Hi Peter,

Yes, Chuo Denki has a long history of using inexpensive copies. This is a paired down copy of the Sony KSM-210AAB or similar transport. AMC used some and they dropped like flies. The fix? Use the original Sony transport. Even the motors were garbage!

Chuo Denki was imported and distributed in Canada by AVS in Montreal.

Anyway, new they can work well, but as you can see there are no real bearing surfaces. It will wear quickly for sure. Use the original Sony mechanism if you want your work to be worth anything. This Chinese stuff is extremely variable in quality.

The best transport of all was the NEC unit used in Nakamichi OMS 5/7 and the first Alpine CD player (single beam like Philips). Too bad the electronics were not as advanced. The Sony KSS-123 types and KSS-151A types were very good. We used to laugh at the KSS-150A (KSS-210A) and KSS-240A heads, but they are high end now! I was never happy with the Philips heads for a number of reasons (I was trained on them at Philips too). The current VAM1202 is complete trash.

I was never happy with the Philips heads for a number of reasons (I was trained on them at Philips too). The current VAM1202 is complete trash.

It doesn't matter whether the preamp is on the head (KSS-240A) or on the board (all others I listed). Proper lead dress makes all the difference. Either way, you can see the results in the eye pattern.

). Philips has historically always had terrible support out of warranty. Too bad, so sad. Buy our new one.

). Philips has historically always had terrible support out of warranty. Too bad, so sad. Buy our new one.

Hi George,

You have to learn how to separate the mechanism from the electronics in your head. The clock doesn't even affect the servos. It will only affect the DSP and memory, then on to the other functions aimed at processing the audio (like D/A's). Your clock only affects the signal after it's off the disc and in memory, period!

Think. If the servos suffered from a jittery clock, it might at most increase the noise in the servo signal towards the driver. The mechanism, motors or lense, can not respond to this. The laser current monitor maybe, but that is only if the noise leaks into the laser power control circuit where it shouldn't be.

-Chris

Yes, Chuo Denki has a long history of using inexpensive copies. This is a paired down copy of the Sony KSM-210AAB or similar transport. AMC used some and they dropped like flies. The fix? Use the original Sony transport. Even the motors were garbage!

Chuo Denki was imported and distributed in Canada by AVS in Montreal.

Anyway, new they can work well, but as you can see there are no real bearing surfaces. It will wear quickly for sure. Use the original Sony mechanism if you want your work to be worth anything. This Chinese stuff is extremely variable in quality.

The best transport of all was the NEC unit used in Nakamichi OMS 5/7 and the first Alpine CD player (single beam like Philips). Too bad the electronics were not as advanced. The Sony KSS-123 types and KSS-151A types were very good. We used to laugh at the KSS-150A (KSS-210A) and KSS-240A heads, but they are high end now!

It doesn't matter whether the preamp is on the head (KSS-240A) or on the board (all others I listed). Proper lead dress makes all the difference. Either way, you can see the results in the eye pattern.

Absolutely! Many good heads are replaced when it's the bearing that has failed. Not really replaceable on Philips and it's the same motor used in most Sony types. What a rip off Philips is!A worn bearing on the t/table motor can effect signal quality.

Well, it is an analog signal. The quality of this signal for slice level and noise is critical to what you are going to pull out of it for data.I remember a few people (one could have been Julian Vereker from Naim) talking about the laser signal being an rf signal and presumably attaching some significance to it.

Teac normally uses Sony heads. I don't know what they are using these days. If I have a choice between Sony and Philips, I'm going with Sony. The reason you see so much Philips around is that they are cheaper than Sony (who always price themselves out of any market!So what I here is Sony and especially Teac should be the best drives?

Hi George,

No George.It may not affect the transport mechanism in any way, but it does affect the VRDS-T1 Transport as a whole unit.

You have to learn how to separate the mechanism from the electronics in your head. The clock doesn't even affect the servos. It will only affect the DSP and memory, then on to the other functions aimed at processing the audio (like D/A's). Your clock only affects the signal after it's off the disc and in memory, period!

Think. If the servos suffered from a jittery clock, it might at most increase the noise in the servo signal towards the driver. The mechanism, motors or lense, can not respond to this. The laser current monitor maybe, but that is only if the noise leaks into the laser power control circuit where it shouldn't be.

-Chris

Hi Andy,

The swing arm mechanism was unrepairable outside of the factory in realistic terms. I looked at setting one up once. The glass disc was $250 at the time (Studer/Revox had one) and the alignment was not fun. They decided to fire them all back to the factory. There were also problems with sagging suspensions with the lense.

The two methods each have their weak points and strong points. Personally, a linear motor / linear tracking type was nice (KSS-151A) as used by Denon and Tascam. The gear drive units are slower to go from one track to the next. That is the biggest problem with a geared linear tracking system.

The radial arm suffered from bearing issues and more so, flexible PCB issues.

So, that's it between the two.

-Chris

I wish that were true (since it's another myth).I always understood the original Philips swing-arm mechanism, as in the cdm-0/1/2/3/4 was 'better' than the rack and pinion type used by Sony and the later Philips mechanisms.

The swing arm mechanism was unrepairable outside of the factory in realistic terms. I looked at setting one up once. The glass disc was $250 at the time (Studer/Revox had one) and the alignment was not fun. They decided to fire them all back to the factory. There were also problems with sagging suspensions with the lense.

The two methods each have their weak points and strong points. Personally, a linear motor / linear tracking type was nice (KSS-151A) as used by Denon and Tascam. The gear drive units are slower to go from one track to the next. That is the biggest problem with a geared linear tracking system.

The radial arm suffered from bearing issues and more so, flexible PCB issues.

So, that's it between the two.

-Chris

Hi Hyldal,

One manufacturer I talked to a few years ago hates Philips with a passion. Support is the issue.

-Chris

That is entirely possible. Also, Sony is famous for pricing themselves too high.I think the reason for seeing so many philips drives around is, because they are easyer available and to work with for smaller companys, through theres sales company Daisy Laser.

One manufacturer I talked to a few years ago hates Philips with a passion. Support is the issue.

-Chris

anatech said:One manufacturer I talked to a few years ago hates Philips with a passion.

-Chris

LOL

I do agree that the SONY / Teac linear trackers are superb...

Arne K

anatech said:Hi George,

The clock is not affecting the transport in any way. It's a fact. It's the rest of the electronics that you are playing with.

Also, I didn't mean to imply the Teac transports were bad - they aren't. Sony heads normally.

I can demonstrate that higher bias than necessary increases THD. I plan to demo that at Burning Amp. Believe it.

-Chris

Chris, George,

there is a misunderstanding between your definition of transport

Chris: by transport you mean the bare drive as supplied by OEM

George: by transport you mean the complete product putting out SPDIF

correct ?

If so, George is right, applying a proper clock and reclcoking SPDIF obviously improves the transport.

best

Guido

anatech said:

It doesn't matter whether the preamp is on the head (KSS-240A) or on the board (all others I listed). Proper lead dress makes all the difference. Either way, you can see the results in the eye pattern.

-Chris

Hi Chris

It does matter. The earlier one amplifies signale, the better the signal to noise ratio obtainable. In the TEAC VRDS10 one only has to point his finger at the flex connection that leaves the pickup, to make the player loose track. Simple to explain, and easy to conclude that induced noise increases jitter.

best

Guido

Yes you are correct Guido, I never implied that a clock would improve the mechanism, rather the transport as a whole up to the spidf.

Also the Teac vrds systems always seam to sound better than other non full cd supported mechs to me and others, even without your clocks fitted, the only other one that has sounded as good that I've heard was the Pioneer Stable Platter system, again another full supported CD system.

When you watch these types of systems there is hardly any up and down movement of the cd edge (flap) while spinning, where in the center only supported systems the outside edge of the cd can (flap) up and down 2 sometimes 3 mm, and the poor focusing mech of the laser tries to follow, I believe the amount of error correction must be far less on a full cd support like the VRDS or Stable patter, this could be the reason for my preference to them.

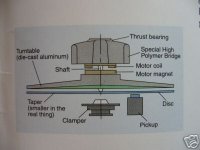

Below is the Pioneer upside down Stable Patter drive, ( note the linear drive laser motor) the platter is machined aluminium in this model (T-09)and it's face was slightly concaved so when the cd was press onto it you had virtually no cd edge (Flap).

The CM3.2 of the Teac VRDS that I have is similar except the other way around, it also has a great Sony KSS-151A Laser linear motor drive.

Cheers George

Also the Teac vrds systems always seam to sound better than other non full cd supported mechs to me and others, even without your clocks fitted, the only other one that has sounded as good that I've heard was the Pioneer Stable Platter system, again another full supported CD system.

When you watch these types of systems there is hardly any up and down movement of the cd edge (flap) while spinning, where in the center only supported systems the outside edge of the cd can (flap) up and down 2 sometimes 3 mm, and the poor focusing mech of the laser tries to follow, I believe the amount of error correction must be far less on a full cd support like the VRDS or Stable patter, this could be the reason for my preference to them.

Below is the Pioneer upside down Stable Patter drive, ( note the linear drive laser motor) the platter is machined aluminium in this model (T-09)and it's face was slightly concaved so when the cd was press onto it you had virtually no cd edge (Flap).

The CM3.2 of the Teac VRDS that I have is similar except the other way around, it also has a great Sony KSS-151A Laser linear motor drive.

Cheers George

Attachments

georgehifi said:

Also the Teac vrds systems always seam to sound better than other non full cd supported mechs to me and others, even without your clocks fitted, the only other one that has sounded as good that I've heard was the Pioneer Stable Platter system, again another full supported CD system. Cheers George

I like both the TEACs and stable platters but would like to mention that a well implemented Philips CDpro can achive similar or better quality as a drive.

best

Guido

Hi Guido,

We have always been in complete agreement there.

Do you?

-Chris

I thought I was very clear when I specified the mechanical systems and the servo section. I did say that the clocking would improve everything from the sram forward.If so, George is right, applying a proper clock and reclcoking SPDIF obviously improves the transport.

We have always been in complete agreement there.

Well, again things are being stretched here. It is not normal for a customer to be poking their finger around inside the unit while it is playing. I specifically also said that it doesn't matter whether the preamp is on the head or the board - as long as it is done properly. That means cable routing and noise pickup. Again, I don't see where we are in disagreement here.In the TEAC VRDS10 one only has to point his finger at the flex connection that leaves the pickup, to make the player loose track. Simple to explain, and easy to conclude that induced noise increases jitter.

Do you?

-Chris

Time for a sanity check!

Hi George, everyone,

1. CD's are not perfect. They can be off center and a number of other defects may present.

2. The system used for CD's is called "constant linear velocity", as opposed to "constant angular velocity". Can anyone tell us what this pivotal truth means?

3. The clamping system espoused by georgehifi to be superior to other methods adds a great deal of rotating mass to the CD. Agreed?

The system of CD playback begins reading the disc in the center at around 500 rpm, agreed? Then it may stop after the TOC is read waiting for the play command. As the CD is played through, often the motor must speed up and brake in order to keep the linear velocity constant. Agreed? Have you seen this term "constant linear velocity" anywhere before? Do you know what this means?

Anyway, near the end of a long CD the speed will drop to around 200 rpm (very roughly). If you want to read tracks back and forth in a mixed mode, the disc motor must accelerate and brake often. The higher the rotating mass is, the more energy is required to change the rotational speed and the more wear there will be on the bearings and the motor. The Pioneer examples even use a cheap plastic platter and a standard CD motor! I've replaced tons of them.

The only system that will benefit from increased rotating mass is a turntable. That's because it works on the principle of "constant angular velocity". In other words, it rotates at the same speed all the time with no change. A high rotating mass is a help here. Conversely, a CD needs to have it's speed adjusted at least on a per rotation basis. You do not want a high rotating mass in this situation.

Very simply .... A CD player ain't a turntable!!! You can't treat it that way.

-Chris

Hi George, everyone,

Why would you even begin to consider this as a good system? Let's go over a couple of facts now to inject some actual reasoning to your assertion that the heavy clamp system is even intelligent - which it isn't.Also the Teac vrds systems always seam to sound better than other non full cd supported mechs to me and others, even without your clocks fitted, the only other one that has sounded as good that I've heard was the Pioneer Stable Platter system, again another full supported CD system.

1. CD's are not perfect. They can be off center and a number of other defects may present.

2. The system used for CD's is called "constant linear velocity", as opposed to "constant angular velocity". Can anyone tell us what this pivotal truth means?

3. The clamping system espoused by georgehifi to be superior to other methods adds a great deal of rotating mass to the CD. Agreed?

The system of CD playback begins reading the disc in the center at around 500 rpm, agreed? Then it may stop after the TOC is read waiting for the play command. As the CD is played through, often the motor must speed up and brake in order to keep the linear velocity constant. Agreed? Have you seen this term "constant linear velocity" anywhere before? Do you know what this means?

Anyway, near the end of a long CD the speed will drop to around 200 rpm (very roughly). If you want to read tracks back and forth in a mixed mode, the disc motor must accelerate and brake often. The higher the rotating mass is, the more energy is required to change the rotational speed and the more wear there will be on the bearings and the motor. The Pioneer examples even use a cheap plastic platter and a standard CD motor! I've replaced tons of them.

The only system that will benefit from increased rotating mass is a turntable. That's because it works on the principle of "constant angular velocity". In other words, it rotates at the same speed all the time with no change. A high rotating mass is a help here. Conversely, a CD needs to have it's speed adjusted at least on a per rotation basis. You do not want a high rotating mass in this situation.

Very simply .... A CD player ain't a turntable!!! You can't treat it that way.

-Chris

Re: Time for a sanity check!

This is exactly my experience. I wear out CD players, as they are running an average of like 8 hours a day, 365 days a year. The pioneer stable platter is a dud. I wore that mech. down about 1 year earlier than the regular mech. systems.

The bearings simply cant support the extra weight, and the motor went south accordingly.

Magura

anatech said:

3. The clamping system espoused by georgehifi to be superior to other methods adds a great deal of rotating mass to the CD. Agreed?

The system of CD playback begins reading the disc in the center at around 500 rpm, agreed? Then it may stop after the TOC is read waiting for the play command. As the CD is played through, often the motor must speed up and brake in order to keep the linear velocity constant. Agreed? Have you seen this term "constant linear velocity" anywhere before? Do you know what this means?

Anyway, near the end of a long CD the speed will drop to around 200 rpm (very roughly). If you want to read tracks back and forth in a mixed mode, the disc motor must accelerate and brake often. The higher the rotating mass is, the more energy is required to change the rotational speed and the more wear there will be on the bearings and the motor. The Pioneer examples even use a cheap plastic platter and a standard CD motor! I've replaced tons of them.

The only system that will benefit from increased rotating mass is a turntable. That's because it works on the principle of "constant angular velocity". In other words, it rotates at the same speed all the time with no change. A high rotating mass is a help here. Conversely, a CD needs to have it's speed adjusted at least on a per rotation basis. You do not want a high rotating mass in this situation.

Very simply .... A CD player ain't a turntable!!! You can't treat it that way.

-Chris

This is exactly my experience. I wear out CD players, as they are running an average of like 8 hours a day, 365 days a year. The pioneer stable platter is a dud. I wore that mech. down about 1 year earlier than the regular mech. systems.

The bearings simply cant support the extra weight, and the motor went south accordingly.

Magura

anatech said:Hi Guido,

I thought I was very clear when I specified the mechanical systems and the servo section. I did say that the clocking would improve everything from the sram forward.

We have always been in complete agreement there.

Well, again things are being stretched here. It is not normal for a customer to be poking their finger around inside the unit while it is playing. I specifically also said that it doesn't matter whether the preamp is on the head or the board - as long as it is done properly. That means cable routing and noise pickup. Again, I don't see where we are in disagreement here.

Do you?

-Chris

Hi Chris

we agree, nearly

My mail was to point out that there was a misundertsanding between you and George. To me it was immediately clear what you and George ment.

No customer pokes around in his/her TEAC but inside many noise sources are present, the worst being the multiplexd display. The driver is on the servo board, the display on the front. Long, radiating cables. Horrible and only 10 or 15cm away from the optical pickup cabling.

I have designed electronivs for DVD recordable pickup heads at Philips. For more than one reason we integrated pre amps and signal processing on the pickup.

best

Guido

Re: Re: Time for a sanity check!

which is why the Philips CDpro (among other types) platter is made as light as possible......

best

Guido

Magura said:

This is exactly my experience. I wear out CD players, as they are running an average of like 8 hours a day, 365 days a year. The pioneer stable platter is a dud. I wore that mech. down about 1 year earlier than the regular mech. systems.

The bearings simply cant support the extra weight, and the motor went south accordingly.

Magura

which is why the Philips CDpro (among other types) platter is made as light as possible......

best

Guido

Hi Guido,

Well, putting the RF preamp / decoder on the head prevents manufacturers from making one mistake anyway. However, it is not required if everyone does their job properly.

Personally, I like to have access to the servo section. There is a wealth of troubleshooting information available in there.

As far as platters are concerned, you can not help but at least double the mass of a CD. The hub clamping will work much better as long as the software is not warped. Some warpage is compensated by the focus servo, and I'd rather that than trash the spindle motor servo. If your media is bad, it's bad. Let's not optimize one issue and throw the rest out.

-Chris

Well, putting the RF preamp / decoder on the head prevents manufacturers from making one mistake anyway. However, it is not required if everyone does their job properly.

Easily seen by looking at the RF signal. If you are getting pick up here, I suspect the leads are no longer dressed properly. The worst interference I see is on the darn VAM1202 types I work on. How in the world did Philips allow that one to leave the barn? It's the worst one I have seen yet.The driver is on the servo board, the display on the front. Long, radiating cables. Horrible and only 10 or 15cm away from the optical pickup cabling.

Personally, I like to have access to the servo section. There is a wealth of troubleshooting information available in there.

As far as platters are concerned, you can not help but at least double the mass of a CD. The hub clamping will work much better as long as the software is not warped. Some warpage is compensated by the focus servo, and I'd rather that than trash the spindle motor servo. If your media is bad, it's bad. Let's not optimize one issue and throw the rest out.

-Chris

anatech said:Hi Guido,

As far as platters are concerned, you can not help but at least double the mass of a CD. The hub clamping will work much better as long as the software is not warped. Some warpage is compensated by the focus servo, and I'd rather that than trash the spindle motor servo. If your media is bad, it's bad. Let's not optimize one issue and throw the rest out.

-Chris

That's your opinion Chris, give me something that is stable and smooth and precise over something that is flapping in the breeze like a Frisbee, and I have never seen a trashed bearing in all the old s/h units I mod, they are built heavier duty to take it. As far as weight is concerned the magnetic clamping weight of the standard Philips/Sony system is almost as heavy as the lightweight clamping patter system of the Teacs and Pioneers.

As far as Magura's statement 8hrs a day 365 days a year, GET REAL, no Philips or Sony or any transport would take that for more than a year, except for maybe the professional studio Tascam CD701 transport

The broadcasting/recording industry still says one of the best most robust transports built, has been the TASCAM CD701 and guess what it uses the TEAC CMK3.2 VRDS mech.

On another note, except for me not a word has been said about the sound of these mechs, am I the only one who listens?

Cheers George

Re: Re: Re: Time for a sanity check!

Yuo seem to have gone through a lot of cd mech's, which of the mech's would you expect is most durable?

I know this question may seem strange, but I'm sick of buying new CD players every 3rd year.

Magura

Guido Tent said:

which is why the Philips CDpro (among other types) platter is made as light as possible......

best

Guido

Yuo seem to have gone through a lot of cd mech's, which of the mech's would you expect is most durable?

I know this question may seem strange, but I'm sick of buying new CD players every 3rd year.

Magura

- Home

- Source & Line

- Digital Source

- Best CD drive mechanism