Hi all,

Ok, so here's a template I drew up - it's as close as I could get, but I drilled/cut my top plate to it and it fits well. BTW, this is for the mechanism without the plastic cover. Just remember (1) if you lay it out from the backside, reverse the drawing, (2) make sure you print it out at 100% (check it before you cut), and (3) from a mechanical drawing point of view, its over-dimensioned, but this way you can start from whatever reference you want.

Bill

Ok, so here's a template I drew up - it's as close as I could get, but I drilled/cut my top plate to it and it fits well. BTW, this is for the mechanism without the plastic cover. Just remember (1) if you lay it out from the backside, reverse the drawing, (2) make sure you print it out at 100% (check it before you cut), and (3) from a mechanical drawing point of view, its over-dimensioned, but this way you can start from whatever reference you want.

Bill

Attachments

Hi, can we see pictures, you seem in heaven? ;0)

Guy

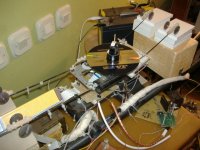

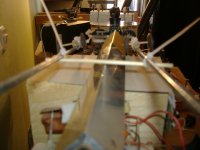

The two left wheels are not used.That side is placed on air cushion.

Attachments

The two left wheels are not used.That side is placed on air cushion.

Ingenious and original. I like it! What is considered the "air cushion", the fact that the transport is suspended from the rods or there is a place on the left side (that I don't see) where there are no contact.

I would have so many questions because I'm curious but I'll keep a reserve. Did you isolate the motors or plan onto?

Is this the prototype or final product? If you plan to bring it to a better level, it is a nice challenge.

Keep it up!

The two left wheels are not used.That side is placed on air cushion.

Also please explain your puck, is that a self centering magnet system or screw type???

Thanks,

Guy

Ingenious and original. I like it! What is considered the "air cushion", the fact that the transport is suspended from the rods or there is a place on the left side (that I don't see) where there are no contact.

I would have so many questions because I'm curious but I'll keep a reserve. Did you isolate the motors or plan onto?

Is this the prototype or final product? If you plan to bring it to a better level, it is a nice challenge.

Keep it up!

Thanks, I am glad that you like it.That aluminium angle on the left side is the air cushion but the air holes can't be seen because I have covered unused part with tape to make cushion more effective.Search for Terminator arm to see what kind of cushion it is.Decoupling is made through the rods but vibrations are compensated with wheels and cushion.Don't have plans to isolate motor because I have bonded both with thick layer of teflon tape with good sonic result,but who knows....The metal frame is clamped with two halves of carbon tubes attached together with screws.This is an infinite prototype since the new changes are coming often and I hate boxes because of sound degradation.Most of my system is without boxes.

Also please explain your puck, is that a self centering magnet system or screw type???

Thanks,

Guy

This is a screw puck.It is made of carbon too.The mas of the puck is little bit less than one cd disc.I have removed the metal part on the plastic cd holder and inserted a carbon ring to make holder as rigid as possible.Puck can be made easy.Just cut one 12mm and one 15mm peace of tube and then make a 6mm thread on 12mm part so it can clamp that horizontal 15 mm part.The diameter of the tube is 28mm.You just have to insert a 6mm screw in the plastic holder hole.When you screw it you center it but you can miss some mm because it so light that it can't cause extra vibrations.It sounds better than plexy and magnet that I tried.I think that lower mass is what that transport need.I have tried hi mass transport configuration but I didn't liked it at all.That rod-air version is correct version to me.We can not eliminate vibrations completly so why don't control them here and there to find some intersinergy instead to kill them completly and some music by the way.

Call me esoteric,but ...

Hi all,

you probably don't really mind but I read the whole thread from A-Z and at this point I decided I wanted one:

Call me esoteric, but I have rarely seen a more "scandinavian" design... you'll have to tell me about that audio1st ... is that an elk ?

is that an elk ?

EZ's are on order for building 2 clones, one for myself which will be "heavily inspired" by the one pictured above and another one (no decision yet on final design) for my cousin pierre aka WaveFlex in the speaker section.

He made me a birthday present in the form of a kit for some sexy bookshelf cabinets using translam/CNC as for these:

http://www.diyaudio.com/forums/multi-way/155739-troels-pms-multilayer-assembly-build-thread.html

My design is more like this one actually but with increased volume to suit the Vifa PL14 (sorry for the forum beeing french, but you get an idea scrolling down having a look at the pics)

Inspiration "SA2K" avec caisses LEGO - Enceintes

Guess what his birthday present will be...

Thanks to Peter for starting this thread and to everybody contributing to it!

Cheers,

Max

Hi all,

you probably don't really mind but I read the whole thread from A-Z and at this point I decided I wanted one:

Call me esoteric, but I have rarely seen a more "scandinavian" design... you'll have to tell me about that audio1st ...

is that an elk ?

is that an elk ?EZ's are on order for building 2 clones, one for myself which will be "heavily inspired" by the one pictured above and another one (no decision yet on final design) for my cousin pierre aka WaveFlex in the speaker section.

He made me a birthday present in the form of a kit for some sexy bookshelf cabinets using translam/CNC as for these:

http://www.diyaudio.com/forums/multi-way/155739-troels-pms-multilayer-assembly-build-thread.html

My design is more like this one actually but with increased volume to suit the Vifa PL14 (sorry for the forum beeing french, but you get an idea scrolling down having a look at the pics)

Inspiration "SA2K" avec caisses LEGO - Enceintes

Guess what his birthday present will be...

Thanks to Peter for starting this thread and to everybody contributing to it!

Cheers,

Max

Are you in need of a EZ31B ?

Well not in Australia, but how about in Canada?

I would be willing to assist those of you having great difficulty locating this model and do a group purchase of 5 or 6 units (Model JVC RC-EZ31B) and then ship to destination. Now this entails certain risks that I am not willing to assume. All you would get is new in the box. My cost here is $68 Canadian, including both Provincial Sales Tax and GST at the pickup depot (I have to pay the taxes). Your cost would be $85 Canadian plus shipping. Participant would have to select shipping method and assume all risks that package may not arrive. You will have to accept shipping in the original box without extra packing (I will tape up the box)... so pick shipping method wisely! I ship on receiving your payment.... and you propose a safe method of payment which I need to approve (no PayPal ).

Now one rule: Be fair and No hoarding and first time purchase only!.. I am doing this to encourage DIY'ers that would otherwise be left out from this project, and want to proceed with the EZ31B version.

To start off, let me have your suggestions to make this safe/secure for me, and we then start the sale... remember 5 or 6 units available (I have mine).

Sorry for making this seem so difficult a process,

Louis

Hi!

It's a massive thread! Any new word on sources for the EZ31/51 preferably in Australia? Or other appropriate models?

Thanks!

Taz.

Well not in Australia, but how about in Canada?

I would be willing to assist those of you having great difficulty locating this model and do a group purchase of 5 or 6 units (Model JVC RC-EZ31B) and then ship to destination. Now this entails certain risks that I am not willing to assume. All you would get is new in the box. My cost here is $68 Canadian, including both Provincial Sales Tax and GST at the pickup depot (I have to pay the taxes). Your cost would be $85 Canadian plus shipping. Participant would have to select shipping method and assume all risks that package may not arrive. You will have to accept shipping in the original box without extra packing (I will tape up the box)... so pick shipping method wisely! I ship on receiving your payment.... and you propose a safe method of payment which I need to approve (no PayPal ).

Now one rule: Be fair and No hoarding and first time purchase only!.. I am doing this to encourage DIY'ers that would otherwise be left out from this project, and want to proceed with the EZ31B version.

To start off, let me have your suggestions to make this safe/secure for me, and we then start the sale... remember 5 or 6 units available (I have mine).

Sorry for making this seem so difficult a process,

Louis

Hi

I have a new and unopened JVC RC-EZ31B boom box for sale at the following link.

http://www.diyaudio.com/forums/swap-meet/166356-shigaclone-donor-jvc-rc-ez31b-boom-box.html

I thought I would post it here as these are quite hard to get hold of.

Regards

I have a new and unopened JVC RC-EZ31B boom box for sale at the following link.

http://www.diyaudio.com/forums/swap-meet/166356-shigaclone-donor-jvc-rc-ez31b-boom-box.html

I thought I would post it here as these are quite hard to get hold of.

Regards

Working on a shigaclone myself, I would like to know which c906 replacements have been done and which ones sound better than the original? A Wondercap 0,01 uF is used by Erik, but what would also be a nice replacement (can't find a wondercap)?

I am also interested in the C906. The following capacitors are tested in my Shigaclone:

1. the original electrolytic, 0.1uF

2. Black Gate NX 0.1uF

3. MKP 0.1uF from a local dealer

4. WonderCap 0.068uF (aluminum foil/PP film)

5. RelCap PPT 0.01uF (tin foil/PP film)

6. Mundorf MKP 0.1uF (white)

7. Ceramic disk 0.22uF

Overall, I like the no. 1 and the no. 2, and both of them are electrolytic.

The strangest sound comes with the no. 5. Though the RelCap PPT is considered a good capacitor, placing it at C906 the sound is thin, bright, and unfocused. The no. 4 is also leading to a bright sound.

In the other side, with a large capacitance (no. 7, 0.22uF) the sound is thick, solid, and slow. The original value 0.1uF seems well-balanced.

Maybe the capacitance is a critical factor. However, Peter prefer the 0.01uF ERO and someone also prefer the 0.01uF MultiCap.

How do you guys think about the replacement of C906?

I just tried the recommended MultiCap RTX (0.015uF) and like it. The capacitance is small but the sound is not as bright and thin as the 0.01uF RelCap PPT. However, this result makes me more confused. What are the key characteristics for choosing the replacement of C906?

I am also interested in the C906. The following capacitors are tested in my Shigaclone:

1. the original electrolytic, 0.1uF

2. Black Gate NX 0.1uF

3. MKP 0.1uF from a local dealer

4. WonderCap 0.068uF (aluminum foil/PP film)

5. RelCap PPT 0.01uF (tin foil/PP film)

6. Mundorf MKP 0.1uF (white)

7. Ceramic disk 0.22uF

Overall, I like the no. 1 and the no. 2, and both of them are electrolytic.

The strangest sound comes with the no. 5. Though the RelCap PPT is considered a good capacitor, placing it at C906 the sound is thin, bright, and unfocused. The no. 4 is also leading to a bright sound.

In the other side, with a large capacitance (no. 7, 0.22uF) the sound is thick, solid, and slow. The original value 0.1uF seems well-balanced.

Maybe the capacitance is a critical factor. However, Peter prefer the 0.01uF ERO and someone also prefer the 0.01uF MultiCap.

How do you guys think about the replacement of C906?

If you have some time and patience you can make copper/cotton capacitor of Alpha Core 12 AWG inductor.You must place a sheets of copper and cotton in between two solid nonmetalic blocks and screw them.For 10nF you will need some 2m of foil.My blocks dimensions are 6x9 cm.Look at this white cube on my previous post with photos(third photo, cube under the right side under disc).You will get just natural ,uncolored sound with balanced timbre.I came on this idea after tried polystirene,various MKP from Vima,ERO,Philips etc. and each one got some mistake, to bright ,to soft,to.......So try this.Nice thing is that you have non inductive cap.After that you can make one for s/pdif and you will hear how this transport sings.

- Home

- Source & Line

- Digital Source

- Finally, an affordable CD Transport: the Shigaclone story