Hi

I have my shigaclone done and playing about two years ago and I can say the total listening time don´t total 200 hours.

Now it´s taking too much time to read the cd, quite a lot different when the unit was new. Is it possible that the laser diode unit is going? Can that unit be replaced somehow?

Thanks for help and comments

JC

I do not think so....Mine is close to 5000 hours (still the first laser out of 10 spares) and spinning as we speak

Hi JC,

Mine does that sometimes too ,I unplug it and restart it, click the cd door switch a couple of times,This is only a occasionally thing,I have considered a reset, but haven't needed it yet......Sometimes it's the cd,try a new one just to see,You have probably cleaned the eye....and watch it move without a cd in place,make sure it moves smooth ,

Hope this helps !!!!!

Might ask Peter he's helped me alot and might know,

Mine does that sometimes too ,I unplug it and restart it, click the cd door switch a couple of times,This is only a occasionally thing,I have considered a reset, but haven't needed it yet......Sometimes it's the cd,try a new one just to see,You have probably cleaned the eye....and watch it move without a cd in place,make sure it moves smooth ,

Hope this helps !!!!!

Might ask Peter he's helped me alot and might know,

Great to see that again Erik!

Happy Xmas to all the shiga people out there....

Hi Fran,

As you can see on the photo I am using te Delrin Puck.

I tried everything to get your ebony puck as practical as possible (playing loads of cd's a day) but in the end the Delrin Puck was much smoother on the Delrin Platform. With humidity conditions the puck was reacting a lot.

Sometimes after leaving it a day on it got way too tight.

I obviously made the thread as wide as posible and in the end leaving only a few thread turn in the wood.

In the end I experimented too much with you puck....if you catch my drift

A real pity since I do find the sound of your ebony puck more "natural"

How is your experience. And the inevital question did you try to make an ebony platform...

Merry christmas to all the clone builders and may they be rewarded big time !!

Hi Fran,

If you're ever in the future build an Ebony platform or a CD Puck for the Shigaclone, please can you also make a masterpice of workmanship for me

Everyone happy Christmas days.

Regards,

Rudy

If you're ever in the future build an Ebony platform or a CD Puck for the Shigaclone, please can you also make a masterpice of workmanship for me

Everyone happy Christmas days.

Regards,

Rudy

Attachments

Last edited:

Spare control boards anyone?

Hi Folks!

Hope the 'mid-winter shopping theme' went well for you and yours...!

I was wondering if anyone has a few extra JVC control boards lying around (perhaps due to unintentional abuse, or other misfortune, with/of the CD/laser units?)?

The Sanyo donor I found locally has a less than ideal control board for my plagiaristic designs...

See the board here.

http://www.diyaudio.com/forums/digi...ansport-shigaclone-story-414.html#post2341172

Please PM if you think you might be able to help!

I am not expecting charity, but any help would be appreciated!

Happy New Year to all at and reading diyAudio!

Cheers

Bill

Hi Folks!

Hope the 'mid-winter shopping theme' went well for you and yours...!

I was wondering if anyone has a few extra JVC control boards lying around (perhaps due to unintentional abuse, or other misfortune, with/of the CD/laser units?)?

The Sanyo donor I found locally has a less than ideal control board for my plagiaristic designs...

See the board here.

http://www.diyaudio.com/forums/digi...ansport-shigaclone-story-414.html#post2341172

Please PM if you think you might be able to help!

I am not expecting charity, but any help would be appreciated!

Happy New Year to all at and reading diyAudio!

Cheers

Bill

Last edited:

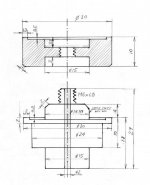

CD Platform with puck.

I have a professional company found that will make a CD Platform with puck.

The first thing he told me that the product Delrin mechanical works, the 14,97mm where the CD around falls he can make it exactly, but later it mechanical works with Delrin.

I got the advice from him, to make the CD platform with puck from aluminum.

Tomorrow morning I have a conversation with the owner of the company.

Would Aluminum be a good choice?

How do you all think about it?

Regards,

Rudy

I have a professional company found that will make a CD Platform with puck.

The first thing he told me that the product Delrin mechanical works, the 14,97mm where the CD around falls he can make it exactly, but later it mechanical works with Delrin.

I got the advice from him, to make the CD platform with puck from aluminum.

Tomorrow morning I have a conversation with the owner of the company.

Would Aluminum be a good choice?

How do you all think about it?

Regards,

Rudy

Attachments

Last edited:

The nice thing about Delrin is that it is dimensionally stable and way stronger than needed for this application. The advantage over aluminum is that when you go to press it on, it will deform as needed and slide on. I would be concerned about getting the press fit right with aluminum. It won't be forgiving at all. This means they will need to drill, bore and then ream the aluminum to be 100% sure it is centered and to size. If they don't you have concerns about damaging the motor putting it on, or it will be loose and need locktite to hold it in place. In which case it won't be 100% on center.

In the end if this is a good place and are able to hold tight tolerances on that bore, you should be fine either way.

In the end if this is a good place and are able to hold tight tolerances on that bore, you should be fine either way.

How do you all think about it?

It is an absolute requirement that CD platform is machined with platform mounted on a shaft, otherwise you will get wobbling problems. For that reason, it's advisable to machine the parts from relatively soft material, like Delrin or acrylic.

The whole batch of Delrin platforms that is shown in your attachment was screwed up and not possible to use only because the shaft holes were drilled last.

I believe that issue can be eliminated if the critical diameters are cut in the same setup as the bore. It will take a bit more material to do it that way, but you should be able to do it.

1) setup stock in a collet

2) drill, bore then ream the shaft hole

3) turn bottom side features

4) turn the top side mating face and center hub ( where disk locates)

5) turn the part around in the collet

6) finish top side features ( thread etc.)

1) setup stock in a collet

2) drill, bore then ream the shaft hole

3) turn bottom side features

4) turn the top side mating face and center hub ( where disk locates)

5) turn the part around in the collet

6) finish top side features ( thread etc.)

It is an absolute requirement that CD platform is machined with platform mounted on a shaft, otherwise you will get wobbling problems. For that reason, it's advisable to machine the parts from relatively soft material, like Delrin or acrylic.

The whole batch of Delrin platforms that is shown in your attachment was screwed up and not possible to use only because the shaft holes were drilled last.

Yeah I have one of those..

Thank you all for the answers and help, I tell the company about the things you all write here.

The last 2 pictures for the screw puck is the right one I think, you all see here also the pictures how I make the Shigaclone: http://www.htforum.nl/yabbse/index.php?topic=86768.450

Regards,

Rudy

The last 2 pictures for the screw puck is the right one I think, you all see here also the pictures how I make the Shigaclone: http://www.htforum.nl/yabbse/index.php?topic=86768.450

Regards,

Rudy

Wow, which is that for a display?

It's a CD Pro with a display board Brian GT designed for his school project (limited functionality though).

Interesting topic,

but the JVC drives are probably not available anymore?

regards,

Hello Harolda yes they are still available

and if you like to hear such a transport your welkom .

ik woon in Echt

15 minuten rijden voor jou

- Home

- Source & Line

- Digital Source

- Finally, an affordable CD Transport: the Shigaclone story