Just read your post but could not find out if the version with the alu pearl caps sounded better or not compared to polymer caps !? Did you measure the one with the Wima caps all over it ? IMO the alu pearl SAL-RPM are slightly better than polymer caps, that is why I am curious. The SAL-RPM have some BG like features. Special caps in a jungle of electrolytic caps of all sorts and they're dry caps too so no deterioration or drying out of the electrolytic fluid.

BTW I also tried Wima MKS but then the smaller MKS2 1 µF version (2,5 mm pitch) and liked it for C35. That is one of the reasons that the track became shorter. The Wima 10 µF MKS-XL won't fit on the final PCB anymore I guess. Again I found that SAL-RPM 10 µF performed better here and thus a footprint for those was added. Parts preferably need to be small on this DAC, please check tracks/pins with an oscilloscope to verify differences after modding.

Did you also try alu pearl SAL-RPM caps for the Avcc (C22) ? I got hold of a few 68 µF which I think is the largest value and that was OK too on a prototype. In fact one of the 3 examples of the final V3 DACs I am building will have those.

As you can see the verdict slowly became that SAL-RPM was the best performing of all (except for the rare BG NX HiQ) and I switched over to these and added footprints. I only tested SAL-RPM 122, the older series as I think they're a tad better than SAL-RPM 128.

Hint for the people that want to experiment, you could use these in 1 µF for C35 but please use the 1 µF ceramic cap close to the pins too and a 4.7 µF tantalum in parallel at the underside of the board:

http://www.wima.com/EN/mks02.htm

BTW I also tried Wima MKS but then the smaller MKS2 1 µF version (2,5 mm pitch) and liked it for C35. That is one of the reasons that the track became shorter. The Wima 10 µF MKS-XL won't fit on the final PCB anymore I guess. Again I found that SAL-RPM 10 µF performed better here and thus a footprint for those was added. Parts preferably need to be small on this DAC, please check tracks/pins with an oscilloscope to verify differences after modding.

Did you also try alu pearl SAL-RPM caps for the Avcc (C22) ? I got hold of a few 68 µF which I think is the largest value and that was OK too on a prototype. In fact one of the 3 examples of the final V3 DACs I am building will have those.

As you can see the verdict slowly became that SAL-RPM was the best performing of all (except for the rare BG NX HiQ) and I switched over to these and added footprints. I only tested SAL-RPM 122, the older series as I think they're a tad better than SAL-RPM 128.

Hint for the people that want to experiment, you could use these in 1 µF for C35 but please use the 1 µF ceramic cap close to the pins too and a 4.7 µF tantalum in parallel at the underside of the board:

http://www.wima.com/EN/mks02.htm

Last edited:

comparisons

JP,

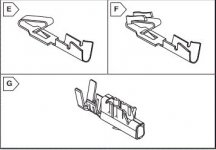

I borrowed a version of the v3 DAC from Subbu with the Alu Pearl Caps (SAL-RPM) for C21, C22, and C35. C21 10uf, C22 68uf, and C35 4.7uf. I compared it to the DAC with 470uf Polymer cap for C22 and Wima MKS2 everywhere else. The two DACs are pictured below. The sound of the Polymer cap / Wima MKS2 DAC was better than the Alu Pearl DAC with fuller bass and better soundstage. Both sound good but the Polymer/Wima DAC was noticeably better. The Alu Pearl DAC was very good and better than my original v2.6 DAC build. But as I said in my previous message, the ES9023 seems very sensitive to the C22 capacitor and likes a very big value for this cap. The sound kept improving when I went from 100uf to 220uf to 470uf. I didn't see much additional benefit when I went to 560uf. The quality of C21 was not that critical but polymer was better than conventional electrolytic. Wima MKS2 was as good but not better than the polymer. For C35, the Wima MKS2 4.7uf is better than polymer in this location. The 4.7uf Wima will fit on the top of the board. You can mount the 10uf Wima below the board if you want to experiment with bigger values.

---Gary

Just read your post but could not find out if the version with the alu pearl caps sounded better or not compared to polymer caps !? Did you measure the one with the Wima caps all over it ? IMO the alu pearl SAL-RPM are slightly better than polymer caps, that is why I am curious. The SAL-RPM have some BG like features. Special caps in a jungle of electrolytic caps of all sorts and they're dry caps too so no deterioration or drying out of the electrolytic fluid.

Did you also try alu pearl SAL-RPM caps for the Avcc (C22) ? I got hold of a few 68 µF which I think is the largest value and that was OK too on a prototype. In fact one of the 3 examples of the final V3 DACs I am building will have those.

JP,

I borrowed a version of the v3 DAC from Subbu with the Alu Pearl Caps (SAL-RPM) for C21, C22, and C35. C21 10uf, C22 68uf, and C35 4.7uf. I compared it to the DAC with 470uf Polymer cap for C22 and Wima MKS2 everywhere else. The two DACs are pictured below. The sound of the Polymer cap / Wima MKS2 DAC was better than the Alu Pearl DAC with fuller bass and better soundstage. Both sound good but the Polymer/Wima DAC was noticeably better. The Alu Pearl DAC was very good and better than my original v2.6 DAC build. But as I said in my previous message, the ES9023 seems very sensitive to the C22 capacitor and likes a very big value for this cap. The sound kept improving when I went from 100uf to 220uf to 470uf. I didn't see much additional benefit when I went to 560uf. The quality of C21 was not that critical but polymer was better than conventional electrolytic. Wima MKS2 was as good but not better than the polymer. For C35, the Wima MKS2 4.7uf is better than polymer in this location. The 4.7uf Wima will fit on the top of the board. You can mount the 10uf Wima below the board if you want to experiment with bigger values.

---Gary

Attachments

JP,Did the SAL-RPM caps have some hours of duty when you compared DACs ?

BTW both DACs have different XO's it seems ? Am I right ? Comparing is difficult then.

You sound like a skeptic, which is probably a good thing when considering audio tweaks. I did mention that the XO didn't make much of a difference. I also retrofitted some of these changes in my older v2.6 DAC with good results. I did this because I was dissatisfied with the sound of the v2.6 DAC after completing the v3 DAC with polymer and wima caps. And my v2.6 used Black Gate NX for Avcc and NEG. It also uses a standard 50Mhz XO. Adding the bigger polymer cap for AVcc, the 4.7uf Wima for NEG, and a 10uf polymer cap for Vreg raised the sound level to a good degree. I also added the bigger SPDIF input cap (3.3uf Wima) but didn't bother changing the other WM8804 caps. Sound quality was close between the builds at this point, so I think the XO isn't a critical part change. Regarding the hours on the SAL-RPM caps, I don't know how long Subbu had played it but I ran it in for at least 48 hours before doing serious listening. Probably longer but that was 6 months ago and I don't recall exactly.

Gary,

when you installed the C22-470uf polymer cap did you uninstalled the ceramic 1uf bypass C36 ? I know polymers dont like to be bypassed especially with ceramics.

I have not heard about polymer caps not liking ceramic bypass. Can you point me towards more information about that? I didn't remove the 1uf bypass cap (C36 in ver3, C10 in v2.6) and didn't hear any bad effects.

---Gary

Hi I am a skeptic regarding hardwired "tuned by ear" devices and need part numbers and values for real comparisons. "V2.6 had Black Gate NX" really says nothing, sorry

The polymer caps have such an incredible low ESR that they might cause a resonance circuit when paralleled with small value ceramic caps. I read all this yesterday evening and think polymer caps are very exciting but should be used with attention. Solid polymer caps can not just be used as a replacement in many many cases ! Manufacturers advise to use larger value bypass ceramic caps and explain the whole matter in white papers.

I ordered 220/10 for Vpos/Avcc and 2.2 uF ceramic caps for decoupling Vpos and Vneg just to test.

Ears are not the best instrument when comparing tweaked DACs. The mind also influences matters. You should back up listening with measuring. Also testing should be done and then changes could be implemented by changing footprints, BOM etc. Better than hardware mods after production.

The polymer caps have such an incredible low ESR that they might cause a resonance circuit when paralleled with small value ceramic caps. I read all this yesterday evening and think polymer caps are very exciting but should be used with attention. Solid polymer caps can not just be used as a replacement in many many cases ! Manufacturers advise to use larger value bypass ceramic caps and explain the whole matter in white papers.

I ordered 220/10 for Vpos/Avcc and 2.2 uF ceramic caps for decoupling Vpos and Vneg just to test.

Ears are not the best instrument when comparing tweaked DACs. The mind also influences matters. You should back up listening with measuring. Also testing should be done and then changes could be implemented by changing footprints, BOM etc. Better than hardware mods after production.

Last edited:

Has anyone found a 2.5mm four position terminal block for X6 (audio out) on the DAC board? I can't find one at DK or Mouser.

Bob, Did you mean terminal block? The BOM calls for header pins, but of course this means that you would have to terminate your cable with a socket. However, mouser have these: 571-282834-4, 282834-4 TE Connectivity / AMP | Mouser

JP,Hi I am a skeptic regarding hardwired "tuned by ear" devices and need part numbers and values for real comparisons. "V2.6 had Black Gate NX" really says nothing, sorry

We discussed this in the earlier "ES9023 / WM8804 S/PDIF DAC Group Buy" thread. Per our earlier discussions and your recommendations at the time, I built one DAC with Black Gate 100uf 6.3v N for AVcc and 4.7uf 50v BG NX for NEG and a 2nd one with BG 100uf 6.3v N for AVcc and 1uf 50v BG NX for NEG. You can see pictures here http://www.diyaudio.com/forums/group-buys/211201-es9023-wm8804-s-pdif-dac-group-buy-56.html#post3176306 and here http://www.diyaudio.com/forums/group-buys/218524-power-supply-pcb-es9023-wm8804-s-pdif-dac-group-buy-13.html#post3417732

The DAC with the 4.7uf for NEG sounded better and I left the 4.7uf BG in that one. But changing out the AVcc 100uf BG for the 470uf polymer cap that I mentioned earlier was a good improvement for both DACs.

For those interested in reading more about the low ESR of polymer caps and the challenges in bypassing them, I suggest the following link http://www.chemi-con.co.jp/e/catalog/pdf/Application_Note_NPCAP_090716e.pdf. It makes me think that increasing the bypass cap for AVcc from 1uf to 10uf MLCC would be worth a try.The polymer caps have such an incredible low ESR that they might cause a resonance circuit when paralleled with small value ceramic caps. I read all this yesterday evening and think polymer caps are very exciting but should be used with attention. Solid polymer caps can not just be used as a replacement in many many cases ! Manufacturers advise to use larger value bypass ceramic caps and explain the whole matter in white papers.

I'm curious to know what measurements you use to validate design choices and parts changes. The bypass effects mentioned with low ESR polymer caps would be hard to measure with anything short of expensive network analyzers, which are definitely out of the realm of amateurs. I do have access to equipment like that at work, but I don't think it's realistic to use that for a project like this.Ears are not the best instrument when comparing tweaked DACs. The mind also influences matters. You should back up listening with measuring. Also testing should be done and then changes could be implemented by changing footprints, BOM etc. Better than hardware mods after production.

Thanks,

---Gary

BB, That's exactly what I was looking for. I just finished a battle with header pins on another project where I eventually had to solder directly to the board/pads. All the available connection methods have their drawbacks. I have found the the small female side of the pin style easily loosen with a lot of on-offs. A dab of RTV helps. I'll probably use a solid fix or pins at the final build. The block may help some during all the activity in the build test/phase.

Thanks.

Thanks.

BB, That's exactly what I was looking for. I just finished a battle with header pins on another project where I eventually had to solder directly to the board/pads. All the available connection methods have their drawbacks. I have found the the small female side of the pin style easily loosen with a lot of on-offs. A dab of RTV helps. I'll probably use a solid fix or pins at the final build. The block may help some during all the activity in the build test/phase.

Thanks.

Glad to help, whilst I'm waiting for the parts GB to materialise in my mail box! Phil (Korben69) must have some task at hand sorting and packing all those parts.

Terminal blocks certainly help in the test phase and I don't think that they are any worse than KK crimp terminals and headers. It's just a matter of preference. As you say, hard wired solder connections are the best for the long term.

Mouser has them, I found the gold plated variant (which i don't use myself) in a few seconds:

26-61-4040 Molex | Mouser

They will have the tinned version too but you will have to scroll around yourself. Never mix gold plated headers with tinned plugs or the other way around. just just both with the same plating material.

BTW hardwired soldered connections are in fact worse then crimped/screwed connections but that is another story.

26-61-4040 Molex | Mouser

They will have the tinned version too but you will have to scroll around yourself. Never mix gold plated headers with tinned plugs or the other way around. just just both with the same plating material.

BTW hardwired soldered connections are in fact worse then crimped/screwed connections but that is another story.

Never mix gold plated headers with tinned plugs or the other way around. just just both with the same plating material.

BTW hardwired soldered connections are in fact worse then crimped/screwed connections but that is another story.

I would agree that mixing dissimilar contact metals should be avoided, due to the galvanic and thermocouple effects amongst other things. Designing for the minimum number of interfaces between conductors is also a good thing. "High pressure" crimped connections can achieve an airtight connection avoiding surface corrosion and possible diode effect etc. But, if the header pins are soldered to the pcb tracks you still have a soldered joint, not to mention the friction joint between the crimp terminal and header pin.

As JP says that is another story, if not a whole book......

JP,

I'm curious to know what measurements you use to validate design choices and parts changes. The bypass effects mentioned with low ESR polymer caps would be hard to measure with anything short of expensive network analyzers, which are definitely out of the realm of amateurs. I do have access to equipment like that at work, but I don't think it's realistic to use that for a project like this.

Thanks,

---Gary

The recommendations of the manufacturers are all I have for the recent polymer caps as I don't have that specific equipment. It is a hobby and not an occupation for me. I can only use what I have and I ordered 220/10 for decoupling Avcc and will bypass it with 2.2 µf 0805 X7R (also 2.2 µF 0603 for the Vneg pin). Will try out different configuration again. Some manufacturers even give ratios for values when mixing polymer caps with ceramic bypass caps like 3:1 . The point is that they seem to differ in opinion in those ratios

You are right about past posts, I also sticked with 4.7 µF tot 10 µF for Vneg. At that time I could not notice differences between 100 µF or larger ones for Avcc/Vpos. I found the Vneg pin to be a sensitive one for capacitor quality like film, BG etc.

Choices, choices.....

Last edited:

OK. I'll bite. What's the rest of the story.

Seriously, would like to hear your information. In the end we want what's best in a permanent install.

With DIYers there is no permanent install I thought ? I burned my fingers too many times thinking I would close the case and just use the device but then ... a new PSU, a new revision DAC PCB, new caps etc. etc. Using Molex KK for some time I can tell it is way easier to replace complete PCBs or to do service on the boards. They are just good connectors for this task. Of course there are knockoffs that are not as good but original ones are fine.

Thanks BackinBlack for neatly steering away a possible disaster regarding discussion on what are the best connections

Last edited:

So are you talking about the crimp end of the female pin? I had a stock of straight square PC sockets similar to these and would make separate leads with heat shrink tubing. I considered having four mating surfaces instead of a single tab to be an advantage.

I even soldered after the crimp was done. Is that not advised?

JP. I am not interested in a long detailed discussion about connectors or the infamous "my favorite hook-up wire" dialogue. As I said earlier, most of those things end up sounding like the "How many angels fit on the head of a pin?" discussions. Been there - done that. Only seeking your best call as the designer.

I even soldered after the crimp was done. Is that not advised?

JP. I am not interested in a long detailed discussion about connectors or the infamous "my favorite hook-up wire" dialogue. As I said earlier, most of those things end up sounding like the "How many angels fit on the head of a pin?" discussions. Been there - done that. Only seeking your best call as the designer.

Attachments

Last edited:

- Home

- Source & Line

- Digital Line Level

- Build thread - building the Subbu DAC V3 SE