the CD's are by far the biggest potential contributor to vibration in the system...and there is nothing you can do about that. Fortunately, the CD tracking system handles the latter pretty well.

For those who want to use a screw down clamp, or something else that you concluded "sounds" better, have at it. Likewise, if you want to go to the effort of "balancing" your CD Clamp, well, go for it. That is afterall the beauty of this hobby!

- Home

- Source & Line

- Digital Source

- Finally, an affordable CD Transport: the Shigaclone story